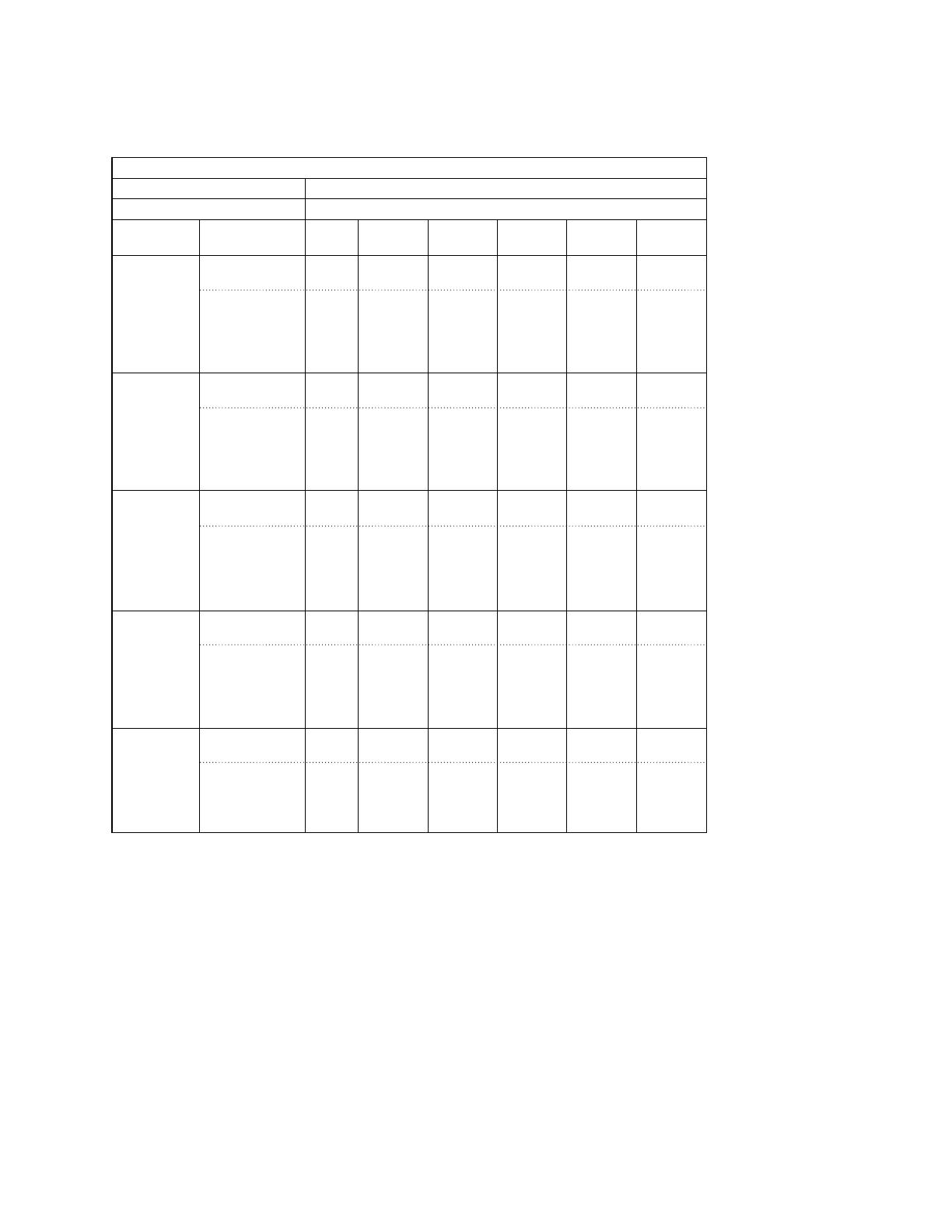

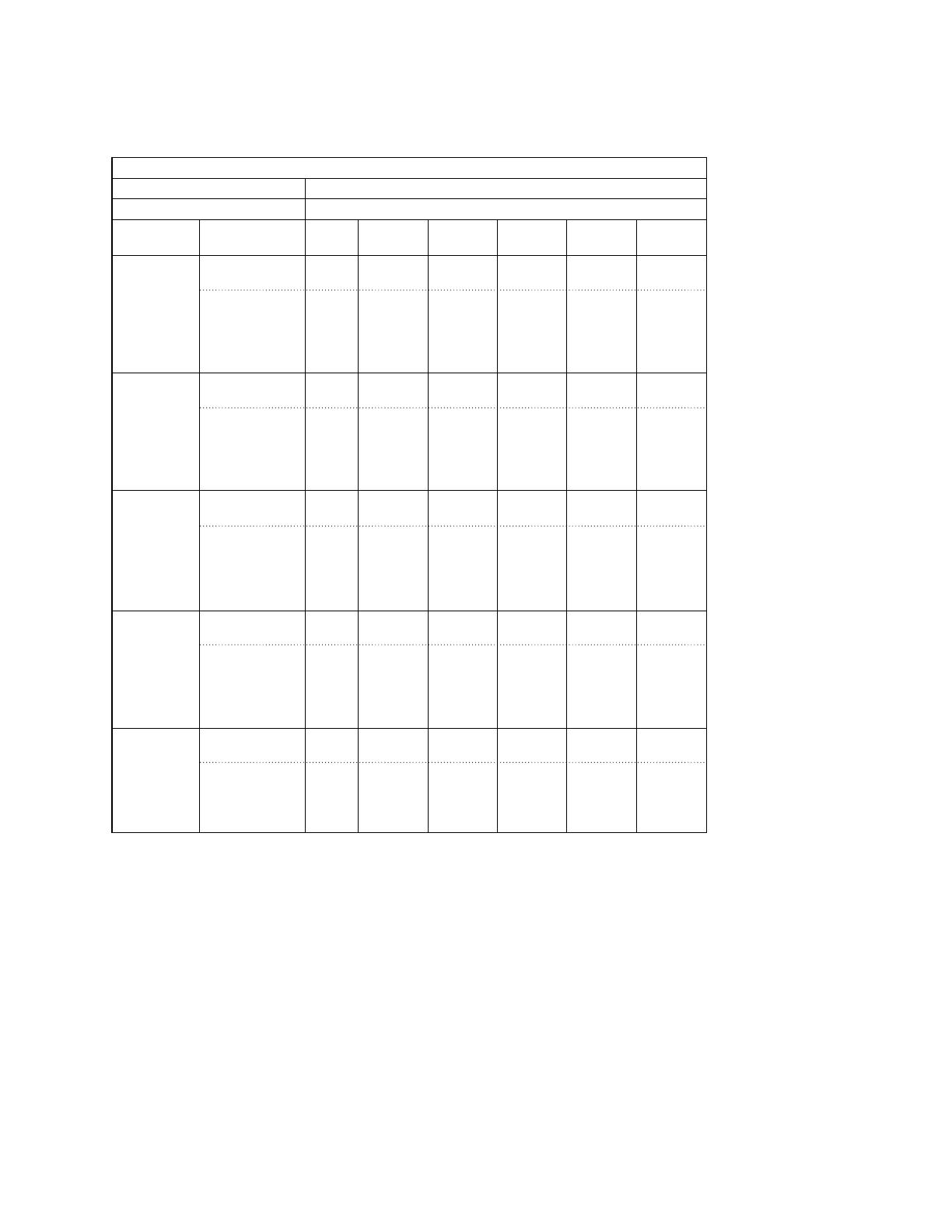

4. COOLING CAPACITY

115V

RS1211 / C1211 and CL1211

5

WM– 700703

TC: Total Cooling Capacity (BTU/H)

SHC: Sensible Heat Capacity (BTU/H)

kW: Compressor Input (kW)

Remarks: Rating conditions (* mark) are: Outside ambient temperature 95°F DB

Indoor unit entering air temperature 80°F DB/67°F WB

Rating Capacity: 11,500 BTU/H Air Flow Rate: 280 CFM

Evaporator Condenser

Ent. Temp. °F/(°C) Ambient Temp. °F/(°C)

WB DB

75 85 95 105 115

(23.9) (29.4) (35.0) (40.6) (46.1)

TC 11,390 10,870 10,350 9,760 8,970

kW 0.85 0.93 1.01 1.10 1.21

59 72 (22.2) SHC 8,140 7,870 7,600 7,310 6,920

(15.0) 76 (24.4) SHC 9,150 8,880 8,610 8,320 7,930

80 (26.7) SHC 10,210 9,940 9,670 9,380 8,970

84 (28.9) SHC 11,220 10,870 10,350 9,760 8,970

88 (31.1) SHC 11,390 10,870 10,350 9,760 8,970

TC 11,780 11,410 10,960 10,360 9,550

kW 0.86 0.94 1.03 1.12 1.23

63 72 (22.2) SHC 6,860 6,680 6,470 6,190 5,820

(17.2) 76 (24.4) SHC 7,870 7,690 7,480 7,200 6,830

80 (26.7) SHC 8,930 8,750 8,540 8,260 7,890

84 (28.9) SHC 9,940 9,760 9,550 9,270 8,900

88 (31.1) SHC 10,950 10,770 10,560 10,280 9,550

TC 12,100 11,900 *11,500 10,870 10,120

kW 0.87 0.95 1.04 1.13 1.26

67 72 (22.2) SHC 5,530 5,450 5,270 5,000 4,690

(19.4) 76 (24.4) SHC 6,550 6,460 6,290 6,020 5,700

80 (26.7) SHC 7,600 7,520 7,340 7,070 6,760

84 (28.9) SHC 8,620 8,530 8,360 8,090 7,770

88 (31.1) SHC 9,630 9,540 9,370 9,100 8,790

TC 12,480 12,270 11,960 11,420 10,750

kW 0.88 0.96 1.06 1.16 1.28

71 72 (22.2) SHC 4,170 4,090 3,970 3,760 3,510

(21.7) 76 (24.4) SHC 5,190 5,110 4,980 4,770 4,520

80 (26.7) SHC 6,240 6,160 6,040 5,830 5,580

84 (28.9) SHC 7,260 7,180 7,050 6,840 6,590

88 (31.1) SHC 8,270 8,190 8,070 7,860 7,600

TC 12,720 12,580 12,310 11,870 11,390

kW 0.89 0.98 1.07 1.19 1.32

75 76 (24.4) SHC 3,830 3,780 3,690 3,530 3,370

(23.9) 80 (26.7) SHC 4,890 4,840 4,740 4,590 4,420

84 (28.9) SHC 5,900 5,850 5,760 5,600 5,440

88 (31.1) SHC 6,910 6,870 6,770 6,620 6,450