16

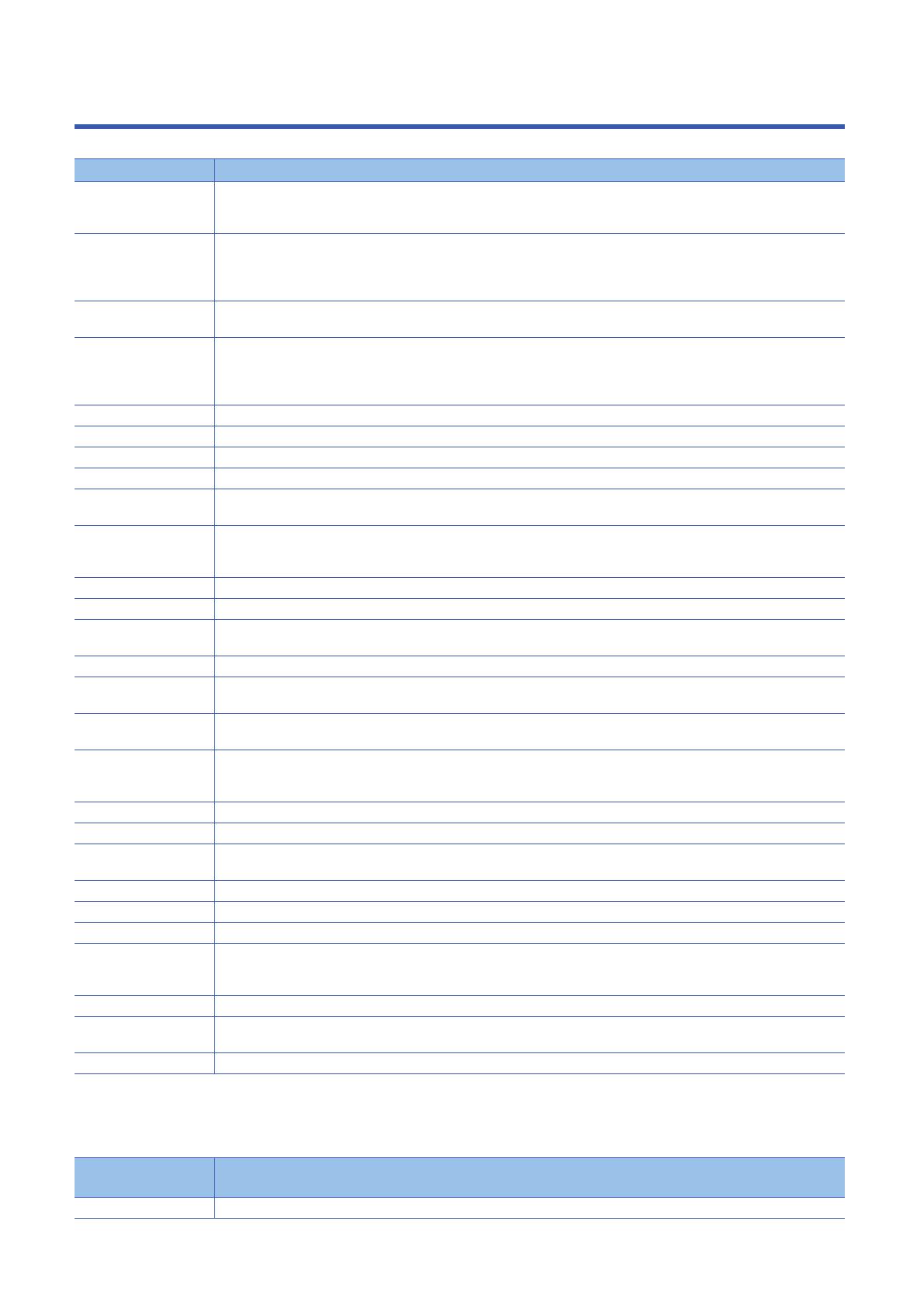

TERMS

Unless otherwise specified, this manual uses the following terms.

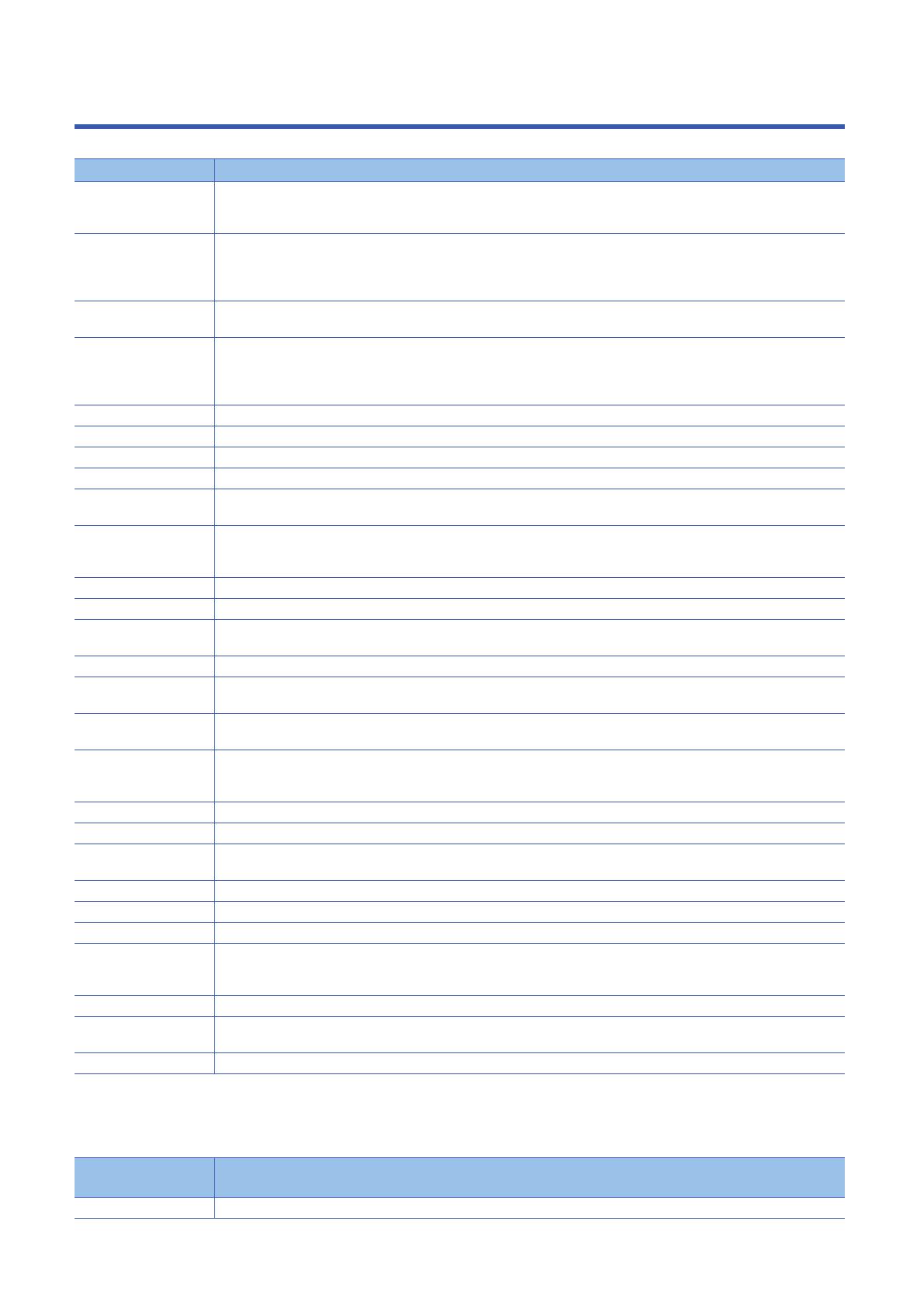

*1 The term has been changed for standardization among manuals and software applications related to CC-Link IE TSN. However, the

term used in some CC-Link IE TSN related software windows may remain unchanged and may be different from the term used in this

manual.

In case of inconsistency, refer to the following.

Term Description

Buffer memory Memory in an intelligent function module to store data such as setting values and monitor values.

For CPU modules, it refers to memory to store data such as setting values and monitor values of the Ethernet function, or data

used for data communication of the multiple CPU system function.

CC-Link IE TSN Class*1 A group of devices and switching hubs compatible with CC-Link IE TSN, ranked according to the functions and performance by

the CC-Link Partner Association.

For CC-Link IE TSN Class, refer to the CC-Link IE TSN Installation Manual (BAP-C3007ENG-001) published by the CC-Link

Partner Association.

CC-Link IE TSN Protocol

version 1.0

This protocol is used to perform communications by using the time sharing method defined by IEEE 802.1AS or IEEE 1588 for

time synchronization.

CC-Link IE TSN Protocol

version 2.0

This protocol is used to perform communications by using the time sharing method defined by IEEE 802.1AS and time-managed

polling method for time synchronization.

Supporting this protocol version mitigates restrictions when "Mixture of CC-Link IE TSN Class B/A or CC-Link IE TSN Class A

Only" is set in the system configuration, and increases the number of connectable devices.

Dedicated instruction An instruction that simplifies programming for using functions of intelligent function modules

Device A memory of a CPU module to store data. Devices such as X, Y, M, D, and others are provided depending on the intended use.

Device station A station other than a master station: a local station and a remote station

Engineering tool A tool used for setting up programmable controllers, programming, debugging, and maintenance

General-purpose hub A CC-Link IE TSN Class A switching hub authorized by the CC-Link Partner Association ( Page 68 Switching Hub

(RJ71GN11-T2 Only))

Global label A label that is valid for all the program data when multiple program data are created in the project. There are two types of global

label: a module specific label (module label), which is generated automatically by GX Works3, and an optional label, which can be

created for any specified device.

Intelligent function module A module that has functions other than an input or output, such as an A/D converter module and D/A converter module

Link device A device (RX, RY, RWr, RWw, LB, or LW) in a module on CC-Link IE TSN.

Link refresh Processing of data transfer between link devices of the network module and CPU module devices. Link refresh is performed in

"END processing" of the sequence scan of the CPU module.

Local station A station that performs cyclic transmission and transient transmission with the master station and other local stations

Master station A station that controls the entire network. This station can perform cyclic transmission and transient transmission with all stations.

Only one master station can be used in a network.

Module label A label that represents one of memory areas (I/O signals and buffer memory areas) specific to each module in a given character

string. For the module used, GX Works3 automatically generates this label, which can be used as a global label.

Multicast filter A filter function that selects whether to send cyclic data of multicast mode received by the own station to the subsequent stations.

Setting parameters for this function are not required because the master station automatically sets the parameters according to

the system configuration.

Multicast mode A communication mode used to send cyclic data to multiple stations

Relay station A station in which multiple network modules are mounted on one programmable controller to relay data link to other stations

Remote station A station that exchanges I/O signals (bit data) and I/O data (word data) with another station by cyclic transmission. This station

can perform transient transmission.

Safety communications A function to exchange safety data between safety stations on the same network

Safety connection A connection established for safety communication

Safety data Data exchanged through safety communication

SLMP SeamLess Message Protocol.

This protocol is used to access an SLMP-compatible device or a programmable controller connected to an SLMP-compatible

device from an external device.

Standard communications Communications other than safety communications, such as cyclic transmission and transient transmission of CC-Link IE TSN

TSN hub A CC-Link IE TSN Class B switching hub authorized by the CC-Link Partner Association ( Page 68 Switching Hub

(RJ71GN11-T2 Only))

Unicast mode A communication mode used to send cyclic data to one station

Term used in

software window

Term after change

Authentication Class CC-Link IE TSN Class