Page is loading ...

Manual, complete

745 - 34 - 1, -3

Sewing Unit for Runstitching of Piped Flap

and Welt Pocket Openings and Pocket Cor ners

WorkingMethods:A,B,D,F

Operating Instructions

Installation Instructions

Service Instructions

Instructions for Programming DAC

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D -33719 Bielefeld

Telefon + 49 (0) 5 21 / 9 25-00 • Telefax + 49 (0) 5 21 / 9 25 24 35 • www.due rkopp-adler.c om

1

2

3

4

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

11/2011 Rev. index: 03.0 Printed in Federal Republic of Germany 0791 745181

745 - 34 - 1, -3

Manual, complete

Content

Operating Instructions

Installation Instructions

Service Instructions

Instructions for Programming DAC

Interconnection Diagram

9870 745154 B

9890 745002 B

Pneumatic Circuit Plan

9770 745005

All rights reser ved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content

in any manner, even in extracts, without prior written permission of Dürkopp Adler AG, is

prohibited.

Copyright ©

Dürkopp Adler AG - 2011

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

instruction book and operated by persons with appropriate training.

2. Before putting into service also read the safety rules and

instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

1

Index Page:

Part 1: Operating Instructions 745-34-1, 745-34-3 – Original Instructions

(Edition 11/2011)

1 Product Description .......................................... 5

1.1 Descriptionofproperuse ....................................... 5

1.2 Briefdescription............................................. 5

1.3. Subclasses................................................ 7

1.3.1 Dürkopp-Adler 745-34-1 ........................................ 7

1.3.2 Dürkopp-Adler 745-34-3 ........................................ 8

1.3 Technicaldata .............................................. 9

1.4 Optionalequipment........................................... 11

2 Operation................................................. 17

2.1 Swingingthefoldingstationaside.................................. 17

2.2 Pushing the covering hood back and removing t he fabric sliding sheet ............ 18

2.3 Tiltingthemachineheadup...................................... 21

2.4 Needlesandthreads .......................................... 22

2.5 Threadingtheneedlethread...................................... 25

2.6 Winding the hook thread ........................................ 26

2.7 Remainingthreadmonitor....................................... 27

2.8 Changingthebobbins.......................................... 28

2.9 Threadtension.............................................. 30

2.10 Stacking control ............................................. 31

2.11 Corner knife station745-34-1 ..................................... 32

2.11.1 Swingingthecornerknifestationout/in.............................. 33

2.12 Slanted pocket cor ners 745-34-3................................... 34

2.12.1 Swingingthecornerknifestationout/in.............................. 35

2.13 Referenceposition-Startingthesewingcycle-Quickstop................... 36

2.14 Flapandpipingprojection....................................... 37

2.15 Pipingstriplength............................................ 38

2.16 Workingmethods ............................................ 39

2.16.1 WorkingmethodA(Productionoftrousers)............................. 40

2.16.2 Sewingwithflap............................................. 43

2.16.2.1 Sewing without light barrier ...................................... 43

2.16.2.2 Sewingwithlightbarrier........................................ 45

2.16.3 Working method A (Production of jackets)

Piped pockets, manual positioning of piping strip, flaps and other additional parts .... 46

2.16.4 Working method B

Piped pockets, automatic feed of the piping strip, without/with incision of the

pipingends................................................ 52

2.16.5 Working method D

Breast welt pockets, automatic feed and matching of t he breast welt............. 62

Index Page:

2.16.6 Working method F

Piped pockets, automatic feed of the piping strip,

incisionofthepipingends,matchingandfeedoftheflap.................... 68

2.16.7 Foldermonitoring ............................................ 72

2.17 Functions and operation of the optional equipment ........................ 73

2.17.1 Automaticincisiondeviceforpipingends.............................. 73

2.117.2 Downholder, pocket bag and waistband clamp .......................... 76

2.17.3 Feeding devices for flaps, pocket bags etc. ............................ 77

2.17.4 Throw-over stacker ........................................... 78

2.17.5 Roll-offdevice .............................................. 80

2.17.6 Blow-outdevice............................................. 81

2.17.7 Bundleclampandroll-offdevice................................... 82

2.17.8 Tapefeedandautomaticcutting................................... 83

2.17.9 Vacuumdevice.............................................. 86

2.17.10 Working method B with set of parts “Pocket bag on flap” .................... 87

2.17.11 ZipperfeedersformethodB...................................... 90

2.17.12 Set of parts “Shaped guide Lining loop triangle” for 745-34-3 methods B and F ...... 91

2.17.13 Smoother................................................. 92

3 Maintenance ............................................... 93

3.1 Cleaning.................................................. 93

3.2 Weekly lubrication ............................................ 96

1 Product description

1.1 Description of proper use

The 745-34-1 and 745-34-3 are sewing units used for sewing light to

medium-weight material. Such material is, as a rule, material made of

textile fibres or leather. These materials are used in the garment

industry.

In general only dry material should be sewn on this machine. The

material must not contain any hard objects.

The seam is generally made with c ore thread, polyester fibre

or cotton threads.

The dimensions for needle and hook threads can be taken from the

table in chapter 2.4.

Before using any other threads it is necessary to estimate the

consequential dangers and to t ake the respective safety measures, if

req ui re d.

This sewing unit must only be installed and operated in dry and

well-kept rooms. If the sewing unit is used in other rooms, which are

not dry and well-kept, further measures to be agreed upon may

become necessary (see EN 60204-31 : 1999).

We, as a manufacturer of industrial sewing machines, assume that at

least semi-skilled operating personnel will be working on our products

so that all usual operations and, where applicable, their risks are

presumed to be known.

1.2 Brief description

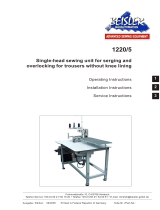

The Dürkopp Adler 745-34-1 and 745-34-3 are s ewing units for

automatic runstitching of piped, flap and welt pocket openings with

rectangular or slanted pocket cor ners.

The slanted pocket cor ners result from t he seam offset of the two

seam rows. At the seam beginning and seam end it is possible to sew

with different slants.

Dependent on the working method different feeding devices, corner

knife stations and optional equipment are used.

Machine head

–

Twin needle lockstitch version

–

Needle bars can be switched separately or together (only

745-34-3)

–

Large vertical hooks

–

Externally driven center knife, speed and circuit timing

programmable

–

Thread trimming device for needle and hook threads

–

Needle thread monitor

–

Photoelectric remaining thread monitor for the hook threads

–

Sewing drive as DC direct drive

1

5

Step motors for the material feed and the length adjustment of the

corner cutting device

The step motor technology results in short machine times and

guarantees an absolutely precise cor ner incision.

Thus, it contributes to a pocket quality as yet unequalled a nd

combined with high productivity.

New generation of “DAC III” controls (DÜRKOPP ADLER Control)

The graphic user guidance exclusively occurs via inter nationally

comprehensible symbols and text lines in the corresponding

language.

The various symbols are combined in groups within the menu

structure of the sewing and test programs.

The ease of use makes short training times possible.

The user can combine 99 freely programmable pocket programs with

up to 20 seam patter ns.

20 pocket sequences can be called up.

Every pocket sequence can be combined of up to 8 pocket programs

in any order whatever.

All slants suitable for practical application can be programmed by the

operator at the touch of a button.

The time-consuming adjustment of the cor ner knives and the tiresome

programming of seam offsets are not required.

The comprehensive test and monitoring system MULTITEST is

integrated in the DAC.

A microcomputer does the control tasks, monitors the sewing cycle

and signals operating faults and malfunctions on the display.

Optional equipment

By means of a flexible system of optional equipment the sewing unit

can be equipped optimally and economically corresponding to the

respective application.

See chapter 1.4 (equipment of the 745-34-1/-3).

Sewing equipment and folders

Data concer ning the sewing equipment and folders for the various

applications can be taken from the Equipment Sheets of cl. 745-34-1

and 745-34-3.

Please direct your enquiries to the DÜRKOPP-ADLER sales offices.

6

1.3 Subclasses

1.3.1 Dürkopp-Adler 745-34-1

Sewing unit for automatic runstitching of piped, flap and welt pocket

openings with rectangular pocket cor ners.

Two different working methods (transfer devices) are possible.

Depending on the working method different feeding devices, corner

knife stations and optional equipment are used.

Corner knife station (rectangular pockets)

The setting of the corner knives in relation to the pocket length can be

set via step motor. The distance between the corner knifes and the

seam can be adjusted manually. The complete knife bracket can be

swung out for setting and service operations.

Working methods

Method A

Manual positioning of piping strip, flap and additional pieces.

Method B

The piping strip is fed automatically. Feeding options of the flap and

the additional pieces: from the right, from the left or from both sides.

7

1

1.3.2 Dürkopp-Adler 745-34-3

Sewing unit for the automatic runstitching of piped, flap and welt

pocket openings with slanted pocket cor ners.

Four different working methods (transfer devices) are possible.

Depending on the working method different feeding devices, corner

knife stations and optional equipments are used.

Corner knife station (manual angle adjustment)

For the methods A, B and D a manual cor ner knife station is delivered

as standard equipment with the sewing unit.

The setting of the corner knives in relation to the pocket length can be

set via step motor. The slanted pocket cor ners result from the seam

offset of the two seam rows. The offset can be adjusted in steps of

0.1 mm. The incisions of the pocket corners can be adjusted with two

knurled screws. It can be selected separately for the seam beginning

and seam end up t o a difference of +/- 13mm in relation to the second

seam. The distance between the cor ner knifes and the seam can be

adjusted manually. The complete knife bracket can be tilted out for

setting and service operations.

The method F contains an additional automatic slant a djustment for a

programmable incision of the pocket corners that is s et via two step

motors.

Working methods

Method A

Manual positioning of piping strip, flap and additional pieces.

Method B

The piping strip is fed automatically. Feeding options of the flap and

the additional pieces: from the right, from the left or from both sides.

Method D

Method D only serves for the matching and sewing of breast welt

pockets. The additional parts are fed automatically.

Method F

The flap that is being fed from the left can be aligned with a

positioning device allowing for a correct matching of the stripes on

the fabric. The piping strip is fed automatically.

Automatic feeding of the flap and the additional parts from the right or

the left.

8

1.3 Technical data

Machine head: Class 0246 992004

Needle system: 2134-85

Number of needles: 2

Needle size: Nm 80 to Nm110

Needle distance:

745-34-1A 8, 10, 12, 14, 16, 18, 20, 22, 24, 26, 28, 30 mm

745-34-1B 10, 12, 14, 16, 20 mm

745-34-3A 8, 10, 12, 14, 16, 18, 20, 22, 24, 26, 28, 30 mm

745-34-3B, F 10, 12, 14, 16, 20 mm

745-34-1D 12 mm

Threads: see table chapter 2.4

Stitch type: Double needle lockstitch

Speed: min. 2000 rpm

max. 3000 rpm

Stitch length: min. 2.0 to 3.0 mm

Number of stitches/condensed

stitches: 1 - 10 stitches

Number of stitches/bartack

stitch: 0 - 5 stitches

Stitch length condensed

stitches / bartack: 0.5 - 3.0 mm

Pocket length: max. 220 mm

Seam offset: max.

+

/- 13 mm

Operating pressure: 6 bar

Air consumption: approx. 6 NL per work cycle

Rated voltage: 3 x 230 / 400 V / 50/60 Hz

Rated load:

Machine with

vacuum blower 0,8 KW

Machine without

vacuum blower 0,5 KW

Dimensions: 1540 x 925 x 1200 mm (L x W x H )

Working height: 790...980 mm

with height adjustment

(upper edge of table top)

Weight: 280 kg

9

1

Rated noise level: LC = 81 dB (A)

Workstation-specific emission value

according to DIN 45635-48-B-1

Stitch length: 2.5 mm

Seam length: 180 mm

Speed: 2750 rpm

Material: double fabric

240 g/m

2

Measuring point according t o DIN

4895 Part 1

X = 600 mm Y = 0 mm Z = 300 mm

10

1.4 Optional equipment

745-34-1 745-34-3

Order No. Optional equipment A B A B D F

0745 407784 Height adjustment stand/pedal

This kit contains a mechanical height adjustment for

the stand and the pedal. It allows for a maximum

working height of 1100 mm. For this the stand is put on

castors and the height is set with adjustable feet. The

pedal’s height and inclination can be set independantly

from the working height.

XXXXXX

0745 517564 Automatic feeding, left 180-220 mm For an automatic

feeding of the flap and the additional parts.

XX

0745 517574 Automatic feeding, right 180-220 mm For anautomatic

feeding of the flap and the additional parts.

XX

0745 567554 Pneumatic clamp adjustment

For an automatic adjustment of the clamps when

changing the folder

XX

0745 597514 Downholder- pocket bag clamp

Downholder for smoothing the fullness

caused by darts as well as a

clamping device for pocket bags

X XXX

0745 597524 Waistband clamp

For smoothing the fullness.

Only possible in conjunction with 0745 597514

X XXX

0745 597554 Throw-over stacker

To be positioned near the machine for stacking to the

side or to the back.

Furthermore, this throw-over stacker is equipped with

an easy-to-operate height adjustment and

a swivel device.

XXXXXX

0745 597604 Blow-out device

For blowing the finished workpieces out

X XXX

0745 597614 Shaped guide “Lining loop triangle”

In case of inside pockets the lining loop triangle

is fed automatically.

XX X

11

1

745-34-1 745-34-3

Order No. Optional equipment A B A B D F

0745 597674 Table extension (large)

The table extension required for the working method

with bundle clamp carriage

X XXX

0745 597684 Table extension (small)

Table extension to be used for stacking to the side

XXXXXX

0745 597694 Bundle clamp

This includes the required large table extension

X XXX

0745 597764 Right zipper feeder

In conjunction with feeding device 0745 517574

For cut-to-length zippers,

without slider, total width 24 mm, chain width

approx. 4 mm, in case of ready-made pocket chain

inside.

XX

0745 597774 Left zipper feeder

In conjunction with feeding device 0745 517564

For cut-to-length zippers,

without slider, total width 24 mm, chain width

approx. 4 mm, in case of ready-made pocket chain

inside.

XX

0745 597784 Right zipper feeder

In conjunction with feeding device 0745 517574

For cut-to-length zippers,

without slider, total width 24 mm, chain width

approx. 4 mm, in case of ready-made pocket chain

inside.

XX

0745 597794 Left zipper feeder

In conjunction with feeding device 0745 517564

For cut-to-length zippers,

without slider, total width 24 mm, chain width

approx. 4 mm, in case of ready-made pockets chain

inside.

XX

0745 597824 Smoother for the 745-34-2 A/B

The smoother has the purpose to smooth the finished

workpiece held by the bundle clamp. Only in

combination with the table extension 0745 597674

and the roll-off device 0745 597954.

X XXX

0745 597874 Set of parts “Pocket bag on flap” NA 10 and 12

for the simultaneous attaching of two pocket bag

halves and flap. Combination only in conjunction with

equipment E 3103 or E 3503 for NA 10

as well as E 3107 or E 3507 for NA 12.

XX

0745 597894 Kit: Pocket bag clamp

XX

12

1

745-34-1 745-34-3

Order No. Optional equipment A B A B D F

0745 597934 Three-pack lasers

Add-on kit: for expanding the existing 5 laser marking

lamps to a maximum of 8 laser marking lamps.

(With the working method F, the standard equipment

includes 8 laser marking lamps).

X XXX X O

0745 597944 Electromotoric tape feed/Automatic cutting

Automatic feeding and cutting of a

reinforcement strip pulled from a roll. Start time and

cutting time can be programmed

corresponding to the pocket.

XXXXXX

0745 597954 Roll-off device

It is used to for transporting short pieces into the

stacker or to eject the pieces to be processed.

The speed and the working cycle of the roll-off device

can also be programmed.

XXXXXX

0745 598004 Kit, sole 10 mm double piping for S175

XX

0745 598054 Kit second light barrier

X

0745 598104 Vacuum device K

For the correct positioning of the material, to connect

to the in-house vacuum unit

Remark:

If there is no in-house v acuum unit, a vacuum generator

has to be ordered additionally.

XX

0745 598124 Racks left and below

This kit contains the left-side racks as well as the tray

underneath the table top.

XOXOXO

0745 598134 Sewing light with transformer

XXXXXX

0745 598144 Two-pack laser

Add-on kit: for expanding the existing 3 laser marking

lamps to a maximum of 5 laser marking lamps. An

expansion to 16 switchable laser lights is possible

(additional cable needed). For an easy replacement the

laser lights are equipped with a short cable and a plug.

XX

0745 598164 Kit: Blowing of piping

For the blowing of the piping w ith high piping

projections. Combination only in connection with clamp

K 22.

XX

0797 003031 Pneumatic connection package

Connection hose to the pneumatic supply line

with the appropriate couplings.

XXXXXX

13

745-34-1 745-34-3

Order No. Optional equipment A B A B D F

0745 599014 Kit, sole 10 mm single piping left for S176

XX

0745 598024 Kit, sole 12 mm double piping for S100 and S177

XX

0745 598034 Kit, sole 12 mm single piping left for S178

XX

0745 598064 Kit, sole 10 mm double piping for S97

XX

0745 598074 Kit, sole 10 mm sinlge piping right for S110

XX

0745 598084 Kit, sole 12 mm single piping right for S111

XX

14

Notes:

15

1

16

1

2

2 Operation

2.1 Swinging the folding station aside

For operations at the sewing point (threading the needle threads,

needle change etc.) the whole folding station with folder and light

barriers can be swung to the right.

–

Swing the complete folding station 1 with folder

to the right.

Note:

With the sewing unit switched on, a safety message

appears on the screen of the control panel.

Folding station swung out

–

The sewing point is freely accessible.

Swinging the folding station back

–

Swing the folding station back.

ATTENTION!

After being swung back the folding station must lock

in the catch 2.

1

17

2.2 Pushing the covering hood back and removing the fabric sliding sheets

Caution: Danger of injury!

Switch the main switch off.

Push the covering hood back and remove the fabric sliding sheet only

with the sewing unit switched off.

–

Switch the main switch off

For a better accessibility of the feeding clamps the covering hood can

simply be displaced.

Pushing the covering hood back

–

Push the covering hood 1 to the left.

The feeding clamps are accessible.

–

Push the covering hood 1 to the right again until you hear it

snapping in.

18

1

1/98