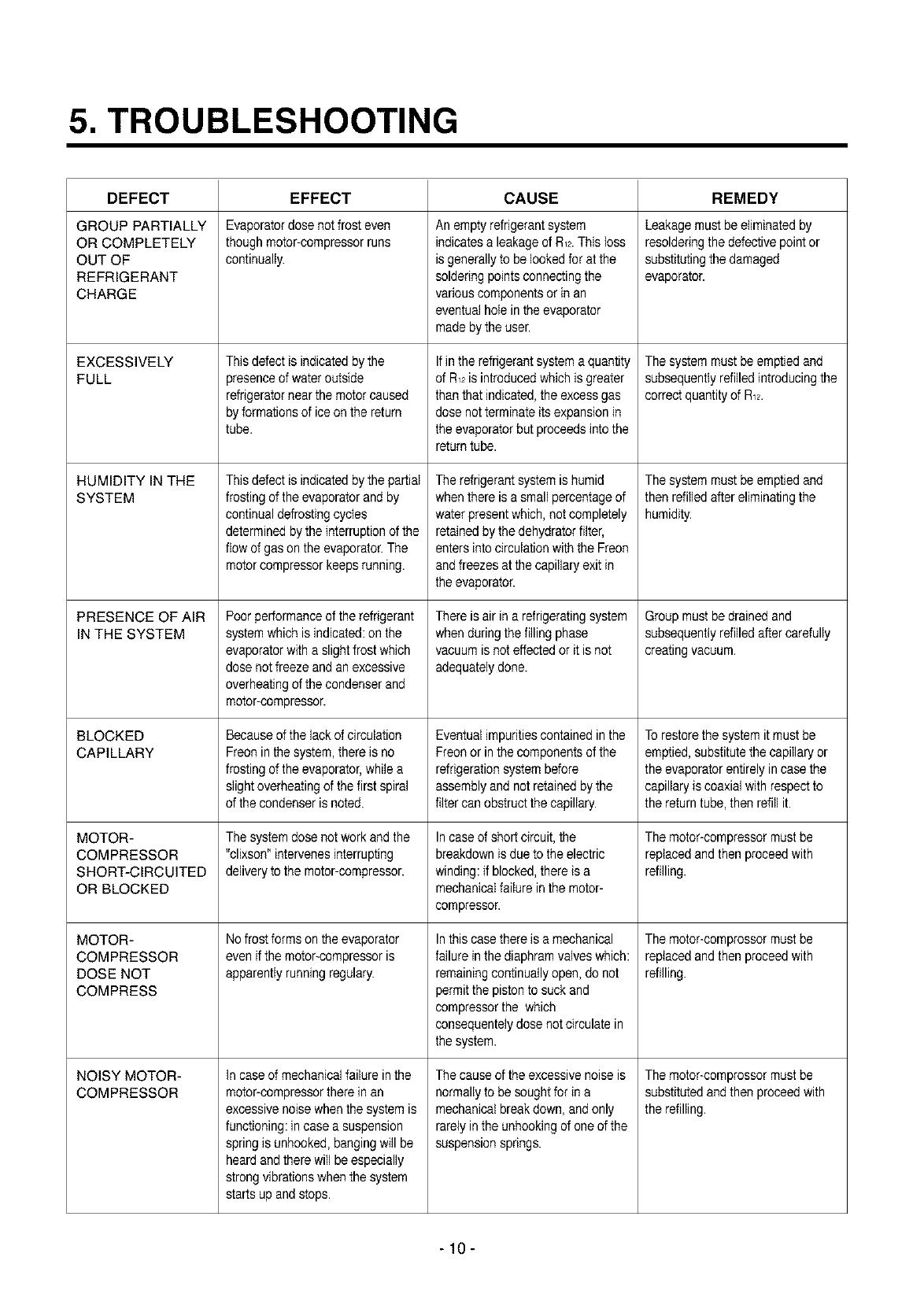

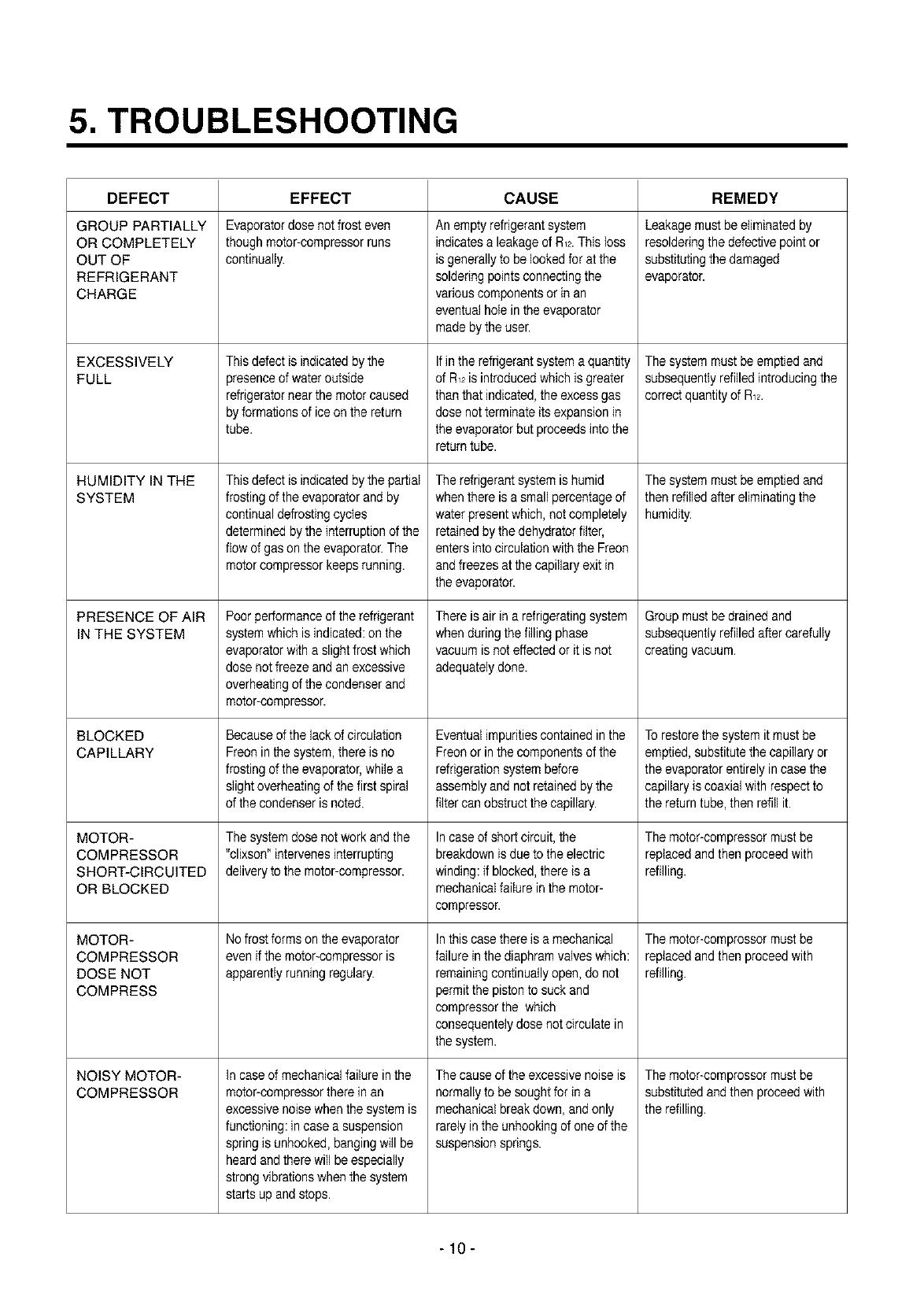

5. TROUBLESHOOTING

DEFECT CAUSE REMEDY

GROUP PARTIALLY

OR COMPLETELY

OUT OF

REFRIGERANT

CHARGE

EXCESSIVELY

FULL

HUMIDITY IN THE

SYSTEM

PRESENCE OF AIR

IN THE SYSTEM

BLOCKED

CAPILLARY

MOTOR-

COMPRESSOR

SHOR_CIRCUITED

OR BLOCKED

MOTOR-

COMPRESSOR

DOSE NOT

COMPRESS

NOISY MOTOR-

COMPRESSOR

EFFECT

Evaporatordosenot frosteven

thoughmotor-compressorruns

continually.

This defectisindicatedbythe

presenceofwateroutside

refrigeratornearthe motorcaused

byformationsof ice onthe return

tube.

This defectis indicatedbythe partial

frosting ofthe evaporatorandby

continualdefrostingcyctes

determinedbythe interruptionofthe

flow ofgas onthe evaporator.The

motorcompressorkeeps running.

Poorperformanceofthe refrigerant

systemwhichis indicated:onthe

evaporatorwith aslightfrostwhich

dosenotfreeze andanexcessive

overheatingof the condenserand

motor-compressor.

Becauseofthe lackofcirculation

Freonin the system,there is no

frosting ofthe evaporator,while a

slightoverheatingof thefirst spiral

ofthe condenser isnoted.

The systemdose notwork andthe

"clixson"intervenesinterrupting

deliverytothe motor-compressor.

Nofrostformsonthe evaporator

evenif the motor-compressoris

apparentlyrunningregulary.

in caseofmechanicalfailure inthe

motor-compressorthere inan

excessivenoisewhenthe system is

functioning:incase asuspension

springis unhooked,bangingwill be

heardand therewillbe especially

strong vibrationswhenthe system

startsup andstops.

An emptyrefrigerantsystem

indicatesaleakageof R_2.This loss

isgenerallyto belookedforatthe

solderingpointsconnectingthe

variouscomponentsor in an

eventual hotein the evaporator

madebythe user.

Ifin therefrigerantsystema quantity

of R_2isintroducedwhich isgreater

thanthat indicated,the excessgas

dosenot terminateits expansionin

the evaporatorbut proceedsinto the

returntube.

The refrigerantsystemis humid

when there isasmall percentageof

waterpresentwhich,notcompletely

retainedbythe dehydratorfilter,

enters intocirculationwiththe Freon

andfreezesat the capillaryexit in

the evaporator.

There isair in arefrigeratingsystem

when duringthe filling phase

vacuum isnot effectedor it is not

adequatelydone.

Eventuatimpuritiescontainedin the

Freonor inthe componentsofthe

refrigerationsystembefore

assemblyandnot retainedbythe

filter canobstructthe capillary.

Incaseof shortcircuit,the

breakdownis dueto the electric

winding:if blocked,there isa

mechanicalfailurein the motor-

compressor.

Inthiscasethere isa mechanical

failureinthe diaphramvalveswhich:

remainingcontinuallyopen, do not

permitthe pistonto suckand

compressorthe which

consequente]ydosenotcirculatein

the system.

The causeof theexcessivenoise is

normallyto be soughtfor in a

mechanicalbreakdown,and only

rarelyin theunhookingof oneof the

suspensionsprings.

Leakagemustbeeliminatedby

resolderingthedefectivepoint or

substitutingthe damaged

evaporator.

Thesystemmustbe emptiedand

subsequentlyrefilledintroducingthe

correctquantityof R_.

Thesystemmustbe emptiedand

thenrefilledafter eliminatingthe

humidity.

Groupmust bedrainedand

subsequentlyrefilledaftercarefully

creatingvacuum.

Torestorethe systemit mustbe

emptied,substitutethe capillaryor

the evaporatorentirelyin casethe

capillaryiscoaxialwith respectto

the returntube, thenrefillit.

Themotor-compressormust be

replacedandthenproceedwith

refilling.

Themotor-comprossormust be

replacedandthenproceedwith

refilling.

Themotor-comprossormust be

substitutedandthenproceedwith

the refilling.

-10-