1 MOTION CONTROL FB OVERVIEW

1.1 Motion Control FBs 11

1

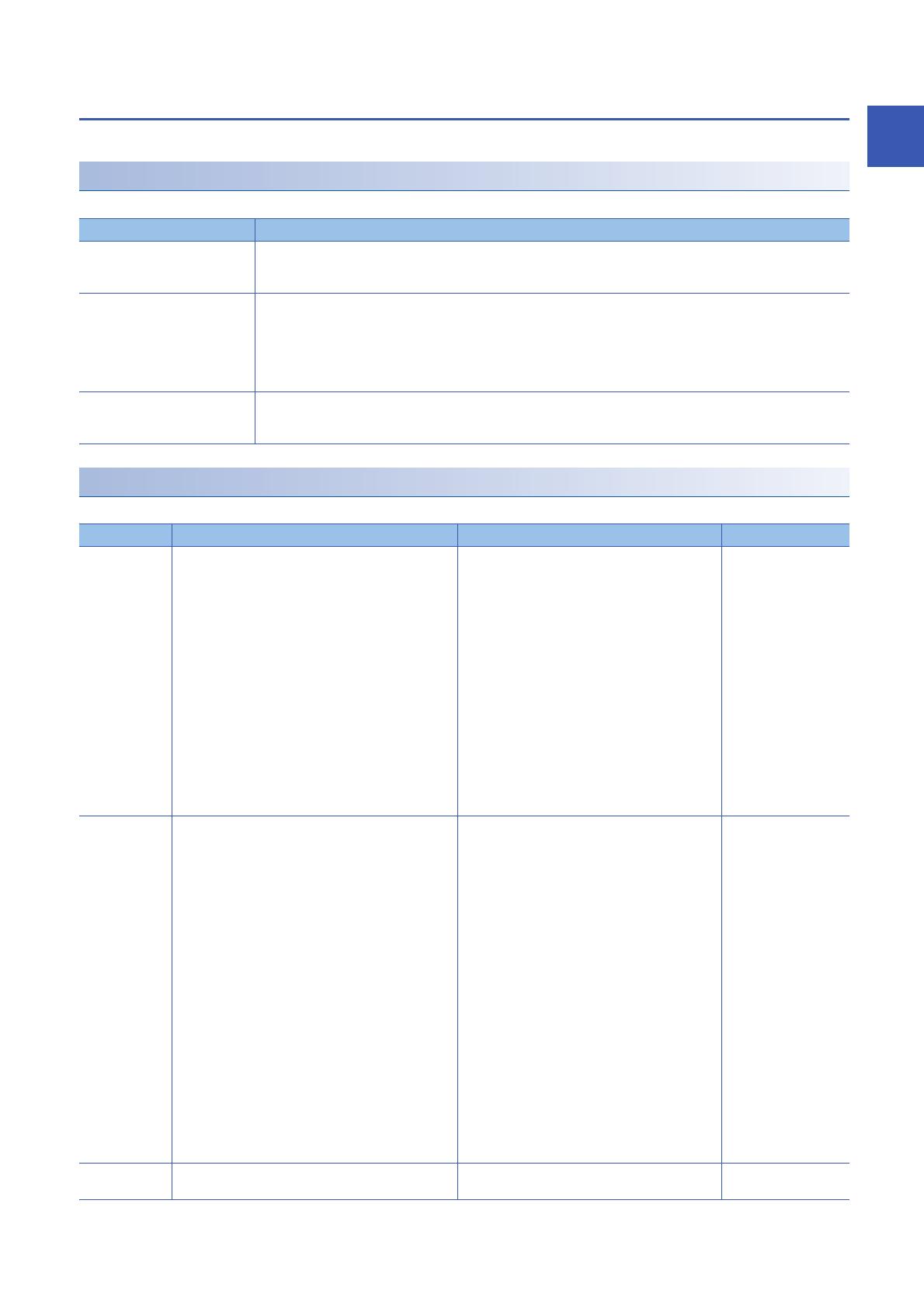

Motion control FB types

Motion control FBs are classified according the operation details and the execution method.

Management FBs/Operation FBs/Standard FBs

Motion control FBs are classified into the following types according to the operation details.

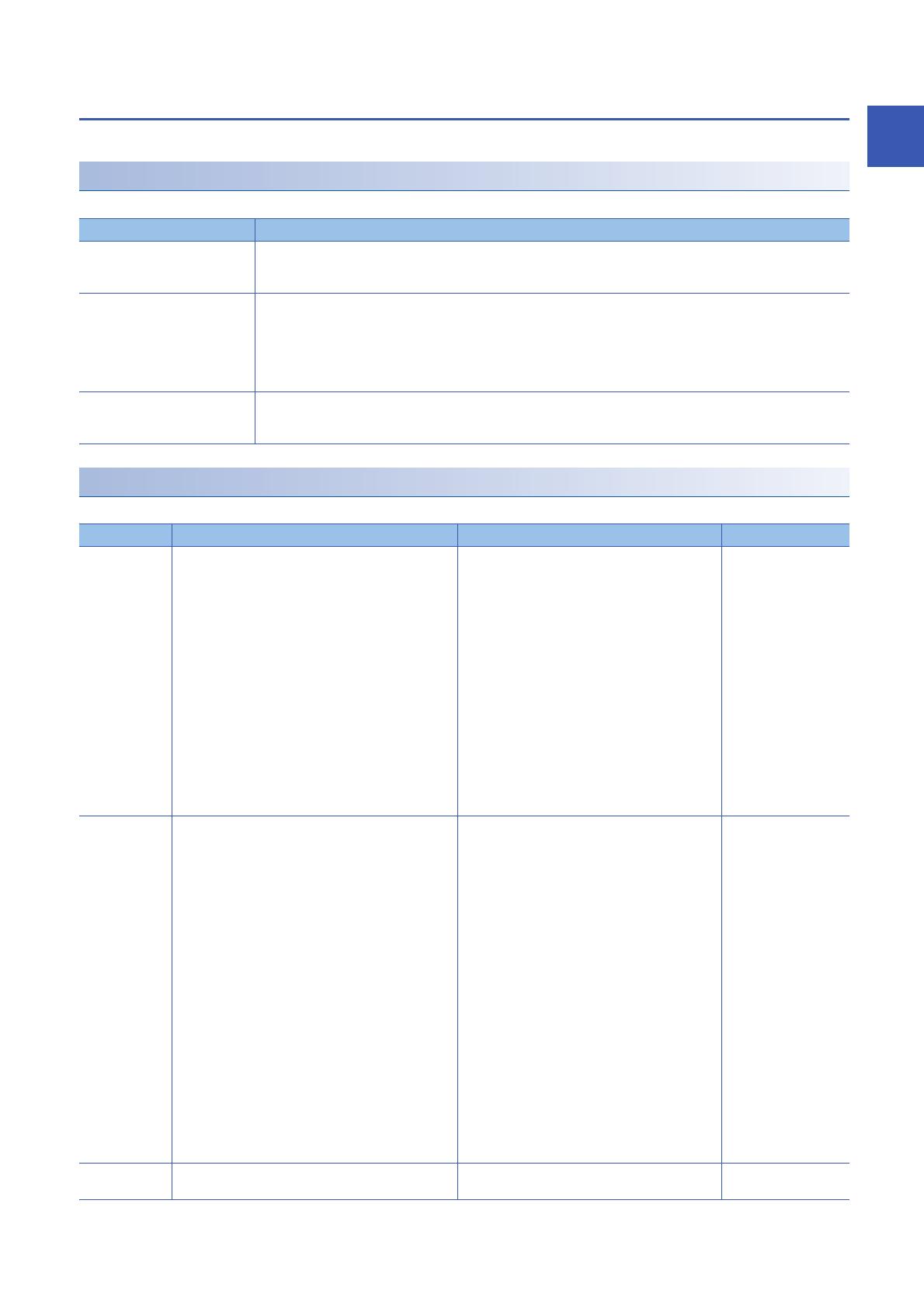

Execute command (Execute) type/Enable (Enable) type

Some Motion control FBs are executed with Execute command (Execute), while others are executed with Enable (Enable).

Type Operation details

Management FB • A Motion control FB that takes an axis or an axes group for the argument and does not change the axis status or the

axes group status by execution. (There are some exceptions.)

• In most cases, a management FB can control multiple instances of an axis or an axes group at the same time.

Operation FB • A Motion control FB that takes an axis or an axes group for the argument and changes the axis status or the axes group

status by execution.

• In most cases, an operation FB can control only one axis or axes group. However, some FBs can control at the same

time.

• In most cases, the axis status or the axes group status will not be changed even if a management FB is executed while

an operation FB is being executed. However, some FBs can cause a specific state transition.

Standard FB • A Motion control FB that does not take an axis or axes group for the argument.

• A standard FB can execute multiple instances at the same time. Since it is not related to the axis, it does not affect

either operation FBs or management FBs.

Type Execute command (Execute) type Enable (Enable) type Other types

Management FB • MC_GroupEnable (Axes Group Enabled)

• MC_GroupDisable (Axes Group Disabled)

• MC_SetPosition (Current Position Change)

• MCv_SetTorqueLimit (Torque Limit Value)

• MC_WriteParameter (Parameter Write)

• MC_Reset (Axis Error Reset)

• MC_GroupReset (Axes Group Error Reset)

• MC_TouchProbe (Touch Probe Enabled)

• MC_AbortTrigger (Touch Probe Disabled)

• MC_CamTableSelect (Cam Table Selection)

• MCv_ChangeCycle (Current Value Change per Cycle)

• MCv_MotionErrorReset (Motion Error Reset)

• MCv_AdvPositionPerCycleCalc (Advanced

Synchronous Control Current Position per Cycle

Calculation)

• MCv_AdvCamSetPositionCalc (Advanced

Synchronous Control Cam Set Position Calculation)

• MC_Power (Operation Available)

• MC_SetOverride (Override Value Setting)

• MC_ReadParameter (Parameter Read)

• MCv_AllPower (All Axes Operation Available)

• MC_GroupSetOverride (Axes Group Override

Value Setting)

Operation FB • MC_Home (OPR)

• MC_Stop (Forced Stop)

• MC_GroupStop (Group Forced Stop)

• MC_MoveAbsolute (Absolute Value Positioning)

• MC_MoveRelative (Relative Value Positioning)

• MC_MoveVelocity (Speed Control)

• MC_TorqueControl (Torque Control)

• MCv_SpeedControl (Speed Control (Including Position

Loop))

• MCv_MoveLinearInterpolateAbsolute (Absolute Value

Linear Interpolation Control)

• MCv_MoveLinearInterpolateRelative (Relative Value

Linear Interpolation Control)

• MCv_MoveCircularInterpolateAbsolute (Absolute

Value Circular Interpolation Control)

• MCv_MoveCircularInterpolateRelative (Relative Value

Circular Interpolation Control)

• MC_CamIn (Cam Operation Start)

• MC_GearIn (Gear Operation Start)

• MC_CombineAxes (Addition/Subtraction Positioning)

• MCv_MovePositioningData (Multiple Axes Positioning

Data Operation)

• MCv_BacklashCompensationFilter (Backlash

Compensation Filter)

• MCv_SmoothingFilter (Smoothing Filter)

• MCv_DirectionFilter (Moving Direction Restriction

Filter)

• MCv_SpeedLimitFilter (Speed Limit Filter)

• MCv_AdvancedSync (Advanced Synchronous

Control)

• MCv_Jog (JOG)

Standard FB • MCv_ReadProfileData (Profile Read)

• MCv_WriteProfileData (Profile Write)