Page is loading ...

Warringtonfire

Chiltern House

Stocking Lane

High Wycombe

HP14 4ND

United Kingdom

T: +44 (0)1494 569750

W: www.warringtonfire.com

Registered Office: Warringtonfire Testing and Certification Limited, 10 Lower Grosvenor Place, London, United Kingdom, SW1W 0EN. Reg No. 11371436

Title:

Field of Application

Sentry Prolite Timber Based Doorsets

30 Minutes Fire Resistance

Report Reference:

Chilt/A04030 Revision C

Report Number:

WF420793

Valid From:

12 November 2019

Valid Until:

30 August 2023

Prepared for:

Jiangsu Sainty Bancom Wood Co.

Ltd, T/A Sentry International

The Lodge

Church Hill

Burstall

Suffolk

IP8 3DU

Report No:

Chilt/A12082 Revision D

WF Contract

515329

Prepared for:

Ahmarra Ltd

Unit 20, Fitzherbert Road

Warringtonfire Report

Chilt/A04030 Rev C

Page 2 of 40

Contents Page Nos

1. Foreword ................................................................................................................ 3

2. Proposal ................................................................................................................. 3

3. Test Evidence ........................................................................................................ 4

4. Technical Specification ........................................................................................... 9

5. Leaf Sizes ............................................................................................................ 10

6. Configurations and Orientation ............................................................................. 10

7. Leaf Size Adjustment ........................................................................................... 10

8. Overpanels ........................................................................................................... 11

9. Glazing ................................................................................................................. 13

10 Door Frames ........................................................................................................ 15

11 Lippings................................................................................................................ 18

12 Leaf Facing Materials ........................................................................................... 18

13 Intumescent Materials .......................................................................................... 19

14 Adhesives ............................................................................................................ 19

15 Tested Hardware .................................................................................................. 20

16 Additional & Alternative Hardware ........................................................................ 20

17 Door Gaps ............................................................................................................ 24

18 Fixings ................................................................................................................. 24

19 Sealing to Structural Opening ............................................................................... 25

20 Smoke Control ..................................................................................................... 26

21 Insulation .............................................................................................................. 26

22 Conclusion ........................................................................................................... 27

23 Declaration by the Applicant for Report WF420793 .............................................. 28

24 Limitations ............................................................................................................ 29

25 Validity ................................................................................................................. 30

Appendix A Performance Data …………………………………………….…………..………... 31

Appendix B Proprietary Glazing Systems …………………………………………………..… 32

Appendix C Revisions ………………………………………………………………….………..… 34

Appendix D Data Sheets ……………………………………………………………………..…… 35

Warringtonfire Report

Chilt/A04030 Rev C

Page 3 of 40

1. Foreword

This field of application report has been commissioned by Jiangsu Sainty Bancom

Wood Co. Ltd, T/A Sentry International, and relates to the fire resistance of 30 minute

Sentry Prolite fire resisting doorsets.

The report is for National Application and has been written in accordance with the

general principles outlined in BS EN 15725: 2010; Extended application reports on the

fire performance of construction products and building elements.

This field of application (scope) uses established empirical methods of extrapolation

and experience of fire testing similar door assemblies, in order to extend the scope of

application by determining the limits for the designs based on the tested constructions

and performances obtained. The scope is an evaluation of the potential fire resistance

performance, if the variations specified herein were to be tested in accordance with BS

476: part 22 and therefore can neither be considered for a CE marking application nor

can the conclusion be used to establish a formal classification against EN13501-2.

This field of application has been written using appropriate test evidence generated at

UKAS accredited laboratories

1

, to the relevant test standard. The supporting test

evidence has been deemed appropriate to support the manufacturers stated door

design and is summarised in section 3.

The scope presented in this report relates to the behaviour of the proposed door design

variations under the particular conditions of the test; they are not intended to be the

sole criterion for considering the potential fire hazard of the door assembly in use.

This field of application has been prepared and checked by product assessors with the

necessary competence, who subscribe to the principles outlined in the Passive Fire

Protection Forum (PFPF) guidelines to undertaking assessments. The aim of the PFPF

guidelines is to give confidence to end-users that assessments that exist in the UK are

of a satisfactory standard to be used for building control and other purposes.

The PFPF guidelines are produced by the UK Fire Test Study Group (FTSG) an

association of the major fire testing laboratories in the UK and are published by the

PFPF, the representative body for the passive fire protection industry in the UK.

1

Test evidence from overseas laboratories has also been considered as supporting evidence

for the designs in this assessment report. The test evidence is from a laboratory that has

been accredited by a national accreditation body which is a signatory of the International

Laboratories Accreditation Co-operation (ILAC).

2. Proposal

It is proposed to consider the fire resistance performance of the doorset design

described in the technical specification in section 4 of this report, for 30 minutes fire

resistance integrity, if the doorset were to be tested to the requirements of BS 476:

Part 22: 1987, Fire tests on building materials and structures – Part 22: Method for

determination of the fire resistance of non-load bearing elements of construction.

The field of application defined in this report is based on the fire resistance test

evidence for the doorset design, which is summarised in section 3. Analysis of specific

construction details that require assessment are given within this report against the

relevant element of construction, as appropriate.

Warringtonfire Report

Chilt/A04030 Rev C

Page 4 of 40

3. Test Evidence

The test evidence summarised below has been generated to support the fire resistance

performance of the door designs that are the subject of this field of application.

3.1 Comparison of Test Standards

The ISO834 time/temperature curve used in BS 476: Part 22: 1987 test is the same as

within BS EN 1634-1, except for the use of Plate Thermometer device(s) for furnace

control in the EN test, which test data has shown to make the EN test more onerous.

This is due to the higher thermal inertia required for the plate thermocouple to read the

same temperature as the probe thermocouple used for the BS 476: Part 22 test,

particularly during the early stages of the test. It is therefore our assessment that the

same integrity performance would be achieved in a test conducted utilizing the

principles of BS 476: Part 22: 1987 and that test data generated to the requirements

of the EN test may therefore be used in support of this scope of application document,

written to the requirements of BS 476: Part 22: 1987.

Note: dimensions are in mm unless otherwise stated.

Abbreviations: (h) = height; (w) = width; (t) = thickness; (d) = depth.

Doorsets with latches fitted but disengaged for the test, are reported as ‘unlatched’.

Warringtonfire Report

Chilt/A04030 Rev C

Page 5 of 40

3.2 Test Reports 181212006SHF-001 and 181212006SHF-002

The referenced test reports, the essential details of which are summarised below, are

primary data for the Type A door design being considered for assessment in this report.

This test supports latched, single leaf, unglazed doorsets, hung in hardwood frames

with steel hinges, and a mortise lock, opening both towards and away from the furnace.

Date of test

30

th

January 2019

Identification of test body:

Intertek testing Services Shenshen Ltd, Shanghai, China

IAS accreditation No. TL-394

Sponsor:

Jiangsu Sainty Bancom Wood Co.Ltd

Tested Product:

Latched, single acting, single leaf, timber based flush

doorsets, referenced Doorset A and Doorset B

Summary of test specimen:

Both door leaf dimensions: 2135 (h) x 915 (w) x 44 (t).

Both leaves comprised a core of 3 layers of 12 (t) Albasia

blockboard lamels laid in alternating horizontal and vertical

directions with a 36 (t) x 32 (w) beech top rail, and faced on

each side with 4 (t) plywood. The leaves were lipped with 8 (t)

Meranti to all four sides and hung in a beech frame on 3 No.

stainless steel, bearing butt hinges. 15 x 4 PVC encased

Pyroplex intumescent seals were centrally fitted into the frame

reveal of the head and jambs. An SS5572-01A mortise lock

with latch and deadbolt was fitted to both doorsets.

The left hand doorset was oriented to open out from the

furnace; the right hand doorset was oriented to open towards

the furnace. Both leaves were latched for the duration of the

test.

Test Standard:

EN 1634-1:2014

Performance

Doorset A

Integrity: 31 minutes

1

Insulation: 31 minutes

Doorset B

Integrity: 31 minutes

1

Insulation: 31 minutes

1

No failures of integrity or insulation had occurred when the test was terminated at 31 minutes

at the request of the sponsor.

Warringtonfire Report

Chilt/A04030 Rev C

Page 6 of 40

3.3 Test Report WF403032

The referenced test report, the essential details of which are summarised below, is

primary data for the Type A door design being considered for assessment in this report.

This test supports latched and unlatched single leaf, single and double acting glazed

and unglazed doorsets, hung in softwood frames with steel lift off hinges, and a mortise

lock, opening towards the furnace.

Date of test

9

th

November 2018

Identification of test body:

Warringtonfire Testing and Certification Ltd.

UKAS No. 1762

Sponsor:

Jiangsu Sainty Bancom Wood Co.Ltd

Tested Product:

An unlatched, single acting, single leaf, timber based flush

doorset with glazing. The doorsets were referenced Doorset

A and Doorset B but only Doorset B is the subject of this

report.

Summary of test specimen:

Door leaf dimensions: 2135 (h) x 920 (w) x 45 (t).

The leaf comprised a core of 3 layers of 12 (t) Albasia falcata

lamels laid in alternating horizontal and vertical directions with

a 36 (t) x 32 (w) beech top rail, and faced on each side with 4

(t) plywood with a 0.5 (t) beech veneer. The leaves were lipped

with 6 (t) sapele to all four sides and hung in a 70 (d) x 32 (w)

Redwood frame on 3 No. steel, lift off hinges. 15 x 4 PVC

encased Pyroplex rigid box Seal Pile intumescent seals were

centrally fitted into the frame reveal of the head and jambs and

a 35 x 14 Norseal NOR810 aluminium drop seal was fitted to

the bottom edge of the leaf. A Rutland TS3204 surface

mounted overhead closer was fitted to the head of the leaf on

the exposed face and an E*S Eurospec tubular steel latch

was fitted to the doorset but disengaged.

The leaf was fitted with a glazed aperture 870 (h) x 715 (w)

incorporating 6 (t) Pilkington Pyroshield 2 GWPP glass glazed

with Lorient Polyproducts Ltd 36/6 Plus and LG1512 Plus

glazing system, fixed with sapele hardwood beads, 20 (h) x 21

(d), including a 5 x 5 bolection return, retained with 4Ø x 40

long steel screws, 50 from each corner and at 115 centres.

The leaf was oriented to open towards the furnace and was

unlatched for the duration of the test.

Test Standard:

BS 476 Part 22:1987

Performance

Doorset B

Integrity: 42 minutes

Insulation: 0 minutes

1

1

In accordance with section 8.6.1 of BS 476 Part 22:1987, the specimen was not evaluated for

insulation.

Warringtonfire Report

Chilt/A04030 Rev C

Page 7 of 40

3.4 Test Report RF04016

The referenced test report, the essential details of which are summarised below, is

primary data for the Type B door design being considered for assessment in this report.

This test supports latched and unlatched single and double, single and double acting

glazed and unglazed doorsets, hung in softwood and hardwood frames with steel lift

off hinges, overhead surface mounted closer, a mortise lock, aluminium handles and

6mm Pyroshield GWPP glass.

Date of test

19

th

February 2004

Identification of test body:

Chiltern International Fire Ltd, now trading as Warringtonfire

Testing and Certification Ltd. UKAS No. 1762

Sponsor:

CIPTA UK Ltd.

Tested Product:

An unlatched, single acting, double leaf, timber based flush

doorset with glazing, referenced doorset A and an unlatched

single acting, single leaf flush doorset, referenced doorset B.

Summary of test specimen:

Doorset A leaf dimensions: 2110 (h) x 852/300 (w) x 43 (t).

Doorset B leaf dimensions: 2415 (h) x 1210 (w) x 43 (t).

The leaves comprised a core of 3 layers of 12 (t) Falcateria

(Albasia falcata) lamels laid in alternating horizontal and

vertical directions with 1No 36 (t) x 22 (w) and 1No 36 (t) x 38

(w) hardwood top rails, a 36 (t) x 23 (w) hardwood stile to the

hanging edge, and faced on each side with 3.5 (t) WBP

hardwood plywood. The leaves were lipped with 8 (t) sapele

to the vertical edges only. Doorset A was hung in a 70 (d) x 32

(w) European redwood frame and doorset B was hung in a 70

(d) x 32 (w) sapele frame. Both doorsets were hung on 3 No.

Royde and Tucker steel, lift off hinges.15 x 4 PVC encased

Therm-A-Seal intumescent seals were centrally fitted into the

frame reveal of the head and jambs and the right meeting

edge of doorsets A. A Dorma TS73V surface mounted

overhead closer was fitted to the head of the leaf on the

exposed face and a tubular mortise latch was fitted to the

doorset but disengaged.

The right leaf of doorset A was fitted with a glazed aperture

700 (h) x 650 (w) incorporating 6 (t) Pilkington Pyroshield

GWPP glass glazed with nominally 2 (t) Sealmaster Fireglaze,

and fixed with sapele hardwood beads, 20 (h) x 21.5 (d),

including a 5 x 5 bolection return and 13° chamfer, retained

with 50 long steel pins, 45 from each corner and at 100

centres.

The leaves were oriented to open towards the furnace and

were both unlatched for the duration of the test.

Test Standard:

BS 476 Part 22:1987

Performance

Doorset A

Integrity: 37 minutes

Insulation: 37 minutes

1

Doorset B

Integrity: 44 minutes

2

Insulation: 44 minutes

2

1

In accordance with section 8.6.1 of BS 476 Part 22:1987, the specimen was not evaluated for

insulation.

2

Failure had not occurred on termination of the test.

Warringtonfire Report

Chilt/A04030 Rev C

Page 8 of 40

3.5 Test Report RF01059B

The referenced test report, the essential details of which are summarised below, is

primary data for the Type B door design being considered for assessment in this report.

This test supports a Type B variation incorporating thicker facings and a thinner core

for latched and unlatched single leaf, single and double acting glazed and unglazed

doorsets, hung in MDF frames with steel lift off hinges, and a tubular mortise latch,

opening towards the furnace.

Date of test

16

th

July 2001

Identification of test body:

Chiltern International Fire Ltd, now trading as Warringtonfire

Testing and Certification Ltd. UKAS No. 1762

Sponsor:

Williamson Associates

Tested Product:

An unlatched, single acting, single leaf, timber based flush

doorset with glazing.

Summary of test specimen:

Door leaf dimensions: 2135 (h) x 915 (w) x 45 (t).

The leaf was identified as a Sentry Superlite construction with

a 34 (t) core and 5.5 (t) ply facings, lipped with 6 (t) sapele to

all four sides, and hung in a 125 (d) x 25 (w) SAM MDF primed

frame, on 3 No. Royde and Tucker lift off hinges. Intumescent

Seals Ltd 20 x 4 PVC encased Therm-A-Seal intumescent

seals were centrally fitted into the frame reveal of the head and

jambs. A Dorma TS73V surface mounted overhead closer

was fitted to the head of the leaf on the exposed face and a

Henderson Hardware Ltd tubular mortise latch was fitted to the

doorset but disengaged. Aluminium lever handles were fitted

appropriate to the latch.

The leaf was fitted with a glazed aperture 704 (h) x 604 (w)

incorporating 6 (t) Pilkington Pyroshield GWPP glass glazed

with nominally 2 (t) Sealmaster Fireglaze, and fixed with

sapele hardwood beads, 26 (h) x 27 (d), including a 10 x 6

bolection return and 24° chamfer, retained with 50 long steel

pins at 100 centres.

The leaf was oriented to open towards the furnace and was

unlatched for the duration of the test.

Test Standard:

BS 476 Part 22:1987

Performance

Integrity: 35 minutes

Insulation: 35 minutes

1

1

In accordance with section 7.6.1 of BS 476 Part 22:1987, the glazing was not evaluated for

insulation.

Warringtonfire Report

Chilt/A04030 Rev C

Page 9 of 40

4. Technical Specification

4.1 General

The technical specification for the proposed door assembly is given in the following

sections based on the test evidence for the door design, summarised in section 3.

4.2 Intended use

The intended use of the proposed door assembly is summarised below:

A pedestrian doorset including any frame, door leaf or leaves which is provided to give

a fire resisting capability when used for the closing of permanent openings in fire

resisting separating elements, which together with the building hardware and any seals

(whether provided for the purpose of fire resistance or smoke control or for other

purposes such as draught or acoustics) form the assembly.

4.3 Description of Construction – Type A

The basic tested construction of the Sentry Prolite door design comprises the following:

Element

Material

Dimensions

(mm)

Density

(kg/m³)

Stiles

None

-

-

Rails (top only)

1No. hardwood

1No. 32 (w) x 36 (t)

565**

Core

Inner

Horizontal Falcateria lamels

12 (t) x nominally 50 (w)

345**

Outer

Vertical Falcateria lamels

12 (t) x nominally 50 (w)

345**

Facings

WBP hardwood plywood

4.0 (t)

550*

Hardwood veneer

0.5 (t)

varies

Lipping

Hardwood

6 - 8 (t)

640*

* Nominal density; ** Stated density, checked by laboratory

4.4 Construction Variation – Type B - double top rail and hanging edge stiles

Element

Material

Dimensions

(mm)

Density

(kg/m³)

Stiles (hanging

edge only)

Hardwood

23 (w) x 36 (t)

549**

Rails (top rail

only)

2No. hardwood

1No. 22 (w) x 36 (t)

1No. 38 (w) x 36 (t)

565**

Core

Inner

Horizontal Falcateria lamels

12 (t) x nominally 50 (w)

345**

Outer

Vertical Falcateria lamels

12 (t) x nominally 50 (w)

345**

Facings

WBP hardwood plywood

3.5 (t), 4.0 (t), or 5.5 (t)

1

550*

Lipping

Hardwood

6 - 8 (t)

640*

1

Core is reduced to 34mm for 5.5 (t) plywood facings. (See table above for * and ** legends.)

Warringtonfire Report

Chilt/A04030 Rev C

Page 10 of 40

5. Leaf Sizes

The approval for increased leaf dimensions is based on the tests listed in section 3

and takes into account the margin of over performance above 30 minutes integrity for

the design and the characteristics exhibited during test. Data sheets specifying the

maximum approved leaf sizes and graphs showing the permitted gradient between

maximum height and width, are contained in appendix D.

Unequal leaf double doorsets are covered by this assessment with no restriction on

the smaller leaf dimension. Doorsets containing leaves with smaller dimensions than

those stated are deemed to be less onerous and are therefore automatically covered.

6. Configurations and Orientation

6.1 Configurations

Based on the test evidence summarised in section 3, this assessment covers the

following doorset configurations:

Abbreviation

Description

Construction

Type

LSASD & ULSASD

Latched & unlatched single acting single

doorset

Types A and B

DASD

Double acting single doorset

Types A and B

LSADD & ULSADD

Latched & unlatched single acting double

doorset

Type B only

DADD

Double acting double doorset

Type B only

6.2 Orientation

The primary fire resistance test for this design was conducted with one doorset hung

such that the door leaf opened towards the fire, and one doorset hung such that the

door leaf opened away from the fire. Based on this testing, assessment is made that

doorsets to this design may be hung to open either away from or towards the fire risk

side of the doorset.

The fire risk may therefore be from both directions with respect to these doorsets.

7. Leaf Size Adjustment

Door leaves constructed to this design may be altered as follows:

Element

Reduction

Leaf Height

The manufactured leaf height may be reduced without restriction

from the bottom edge only.* The top rail must remain intact

Leaf

Width

Type A

The manufactured leaf width may be reduced without restriction

from either edge.*

Type B

The manufactured leaf width may be reduced from the closing,

lock edge, only. The hanging edge stile must remain intact.*

Timber lippings

The lipping dimensions stated in section 11 may be reduced by

20% for site - fitting purposes.

* Following reductions, all lippings must be reinstated in accordance with section 11.

Warringtonfire Report

Chilt/A04030 Rev C

Page 11 of 40

8. Overpanels

8.1 Solid

Overpanels of the same construction as the Type A and Type B door leaves detailed

in sections 4.3.and 4.4 may be used with this doorset design only when a transom is

fitted. The transom must be softwood or hardwood and must have a minimum section

of 70mm x 32mm.

Joints must be mortise and tenon, mortise housed or butt jointed and glued and

screwed.

Overpanels must be fixed using the following method:

screwing through the rear of the frame with steel screws passing at least 30mm

into the centre line of the overpanel. Fixings must be no more than 100mm from

each corner and a maximum of 250mm centres in between.

The intumescent seal specification for overpanel assemblies must be as the jamb for

vertical edges and the head for horizontal edges and must be on all 4 edges of the

overpanel as defined in appendix D for the different designs and configurations.

Overpanels must be lipped on all edges, meeting the specification in section 11.

Maximum assessed overpanel heights are as follows:

Configuration

Max Overpanel Height (mm)

Single doorsets

2000

Double Doorsets

1000

Drawing is representative of doorset construction. Exact construction must comply with

the specification contained in this document.

Warringtonfire Report

Chilt/A04030 Rev C

Page 12 of 40

8.2 Glazed Fanlights

Doorsets including a transom may have the overpanel section glazed in lieu of a

section of door. The timber frame and glazing beads must be hardwood with a

minimum density of 640 kg/m

3

and the transom section must be a minimum of 70mm x

44mm.

The maximum assessed fanlight dimensions are detailed in the table below, subject to

the following restriction:

The glazing system and glass must be able to demonstrate adequate performance

when tested as a window or screen in accordance with BS 476: Part 22: 1987 or

BS EN 1634-1, at the pane dimensions to be installed.

Configuration

Height (mm)

Width (mm)

Single & double doorsets

≤600

Overall door width

Note: Drawing is representative of doorset construction. Exact construction must

comply with the specification contained in this document.

Warringtonfire Report

Chilt/A04030 Rev C

Page 13 of 40

9. Glazing

9.1 General

The testing on the Sentry Prolite design has successfully demonstrated that it is

capable of tolerating the inclusion of glazing.

The permitted glazed area for all configurations is 0.91m² and the glazing must meet

the following criteria:

9. 2 Assessed Glazing Systems

The glazing system must be one of the following tested proprietary systems:

Glazing System

Manufacturer

1. Therm-A-Strip 30

Intumescent Seals Ltd

2. Fireglaze 30

Sealmaster Ltd

3. Firestrip 30

Hodgson Sealants Ltd

4. System 36 Plus

Lorient Polyproducts Ltd

5. Pyroglaze 30

Mann McGowan Ltd

6. R8913

Pyroplex Plc

7. Flexible Figure 1

Lorient Polyproducts Ltd

9.3 Assessed Glass Products

Assessed glass types are as follows:

Glass Type

Manufacturer

1. 6 & 7mm Pyroshield 2

Pilkington UK Ltd

2. 6mm Pyran S

Schott Glass Ltd

3. 7mm Pyroguard EW30

Pyroguard UK Ltd

4. 7mm Pyrobelite 7

AGC Flat Glass UK

5. 7mm Pyrodur 30-104 or 30-105

Pilkington UK Ltd

6. 10mm Pyrodur 30-201/60-10

Pilkington UK Ltd

7. 12mm Pyrobelite 12

Pyroguard UK Ltd

8. 15mm Pyrostop 30-10

Pilkington UK Ltd

9. 16mm Pyrobel 16

AGC Flat Glass UK

Notes:

1. All glass must be fitted in accordance with the manufacturers' tested installation

requirements, particularly with respect to edge cover and expansion clearance.

2. Glass types 8 and 9 are fully insulating for 30 minutes in terms of the criteria set

out in BS 476: 20: 1987.

Warringtonfire Report

Chilt/A04030 Rev C

Page 14 of 40

9.4 Glazing Beads & Installation

Glazing beads must be from hardwood as specified in the following table:

Material

Profile

Min Density

(kg/m

3

)

Application

Hardwood

Splayed

640

All proprietary systems detailed in 9.2

and shown in appendix B and all glass

types specified in 9.3

Hardwood

Square

640

Proprietary systems 1,2 & 3 as specified

in 9.2 and shown in appendix B, and

glass types 4-9 specified in 9.3

Timber for glazing beads must be joinery quality straight grained hardwood, free from

knots, splits and checks.

A square bead profile may be used as an alternative to the splayed beads required for

the proprietary systems, subject to the restricted glass types and glazing systems

specified in the table above (see appendix B for square bead profile options).

Glazing beads must be retained in position with 50mm long x 2mm diameter steel pins

or 40mm long No 6-8 screws, inserted at 35-40º to the vertical at no more than 50mm

from each corner and at 150mm maximum centres.

Pneumatically (gun) fired steel pins are acceptable providing the pins meet the

specifications shown below, are a minimum of 60mm long, and wherever possible are

orientated perpendicularly to the glass.

Round pin diameter (mm) = minimum 1.6mm:

Oval/rectangular pin minimum linear dimensions = 1.6mm x 1.4mm:

Glazed openings must not be less than 100mm from any door edge. Multiple apertures

are acceptable within the permitted glazed area, with a minimum of 80mm of door core

separating the apertures.

Aperture shape is not restricted, providing the glazing system and beads are

compatible with that shape.

1.6mm

1.6mm

1.6mm

1.4mm

1.4mm

Warringtonfire Report

Chilt/A04030 Rev C

Page 15 of 40

9.5 False Glazing Beads

False timber beads may be bonded to the glass face. Suitable glass for this application

is restricted to types 4 - 9. One of the following intumescent glazing products must be

used.

Glazing System

Manufacturer

1. Therm-A-Strip 30

Intumescent Seals Ltd.

2. Fireglaze 30

Sealmaster Ltd.

3. Firestrip 30

Hodgsons Sealants Ltd.

4. Envirograf Product 77 – G10/10

Intumescent Seals Ltd.

Seals for false glazing beads must be a minimum of 10mm wide x 0.5 – 3mm thick.

Preformed strip systems 1 – 4 may be self-adhesive and grooved into the rear of the

glazing bars.

10 Door Frames

10.1 Door Frame Construction

Door frames for Sentry Prolite must be constructed as follows:

Application

Material

Section

Size (mm)

Min Density

(kg/m³)

Door frames with

or without

transomed solid

overpanels

Softwood or hardwood

70 x 32

510

Hardwood

(extended leaf size range for single

doorsets-see note 1)

70 x 32

640

MDF

(single doorsets only-see note 2)

95 x 25

700

Door frames with

glazed fanlights

Hardwood

70 x 44

640

Notes:

1. The single leaf doorset B tested in RF04016, evaluated the performance of the Sentry

Prolite design utilising a hardwood door frame (see graph contained in appendix D for

extended single leaf size range).

2. The doorset tested in RF01059B (AR2), evaluated the performance of the Sentry

Superlite design, utilising an MDF door frame (see graph contained in appendix D for

the permitted single leaf size range).

3. Timber used for constructing door frames must meet or exceed class J30 as specified

in BS EN 942: 2007, providing any defects are adequately repaired.

4. A 12mm deep planted stop is adequate for single acting frames whilst double acting

frames must may be scalloped or square. If frames are square, the maximum radius

to the corners of the leaf is 8mm. Frame joints must be mortice and tenoned, mitred,

butt, half lapped nailed or screwed and with no gaps.

Warringtonfire Report

Chilt/A04030 Rev C

Page 16 of 40

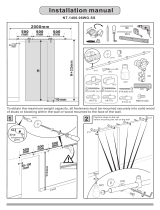

The following diagram depicts the assessed frame profiles and dimensions:

A = min 70mm

MDF = min 95mm

B = min 32mm

MDF = min 25mm

C = min 12mm

R = radius from floor spring

R8 = 8mm radius to create maximum 2mm edge profiling

10.2 Door Frame Joints

Half Lapped Joint

Mitre Joint

Mortice and Tenon Joint

Butt Joint

Warringtonfire Report

Chilt/A04030 Rev C

Page 17 of 40

10.3 Door Frame Installation

The following diagrams indicate acceptable door frame installations.

Permitted Installations

6 to 10mm

Max 10 x 10mm shadow gap with 2mm

intumescent mastic capping or

10 x 4mm PVC encased intumescent seal

15mm

Permitted Permitted

PermittedNot PermittedNot Permitted

Permitted

6-10mm is the maximum a frame is permitted

to be proud of the structural surround when

combined with a 12mm bolection return.

Projecting frames outside these dimensions will

require specific test evidence or assessment.

6 to 10mm

Max 10 x 10mm shadow gap with 2mm

intumescent mastic capping or

10 x 4mm PVC encased intumescent seal

15mm

Permitted Permitted

PermittedNot PermittedNot Permitted

Permitted

6 to 10mm

Max 10 x 10mm shadow gap with 2mm

intumescent mastic capping or

10 x 4mm PVC encased intumescent seal

15mm

Permitted Permitted

PermittedNot PermittedNot Permitted

Permitted

Shadow gaps are permitted as shown in the

above diagram providing the frame to structural

surround is infilled with timber of the same

density as the frame or a non-combustible

material such as plasterboard. Other shadow

gap dimensions will require specific test

evidence or assessment.

6 to 10mm

Max 10 x 10mm shadow gap with 2mm

intumescent mastic capping or

10 x 4mm PVC encased intumescent seal

15mm

Permitted Permitted

PermittedNot PermittedNot Permitted

Permitted

Architraves overlapping the frame to structural

surround junction are always permitted where

required but may be mandatory depending on

the size of frame to surround junction gap and

the fire stopping used. See section on Sealing

to the Structural Surround.

6 to 10mm

Max 10 x 10mm shadow gap with 2mm

intumescent mastic capping or

10 x 4mm PVC encased intumescent seal

15mm

Permitted Permitted

PermittedNot PermittedNot Permitted

Permitted

Depending on the size of the frame to surround

junction gap and the fire stopping methods

used, it may be permitted to install doorsets

without architraves. See section on Sealing to

the Structural Surround.

Installations Not Permitted

6 to 10mm

Max 10 x 10mm shadow gap with 2mm

intumescent mastic capping or

10 x 4mm PVC encased intumescent seal

15mm

Permitted Permitted

PermittedNot PermittedNot Permitted

Permitted

Projecting frames without bolection returns are

not permitted without specific test evidence or

assessment due to the potential for increased

charring to the back of the frame.

6 to 10mm

Max 10 x 10mm shadow gap with 2mm

intumescent mastic capping or

10 x 4mm PVC encased intumescent seal

15mm

Permitted Permitted

PermittedNot PermittedNot Permitted

Permitted

Quirks between the leaf and frame are not

permitted without specific test evidence or

assessment due to the potential for increased

charring of the leaf to frame gap.

Notes: Dark brown = lippings and architraves; blue = 5-10mm fitting tolerance for sealing*.

Structural openings may be thicker than frames providing the minimum frame sections in 10.1 are

maintained and frame to structural opening junctions are sealed in accordance with section 19.

The diagrams above are representative; actual installation must be as the text within this

document specifies. *See section 19 for sealing to structural opening.

12-15mm

Warringtonfire Report

Chilt/A04030 Rev C

Page 18 of 40

11 Lippings

Sentry Prolite doors only require lipping on the vertical edges but may be lipped on all

edges if required. Lippings must meet the following specification:

Type

Dimensions

(mm - thick)

Min Density

(kg/m³)

Flat

8 - 11

640

Rounded

8 - 11 with a max of 2 rounding (see section

10.1)

Rebated

Not permitted

Timber for lippings must be joinery quality straight grained hardwood, free from knots,

splits and checks.

12 Leaf Facing Materials

The primary tested facing material for this doorset design is 3.5mm thick hardwood

plywood. However, tests RF01059B (AR2) and WF403032, evaluated thicker plywood

faces.

The following table defines the acceptable facing options:

Material

Dimension (mm)

Minimum Density (kg/m³)

Plywood

3.5 or 4.0

1

640

Plywood

5.5

2

600

Chipboard

3.5 or 4.0

1

650

MDF

3.5 or 4.0

1

700

1

when utilising 3.5mm or 4.0mm thick facings, the core must be 36mm thick.

2

when utilising 5.5mm thick ply facings the core must be 34mm thick.

12.1 Decorative and Protective facings

The following materials are permitted for this door design since they would degrade

rapidly under fire test conditions without significant effect:

Facing Material

Maximum Permitted Thickness (mm)

Paint

0.5

Timber veneers

2

Plastic laminates

2

Cellulosic paper/non-metallic foils

0.4

Notes:

1. Metallic facings are not permitted (except for push plates and kick plates)

2. The door leaf thickness must not be reduced to accommodate the finish

3. Materials must not conceal intumescent strips

4. Plastic laminates must not be applied to the edges of leaves

Warringtonfire Report

Chilt/A04030 Rev C

Page 19 of 40

13 Intumescent Materials

The intumescent materials tested and assessed for this doorset design are as follows:

Application

Location

Product/Manufacturer

Edge seals

Fitted in the

frame jambs or

leaf edges

1. Pyroplex rigid Box Seals – Pyroplex Ltd

2. Therm-A-Seal – Intumescent Seals Ltd

Hinges

Under hinge

blades

1. 1mm MAP paper - Lorient Polyproducts Ltd

2. 1mm Interdens - Dufaylite Developments Ltd

3. 1mm G30 – Sealmaster Ltd

4. 1mm Therm-A-Strip - Intumescent Seals Ltd

Lock/latch

Under forend &

keep

Top pivots &

flush bolts

Lining all sides

of the mortices

1. 2mm MAP paper - Lorient Polyproducts Ltd

2. 2mm Interdens - Dufaylite Developments Ltd

3. 2mm G30 – Sealmaster Ltd

4. 2mm Therm-A-Strip - Intumescent Seals Ltd

The seal specification for each configuration is shown in appendix D.

14 Adhesives

The adhesives used in construction must be as detailed in the following table:

Element

Adhesive Type

Timber Lippings

Urea formaldehyde (e.g. Cascamite) or PU

Facing

WBP

Core lamels

PVA

Warringtonfire Report

Chilt/A04030 Rev C

Page 20 of 40

15 Tested Hardware

The following hardware has been successfully incorporated in the tests on this design:

Element

Product

Dimensions

(mm)

Location

Hinges

Royde & Tucker H105 lift off

hinges

100 x 35

(blade size)

152mm, 1008mm

and 1864mm from

the leaf head

Royde & Tucker Hi Load 101

lift off hinges

100 x 35

(blade size)

150mm, 1000mm

and 1855mm from

the leaf head

Stainless Steel 304 2BB

hinges

102x 35

(blade size)

182mm and

384mm from the

leaf head and 322

from leaf bottom

Closers

Dorma Door Controls Ltd

TS73V surface mounted

overhead closer

233 x 60

(footprint size)

Fitted to the

exposed face as

per manufacturer’s

instructions

Rutland TS3204 surface

mounted overhead closer

220 x 59

(footprint size)

Locks and

Latches

Standard tubular mortise latch

- disengaged

57 x 26

(forend size)

Fitted 1412 from

the leaf head

SS5572-01A Mortise lock

240 x 33

(forend size)

Fitted 1000 from

the leaf bottom

E*S Eurospec tubular steel

latch TL2

55 x 25

(forend size)

Latch nib 1000 from

the leaf bottom

Furniture

Zoo Hardware aluminium

lever type handle

100 x 38

(footprint size)

Fitted appropriate

to the latch

16 Additional & Alternative Hardware

16.1 Certifire

The Certifire third party certification scheme approves various items of hardware for

different door types and different fire ratings and has its own set of requirements

relating to that item of hardware.

Where the alternative hardware sections in this report allow alternatives to the tested

hardware, Certifire approved hardware may be used as an alternative, subject to the

following provisos:

In all cases, the requirements of this report must take precedence.

The hardware must comply with the requirements of the relevant section

e.g. hinges.

The hardware must comply with the limitations specified in terms of design,

/