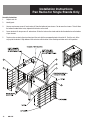

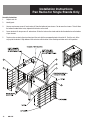

Blodgett 6E-SBF is a connectionless steamer designed to give years of service. It has a stainless steel cavity which is served by an inside water reservoir which is electrically heated. A powerful blower circulates the steam in the cavity to increase heating efficiency. The cavity holds up to six standard 12” x 20” x 2-1/2” or four 12” x 20” x 4” steamer pans.

Blodgett 6E-SBF is a connectionless steamer designed to give years of service. It has a stainless steel cavity which is served by an inside water reservoir which is electrically heated. A powerful blower circulates the steam in the cavity to increase heating efficiency. The cavity holds up to six standard 12” x 20” x 2-1/2” or four 12” x 20” x 4” steamer pans.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

Blodgett 6E-SBF Operating instructions

- Type

- Operating instructions

- This manual is also suitable for

Blodgett 6E-SBF is a connectionless steamer designed to give years of service. It has a stainless steel cavity which is served by an inside water reservoir which is electrically heated. A powerful blower circulates the steam in the cavity to increase heating efficiency. The cavity holds up to six standard 12” x 20” x 2-1/2” or four 12” x 20” x 4” steamer pans.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

jbc S7034 User manual

-

Groen VRC-3E Operating instructions

-

EcoWater Dol-Fyn Owner's manual

-

Groen VRC-3E Operating instructions

-

Groen VRC-3E Operating instructions

-

Groen (2)SSB-10G Specification

-

Groen SSB-5G Operating instructions

-

Groen SSB-3E Specification

-

Groen SSB-3E Operating instructions

-

Groen VRC-3E Datasheet