American Water Heater 520 Owner's manual

- Category

- Water heaters & boilers

- Type

- Owner's manual

This manual is also suitable for

‐Do not store or use gasoline or other

flammablevaporsandliquidsinthevicinityof

thisoranyotherappliance.

‐WHATTODOIFYOUSMELLGAS

Donottrytolightanyappliance.

Do not touch any electric switch, do not

useanyphonein

yourbuilding.

Immediatelycallyourgassupplierfroma

neighbor's phone. Follow the gas

supplier'sinstructions.

Ifyoucannotreachyourgassupplier,call

thefiredepartment.

‐Installation and service must be performed

byaqualifiedinstaller,serviceagencyorthe

gassupplier.

520(T‐H2)and320(T‐H2S)

InstallationManualandOwner’sGuide

FEATURING

ENDLESSHOTWATER

ONDEMANDUSAGE

COMPACT,SPACESAVING

ENERGYCONSERVATION

COMPUTERIZEDSAFETY

NOPILOTLIGHT

EASY‐LINKSYSTEM

Ifyouhaveanyquestions,please

callorwriteto:

500TennesseeWaltzParkway

AshlandCity,TN37015

TollFree:1‐877‐737‐2840

ANSI Z21.10.3andCSA4.3

GasTanklessWaterHeater

DirectVentIndoormodels(520Indoor(T‐H2‐DV),

320Indoor(T‐H2S‐DV))

Outdoormodels(520Outdoor(T‐H2‐OS),

320Outdoor(T‐H2S‐OS))

Suitableforpotablewaterheatingandspace‐heating

*

*Pleaserefertolocalcodesforspace‐heatingcompliance.

Iftheinformationinthese

instructionsisnotfollowed

exactly,afireorexplosion

mayresultcausing

propertydamage,personalinjuryordeath.

WARNING

520(T‐H2)models

only

Contents

2│Page

NOTE

Checktheratingplatetoensurethisproductmatchesyour

specifications.

In accordance with ANZI Z21.10.3, CO emission does not

exceed400PPMfornormalinput.

CONTENTS

SPECIFICATIONS

520 (T‐H2) and 320(T‐H2S)models

GasInput

520

(T‐H2)

models

Natural

Min:13,000Btu/h

Max:199,000Btu/h

Propane

320

(T‐H2S)

models

Natural

Min:13,000Btu/h

Max:180,000Btu/h

Propane

GasConnection ¾”NPT

WaterConnections ¾”NPT

CondensateDrainPort

Connection

½”NPT

WaterPressure* 15‐150psi

NaturalGas

Inlet Pressure

Min.5.0”WC

Max.10.5”WC

Propane

Inlet Pressure

Min.8.0”WC

Max.14.0”WC

ManifoldPressure**

520Direct

VentIndoor

(T‐H2‐DV)

Natural:3.2”WC

Propane:5.5”WC

520Outdoor

(T‐H2‐OS)

Natural:2.7”WC

Propane:4.6”WC

320Direct

VentIndoor

(T‐H2S‐DV)

Natural:2.5”WC

Propane:4.3”WC

320Outdoor

(T‐H2S‐OS)

Natural:1.9”WC

Propane:3.6”WC

Weight

73lbs.

(DirectVentIndoormodels)

71lbs.(Outdoormodels)

Dimensions H25.6”xW18.5”xD12.4”

Ignition ElectricIgnition

Electric

Supply 120VAC/60Hz

Consumption

Operationofthe

DirectVent

Indoormodels

152W

(1.27A)

Operationofthe

Outdoormodels

102W

(0.85A)

Standby

8.2W

(0.07A)

Freeze‐

Protection

207W

(1.73A)

SPECIFICATIONS………………………………...

INTRODUCTION……………………………….…

SAFETYGUIDELINES…………….……………..

INSTALLATION………………………………..….

General………………………………………..…

IncludedAccessories…………………..…

Optionalitems…………………………..…..

WarningforInstallations………..….....

High‐altitudeInstallations………………

Installationforoutdoormodels……..

Installationfordirectventindoor

models……………………………………………

VentingInstructions……………………....

GasSupply/GasPipeSizing………...…

WaterConnections……………..……….…

PressureReliefValve………………………

Condensatedrain…………………………..

ElectricalConnections…………….........

RemoteControllerConnection…….…

PumpControlConnections………..……

PumpControlMode…………………….…

Easy‐LinkSystem…………………………....

APPLICATIONS...…………………………………

SpaceHeating……….………….……………

INITIALOPERATION..…………………….……

OPERATINGSAFETY……………………………

NORMALOPERATION…………………………

General………..……….………….……………

Temperaturesettings.…….…..…………

Flow……………………………………………….

FreezeProtectionSystem…….…………

MaintenanceandService………………

UnitDrainingandFilterCleaning……

TROUBLESHOOTING……..……………………

General………..……….………….……………

Errorcodes.…………………….…..…………

COMPONENTSDIAGRAM………………..…

PARTSLIST………………….………………………

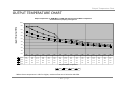

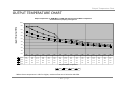

OUTPUTTEMPERATURECHART……...…

LIMITEDWARRANTY…………………….……

2

3

4

5

6

6

7

8

9

9

10

10

17

19

20

20

22

23

24

25

27

31

31

33

34

36

36

36

38

38

39

39

40

40

42

44

47

50

51

Themanufacturerreservestherighttodiscontinue,orchangeat

anytime,specificationsordesignswithoutnoticeandwithout

incurringobligations.

InstallationManual

Owner’sGuide

*40psioraboveisrecommendedformaximumflow.

**TheManifoldPressureisthefactorysettingandgenerally

shouldnotneedadjustment.

Introduction

3│Page

INTRODUCTION

*Thisdiagram

illustratestankless

waterheaterdesign

conceptsonlyand

doesnotaccurately

representtothewater

heater’sphysical

description.

This manual provides information necessary for the installation, operation, and

maintenanceofthewaterheater.

Themodeldescriptionislistedontheratingplatewhichisattachedtothesidepanelof

thewaterheater.

Pleasereadallinstallationinstructionscompletelybeforeinstallingthisproduct.

If you have any problems or questions regarding this equipment, consult with the

manufactureroritslocalrepresentative.

Thisequipmentisanon‐demand,tanklesswaterheatersdesignedtoefficientlysupply

endlesshotwaterforyourneeds.

Theprinciplebehindthewaterheaterissimple:

1. Ahotwatertapisturnedon.

2. Waterenterstheheater.

3. Thewaterflowsensordetectsthewaterflow.

4. Thecomputerautomaticallyignitestheburner.

5. Watercirculatesthroughtheheatexchangerandthengetshot.

6. Thecomputerwillmodulate the

gassupplyvalveandwaterflowtoproducetheright

amountofhotwateratthecorrecttemperature.

7. Whenthetapisturnedoff,theunitshutsdown.

Thewaterheaterishigh efficiencymodelswithanin‐buildsecondaryheatexchanger

thatabsorbslatentheatfromtheexhaustgas.

Burner

Condensate

drainport

Secondaryheatexchanger

Thermistor

Thermistor

GasValve

Flowsensor

Watercontrolvalve

B

yp

assvalve

Intake

p

ort

Exhaust

Fanmotor

Primaryheat

exchanger

Thermistor

PCB

HotWaterOutlet

ColdWaterOutlet

Gas

SafetyGuidelines

4│Page

Watertemperaturesover125°F(52°C)cancausesevereburnsinstantlyordeathfromscalding.

Thewatertemperatureissetat120°F(49°C)fromthefactorytominimizeanyscaldingrisk.

Beforebathingorshoweringalwayscheckthewatertemperature.

Donotstoreorusegasolineorotherflammables,vapors,orliquidsinthevicinity

ofthisappliance.

Donotreversethewaterand/orgasconnectionsasthiswilldamagethegas

valvesandcancausesevereinjuryordeath.Followthediagramonp.19when

installingyourwaterheater:

Donotusethisapplianceifanyparthasbeenincontactwithorbeenimmersedin

water.Immediatelycallalicensedplumber,alicensedgasfitter,oraprofessional

servicetechniciantoinspectand/orservicetheunitifnecessary.

Donotdisconnecttheelectricalsupplyiftheambienttemperaturewilldrop

belowfreezing.TheFreezePreventionSystemonlyworksiftheunithaselectrical

power.Thewarrantywillnotbecoverediftheheatexchangerisdamageddueto

freezing.RefertothesectionontheFreezePreventionSystemon

p.38formore

information.

SAFETYGUIDELINES

GENERAL

1. Follow all local codes, or in the absence of local codes, follow the most recent edition of the

NationalFuelGasCode:ANSIZ223.1/NFPA54intheUSAorCAN/CSAB149.1NaturalGas,Propane

InstallationCodeinCanada.

2. Properlygroundtheunitinaccordance withalllocal codes or in

theabsenceoflocalcodes,with

theNationalElectrical Codes:ANSI/NFPA70 in theUSAorCSAstandard C22.1 Canada Electrical

CodePart1inCanada.

3. Carefullyplanwhereyouintendtoinstallthe waterheater.Pleaseensure:

Your water heater will have enough combustible air and proper

ventilation.

Locate your heater where water leakage will not damage

surroundingareas(pleaserefertop.5).

4. ChecktheratingplateforthecorrectGASTYPE,GASPRESSURE,WATER

PRESSUREandELECTRICRATING.

*If this unit does not match your requirements, do not install and

consultwiththemanufacturer.

5. Ifanyproblemshouldoccur,turnoffallhotwatertapsandturnoffthe

gas. Then call a trained technician or the Gas Company or the

manufacturer.

Prohibited

WARNING

RATINGPLATE

Installation

5│Page

Installation and service must be performed by a qualified installer (for

example, a licensed plumber or gas fitter), otherwise the warranty will be

void.

Theinstaller(licensedprofessional)isresponsibleforthecorrectinstallation

of the water heater and for compliance with all national, state/provincial,

andlocalcodes.

Thewarrantywillnotcoverdamagecausedbywaterquality.

Onlypotablewaterorpotablewater/glycolmixturescanbeusedwiththis

water heater.Do not introduce pool or spa water, or any chemically

treatedwaterintothewaterheater.

Water hardness levels must not exceed 7 grains per gallon (120 ppm) for

single family domestic applications or more than 4 grains per gallon (70

ppm) for all other types of applications.Water hardness leads to scale

formation and may affect/damage the water heater.Hard water scaling

mustbeavoidedor

controlledbyproperwatertreatment.

WaterpHlevelsmustbebetween6.5and8.5

Wellwatermustbetreated.

Although th is water heater is designed to operate with minimal sound, the

manufacturerdoesnotrecommendinstallingtheunitonawalladjacenttoa

bedroom,oraroomthatisintendedforquietstudyormeditation,etc.

Locateyourheatercloseto adrainwherewaterleakagewillnotdodamageto

surrounding areas.As with any water heating appliance, th e potential for

leakage at some time in the life of the product does exist.The manufacturer

will not be responsible for any water damage that may occur.

If you install a

drainpanundertheunit,ensurethatitwillnotrestrictthecombustio nairflow.

The water heater is high efficiency products that create condensation. A

condensation drain tube must be installed with these models to discharge

condensateintoadrainoutlet.Formoreinformation,refertop.20.

The manufacturer does not recommend installing the Direct Vent Indoor

modelsin an atticduetosafetyissues.IfyouinstallyourDirectVentIndoor

modelsinanattic:

Make sure your unit will have enough combustion air and proper

ventilation.

Keeptheareaaround you’rethewaterheaterclean.Whendustcollectson

theflamesensor,thewaterheaterwillshutdownonerrors.

Locateunitforeasyaccessforserviceandmaintenance.

A drain pan, or other means of protection against water damage, is

requiredtobeinstalledunderthewaterheaterincaseofleaks.

INSTALLATION

Allgaswaterheatersrequirecarefulandcorrectin stallationtoensuresafeandefficientoperation.This

manualmustbefollowedexactly.Readthe“SafetyGuidelines”section atthebeginningofthismanual.

WARNING

WARNING

CAUTION

PLEASEREADTHISMANUALCAREFULLYANDFOLLOWALLDIRECTIONS.

Installation

6│Page

GENERAL

1. Follow all local codes, or in the absence of local codes, follow the most recent edition of the

National Fuel Gas Code: ANSI Z223.1/NFPA 54 in the USA or CAN/CSA B149.1 Natural Gas,

PropaneInstallationCodeinCanada.

2. Themanifoldgaspre s sureispresetatthefactory.It

iscomputercontrolledandshouldnot

needadjustment.

3. Maintainproperspaceforservicing.Installtheunitsothatitcanbeconnectedorremoved

easily.Refertop.8,p.9andp.10forproperclearances.

4. Theelectricalconnectionrequiresameansofdisconnection,toterminatepowertothewater

heaterforservicingandsafetypurposes.

5. Ifyouwillbein stallingtheunitinacontaminatedareawithahighlevelofdust,sand,flour,

aerosolsorothercontaminants/chemicals,theycanbecomeairborneandenterandbuildup

withinthefanandburnercausingdamagetotheunit.

6. Particles from flour, aerosols, and other contaminants may clog the air vent or reduce the

functions of the rotatingfanandcauseimproperburningofthegas.Regularlyensurethatthe

area around the unit is dust‐ or debris‐free; regular maintenance is recommended for these

typesofenvironment.

7. Donotinstalltheunitwheretheexhaustventispointingintoanyopeninginabuildingorwhere

the noise may disturb your neighbors. Make sure the vent termination meets the required

distancebylocalcodefromany doorwayoropeningtopreventexhaustfromenteringabuilding

(refer

top.15).

INCLUDEDACCESSORIES

Checkthattheinstallationmanual,thecommunicationcable,theproductregistrationcardandthePVC

adaptorareincludedwiththeunit(theadapto rcomeswiththeDirectVentIndoormodelsonly.

Fordetailsonhowtoconnecttheadaptor,refertoP.14.

1.Manual

2.Communicationcable

520(T‐H2)modelsonly

3.ProductRegistrationCard

4.PVCadaptor

DirectVentIndoormodelsonly

Qty:1

Qty:1

Q

t

y

:1

Qty:1

Installation

7│Page

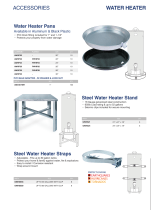

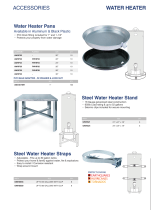

OPTIONALITEMS

1.TemperatureRemoteController:9007603005(TM‐RE30)

The Temperature Remote Controller has two functions. It allows

the output temperature from the water heater to be adjusted

within the range of 100 °F to 185 °F, and it also works as a

diagnostictoolthatwillgiveaconciseerrorcodewheneverthere

is a problem with the unit. The temperature options are 100°F,

105°F, 110°F, 115°F, 120°F, 125°F, 130°F, 135°F, 140°F, 145°F,

150°F,155°F,160°F,165°F,170°F,175°F,180°Fand185°F.Seethe

troubleshootingsectionforinformationonpossibleerrorcodes.

2.Pipecover:9007606005(TH‐PC02)

ThePipecoverprotectstheplumbingpipestothewaterheater

fromunexpectedadjustments.Thispipecoverisfixedtothe

bottomofthewaterheater,whichhidestheplumbingand

improvesthevisualaspectsofthewholeinstallationforthewater

heater.

3.WallthimblewithTermination:9007608005(TK‐KPWL4)and9007609005(TK‐KPWH4)

Theseterminationsareusedwhenventingoutthroughthewalland

arecompatiblewiththeT‐Ventpipesystem.

Theseterminationsarespecialstainlesssteelventsforgasappliances

andareULlistedasCategoryII,IIIandIV.Therearetwotypesof

terminations:theLouverterminationandtheHood

termination.For

differentwallthicknesses,therearetworangesof lengthsavailable

(refer totheventingbrochurefordetails).

Installthesevent terminationsinaccordancewiththeirinstallation

instructionsandanyapplicablelocalcodes.

4.Neutralizerkit:9007607005(TH‐NT01)

TheNeutralizerassemblyneutralizesthecondensate(acidic

water)thatformsinthesecondaryheatexchangerofthe

waterheater.

Itconnectstothecondensatedrainportofthewaterheaterby

usingconnectorsincludedwiththeneutralizerkit.Refertop.

21forthe

details.

Louver

Termination

9007608005

(TK‐KPWL4)

Hood

Termination

9007609005

(TK‐KPWH4)

Installation

8│Page

WARNINGFORINSTALLATIONS

FORYOURSAFETY,READBEFOREINSTALLATION:

Do not install the heater where water, debris or

flammablevaporsmaygetintotheflueterminal.

This may cause damage to the heater and void

thewarranty.

Do not have the vent terminal pointing toward

any opening into a building. Do not locate your

heater in a pit or

location where gas and water

canaccumulate.

Donotinstallthiswaterheaterunderan

overhanglessthan3feetfromitstoporeaves.

Theareaunderanoverhangmustbeopento

threesides.(Outdoormodelsonly)

Do not install the water heater vent terminator

within1ft.intheUSAofanyairintake

orbuilding

opening, and with in 3 ft. in Canada of any air

intake or building opening. (Outdoor models

only)(Refertop.15)

Donotinstallnexttoadryeroranysourceof

airbornedebristhatcanbetrappedinsidethe

combustionchamber,unlessthesystemisdirect

vented.

Prohibited

Prohibited

FORYOURSAFETY,READBEFOREINSTALLATION:

Installation

9│Page

Thedarksquaresindicatethedirectionthe

dipswitchesshouldbesetto.

Leftbankofdipswitches

Leftbankofdipswitches

There is a 3” clearance from

the left and right sides of the

unit to combustible and non‐

combustible

surfaces.However, if any

portion or area of the surface

is exposed to the exhaust

fumes(i.e.directlytothesides

of the vent cap), that surface

mustbeatleast24”

away.

Keeptheclearances.

2,500to4,000ft

4,000 to5,000 ft

Altitude

HIGH‐ALTITUDEINSTALLATIONS

Checktheelevationwhereyourwaterheaterisinstalled.Setdipswitchesshowninthetablebelow

dependingonthealtitude.Thesedipswitches(No.5andNo.6)areonthecomputerboardontheleft

bankonly.

0to2,500ft

(DEFAULT)

Over5,000ft

SwitchNo.5 OFF

ON

OFF

Consult

our Technical

Services

Department

at1‐877‐

737‐2840

SwitchNo.6

OFF OFF ON

INSTALLATIONFOROUTDOORMODELS

1. InstalltheOutdoormodelonlyinareaswithmild,temperateclimates.

2. TheOutdoormodelshallbewall‐mountedormountedonastand.Locate theOutdoormodelin

anopen,unroofedareaandmaintainthefollowingminimumclearances:

DONOTadjustanydipswitchesontherightbank.

1

2

3

4

5

6

7

8

N

O

9

1

0

N

O

1

2

3

4

5

6

7

8

9

1

0

N

O

1

2

3

4

5

6

7

8

9

1

0

Side3”

Top36”

Side3”

Front24”

Bottom12”

Back0.5”

Installation

10│Page

Improperventingofthisappliancecanresultinexcessivelevelsofcarbonmonoxide

whichcanresultinseverepersonalinjuryordeath.

Wheninstallingtheventsystem,allapplicablenationalandlocalcodesmustbe

followed.Ifyouinstallthimbles,firestopsorotherprotectivedevicesandthey

penetrateanycombustibleornoncombustibleconstruction,besuretofollowall

applicablenationalandlocalcodes.

INSTALLATIONFORDIRECTVENTINDOORMODELS

TheDirectVent Indoor modelsareequippedwithathermistorandhi‐limitswitchfor the exhaustgas,

detectingexcesstemperatureswithintheflueandenablingtheunittosafelystopoperationsifneeded.

These components are always monitoring exhaust gas conditions in order to prevent heat damage to

PVC(Plastic)ventingifPVCisused.

If the exhaust gas temperature exceeds 140°F, these components will enable the unit to safely stop

operations.(For the Outdoor model, these components are not available since there’s no exhaust

ventingrequ ired.)

TheDirectVentIndoormodelrequiresa

4” make‐up intake air supply pipe. The

intakepipemustbesealedairtight.

AirsupplypipecanbemadeofABS,PVC,

galvanized steel, corrugated stainless

steel,orCategorylll/IVstainlesssteel.

Sidewallventingisrecommendedforthe

Direct Vent Ind oor model. Vertical

venting(rooftermination)isacceptable.

The manufacturer recommends

running the exhaust vent and the

intakepipeasparallelasp ossible.

ThePVCadaptorisusedtomake the

connection between the Direct Vent

Indoor model vent collar and PVC

ventpipeeasierand

formaintenance

purposes.

VENTINGINSTRUCTIONS

‐General‐

TheDirectVentIndoormodelsmustbeventedinaccordancewiththesection“VentingofEquipment"

of the latest edition of the National Fuel Gas Code: ANSI Z223.1/NFPA 54 in the United States and/or

Section 7 of the CAN/CSA B149.1 Natural Gas and Propane Installation Code in

Canada, as well as

applicablelocalbuildingcodes.

TheuseofventingmaterialsapprovedforCategoryIII/IVappliance sisrecommendedwheneverpossible.

However,theDirectVentIndoormodelsmayalsobeventedwithplasticpipematerialssuchasPVC.For

details,pleasereferto theExhaustVent(PVC Vent)sectiononp.11.VentinstallationsinCanadawhich

utilize

plasticventsystemsmustuseventingthatcomplieswithULCS636.

WARNING

Top12”

Side3”

Back0.5”

Side3”

Front4”

(24”Recommended

forMaintenance)

Bottom12”

Keeptheclearance s.

Installation

11│Page

Excludeselbowtermination,raincaps,orthe3”PVCConcentricTermination

FordetailsontheventconnectiontotheDirectVentIndoormodels

,

re

f

er toP.14

*Foreachelbowadded,deduct5ft.frommax.ventlength.

‐Exhaustvent(PVCandABSvent)‐

TheDirectVentIndoormodelscanbeconnectedwithPVCorABSventing(temperatureratedupto

149°F).However,themanufacturerrecommendsPVC(orABS)ventingcertifiedtoULCS636standards.

Item Material UnitedStates Canada

Exhaustpipeand

Fittings

Schedule40PVC ANSI/ASTMD1785

ULCS636Certified

MaterialsOnly

PVC‐DWV ANSI/ASTMD2665

Schedule40CPVC ANSI/ASTMF441

Schedule40ABS‐DWV ANSI/ASTMD2661

PipeCement/Primer

PVC ANSI/ASTMD2564

CPVC ANSI/ASTMF493

ABS ANSI/ASTMD2235

NOTE:DoNOTUseCellularFoamCorePipe

Themaximum lengthofexhaustventpipingmustnotexceed50ft.for4”ventingand25ft.for

3”venting(deducting5ft.foreachelbowusedintheventingsystem).Donotusemorethan5

elbowsfor4”ventingand2elbowsfor3”venting.

When

thehorizon t alventrunexceeds5ft.,supporttheventrunat3ft.intervalswithoverhead

hangers.

Diameter Max.No.ofElbow Max.VerticalandHorizontal(Total)VentLength

3” 2 25ft.

4” 5 50ft.

No.ofElbows

Max.VerticalorHorizontalLength

3”venting 4”venting

0 25ft. 50ft.

1 20ft. 45ft.

2 15ft. 40ft.

5 N/A 25ft.

ThisisaCategoryIVapplianceandmustbeventedaccordingly.Theventsystemmustbesealedairtight.

AllseamsandjointswithoutgasketsmustbesealedwithhighheatresistantsiliconesealantorULlisted

aluminumadhesivetapehavingaminimumtemperatureratingof160°F.Forbestresults,a

vent system

shouldbeasshortandstraightaspossible.

TheDirectVent IndoormodelsareaCategoryIVapplianceandmustbeventedaccordinglywith

any4”ventapproved forusewithCategoryIII/IVorSpecialBHtypegasvent.

The manufacturer recommends the “T‐Vent”line

manufactured by TAKAGI (Refer to Takagi’s

“T‐Vent”brochurefordetails).However,thefollowingarealsoULlistedmanufacturers:ProTech

SystemsInc.(FasNSeal),Flex‐LInc.,Z‐FlexInc.(Z‐VentIII),Metal‐FabInc.,andHeat‐FabInc.(Saf‐

TVent).

Followtheventpipemanufacturer’sinstructionswheninstalling

theventpipe.

‐Exhaustvent(Stainlesssteelvent)‐

Installation

12│Page

Improperinstallationcancausenauseaorasphyxiation,severeinjuryordeathfrom

carbonmonoxideandfluegasespoisoning.Improperinstallation willvoidproduct

warranty.

Do not common vent thisappliance with any ot hervented appliance(Donot terminate vent

intoachimney.Iftheventmustgothroughthechimney,theventmustrunallthewaythrough

thechimneywithCategoryIII/IVapprovedorSpecialBHventpipe).

The

maximum length of exhaust vent piping must not exceed 50 ft. (deducting 5 ft. for each

elbowusedintheventingsystem).Donotusemorethan5elbows.

Whenthehorizontalventrunexceeds5ft.,supporttheventrunat3ft.intervalswithoverhead

hangars.

Diameter Max.No.ofElbow Max.VerticalandHorizontal(Total)VentLength

4” 5 50ft.

*Foreachelbowadded,deduct5ft.frommax.Ventlength.

No.ofElbows Max.VerticalorHorizontalLength

0 50ft.

1 45ft.

2 40ft.

5 25ft.

‐Venttermination‐

Theventterminatorprovidesameansofin stalling ventpipethroughthebuildingwallandmustbe

located in accordance with ANSI Z223.1/NFPA 54, or in Canada with CAN/CSA‐B149.1 and local

applicablecodes.

Apropersidewalldirect‐ventterminatorisrecommendedwhenthewaterheaterisventedthrough

a

sidewall.

GeneralrulesforventingtheDirectVentIndoormodelsare:

1. Placethewaterheaterascloseaspossibletotheventterminator.

2. TheventcollarofthewaterheatermustbefasteneddirectlytoanunobstructedventpipeorPVC

adaptor.

3. Donotweldtheventpipeto

thewaterheatercollar.

4. Donotcuttheventcollaroftheunit.

5. Theweightoftheventstackmustnotrestonthewaterheater.

6. The vent must be easily removable from the top of the water heater for normal service and

inspectionoftheunit.

7. Thewaterheaterventmustnotbeconnectedtoanyothergasapplianceorventstack.

8. Avoidlo cating the waterheaterventterminatornearanyair intake devices.Thesefanscanpick

up the exhaust flue products from the water heater and return them to the building. This

can

createahealthhazard.

9. Avoidusinganoversizedventpipeorusingextremelylongrunsofthepipe.

10. Locate the vent terminator so that it cannot be blocked by any debris, at any time. Most codes

requirethatthet erminatorbeatleast12inchesabovegrade,buttheinstallermaydetermineifit

shouldbehigherdependingonthejobsiteconditionandapplicablecodes.

11. For

rooftopventing,arain capor otherformofterminationthatpreventsrainwaterfromentering

intothewaterheatermustbeinstalled.

WARNING

Installation

13│Page

1. ConnectthePVCadaptor*directlyontheexhaustventcollarofthewaterheater.

2. Connecta4”PVCcoupler(or4x3”PVCreducer)tothePVCadaptor.

3. Fromthecoupler(orreducer),continueontherestoftheventrunwith4”PVCpipe(or3”PVC

pipe.)

(ForExhaust)

HorizontalInstallationDiagram

(Withelbowterminations)

HorizontalInstallationDiagram

(With3”PVCConcentricTermination)

Keepa1”cle arancebetweenwall

andtheintakesectionofthe

concentrictermination.Seethe

diagramtotheleft.

‐PVCVentingIllustrations‐

HowtoinstallPVCventingwiththeDirectVentIndoormodels

ConnectionbetweenexhaustventcollarandPVCpiping

Seethenextpageforinstructions.

Wall

ConnectionbetweenexhaustventcollarandPVCpiping

Seethenextpageforinstructions.

Wall

1” minimum

clearance

ConcentricTermination

Insertthebirdscreenincludedwith

thetermination

VerticalInstallationDiagram

Roo

f

RoofFlashing

Firestop

Installation

14│Page

1. Connecta4”PVCStraightpipedirectlyontheintakeventcollarofthewaterheater.

2. Connecta4x3”PVCreducertothe4”PVCStraightpipe.

3. Fromthereducer,continueontherestoftheventrunwith3”PVCpipe.

(ForIntake:4”only)

(ForIntake:

3”only)

Regardingtheclearancesfromtheexhaustterminatorto

theairinletoropening,refertothenextfewpages.

Followallventsystemmanufacturer’sinstructionsandall

localcodes.

Do not common vent or connect any vent from other

appliancestotheDirectVentIndoormodelsvent.

Use 4” Category III/IV approved or Special BH, single or

doublewallstainlesssteelventpipe.

VerticalInstallationDiagram

HorizontalInstallationDiagram

*PVCadaptorisincludedwiththeDirectVentIndoormodels.

4”ventconnectionDiagram

3”ventconnectionDiagram

‐

S

tainlessstee

l

VentingIl

l

ustrations‐

1.Connecta4”PVCStraightpipedirectlyontheintakeventcollarofthewaterheater.

RoofFlashing

Roo

f

RainCap

Firestop

Wall

SidewallVent

Terminator

Exhaustventcollar

oftheDirectVent

Indoormodels

(Female)

PVCadaptor*

4”PVCcoupler

4”PVCStraightpipe

4”PVCStraight

pipe

Intakeventcollar

3”PVCStraightpipe

4x3”PVCreducer

PVCadaptor*

3”PVCStraight

pipe

4x3”PVCreducer

4”PVCStraight

pipe

Intakeventcollar

Exhaustventcollar

oftheDirectVent

Indoormodels

(Female)

Installation

15│Page

‐Ventclearances‐

Canada U.S.A

Directventand

otherthanDirect

Vent

Directvent OtherthanDirectVent

A

Clearanceabovegrade,veranda,porch,deck,

orbalcony.

1foot 1foot 1foot

B

Clearancetowindowordoorthatmaybe

opened.

3feet 1foot

4feetfrombeloworside

opening.1footfrom

aboveopening.

C Clearancetopermanentlyclosedwindow * * *

D

Verticalclearancetoventilatedsoffitlocated

abovetheventterminatorwithinahorizontal

distanceof2feet(61cm)fromthecenterline

oftheterminator.

* * *

E Clearancetounventilatedsoffit * * *

F Clearancetooutsidecorner * * *

G Clearancetoinsidecorner * * *

H

Clearancetoeachsideofcenterlineextended

abovemeter/regulatorassembly

3feet * *

I Clearancetoserviceregulatorventoutlet. 3feet * *

J

Clearancetonon‐mechanicalairsupplyinlet

tobuildingorthecombustionairinlettoany

otherapplication.

3feet 1foot

4feetfrombeloworside

opening.1footfrom

aboveopening.

K Clearancetomechanicalairsupplyinlet. 6feet 3feet 3feet

L

Clearanceabovepavedsidewalkorpaved

drivewaylocatedonpublicproperty.

7feet * 7feet

M

Clearanceunderveranda,porchdeck,or

balcony.

1foot * *

*ForclearancesnotspecifiedinANSIZ223.1/NFPA54orCAN/CSA‐B149.1,pleaseuseclearancesinaccordancewith

localinstallationcodesandtherequirementofthegassupplier.

Installation

16│Page

‐Additionalclearances‐

Pleasefollowalllocalandnationalcodesinregardstoproperterminationclearances.Intheabsenceof

suchcodes,thefollowingclearancescanbeusedasguidelines.Localcodessupersedetheseguidelines.

Forsidewallterminations

Exhausttermination

1ft.

1ft.

2ft.

Inside

corner

Formultiplesidewallexhaust

terminations(e.g.multi‐unit

systems),anexhausttermination

mustbeatleast1ft.awayfrom

anotherexhausttermination.An

exhaustterminationmustalsobe

atleast2ft.awayfromaninside

corner(iftheadjacentwallisless

than2ft.oflength,theminimum

requireddistanceawayfromthe

insidecornerwillbeequaltothe

lengthofthatadjacentwall).

Fordirect‐ventsidewall

terminationsthatusetwo

separatepenetrationsforthe

intakeandexhaust,distance

theintakeandexhaust

terminationsatleast3ft.away

fromeachother,nomatterthe

orientation.

Formultiple‐unit,direct‐ventsidewall

terminationsthatcombinetheintake

andexhaustintoasinglepenetration,

spaceeachdirect‐ventterminationat

least1ft.awayfromeachother,no

mattertheorientation.Adirect‐vent

terminationmustalsobeatleast2ft.

awayfromaninsidecorner(if

the

adjacentwallislessthan2ft.of

length,theminimumrequired

distanceawayfromtheinsidecorner

willbeequaltothelengthofthat

adjacentwall).

Formultiple‐unitrooftopterminations(whetherforstandardindooror

direct‐ventinstallations)spaceallexhaustandintaketerminationsin

accordance

withlocalcodes.Anexhaustterminationmustbespacedfrom

awallorsurfaceinaccordance withlocalcodes aswell.Intheabsenceof

suchacode,anexhaustterminationmustbeahorizontaldistanceofat

least2ft.awayfromawallorsurface.

A:inaccordancewith

localcodes

Forrooftopterminations

Airintake

Exhaust termination

A

A

A

A

A

2ft.

Airintake

Exhaust

termination

Exhaustand/ordirect‐vent

sidewallterminationsshould

beatleast2ft.awayfroman

oppositesurface/wall.Do

notplacethetermination

directlyinfrontofan

openingintoabuilding.

2ft.

Exhaust

termination

Airsupplyinlet

3ft.

3ft.

3ft.

Directventtermination

1ft.

1ft.

Inside

corner

2ft.

Installation

17│Page

1. Turnoffallelectricpowertothewaterheaterifserviceistobeperformed.

2. Turnthemanualgasvalvelocatedontheoutsideoftheunitclockwisetotheoffposition.

Checkthatthetypeofgasmatchestheratingplatefirst.

Ensure that any and all gas regulators used are operating properly and

providing gas pressures within the specified range shown below. Excess gas

inletpressuremaycauseseriousaccidents.

Conversion of th is unit from natural gas to propane or vise versa will void all

warranty. Contact your local distributor to get the correct unit for your gas

type.Themanufacturerisnotliableforanypropertyand/orpersonaldamage

resultingfromgasconversions.

Sizethegaspipeappropriatelytosupplythenecessaryvolumeofgasrequiredfor

thewaterheaterusingANSI233.1/NFPA54intheUSAorCAN/CSAB149.1inCanada

orlocalcodes.Otherwise,flowcapabilitiesandoutputtemperatureswillbelimited.

GASSUPPLYANDGASPIPESIZING

Theminimumandmaximuminletgaspressuresare:

Gastype Inletgaspressure

NaturalGas Min.5.0”WC–Max.10.5”WC

Propane Min.8.0” WC– Max.14.0” WC

Gas pressure above this specified range for the water heater and/or insufficient gas volume will

adversely affect performance.These pressures are measured when the water heater is in full

operation.

Inlet gas pressure must not exceedthe above maximum values; gas pressure above the specified

rangewillcausedangerous

operatingconditionsanddamagetotheunit.

Until testing of the main gas line supply pressure is completed, ensure the gas line to the water

heaterisdisconnectedtoavoidanydamagetothewaterheater.

‐Gasconnections‐

1. Installamanualgasshut‐offvalvebetweenthewaterheaterandthegassupplyline.

2. When the gas connections are completed, it is nece ssary to perform a gas leak test (see below)

eitherbyapplyingsoapywatertoallgasfittingsandobserving for bubblesorbyusing

agasleak

detectiondevice.

Thewaterheater anditsindividualshutoff valve mu st bedisconnectedfromthegassupply

pipingsystemduringanypressuretestingofthatsystemattestpressuresinexcessof1/2psi

(3.5kPa).

Thewaterheatermustbeisolatedfromthegassupplypipingsystembyclosingitsindividual

manual shutoff valve during any pressure testing of the gas supply piping system at test

pressuresequaltoorlessthan1/2psi(3.5kPa).

3. Alwayspurgethegaslineofanydebrisand/orwater

beforeconnectingtothegasinlet.

WARNING

TOTURNOFFGASTOAPPLIANCE

NOTICE

Installation

18│Page

‐NaturalGasSupplyPiping‐

MaximumDeliveryCapacityofCubicFeetofGasperHourofIPSPipeCarryingNaturalGasof0.60SpecificGravity

BasedonPressureDropof0.5”WC

BasedonEnergyContentof1,000BTU/CubicFt.:Thewaterheaterrequires199CubicFt./hrforthe520(T‐H2)

models,and180CubicFt./hrforthe320(T‐H2S)models.

Unit:CubicFeetperHour

PipeSize Length

Diameter 10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ 100’ 125’ 150’ 200’

¾” 363 249 200 171 152 138 127 118 111 104 93 84 72

1” 684 470 377 323 286 259 239 222 208 197 174 158 135

1¼” 1,404 965 775 663 588 532 490 456 428 404 358 324 278

1½” 2,103 1,445 1,161 993 880 798 734 683 641 605 536 486 416

2” 4,050 2,784 2,235 1,913 1,696 1,536 1,413 1,315 1,234 1,165 1,033 936 801

‐Propane(LP)GasSupplyPiping‐

MaximumCapacityofPropane(LP)GasBasedon11”WCsupplypressureata0.5”WCpressuredrop

Unit:kBTUperHour

PipeSize

Length

Diameter

10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ 100’ 125’ 150’ 200’

¾” 567 393 315 267 237 217 196 185 173 162 146 132 112

1” 1,071 732 590 504 448 409 378 346 322 307 275 252 213

1¼” 2,205 1,496 1,212 1,039 913 834 771 724 677 630 567 511 440

1½” 3,307 2,299 1,858 1,559 1,417 1,275 1,181 1,086 1,023 976 866 787 675

2” 6,221 4,331 3,465 2,992 2,646 2,394 2,205 2,047 1,921 1,811 1,606 1,496 1,260

Formoreinformation,pleaseseethenextpage.

BasedonEnergyContentof1,000BTU/CubicFt:

Divideeachappliance’sBTUrequirementby1,000BTUtoget

theappliancesCubicFt.requirement.

Takeintoaccountthedistancetheapplianceisfromthegas

meter,lookintheabovegascharttoproperlysizetheline.

Forsectionsofthegasline

supplyinggastomorethanone

appliance(Ex:PointAtoPointB),addupthecubicft.

requirementsoftheappliancesthatarebeingsuppliedbythat

section,andsizetothefarthestappliance.

ForExample:ThesectionfromAtoBsuppliesgastothe

furnace,range,anddryer.

AddinguptheBTUrequirements

anddividingby1,000yieldsacubicft.requirementof220

cubicft.ofgas.Thefarthestapplianceistherange,whichis50

ft.awayfromthemeter.Lookingattheabovechart,and

underthecolumnof50ft.,SectionAtoBneeds

tobe1”in

ordertosupply220cubicft.

Range

65,000BTU

C

10’Length

1”PipeSize

GasSizingExample

(NaturalGas)

10’Length

3/4”PipeSize

15’Length

1/2”PipeSize

10’Length

1/2”PipeSize

Furnace

120,000BTU

WaterHeater

5’Length

1‐1/4”PipeSize

10’Length

3/4”PipeSize

Dryer

35,000BTU

15’Length

1”PipeSize

5’Length

1‐1/4”PipeSize

GasMeter

B

A

199,000BTU

or

180,000BTU

Installation

19│Page

1.Turnoffallelectricpowertothewaterheaterifserviceistobeperformed.

2.Turnthemanualgasvalvelocatedontheoutsideoftheunitclockwisetothe

off

p

osition.

Do not use this water heater if any part has been submersed under water.

Immediatelycallalicensedprofessionaltoinspectthewaterhe atertoreplace

anydamagedparts.

Donotreverse thehotoutletandcold inletconnections tothewaterheater.

Thiswillnotproperlyactivatethewaterheater.

‐Measuringinletgaspressure‐

Thewaterheatercannotperformproperlywithoutsufficientinletgaspressure.Belowareinstructions

onhowtochecktheinletgaspressure.THISISONLYTOBEDONEBYALICENSEDPROFESSIONAL.

1. Shutoffthemanualgasvalveonthesupplygasline.

2. Removethescrewforthe

pressureportlocatedon

thegasinletofthewaterheatershowninthe

diagramtotheright.

3. Connectthemanometertothepressureport.

4. Re‐openthemanualgasval ve.Checktoseethat

therearenogasleaks.Opensomeofthefixtures

thatusethehighest

flowratetoturnonthewater

heater.

5. Checktheinletgaspressure.Whenthewaterheater

isonmaximumburn,themanometershouldread

from5.0”to10.5”WCforNaturalgas,from8.0”to

14.0”WCforPropane.

WATERCONNECTIONS

Allpipes,pipefittings,valvesandothercomponents,includingsolderingmaterials,mustbesuitablefor

potablewatersystems.

1. A manual shut off valve mustbeinstalledon the

coldwaterinlettothewaterheaterbetweenthe

mainwatersupplylineandthewaterheater.

2. In addition, a manual

shut off valve is also

recommendedonthehotwateroutletoftheunit.

If the water heater is installed with in, or

subjected to, a closed loop water system, a

thermalexpansiontankmustbeinstalled.

3. Before installing the water heater, flush the

water line to remove all debris,

and after

installation is comp lete, purge the air from the

line.Failuretodosomaycause damagetothe

heater.

4. Thereisawiremeshfilterwithin thecold inlettotrapdebrisfromenteringyourheater.Thiswill

needtobecleanedperiodicallytomaintainoptimumflow.

CAUTION

Pressure

ReliefValve

Hot

outlet

Cold

inlet

Gas

AsCloseas

Possible

Installation

20│Page

‐Pressurereliefvalve‐

Thewaterheaterhasahigh‐temperatureshutoffswitchbuiltinas a standard safety feature(calleda

Hi‐Limitswitch)thereforea“pressureonly”reliefvalveisrequired.

Thisunitdoesnotcomewithanapprovedpressurereliefvalve.

Anapprovedpressurereliefvalvemustbeinstalled

onthehotwateroutlet.

ThepressurereliefvalvemustconformtoANSIZ21.22orCAN1‐4.4andinstallationmustfollow

localcode.

The discharge cap acity must be at least 199,000 BTU/h for th e 520 (T‐H2) models, and 180,000

BTU/hforthe320(T‐H2S)models.

Thepressurereliefvalveneedstoberatedforamaximumof150psi.

Thedischargepipingforthepressurereliefvalvemustbedirectedsothatthehotwatercannot

splashonanyoneoronnearbyequipment.

Attach the discharge tube to the pressure relief valve and

run the end of the tube to within 6"

from the floor. This discharge tube must allow free and complete drainage without any

restrictions.

Ifthepressurereliefvalveinstalledonthewaterheaterdischargesperiodically,thismaybedue

toadefectivethermalexpansiontankordefectivepressure

reliefvalve.

Thepressurereliefvalvemustbemanuallyoperatedperiodicallytocheckforcorrectoperation.

Novalvemustbeplacedbetweenthereliefvalveandthewaterheater.

CONDENSATEDRAIN

Thewaterheaterdoesnotincludeabuilt‐incondensateneutralizercartridgeforreducingthepH

levelofcondensatewater.Iflocalcodesdictatethatcondensatemustbeneutralizedpriorto

drainage,acondensateneutralizermustbeinstalled.AnaccessoryNeutralizerassemblyissold

separately.

Intheabsenceof

applicablelocalcodesandregulations,themanufacturerrecommendsthat

condensatebedisposedofintoastandarddrain.Connectadraintubefromthecondensatedrain

port(shownbelow)locatedonthebottomofthewaterheatertoastandarddrain.

Follow all code requirements

of the local authority on

condensate neutralizers and

whether or not they are

requiredfortheinstallation.

Condensatedrainport

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

American Water Heater 520 Owner's manual

- Category

- Water heaters & boilers

- Type

- Owner's manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Other documents

-

A.O. Smith ATI-110-P Technical Documents

-

A.O. Smith ATI-510-N Technical Documents

-

A.O. Smith ATI-310-N Technical Documents

-

Takagi Mobius T-M1 Owner's manual

-

State Water Heaters 710 Installation Manual And Owner's Manual

-

Takagi 9320053005 Owner's manual

-

State 100282551 User manual

-

Takagi Flash T-K2 Owner's manual

-

The Plumber's Choice 12HCSGE Installation guide

The Plumber's Choice 12HCSGE Installation guide

-

The Plumber's Choice 21GWHS User manual

The Plumber's Choice 21GWHS User manual