Page is loading ...

DIRECTVENT

GAS WATER HEATE

USER'S GUIDE

For Your Safety

AN ODORANT ISADDED TO THE GAS USED BY THIS Model Numbers

WATER HEATER HJ640NBDS

HJ640PBDS

WARNING: If the information in these instructions are not fol- I-IJ650NBDS

lowed exactly, a fire or explosion may result, causing property HJ650PBDS

damage, personalinjuryordeath.

-Do not store or usegasoline or other flammable vaporsand liq-

uidsinthe vicinity of this or any other appliance.

-WHAT TO DO IFYOU SMELLGAS

• Do nottry to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor's phone,

Followthe gassupplier'sinstructions.

• If you cannot reachyourgassupplier,callthe fire department.

-Installation and servicemustbe performedby a qualified installer,

serviceagencyorthe gassupplier. FOR POTABLE WATER

•,WARNING HEATING ONLY

Improper installation, adjustment, alteration, service or mainte- NOT SUITABLEFOR

nance can cause DEATH, SERIOUSBODILYINJURY,OR PROPERTY SPACE HEATING

DAMAGE. Refer to this manual for assistanceor consultthe local

gas utility for further information. NOT FOR USE IN

MANUFACTURED

AWARNING other (MOBILE) HOMES

Flammable vapors may be drawn by air currents from

areas of the structure to this app lance. Caution:

Read and Follow All

•,WARNING I Safety Rulesand

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE I Operating Instructions

COVER AND THEN THIS ENTIRE MANUAL BEFOREINSTALLING Before First Use of

OR OPERATING THIS WATER HEATER. This Product.

Save this Manual for Future Reference.

Safety Instructions

&WARNING _,WARNING

The water heater must be properly vented out- HYDROGEN GAS: Hydrogen gas can be produced in

doors. Never operate the water heater unless it is a hot water system that has not been used for a

vented to the outdoors and has adequate air sup- long period of time (generally two weeks or more).

ply to avoid risks of improper operation, explosion Hydrogen gas is extremely flammable and explosive.

or asphyx ation. To prevent the possibility of injury under these con-

ditions, we recommend the hot water faucet be

opened for several minutes at the kitchen sink

_WARNING before any electrical appliances which are connected

to the hot water system are used (such as a dish-

Minimum clearances between the water heater and washer or washing machine). If hydrogen gas is pre-

combustible and noncombustible construction are: 0 sent, there will probably be an unusual sound simi-

inches from sides, 0 inches from back, 4 inches from lar to air escaping through the pipe as the hot water

front of jacket to closet door and 3 inches from top faucet isopened. There must be no smoking or open

of jacket to combustible and noncombustible ceiling, flame near the faucet at the time it is open.

Minimum vent clearance: 0 inches. NOTE: provide 24

inches front clearance for servicing. (See Figure 1)

Page 9.

A, CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

the water heater must be accomplished in such a

_,WARNING

Flood damage to a water heater may not be readily manner that if the tank or any connections should:

leak, the flow of water will not cause damage to the

I visible or immediately detectible. However, over a structure. For this reason, it is not advisable to install

period of time a flooded water heater will create the water heater in an attic or upper floor. When

dangerous conditions which can cause DEATH, SERI- such locations cannot be avoided, a suitable drain

OUS BODILY INJURY, OR PROPERTY DAMAGE.

pan should be installed under the water heater. Such

Contact the Maytag dealer from whom the appli- a drain pan must have a minimum length and width I

ance was purchased or call Maytag Customer Service of at least 2 inches greater than the water heater

at 1-800-788-8899 for an authorized servicer to dimensions and must be piped to an adequate drain.

replace a flooded water heater. Do not attempt to Drain pan depth must allow for access to the outer

repair the unitJ It must be replaced! doors for lighting the pilot and servicing the burner.

Under no circumstances is the manufacturer or

Maytag to be held liable for any water damage in'

A WARNING connection with this water heater.

INSULATING JACKETS: When installing an external

water heater insulation jacket on a gas water

heater:

a. DO NOT cover the temperature-pressure relief

valve.

b. DO NOT put insulation over any part of the top of

the gas water heater.

c. DO NOT put insulation over the gas control valve

or gas control valve/burner cover, or any access

areas to the burner.

d. DO NOT let insulation around the gas water

heater to get within 8 inches of the floor to allow

accessto the burner assembly.

e° DO NOT cover or remove operating instructions,

and safety related warning labels and materials

affixed to the water heater,

Failure to heed this will result in the possibility of a

fire or explosion.

4

Table of Contents

Safety Instructions ................................................................................................................................ 2-4

Table of Contents .......................................................................................................................................5

Customer Information .......................................................................................................................6

Product Specifications ........................................................................................................................6

Accessories and Tools Needed ...............................................................................................7

Accessories ............................................................................................................................................................................ 7

Tools ..................................................................................................................................................................................... 7

Instructions for Installation ..............................................................................................._-_

Removing the Old Water Heater .......................................................................................................................................... 8

Typical Installation ................................................................................................................................................................ 9

Locating the New Water Heater ......................................................................................................................................... 10

Combustion Air and Ventilation ................................................................................................................................... 11, 12

Venting Clearances ..................................................................................................................................................... 11, 12

Optional Wire Grill .......................................................................................................................................................... 12

Flue Extensions ............................................................................................................................................................. 12, 13

Vertical (Extension Kit) Height .................................................................................................................................. 12, 13

Horizontal (Extension Kit) ............................................................................................................................................... 13

All Installations ................................................................................................................................................................... 14

Standard Vent Kit Installation ....................................................................................................................................... 14-I7

Optional Vertical Kit Installation .................................................................................................................................. 17-21

Optional Horizontal Kit Installation ............................................................................................................................. 21-25

O_tlonal Vertical and Horizontal Kit Installation ......................................................................................................... 25-29

water Piping ....................................................................................................................................................................... 30

Temperature-Pressure Relief Valve ..................................................................................................................................... 31

Fillip. the Water Heater ..................................................................................................................................................... 32

Gas Piping .................................................................................................................................................................... 32, 33

Installation Checklist .......................................................................................................................................................... 34

Instructions for Operation ...................................................................................................a5-3_

Lighting ........................................................................................................................................................................ 35, 36

Temperature Regulation ...................................................................................................................................................... 37

Service and Maintenance ....................................................................................................... 38-40

Venting System Inspection .................................................................................................................................................. 38

Burner Inspection ............................................................................................................................................................... 38

Burner Cleaning .................................................................................................................................................................. 38

LR Gas Control Valve and Burner Assembly Replacement information .......................................................................... 39

Draining .............................................................................................................................................................................. 39

Anode tcod Inspection ........................................................................................................................................................ 39

Temperature-Pressure Relief Valve Operation .................................................................................................................... 40

Drain Valve Washer Replacement ...................................................................................................................................... 40

Housekeeping ..................................................................................................................................................................... 40

Service ................................................................................................................................................................................. 40

Troubleshooting .................................................................................................................................... 41-44

Start Up Cor_ditioas ............................................................................................................................................................ 41

Condensation .................................................................................................................................................................... 41

Smoke/Odor ..................................................................................................................................................................... 41

Thermal Expansion ........................................................................................................................................................... 41

Strange Sounds ................................................................................................................................................................. 41

Operational Conditions ................................................................................................................................................ 42, 43

_meUcvWater ..................................................................................................................................................................... 42

'_lir m Hot Water Faucets ............................................................................................................................................... 42

High Temperature Shut Off System ................................................................................................................................. 42

Not Enoch or No Hot Water ......................................................................................................................................... 42

Water Is xoo Hot .............................................................................................................................................................. 43

Leakage Checkpoints .......................................................................................................................................................... 44

Repair Parts List ...................................................................................................................................46-_0

Warranty ...................................................................................................................................................................52

5

Customer Information

Thank Youfor purchasing aMaytag water heater, cannot put everything on the first fewpages, READ THE

Properly installed and maintained, it should give youyears of ENTIRE MANUAL BEFORE ATTEMPTING TO

trouble free service. It is strongly suggested that this new water INSTALL OR OPERATE THE WATER HEATER.

heater be professionally installed, contact Maytag Customer The installation must conform with the instructions in this

Service (1-800-788-8899) for recommended installers, manual; gascompany rules; and Local Codes, or in the absence

ofLoca/Codes, with the current edition of the National Fuel

Abbreviations Found In This Instruction Manual Gas code, ANSI Z223.1, also referred to as NFPA 54. This

CSA - Canadian Standards Association publication is availablefrom your localgovernment or public

ANSI - American National Standards Institute library or gas company or by writing NFPA, Batterymarch

NFPA - National Fire Protection Association Park, Quincy, MA 02269.

• After reading this manual you have any questions or do not

&WARNING understand any portion of the instructions, call Maytag

This gas-fired water heater is design certified by Customer Serviceat 1-800-788-8899 for an authorized ser-

CSA INTERNATIONAL under American National vicer.

Standard/CSA Standard for Gas Water Heaters ANS

Z21.10.1 • CSA 4.1 (current edition). The installation • Carefully plan the place where you are going to put the water

must conform with this manual, Local Codes and heater. Correct combustion, vent action, and vent pipe installa-

with the current edition of the National Fuel Gas tion are very important in preventing death from possible car-

Code, ANSI Z223.1,

This publication isavailable from your local govern- bon monoxide poisoning and fires.

ment or public library, gas company, or by writing' Examine the location to ensure the water heater complies with

NFPA, Batterymarch Park, Quincy, MA 02269. I the "Locating the New Water Heater" section in tbJs manual.

• For California installation this water heater must be braced,

• Read the "SafetyInstructions" section, pages 2, 3 and 4 ofthis anchored, or strapped to avoid tailing or moving during an

manual first and then the entire manual carefully.If you don't earthquake. See instructions for correct installation procedures.

followthe safetyrules, the water heater will not operate proper- Instructions maybe obtained from your local dealer, whole-

13_It could cause DEATH, SERIOUS BODILY INJURY saler,public utilities or California Office of the State Architect,

AND/OR PROPERTY DAMAGE. 400 P Street, Sacramento, CA 95814.

• This manual contains instructions for the installation, opera- • Massachusetts Code requires this water heater to be installed in

tion, and maintenance of the gas-fired water heater. It alsocon- accordancewith Massachusetts 248-CMR 2.00: State

tains warnings that you must read and be aware of through out Plumbing Code and 248-CMR 5.00.

the rnanual. All wamlngs and allinstructions are essential to the • Complies with SCAQ_MDrule #1121 and districts having

proper operation of the water heater and your safety.Since we equivalent NOx requirements.

Product Specifications

•Model HJ640NBDS HJ640PBDS HJ650NBDS HJ650PBDS

AVAILABLE OPTIONS:

Tank Capacity Suffix"W" - Heat Traps

In Gallons 40 40 50 50 * Suff,x"D" - High Altitude

Type of

Gas Natural Propane Natural Propane

B.T.U.

Rate 40,000 40,000 48,000 44,000

Recovery Rate

In Gals Per Hour 41 41 49 45

@ 90°F Rise

Vent Inlet

(Outlet) Size 6" (3") 6" (3") 6" (3") 6" (3")

Diameter 21" 21" 21" 21"

Height To

Top of 483/4" 48'/," 61" 61"

Water Heater

• High altitude models have a B.T.U./Recovery Rate 10% less than shown.

6

Accessories and Tools Needed

Accessories

To simplify the installation Maytag has available the installa-

tion parts shown below. You may or may not need alI of these

accessoriesdependingonyourtypeofinstallation.Call

Maytag Customer Service at 1-800-788-8899 for an

authorized installer.

DRAINPANSAVAILABLEIN 22" DIAMETER

(PARTNUMBER66001011) FORWATER

HEATERSHAVINGA DIAMETER20° ORLESS,

24" DIAMETER(PARTNUMBER66001105) FOR

EXPANSIONTANKSFORTHERMALEXPANSION WATERHEATERSHAVINGA DIAMETER22"

CONDITIONSAVAILABLEIN 2 GALLON(PART OR LESSAND 28" DIAMETER(PARTNUMBER

NUMBER66001013) AND 5 GALLON(PART 66001012) FORWATERHEATERSHAVINGA

NUMBER66001014) CAPACITY DIAMETER26_'OR LESS

Tools

You may or may not need all of these tools, depending on your ADDITIONAL TOOLS NEEDED

type of installation. These tools can be purchased at your local WHEN SWEAT SOLDERING

hardware store. * Tubing Cutters or Hacksaw

• Propane Torch

• Pipe Wrenches (2) 14" • Soft Solder

• Screwdriver _ _ • Solder Flux

• Emery Cloth

• Tin Snips • Wire Brushes

• 6 Foot Tape of Folding Rule

• Garden Hose GARDENHOSE

• Drill

• Pipe dope or Teflon Tape

HACKSAW

P,PE6 FOOTTAPE WRENCH

ROLLOFTEFLONTAPE 3/4" WIREBRUSH

(USEONLYON WATER

CONNECTIONS)

1/2" WIREBRUSH

_ _ PROPANETORCH

SLOT-HEADSCREWDRIVER

TIN SNIPS _;_

PHILLIPSSCREWDRIVER ROLLOF LEADFREE

SOFTSOLDER

PIPEDOPE(SQUEEZETUBE) ROLLOF EMERY

(USEFORWATERAND CLOTH SOLDERFLUX TUBINGCU'I'I'ER

GAS CONNECTIONS)

7

Instructions for Installation

Removing the Old Water Heater

@ Turn "OFF" the gas supply to the water heater. @ Disconnect the vent pipe from the draft hood, if provid-

ed, where they connect to the water heater. In most

iI WARNING installations the vent pipe(s) can be lifted off after any

screw or other attached devices are removed. Dispose of

If the maingasline shutoffservingall gas appliancesisused,

alsoshut"OFF"the gasat eachappliance.Leaveall gasappli- the draft hood, if provided. The new water heater has a

ancesshut"OFF"untilthewaterheater nstaaton iscomplete, vent kit which mustbe usedfor proper operation.

a. If you have copper piping to the water

heater, the two copper water pipes can

@ @ be cut with a hacksaw approximately

four inches away from where they con-

nect to the water heater. This will

avoid cutting off the pipes too short.

Additional cuts can be made later if

necessary. Disconnect the temperature-

pressure relief valve drain line. When

the water heater is drained, disconnect

Turn the hose from the drain valve. Close

the water to the water

heater. Some installations

require

that

{J_ the drain valve. The water heater is

house.thewater be turned offto the entire _ now completely disconnected and

Q1) ready to be removed.

Check again sure gas sup-

to make the

ply is "OFF" to the water heater. Then la_ I_ ll_l @ b. If you have galvanized pipe to the water

disconnect the gas supply connection _ heater, loosen the two galvanized pipes

from the gas control valve, with a pipe wrench at the union in each

line. Also disconnect the piping

remaining to the water heater. These

Attach a pieces should be saved since they may

hose to the water heater drain

valve and put the other end in a floor be needed when reconnecting the new

drain or outdoors. Open the water water heater. Disconnect the tempera-

heater drain valve. Open a nearby hot ture-pressure relief valve drain line.

water faucet which will relieve pressure When the water heater is drained, dis-

in the water heater and speed draining, connect the hose from the drain valve.

Close the drain valve. The water heater

r;LW'° bmPrleCte°lvYead?c°nnecredand

WARNING & CAUTION

Thewaterpassingout ofthe drainvalvemaybeextremelyhot. Mineralbuildupor sedimentmayhaveaccumulatedin the oldI

Toavoidbeingscalded,makesureall connectionsaretight and waterheater.Thiscausesthewater heaterto bemuchheavier

thatthewaterflow isdirectedawayfromanyperson, thannormalandthsresidue,f spi edout,coudcausestanng.

8

Instructions for Installation (cont'd)

Typical Installation

CHECK ALL CONNECTIONS FOR LEAKS. CONSULT THE LOCAL UTILITY COMPANY TO EXAMINE INSTALLATION FOR PRO-

PRIETY AND SAFETY.

i VACUUM RELIEFREQUIREDBYSOMECODES

' (REFERTO LOCALCODES)

VENTTO

OUTDOORS

WATERINLET

\\

\\

TEMPERED-- _'_

WATEROUTLET \\

\\

\\

MtXtNGVALVE"

\\_ GAS

\\ SUPPLY

_\ RELIEFVALVE

\\

\\ -DISCHARGEPIPE

\\ (Do not capor plug)

\\

\\

\\

\\

\\

\\

\\

\\

DRAIN PAN TO SUITABLEDRAIN

This appliance has been design certified as complying with American National Standard/CSA Standard for water heaters and is con-

sideredsoitable for:

Water (Potable) Heating: A]J models are "considered suitable for water (potable) heating."

AWARNING A WARNING to any heat-

HOTTER WATER CAN SCALD: Water heaters are This water heater shall not be connected

intended to produce hot water. Water heated to a ing systems or component(s) previously used w th a

temperature which will satisfy clothes washing, non-potable water heating appliance.

dish washing, end other sanitizing needs can scald

and permanently injure you upon contact. Some

people are more likely to be permanently injured by

!hot water than others. These include the elderly, _, WARNING

children, the infirm, or physically/mentally handi-

capped. If anyone using hot water in your home fits iToxic chemicals such as used for treatment of boilers

into one of these groups or if there is a local code or or non-potable water heating appliances shall never I

state law requiring a certain temperature water at be introduced into a potable water space heating|

the hot water tap, then you must take special pre- system.

J

icautions. In addition to using the lowest possible

temperature setting that satisfies your hot water

needs, a means such as a mixing valve, should be

used at the hot water taps used by these people or NOTE: To protect against untimely corrosion of hot and

at the water heater. Mixing valves are available at cold water fittings, it is strongly recommended that di-elec-

plumbing supply or hardware stores. Follow manu- tric unions or couplings be installed on this water heater

facturers instructions for installation of the valves,

Before changing the factory setting on the thermo- when connected to copper pipe.

,stat, read the "Temperature Regulation" section in

this manual.

9

Instructions for Installation (cont'd)

Locating the New Water Heater • The location selection must provide adequateclearancesfor

You should carefully choose an indoor location for the new water servicing and proper operation of the water heater.

heater, because the placement is a very important consideration

for the safety of the occupants in the building and for the most [ &WARNING

economical use of the appliance. Thiswater heateris not foruse [ Propellants of ae_and volatile com-

inmanu_ctured(mobile)homesoroutdoorinstallation. |pounds, (cleaners, chlorine based chemicals, refrig-

/erants, etc.) in addition to being highly flammable

in many cases, will also change to corrosive

Whether replacing an old water heater or putting the water hydrochloric acid when exposed to the combustion

heater in a new location, the following critical points must be products of the water heater. The results can be

observed. [hazardous, and a so cause product fa ure.

The location selected should be indoors as dose as practical to

the outside wall to which the water heater vent is going to be AWARNING

installed through, and as centralized with the water piping sys- This water heater must not be installed directly on

tern as possible. The water heater, as all water heaters, wiU even- carpeting. Carpeting must be protected by a metal

tually leak. Do not install without adequate drainage provisions or wood panel beneath the appliance extending

where water flow will cause damage, beyond the full width and depth of the appliance by

at least 3 inches (76.2mm) in any direction, or if the

appliance is installed in an alcove or closet, the

entire floor must be covered by the panel. Failure to

ACAUTION heed this warning may result in a fire hazard.

WATER HEATERS EVENTUALLY LEAK: Installation of

the water heater must be accomplished in such a

manner that if the tank or any connections should

leak, the flow of water will not cause damage to the AWARNING

structure. For this reason, it is not advisable to install Minimum clearances between the water heater and

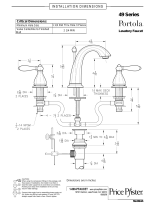

the water heater in an attic or upper floor. When combustible and noncombustible construction are: 0

such locations cannot be avoided, a suitable drain inches from sides, 0 inches from back, 4 inches from

pan should be installed under the water heater. Such front of jacket to closet door and 3 inches from top I

a drain pan must have a minimum length and width of jacket to combustible and noncombustible ceiling. I

of at least 2 inches greater than the water heater Minimum vent clearance: 0 inches. NOTE: provide 24

dimensions and must be piped to an adequate drain, inches front clearance for servicing. (See Fgure 1).

Drain pan depth must allow for access to the outer

doors for lighting the pilot and servicing the burner.

Under no circumstances is the manufacturer or Ventto

Maytag to be held liable for any water damage in ou__

connection with this water heater. 0-m_:._;,l_-

0" rain. >

AWARNING _i_j"_

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ- 0"

UIDS (VAPORS)ARE LIKELYTO BEPRESENTOR STORED

(GARAGES, STORAGE, AND UTILITY AREAS, ETC):

Flammable liquids (such as gasoline, solvents, propane outdoors

(LP) or butane, etc.), all of which emit flammable

vapors, may be improperly stored or used in such _- --

areas. The gas water heater pilot light or main burner

can ignite suchvapors, The resulting flashback and fire

can cause death or serious burns to anyone in the --°m_n"

area, as well as property damage. _

If installation in such areas is your only option, then

the installation must be accomplished in a way that

the pilot flame and main burner flame are elevated ....._.........

from the floor at least 18 inches.While this may reduce ........

the chances of flammable vapors from a floor spill I I

being ignited, gasoline and other flammable sub- I Figure 1 ]

stances should never be stored or used in the same

room or area containing a gas water heater or other

open flame or spark producing appliance.

NOTE: Flammable vapors may be drawn by air currents

[,from other areas of the structure to the app lance.

10

Instructions for Installation (cont'd)

Combustion Air and Ventilation

When determining the installation location for a direct vent

water heater, snow accumulation and drifting should be con-

sidered in areas where applicable.

any overhang

VENTINGCLEARANCES 18"mJn.

• 18" minimum in alldirections from any obstructionthat may

interfere.

I Figure2 ]

• 18" minimum from the ground and 12" fromceiling overhangs.

Figure2.

• The directvent terminal shall terminate at least 3 feetaboveany

* 9"minimum horizontallyfrom or aboveany door,windowor CTVE'V_N__'_ 9"__

gravityair inlet into the building.

* 12" minimum belowany door,window orgravityairinlet into the

building. _ IF LESS ,,

• 18"minimumfromothergravityornaturalapplianceoutletvents -._1_ _'_'_ "i -N120

when dimcdy ab°ve°r 135°t° either side°fcenter line"Figum4"page DIRE__ /_ _FtRC[DTA

• 36" minimum from anyoutlet ventswhen directlybelowor 45°to TERMI

either side of center line. Figure5, page 12. IR

• 36" minlmum in alldirections from anyother forced airappfiance

outlet vent. Figure 5, 12. [ Figure 3 ]

• The location selectionmust provide clearancesforservicing and

proper operation of the water heater. Figure 6,page 12.

• Vent termination must not be within 4 feet ofany items such as

/ Any gravity or natural

gas meters,gasvalvesorother gas regulatingequipment. _vented appliance.

THEN THE DIMENSION IS _ _..z_'_'\

i INCREASED TO 24" " \ _ _ --

a_ WARNING /- 18"min.-_ ' I --- \ ---

such as gas meters, gas valves or other gas regulating

equipment.

I _-- t3_° 13s°--

Failureto have required clearancesbetween vent piping I

and combustible material will result in a fire hazard. I I Figure 4 I

I I

11

Instructions for Installation (cont'd)

Combustion Air and Ventilation Flue Extensions

(cont'd) There arethree optional extension kits available. Any combi-

nation of the three kits can be chosen; however, only one kit

can be used vertically and/or horizontally.

(See Figures 8 & 9.)

4_

/36" min.if withid"

e thisiarea \ Unless otherwise specified at the time of ordering, a standard

d__ extension kit (66001422) is individually packaged and

shipped within the water heater carton.

36" min. within a360° ra Any other gravity or natural

if vent isaforced air appli- appliance outlet vent

ante outlet vent. POSSIBLE EXTENSION COMBINATIONS

[Figure,]

-- _ / TAL

Must maintain _ I'''" "_ TWO VERTICAL J J KITS

adequate service _ '_

and maintenance _ _ i KITS NOT OK

accessibility._ _.¢ _o) \ _ NOT OK

i_!_N i%_

i_ • _ available for vent

.--,on _U_°

IFigure"I ------- RT, L

OK

0

HORIZONTAL I----I

Optional Wire Grill KITOK _ i i

When the water heater vent cap is low enough to be touched _A_'T--"_C A

accidentally, or is accessible to small children, installation of a

protective vent cover is recommended. Some local codes may LKITAND

require a vent cap cover. Figure 7 shows the optional wire vent [ I ONEHORIZONTAL

cap protector available from the water heater manufacturer. I I K/rOK

I Figure8 I I I'--I

A wire mesh chain link fence (as shown in Figure 7) may be

used instead of the factory cover. Care should be taken to I

maintain adequate ventilation around the vent cap. If a chain _kWARNING

I

At no time can more than one Vertical and/or one

link fence is installed, it must not be used as a storage area for Horizontal Vent Kit be used.

items that may block proper ventilation.

VERTICAL (EXTENSION KIT) HEIGHT

NOttobeused It is simple to determine which kit is needed for vertical height.

/ asastoragearea _ Take the total height (to the top of the flue) required and com-

J4_ _-I- pating that to "F dim." in the chart #1, it can be determined

Failure to have required clearances between vent

piping and combustible material will result in a fire

hazard.

] WARN, G may

Obstructions and deteriorated vent systems

present serious health risk or asphyxiation.

12

Instructions for Installation (cont'd)

I HORIZONTAL (EXTENSION KIT)

A 66001423

r 66001424 simply plug the dimensions "D" and "G" into the equation

[ 6600142S ,_v-,[r_ _7_ below. The answer "E" should then be located in chart #2.

The size range in which "E" dimension falls indicates the kit

e!ste!teithe_r )U __ "D"thatshould be used horizontally to obtain the desiredlength.=Thewallthickness

"G" --The distance wanted between the edge of the water

heater and the inside edge of the wall

"E" = The distance the extension kit must be able to extend

_ " " The Equation D + G =E

Iigure'I ::°°0',::; ,

NOTE: Only one vent kit can be used horizontally and/or

CHART #2

!0

DIMENSION

40-50 Gal.

VENT KITS MIN MAX

66001422-Std. 3½ 10

66001423 10 15Y2

66001424 15½ 26½

66001425 26½ 48

*BTU'S

*GAL. in 1000's

CAP. NAT A B C

, _ .. 40 40/40 483h 413/,, 21

50 48144 61 54 21

CHART #1 *Seemodels and rating plate attached to the water heater for

_ BTU's _ specific model number and other detailed informafion

in1000'SNAT. _MIN' [ MIN ' ' &WARNING I

IMAXI IMAX I Be sure vent pipe is properly connected to prevent I

40/40 77 I 88 I 88 I 110 I escape of dan_ierous flue gases which could cause

48144 893h]100%11003h1122V4[ deadly asphyxiation.

*Seemodel and rating plate attached to the water heater for ]

specific model number and other detailed information. A WARNING

L

Obstructionsand deteriorated vent systemsmay present

serioushealth risk or asphyxiation.

13

Instructions for Installation (cont'd)

All Installations Standard Vent Kit

Fureaseofassemblytheinstalladonofthevariouskit Installation #1

combinations has been broken into individual sections,

The two steps below are common to all installations. Standard Vent Kit 66001422

Once these have been performed, you need only to refer

o.eeoo.te ,oyou

Installation Using Vent Kits:

1.Standard Vent Kit 66001422 ........................... Page 14

2. Optional Vertical Vent Kit _

with Standard Vent Kit .................................. Page 17

3. Optional Horizontal Vent Kit ........................ Page 21

4.Optional Hotizontal

and Vertical Vent Kits .................................... Page 25 *Eachpartisstampedwitha partnumber

CUTTING THE OPENING THROUGH THE OUTSIDE The opening through the wall should be cut at this time. If it

WALL hasn't been, refer back to that section.

After thoroughly reading the "Locating the New Water

Heater" section of this manual and you have chosen a suit- 1. Lock the elbow to the straight 3" flue pipe. Set this assem-

able water heater installation site, use the chart below to bly in place on the end of the water heater's flue collar.

determine dimensions for the opening in the wall.

Cut a C/4" diameter hole completely through the outside

wall.

2. Mark the flue collar at the slots in the elbow. Using a #22

drill hit, drill holes into the flue collar at the two slots and

WATER HEATER ATTITUDE secure the elbow to the flue collar using the screws provided.

There is a certain amount of variance with regard to the direc- NOTE: Make sure elbow is properly aligned to opening

tion the water heater faces, in the outside wall.

Standing in front of the water heater (gas control facing you),

set the 3" diameter elbow (slotted end) on the flue. This will

give you a better understanding of the relation of the vent __//)I_ "_"_

assembly to the opening in the wafl and more importantly any

possibility of interference of venting and water piping.

The direction of the water heater can now be made. Also con- _ _ _ _ -#

sider the gas control valve to insure installation, lighting, and 0" --__"I_S

maintenance accessibility are retained.

14

Instructions for Installation (cont'd)

3. Using the tube of sealant supplied, run an ample amount 6. The standard vent kit includes a6° diameter extension

around the oval flare of the jacket, pipe which is used when "E" dimension is over 6V2".

4. First remo e the 3 honzontaI extension from the elbow. X

Starting with the long end (with four securing holes), _] --_ _ ,__

place the 6" diameter vent elbow over the 3" diameter ,,

elbow. Bend the round end "oval_ to fit the flared oval end

of the jacket top.

I / I

7 If_E " dimension is less than 6VI' move to next step.

_)_ If"E" dim ensionis over6_/I', assemble the 6" diameter

extension pipe (crimped end) to the 6" diameter vent

elbow and secure using two sheet metal screws. Using the

tube of sealant supplied, run an ample amount around the

joint to insure a good seal.

t

5. Making sure the 6" diameter elbow is centered around the __ __

3" diameter flue, secure the 6" diameter vent pipe using

four sheet metal screws at the connection of the jacket top.

(_)-?__ _-'" 8. eSll_do;ihevent collar (to be installed later)over the 6" vent

15

Instructions for Installation (cont'd)

Standard Vent Kit (cont'd)

9. Place the water heater at the opening in the wall, at the 12. We have supplied 4 wood screws to temporarily attach the

predetermined clearance, collar to the exterior wall of the building. However, other

types of screws may have to be substituted depending on

\\

\\

\\ 13. Insert the 3" diameter flue extension pipe into the vent

\\ collar assembly (flared & notched end first) and lock (turn

'\ \

clockwise to lock studs to slots) the flue extension pipe to

\\ _ _ the flue elbow.

\\

10. Move outdoors with all the remaining vent parts. Using _ ..... _ ....

the tube of seal.ant supplied, run an ample amount on the :: ....

inside surface of the collar assembly that will contact the

exterior wall and also fill the bead on the end of the 6"

diameter vent collar.

__ 14. Connect the vent cap by sliding its end over the 3" diame-

ter extension pipe and O-ring.

NOTE: To facilitate ease of assembly of the vent cap to

the 3" pipe, a soap solution can be applied to the O-ring

gasket.

11. In:t tallt:htheVenteCOsUo_na:sTolz_yeltbho_u(ghe;ehediwa_g,oCOnh_:h VJ_/////_

16

Instructions for Installation (cont'd)

15. The vent cap has 4 holes around the outer edge. Remove

the 4 screws used to temporarily attach the collar to the

exterior wall. Then secure the vent cap assembly with the

vent collar assembly to the exterior wall using the same 4

screws.

NOTE: Screws are suppfied; however, substitution may

be necessary depending on the exterior wall material.

A CAUTION

Toprevent unlocking the previouslyinstalled 3" diameter

extension, the vent cap assembly must be rotated in a

cockwise mot on when the vent cap s nsta ed.

OW/_ihO_(/n_er _idca/oVre22K ia_

Any Optional Vent Kit

16. Go back indoors to attach inside collar to the inside wall.

Place the collar against the wall. Secure to wall by using 4 _ _

long sheet metal screws.

U

U

NOTE: Screws are supplied; however, substitution may

be necessary depending on the interior wall material.

The opening through the wall should be cut at this time. If it

hasn't been, refer back to that section.

1. First it must be determined how far the vertical (3" dia.)

telescoping flue sections are set and locked together using

the two screws supplied as shown below.

I

17. Using the tube of sealant supplied, run an ample amount II I

of sealant around the edge of the vent pipe where it is ____

inserted through the inside collar to seal air drafts from

wall.

17

Instructions for Installation (cont'd)

Optional Vertical Vent Kit

(Cont'd)

Use the chart, drawing and simple equation below to find 3. Sfide the 6"vent telescoping section apart to reveal the

the length of expansion of the telescoping flue sections, beads. Using the caulking supplied, fill the beads.

Because of manufacturing tolerances, place the telescoping

extension on the water heater and adjust the height ("X"

and mark the point. Once the length has

Dimension)

been determined, lock the two sections together by _ _

drilling two holes (180" apart) in the pipe and securing _ I

with the screws supplied. !

H ,1

7--L-_- -6,/,-

10" i :.... .a_

' _ ]'-- _ H 4. Using the tube of sealant supplied, run an ampleamoUntaroundthe oval flare of the j acket.

C- A- 10"= X A _

5. Place the 6" vent section over the 3" flue section. Subtract

%" from the X dimension used earlier and this gives the

length of the 6" vent extension. Slide the 6" vent exten-

sion apart to this dimension and lock it together using the

*GALLON *BTU's in 1000's two screwssupplied.

CAPACITY NAT. A

40 40140 48%

50 48/44 61

*See models and rating plate attached to the water heater

for specific model number and other detailed information. _

2. Set the vertical (3" dia.) telescoping flue section in place

on the flue collar. Using a #22 drill bit, drill two holes

(180° apart) and secure the vertical assembly to the flue

coUaL

6. Bend the round end of the 6" vent extension oval at the

jacket top and secure it using four sheet metal screws.

18

Instructions for Installation (cont'd)

7. Place the 3" elbow on the flue extension.

10. If"E" Dimension is less than 61/2# move to next step.

NOTE: Make sure elbow is properly aligned to opening If "E" dimension is over 6V:', assemble the 6" diameter

in the outside wail. extension pipe to the 6" diameter vent elbow and secure

Mark the 3" dia. end of the flue extension at the slots the using two sheet metal screws. Using the tube of sealant

elbow. Using a #22 drill bit, drill holes into the flue exten- supplied, run an ample amount around the joint to insure

sion at the two slots and secure the elbow to the flue a good seal.

extension using the screws provided.

__t_o!s, _[ ___

3.1.Slide the vent collar (to be installed later) over the 6" vent

8. Making sure the 6" diameter elbow is centered around the

elbow.

ure " "

3" diameter flue, sec the 6 diameter vent pipe using

two sheet metal screws at the connection of the elbow and

6" vertical extension.

12. Place the water heater at the opening in the walI, at the

predetermined clearance.

9. The standard vent kit [_J[

includes a 6# diameter

extension pipe which is _1

used when "E" dimension ,_

over 6V:'.

\\

-

19

Instructions for Installation (cont'd)

Optional Vertical Vent Kit

(cont'd)

13. Move outdoors with all the remaining vent pans. Using the 16. Insert the 3" diameter flue extension pipe into the vent

tube of sealant supplied, run an ample amount on the inside collar assembly (flared &. notched end first) and lock (turn

surface of the collar assembly that will contact the exterior clockwise to lock studs to slots) the flue extension pipe to

wall and also fill the bead on the end of the 6" diameter vent the flue elbow.

collar.

/

1

17. Connect the vent cap by sliding its end over the 3" diame-

ter extension pipe and O-ring.

14. Install the vent collar assembly through the wall, connect- NOTE: To _¢ili_ate ease of _ssembly of the vent cap to

ing it to the extension and/or elbow (depending on which the 3" pipe, a soap solution can be applied to the O-ring

one was used), gasket.

15. We have supplied 4 wood screws to temporarily attach the 18. The vent cap has 4 holes around the outer edge. Remove

collar to the exterior wall of the building. However, other the 4 screws used to temporarily attach the collar to the

types of screws may have to be substituted depending on exterior wall. Then secure the vent cap assembly with the

the construction of the external wall. vent collar assembly to the exterior wall using the same 4

screws.

A CAUTION

j__41/ /TOprevent unlocking the previously installed 3" diameter

I extension, the vent cap assembly must be rotated in a

[ clockwisemotion when the vent capisinstalled.

20

Instructions for Installation (cont'd)

Optional Horizontal Vent Kit

Installation #3

19. Go back indoors to attach inside collar to the inside wall. Any Optional Vent Kit

lottgPlacethecollaragainstthewaU.SecuretowaUbyusing4sheetmetaJ, screws. ___ _

NOTE: Screws are supplied; however, substitution may

be necessary depending on the interior wall material. _ _

These _

parts are

not used

*Each part is stamped with a part number

The opening through the wall should be cut at this time. If it

hasn't been, refer back to that section.

1. Lock the elbow to the straight 3" flue pipe. Set the assem-

bly in place on the end of the water heater's flue collar.

20. Using the tube of sealant supplied, run an ample amount

of sealant around the edge of the vent pipe where it is =,_

inserted through the inside collar to seal air drafts from ._ _ __

wall.

2. Mark the flue collar at the slots in the elbow. Using a #22

drill bit, drill holes into the flue collar at the two slots and

secure the elbow to the flue collar using the screws provided.

NOTE: Make sure elbow is properly aligned to opening

in the outside wall.

21

Instructions for Installation (cont'd)

Optional Horizontal Vent Kit

(Cont'd)

3. Using the mbe ofsealant supplied, run an ample amount 6. The standard kit includes a single piece of3" flue and 6"

around the oval flareof the jacket, vent pipe which will not be used in conjunction with the

horizontal kit.

7. Slide the vent collar (to be installed later) over the 6" vent

4. First remove the 3" horizontal extension from the elbow.

elbow.

Starting with the long end (with four securing holes),

place the 6" diameter vent elbow over the 3" diameter

of theelbow. Bend the round end "oval" to fit the flared oval endjacket top. _ "_ /"_"',_

_/_ 8. Place the water heater at the opening in the wall, at the

predetermined clearance.

5. Making sure the 6" diameter elbow is centered around the _4_ 0_ _111

3" diameter flue, secure the 6" diameter vent pipe using _

four sheet metal screws at the connection of the jacket top.

E

\\

\\

22

/