iii

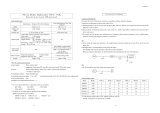

8.3 Use of surface-treated accessories ...................................................................................................43

8.4 How to mount small size (standard) sensor and small outer diameter sensor to pipe .....................44

8.4.1 How to mount a sensor (V method) .........................................................................................44

8.4.2 How to mount a small size (standard) sensor (Z method) ........................................................45

8.5 How to mount large and medium size sensor ..................................................................................47

8.5.1 How to determine mounting position .......................................................................................47

8.5.2 How to connect medium size sensor ....... ...............................................................................48

8.5.3 How to connect large size sensor ................................... ........................................................50

8.5.4 Mounting of medium type sensor on pipe ................................................................................51

8.5.5 How to mount large size sensor to pipe ...................................................................................53

8.6 How to mount high temperature sensor to pipe ...............................................................................54

8.6.1 How to mount a sensor (V method) .........................................................................................54

8.6.2 How to mount a sensor (Z method) ..........................................................................................55

8.7 How to fold gage paper (used for determining mounting position) ................................................57

9. START MEASURING .......................................................................................................... 58

10. SETTING OPERATION (APPLICATION) .......................................................................... 63

10.1 How to use SITE SETUP function (SITE SETUP page) ................................................................64

10.1.1 SITE MEMORY: when registering data which are set and calibrated on the page ................64

10.1.2 ZERO ADJUSTMENT: when performing zero adjustment ...................................................66

10.1.3 UNIT OF OUTPUT: when changing unit of each output ........................................................67

10.1.4 OUTPUT CONTROL: when controlling measured value (output control function) ..............69

10.1.5 TOTALIZER: when performing the total process of measured data (totalize) .......................73

10.2 Setting of data logger function ........................................................................................................76

10.2.1 “Logger Operation” mode ........................................................................................................77

10.2.2 Logger data fi le format .............................................................................................................79

10.2.3 LOGGING: when logging (recording) measured data ............................................................80

10.2.4 “LOGGER DATA”: when checking or printing logged data ..................................................83

10.3 Setting of system (SYSTEM SETUP screen)..................................................................................88

10.3.1 BASIC SETUP: when setting the system................................................................................88

10.3.2 “ANALOG INPUT/OUTPUT”: when performing analog input/output and calibration ........95

10.3.3 “CALORIE MODE”: when measuring consumed heat quantity ..........................................103

10.4 Setting of range (setting screen for input/output range) ................................................................106

10.4.1 Setting the input range: When setting the range for the input current or input voltage.

Setting range: 0.000 to ±9999999999 ....................................................................................106

10.4.2 Setting the output range ..........................................................................................................108

10.5 Use of printer function (PRINTER screen) ...................................................................................112

10.5.1 Selection of printing mode .....................................................................................................112

10.5.2 Example of printing ................................................................................................................113

10.5.3 PRINT OF TEXT ...................................................................................................................114

10.5.4 PRINTING OF GRAPH .........................................................................................................115

10.5.5 PRINT OF LIST .....................................................................................................................116

10.5.6 STATUS DISPLAY ...............................................................................................................116

10.6 Maintenance function (MAINTENANCE screen) ........................................................................117

10.6.1 Checking receiving status for transit time ..............................................................................117

10.6.2 Check for analog input/output ................................................................................................122

Bulletin F-9-PUX2