Page is loading ...

FRONTRUNNERTM

DIESELMODELS

ForSerialNos.

720,000&Higher

PartNo.4500-227Rev.A

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Whenthemowerisusedoroperated

onanyCaliforniaforest,brushorgrasscovered

land,aworkingsparkarrestermustbeattached

tothemufer.Ifnot,theoperatorisviolating

statelaw,Section4442PublicResourceCode.To

acquireasparkarresterforyourunit,seeyour

EngineServiceDealer.

ThissparkignitionsystemcomplieswithCanadian

ICES-002Cesystèmed’allumageparètincellede

vèhiculeestconformeàlanormeNMB-002du

Canada

TheenclosedEngineOwner’sManualis

suppliedforinformationregardingTheU.S.

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenanceandwarranty.

KeepthisengineOwner’sManualwithyourunit.

ShouldthisengineOwner’sManualbecome

damagedorillegible,replaceimmediately.

Replacementsmaybeorderedthroughthe

enginemanufacturer.

Exmarkreservestherighttomakechangesor

addimprovementstoitsproductsatanytime

withoutincurringanyobligationtomakesuch

changestoproductsmanufacturedpreviously.

Exmark,oritsdistributorsanddealers,accept

noresponsibilityforvariationswhichmaybe

evidentintheactualspecicationsofitsproducts

andthestatementsanddescriptionscontained

inthispublication.

©2006–2008—ExmarkMfg.Co.,Inc.

IndustrialParkBox808

Beatrice,NE68310

2

Contactusatwww.Exmark.com.

PrintedintheUSA.

AllRightsReserved

Introduction

CONGRATULATIONSonthepurchaseofyour

ExmarkMower.Thisproducthasbeencarefully

designedandmanufacturedtogiveyouamaximum

amountofdependabilityandyearsoftrouble-free

operation.

Thismanualcontainsoperating,maintenance,

adjustment,andsafetyinstructionsforyourExmark

mower.

BEFOREOPERATINGYOURMOWER,

CAREFULLYREADTHISMANUALINITS

ENTIRETY.

Byfollowingtheoperating,maintenance,andsafety

instructions,youwillprolongthelifeofyourmower,

maintainitsmaximumefciency,andpromotesafe

operation.

Ifadditionalinformationisneeded,orshouldyou

requiretrainedmechanicservice,contactyour

authorizedExmarkequipmentdealerordistributor.

AllExmarkequipmentdealersanddistributorsare

keptinformedofthelatestmethodsofservicing

andareequippedtoprovidepromptandefcient

serviceintheeldorattheirservicestations.They

carryamplestockofservicepartsorcansecurethem

promptlyforyoufromthefactory.

AllExmarkpartsarethoroughlytestedandinspected

beforeleavingthefactory,however,attentionis

requiredonyourpartifyouaretoobtainthefullest

measureofsatisfactionandperformance.

Wheneveryouneedservice,genuineExmarkparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorExmarkCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

3

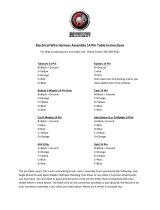

Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

SafeOperatingPractices..................................5

SafetyandInstructionalDecals.....................10

Specications.......................................................14

ModelNumbers............................................14

Systems.........................................................14

Dimensions...................................................16

TorqueRequirements....................................16

ProductOverview................................................17

Operation.............................................................17

Controls........................................................17

Pre-Start........................................................19

OperatingInstructions..................................19

Transporting.................................................21

Maintenance.........................................................23

RecommendedMaintenanceSchedule(s)...........23

PeriodicMaintenance.......................................24

CheckEngineOilLevel.................................24

CheckEngineCoolantLevel..........................24

ChangeEngineCoolant.................................25

CheckBatteryCharge....................................25

CheckSafetyInterlockSystem.......................26

CheckRolloverProtectionsSystems(Roll

Bar)Pins...................................................27

CheckSeatBelt..............................................27

CheckforLooseHardware............................27

ServiceAirCleaner........................................27

ChangeEngineOil........................................27

CheckHydraulicOilLevel.............................28

CheckTirePressures.....................................28

CheckConditionOfBelts..............................28

LubricateGreaseFittings...............................29

LubricateRearCasterWheelHub(s)...............29

LubricateBrakeHandlePivot........................30

LubricateBrakeRodBushings.......................30

LubricateMotionControlBronze

Bushings...................................................30

LubricateMotionControlShaft.....................30

LubricateSteeringLinkageRodEnds.............31

ChangeFuelFilter.........................................31

ChangeHydraulicSystemFilter.....................31

CheckWheelHubLocknuts..........................32

ThreadLockingAdhesives.............................32

DielectricGrease...........................................32

Adjustments.....................................................33

PumpDriveBeltTension...............................33

PumpDriveBeltReplacement.......................33

AlternatorBeltTension.................................33

ParkBrakeAdjustment..................................33

MotionControlLinkageAdjustment.............34

ReverseIndicatorAdjustment........................35

WeightTransferSpringAdjustment...............35

RearCasterPivotBearingsPre-Load

Adjustment...............................................36

Cleaning...........................................................37

CleanEngineCoolingSystem........................37

WasteDisposal..............................................37

Troubleshooting...................................................38

Schematics...........................................................40

4

Safety

Safety

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents

Thissymbolmeans:ATTENTION!BECOME

ALERT!YOURSAFETYISINVOLVED!

Figure2

1.Safetyalertsymbol

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituations

andwillbefollowedbythewordDANGER,

WARNING,orCAUTION.

DANGER:Whitelettering/Redbackground.

Indicatesanimminentlyhazardoussituationwhich,if

notavoided,Willresultindeathorseriousinjury.

WARNING:Blacklettering/Orangebackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Couldresultindeathorseriousinjury.

CAUTION:Blacklettering/Yellowbackground.

Indicatesapotentiallyhazardoussituationwhich,if

notavoided,Mayresultinminorormoderateinjury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizes

generalinformationworthyofspecialattention.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglishitistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperate

orservicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyExmark.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,longtrousers,andhearing

protection.DoNotoperatewhenbarefootor

whenwearingopensandals.Longhair,loose

clothingorjewelrymaygettangledinmoving

parts.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjectswhichcanbe

thrownbythemachineandmaycausepersonal

injurytotheoperatororbystanders.

5

Safety

DANGER

Incertainconditionsdieselisextremely

ammableandvaporsareexplosive.

Areorexplosionfromdieselcanburnyou,

others,andcausepropertydamage.

•Fillthefueltankoutdoorsinanopen

area,whentheengineiscold.Wipeup

anydieselthatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Adddieseltothefueltankuntilthelevel

is1/4to1/2inch(6–13mm)belowthe

bottomofthellerneck.Thisempty

spaceinthetankallowsdieseltoexpand.

•Neversmokewhenhandlingdiesel,and

stayawayfromanopenameorwhere

dieselfumesmaybeignitedbyspark.

•Storedieselinanapprovedcontainerand

keepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.

Neverremovethecapofthefueltankor

addfuelwhenengineisrunningorwhen

theengineishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

WARNING

Dieselfuelisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleanddiesel

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

•Checkthattheoperator’spresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.DoNotoperateunlessthey

arefunctioningproperly.

Operation

WARNING

Operatingengineparts,especiallythe

mufer,becomeextremelyhot.Severeburns

canoccuroncontactanddebris,suchas

leaves,grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

•Installandmaintaininworkingordera

sparkarresterbeforeusingequipment

onforest-covered,grass-covered,or

brush-coveredunimprovedland.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

6

Safety

WARNING

OperatingaFrontRunnertractorwithoutan

approvedExmarkfrontmountattachment

increasesthepossibilityofforwardtipover.

Tip-overcouldcauseseriousinjuryordeath.

WhenoperatingaFrontRunnertractor

withoutanapprovedExmarkfrontmount

attachment,observethefollowing:

•Limitoperationtominimumrequiredto

installadifferentfrontmountattachment.

•Minimizespeedanduseextremecaution.

•Onlyoperateonaatlevelsurface.

•DoNotoperateupordownatrailerramp.

•Avoidsuddenaccelerationordeceleration.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.Useseatbelts.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Nevermowwiththedischargedeectorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceand

workingproperly.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Stopengine,waitforallmovingpartstostop,

removekeyandengageparkingbrake:

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

–Beforeclearingblockages.

–Wheneveryouleavethemower.

•Stopengine,waitforallmovingpartstostop,and

engageparkingbrake:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•NEVERcarrypassengers.DONOToperate

themowerwhenpeople,especiallychildren,or

petsareinthearea.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebefore

changingdirections.

•Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareato

bemowed.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.

•DoNotoperatethemowerundertheinuence

ofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

UseExtremecautionwhenmowingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

7

Safety

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.Wheels

droppingoveredges,ditches,steepbanks,or

watercancauserollovers,whichmayresult

inseriousinjury,deathordrowning.

•DoNotmowslopeswhengrassiswet.

•DoNotmowneardrop-offsornearwater.

•DoNotmowslopesgreaterthan15

degrees.

•Reducespeedanduseextremecaution

onslopes.

•Avoidsuddenturnsorrapidspeed

changes.

•Seeinsidethebackcovertodeterminethe

approximateslopeangleoftheareatobemowed.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

(Figure3).

Figure3

1.SafeZone-Usethemowerhereonslopeslessthan15

degrees

2.DangerZone-Useawalkbehindmowerand/orhand

trimmerneardrop-offsandwater.

3.Water

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromthemowingarea.Tallgrasscan

hideobstacles.

•Watchforditches,holes,rocks,dipsandrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstopswhenmowingdownhill

becausethemowermaytipforwards.

•Beawarethatlossoftractionmayoccurgoing

uphill.Weighttransfertotherearwheelsmay

causedrivewheelstoslipandcauselossof

brakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagetheblades

andproceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextremecarewithgrasscatchersor

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

UsingtheRolloverProtectionSystem

(ROPS)

ARolloverProtectionSystem(rollbar)isinstalled

ontheunit.

WARNING

Thereisnorolloverprotectionwhentheroll

barisdown.Wheelsdroppingoveredges,

ditches,steepbanks,orwatercancause

rollovers,whichmayresultinseriousinjury,

deathordrowning.

•Keeptherollbarintheraisedandlocked

positionanduseseatbelt.

•Lowertherollbaronlywhenabsolutely

necessary.

•DoNotwearseatbeltwhentherollbar

isdown.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,andelectricalwires)before

drivingunderanyobjectsanddonotcontactthem.

8

Safety

MaintenanceandStorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Keepengine,enginearea,andpumpdrivebelt

compartmentfreefromaccumulationofgrass,

leaves,excessivegreaseoroil,andotherdebris

whichcanaccumulateintheseareas.These

materialscanbecomecombustibleandmayresult

inare.

•LetenginecoolbeforestoringandDoNotstore

nearameoranyenclosedareawhereopenpilot

lightsorheatappliancesarepresent.

•Shutofffuelwhilestoringortransporting.Do

Notstorefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallow

untrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplaceblades.Neverstraightenor

weldthem.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugcharger

beforeconnectingordisconnectingfrombattery.

Wearprotectiveclothinganduseinsulatedtools.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

•Allreplacementpartsmustbethesameas

orequivalenttothepartssuppliedasoriginal

equipment.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbya

doctorfamiliarwiththisformofinjuryor

gangrenemayresult.

•Makesureallhydraulicuidhoses

andlinesareingoodconditionand

allhydraulicconnectionsandttings

aretightbeforeapplyingpressureto

hydraulicsystem.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpaper,notyourhands,

tondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembyplacingthemotioncontrol

leversinneutralandshuttingoffthe

enginebeforeperforminganyworkon

thehydraulicsystem.

WARNING

Fuelsystemcomponentsareunderhigh

pressure.Theuseofimpropercomponents

canresultinsystemfailure,fuelleakageand

possibleexplosion.

Useonlyapprovedfuellinesandclampsfor

highpressuresystems.

9

Safety

SafetyandInstructionalDecals

•Keepallsafetysignslegible.Removeallgrease,

dirtanddebrisfromsafetysignsandinstructional

labels.

•Replaceallworn,damaged,ormissingsafety

signs.

•Whenreplacementcomponentsareinstalled,be

surethatcurrentsafetysignsareafxedtothe

replacedcomponents.

•Ifanattachmentoraccessoryhasbeeninstalled,

makesurecurrentsafetysignsarevisible.

•Newsafetysignsmaybeobtainedfrom

yourauthorizedExmarkequipmentdealeror

distributororfromExmarkMfg.Co.Inc.

•Safetysignsmaybeafxedbypeelingoffthe

backingtoexposetheadhesivesurface.Apply

onlytoaclean,drysurface.Smoothtoremove

anyairbubbles.

•Familiarizeyourselfwiththefollowingsafetysigns

andinstructionlabels.Theyarecriticaltothesafe

operationofyourExmarkcommercialmower.

103-2076

1-513747

1-523552

1-643339

98-4361

98-5954

103-0223

10

Safety

103-1636

103-5881

103-7218

107-2102

107-2112

11

Safety

109-2355

109-2356

1.Fast3.Neutral

2.Slow

4.Reverse

109-2357

1.Fast4.Reverse

2.Slow

5.ParkBrake—Release

3.Neutral6.ParkBrake—Engage

109-2358

109-2377

109-2396

12

Safety

109-2698

1.Cylinder—extend

3.Fast

2.Cylinder—retract4.Slow

109-3637

109-7949

19426-87881

19426-87903

109-2360

13

Specications

Specications

ModelNumbers

SerialNos:720,000andHigher

FR25KD

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•RPM:FullSpeed:3870+50/-100RPM(No

Load)Idle:1400±50RPM(NoLoad)

FuelSystem

•Capacity:8.5gal.(32L)

•TypeofFuel:Dieselfuel,40cetaneorhigher.

•FuelFilter:TwoIn-line15MicronKubotaP/N

12581-43012,beforeandaftertheelectricfuel

pump.

•Fuelgaugeattherearoftherighthandfueltank.

ElectricalSystem

•ChargingSystem:ExternalAlternator

•ChargingCapacity:60amps

•BatteryType:BCIGroup26

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuses:One15amp,one20amp,andone40amp

bladetype

SafetyInterlockSystem

•PTOmustbedisengaged,brakeengaged,and

motioncontrolleversout(neutrallock)tostart

engine.(Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.)

•OperatormustbeinseatwhenPTOisengaged,

brakeisdisengaged,ormotioncontrolleversare

movedinorenginewillstop.

•Enginewillstopifthemotioncontrollevers

aremovedfromneutralpositionwhilebrakeis

engaged.

CoolingSystem

•Fan:Beltdrivenwithcontinuousoperationwith

enginerunning.

•CoolantLiquid:50/50mixofDexCool©

extendedlifeantifreezeandwater.

•CoolantCapacity:4quarts

OperatorControls

•SteeringandMotionControl:

Note:Motioncontrolleversareadjustableto

threeheights.

–Separatelevers,oneachsideoftheconsole,

controlspeedanddirectionoftravelofthe

respectivedrivewheels.

–Steeringiscontrolledbyvaryingtheposition

oftheleversrelativetoeachother.

–Movingmotioncontrolleversoutward(in

slots)locksthedrivesysteminneutral.

•PTOEngagementSwitch:EngagesdrivetoPTO

(mowerdeck).

•ParkingBrakeLever:Engagesparkingbrakeby

pullingback.

Seat

•Type:Standardseatwithhighback,foampadded

(internalsuspension)andarmrestsandintegral

safetyswitch.

Optionalseataccessoriesforunitswithstandard

seats:

–Customridesuspensionsystemtoenhance

StandardSeat.

–Deluxesuspensionseatwithhighback,low

prolefoam-in-placecushion(dampened,

adjustablespringsuspension),armrests,and

integralsafetyswitch.

14

Specications

•Mounting:Hingedtotiltupforaccessto

hydraulicpumps,batteryandothercomponents.

Theseatisheldinthetiltedpositionwitha

linkage.Adjustableforeandaftseattrack.

•Armrests:Standardseat:foampaddedip-up

armrests.Optionalsuspensionseat:molded

adjustableip-uparmrests.

•SeatSafetySwitch:Internaltothebottomseat

cushion,nonserviceable.Timedelaymodule

incorporatedintotheSafetyInterlockSystem

eliminatesroughgroundcut-outs.

HydrostaticGroundDriveSystem

•HydrostaticPumps:TwoHydroGearPR16cc

variabledisplacementpistonpumps.

•HydraulicOilType:UseMobil115W-50

Syntheticmotoroil.

•HydraulicOilCapacity:5.2qt(4.9L)

•HydraulicFilter:Replaceablecartridgetype.

P/N103-2146:25microns,Nobypass

•Speeds:

0-10.5mph(16.9km/hr)forward

0-6.6mph(10.6km/hr)reverse

•Drivewheelreleasevalvesallowmachinetobe

movedwhenengineisnotrunning.

Tires&Wheels

Drive

Pneumatic

(Air-Filled)

(Standard)

Pneumatic

(Air-Filled)

(Optional)

Quantity

22

TreadAT101

TurfMate

Size24x12.00-1223x10.50-10

PlyRating

44

Pressure

9psi(62kPa)13psi(90kPa)

Caster

FrontCasterRearCaster

(DualTail

Wheel)

Semi-PneumaticSemi-Pneumatic

Quantity

22

Tread

SmoothSmooth

Size9x3.50-413x6.5-6

PlyRating

Pressure

CuttingDeck

(SoldSeparately)

•ModelNumbers:

–FR524

–FR604

–FR724

•CuttingWidth:

–52inch(132cm)

–60inch(152cm)

–72inch(183cm)

•Discharge:Side

•BladeSize:(3ea.)

–52inchDeck:18.00inches(45.7cm)

–60inchDeck:20.50inches(52.1cm)

–72inchDeck:24.50inches(62.2cm)

•BladeSpindles:Solidsteelspindleswith13/4

inch(4.45cm)I.D.bearings.

•DeckDrive:“B”-Sectionbeltfromjackshafton

decktobladespindles.

•Deck:Fulloatingdeckisattachedtoout-front

supportframe,removableforservice.Six

anti-scalprollersprovidemaximumturf

protection.Deckdesignallowsforbagging,

mulchingorsidedischarge.

•DeckDepth:

–52inchDeck:5.5inches(14.0cm)

–60inchDeck:5.5inches(14.0cm)

–72inchDeck:5.5inches(14.0cm)

•CuttingHeightAdjustment:Adjustsfrom11/2

inches(3.8cm)to5inches(12.7cm)innitely

variable.

15

Specications

•MulchingKit:Optional

•Bagger:Optional

Dimensions

OverallWidth:

52inch

Deck

60inch

Deck

72inch

Deck

Without

Deck

49.0inches

(124.5cm)

49.0inches

(124.5cm)

53.0inches

(135cm)

Deector

Up

53.3inches

(135.4cm)

61.4inches

(156cm)

73.4inches

(186cm)

Deector

Down

64.0inches

(163cm)

72.0inches

(183cm)

84.3inches

(214cm)

OverallLength:

Withoutdeckandoor

panfolded

82.3inches(209.0cm)

52inchDeck114.3inches(290.3cm)

60inchDeck114.3inches(290.3cm)

72inchDeck114.3inches(290.3cm)

OverallHeight:

RollBar-UpRollBar-Down

69.2inches(175.8cm)50.7inches(128.8cm)

TreadWidth:(CentertoCenterof

Tires,Widthwise)

52inchDeck60inchDeck72inchDeck

41.4inches

(105.2cm)

41.4inches

(105.2cm)

45.4inches

(115.3cm)

WheelBase:(CenterofCasterTireto

CenterofDriveTire)

51.2inches(130.0cm)

MinimumTurningRadius

55.25inches(140.3cm)

CurbWeight:

Withoutdeck1163lb(528kg)

52inchDeck

1555lb(705kg)

60inchDeck

1600lb(726kg)

72inchDeck

1660lb(753kg)

TorqueRequirements

BoltLocation

Torque

WheelLugNuts

90-95ft-lb(122-129N-m)

WheelMotorMounting

Bolts

72-77ft-lb(98-104N-m)

WheelHubLockNut210-250ft-lb

(285-339N-m)

RolloverProtectionSystem

(RollBar)MountingBolts

30-35ft-lb(41-47N-m)

ClutchRetainingBolt

(securedwiththreadlocker)

55-60ft-lb(75-81N-m)

16

Operation

ProductOverview

Figure4

1.FuelCap4.SeatBelt

2.RollBar

5.MotionControlLever

3.Controls

6.ParkingBrakeLever

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Controls

MotionControlLevers

Themotioncontrolleverslocatedoneachsideofthe

consolecontroltheforwardandreversemotionof

themachine.Theleverscontroltheowofhydraulic

oilfromthehydrostaticpumptothedrivewheel

motorforeachside.

Movingtheleversforwardorbackwardturnsthe

wheelonthesamesideforwardorinreverse.Wheel

speedisproportionaltotheamounttheleveris

moved.

Movingtheleversoutwardfromthecenterposition

intotheT-slotlocksthemintheneutralposition

(Figure6).

ThrottleControl

Locatedonrightfueltankconsole.

Thethrottleisusedtocontrolenginespeed.Moving

thethrottleleverforwardwillincreaseenginespeed

andmovingthethrottlelevertotherearwilldecrease

enginespeed.Movingthethrottleforwardintothe

detentisfullthrottle.

ParkBrakeLever

Locatedonleftsideofunit,betweentheseatandthe

dummytank.

Thebrakeleverengagesaparkingbrakeonthedrive

wheels.

Pulltheleverupandrearwardtoengagethebrake.

Pushtheleverforwardanddowntodisengagethe

brake.

Theunitmustbetieddownandbrakeengagedwhen

transporting.

IgnitionSwitch

Locatedonrightfueltankconsole.

Theignitionswitchisusedtostartandstopthe

engine.Theswitchhasthreepositions“OFF”,“ON”

17

Operation

and“START”.Insertkeyintoswitchandrotate

clockwisetothe“ON”position.Rotateclockwiseto

thenextpositiontoengagethestarter(keymustbe

heldagainstspringpressureinthisposition).

Note:Brakemustbeengaged,motioncontrollevers

out(neutrallockposition),andPTOswitch“OFF”

tostartengine.(Itisnotnecessaryfortheoperator

tobeintheseattostarttheengine.)

HourMeter

Locatedontherightfueltankconsole.

Thehourmeterrunswhenthealternatorischarging

anditrecordsthenumberofhoursthattheengine

hasrun.Iftheignitionswitchisleftonwithout

enginerunning,hourmeterwillnotrun.

Note:Thisswitchisnotalowoilsensorandwillnot

alerttheoperatoriftheengineoilislow.

FuelGauge

Locatedattherearoftherightfueltank.

Thefuelgaugemonitorstheamountoffuelinthe

rightfueltankonly.Thelefttankdoesnotholdfuel.

DriveWheelReleaseValves

Locatedonthetopleftfrontcornerofhydrostatic

pumps.

Drivewheelreleasevalvesareusedtoreleasethe

hydrostaticdrivesystemtoallowthemachinetobe

pushedwithouttheenginerunning.

Withawrench,turnbothvalvesoneturn

counterclockwisetoreleasedrivesystem.Turn

clockwisetoresetsystem.DoNotovertighten.Do

Nottowmachine.

Usea5/8inchwrenchtoturnthevalves.

PTOEngagementSwitch

Locatedontherightfueltank.

Switchmustbepulledouttothe“ROTATE”

positiontoengagetheblades.Switchispushedinto

the“STOP”positiontostoptheblades.

HydraulicLiftSwitch

Locatedontherightfueltankconsole.

Thehydraulicliftswitchisusedtoraiseandlower

themowerdeck.

Pushthefrontportionofthehydraulicliftswitch

downtoraisethemowerdecktothedesiredheight.

Pushtherearportionofthehydraulicliftswitch

downtolowerthemowerdecktothedesiredheight.

CoolantTemperatureGauge

Locatedontherightfueltankconsole.

Thecoolanttemperaturegaugemonitorsthe

temperatureoftheenginecoolant.Anengine

overheatingconditionisindicatedbytheredarea

onthegaugeandanalarmwillsound.Refertothe

WarningBuzzerintheTroubleshootingsection.

CoolantTemperatureLight

Locatedontherightfueltankconsole.

Thelightwillcomeoniftheengineisoverheating

andanalarmwillsound.RefertotheWarning

BuzzerintheTroubleshootingsection.

GlowPlugSwitchandLight

Locatedontherightfueltankconsole.

Depressandholdtheswitchtoheattheglowplugs.

Theglowpluglightcomesonwhentheglowplug

switchisdepressed.Theglowpluglightindicatesthe

glowplugsarepreheatingthecombustionchamber.

AlternatorChargingLight

Locatedtotherearofthekeyswitch.

Lightwillcomeonwhenthealternatorisnot

charging.

LowOilPressureLight

Locatedtotherearofthekeyswitchwiththe

alternatorlight.

Lightwillcomeonwhenengineoilpressureislow

orlost.

Note:Thisswitchisnotalowoillevelsensorand

willnotalerttheoperatoriftheengineoillevelislow.

WarningBuzzer

Locatedbehindtheseatundertheenginecoveron

therighthandsideoftheenginefanshroud.

18

Operation

Thebuzzerisawarningsignalthattheengine

isoverheatingortheoilpressureislow .Seethe

Troubleshootingsection.

Pre-Start

Fillfueltank.Forbestresultsuseonlyclean,fresh

dieselfuel,withacetaneratingof40higher

Note:DoNotusekeroseneorgasolineinstead

ofdieselfuel.Failuretoobservethiscautionwill

damagetheengine.

DoNotaddoiltofuel.

DoNotoverllfueltank.Neverllthefueltankso

thatthefuellevelrisesabovealevelthatis1/2inch

(13mm)belowthebottomofthellernecktoallow

forfuelexpansionandpreventfuelspillage.

Makesureyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

RefertotheMaintenancesectionandperformallthe

necessaryinspectionandmaintenancesteps.

OperatingInstructions

RaisetheRolloverProtectionSystem

(ROPS)

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.Removethehairpincotterpinsandremovethe

tworollbarpins(Figure5).

2.Raisetherollbartotheuprightpositionand

installthetwopinsandsecurethemwiththe

hairpincotterpins(Figure5).

Important:Alwaysusetheseatbeltwiththe

rollbarintheraisedposition.Ensurethatthe

rearpartoftheseatissecuredwiththeseat

latch.

Figure5

1.Rollbar3.Pin

2.Raisedposition4.Hairpincotterpin

StartingtheEngine

1.Movethemotioncontrolleversouttotheneutral

lockposition.

2.Pullupandbackontheparkingbrakeleverto

engagetheparkingbrake.

3.PushinonthePTOswitchtothe“STOP”

position.

Note:Itisnotnecessaryfortheoperatortobe

intheseattostarttheengine.

4.Onawarmengine,placethethrottleinthe

“SLOW”position.

5.Onacoldengine,(below14°F(-10°C)),placethe

throttleinthe“MIDWAY”position.

Note:DoNotusefuelleftoverfromsummer.

6.Turnignitionswitchtothe“ON”position.

Depresstheglowplugswitchandtheglowplug

lightwillturnon.Holdswitchasrequiredby

chartbelow.Turntheignitionswitchtothe

“START”position.Releasetheignitionswitchas

soonastheenginestarts.

19

Operation

GlowPlugChart

AmbientTemperature

HoldGlowPlugsOn

Above50°F(10°C)

NONEED

50°F(10°C)to23°F(-5°C)

Approximately5seconds

Below23°F(-5°C)

Approximately10seconds

Limitofcontinuoususe

20seconds

Theglowpluglight,locatedneartheglow

plugswitch,willilluminatewhentheswitchis

depressed.Theglowpluglightindicatestheglow

plugsarepreheatingthecombustionchamber.

Important:DoNotcranktheengine

continuouslyformorethentensecondsata

time.Iftheenginedoesnotstart,allowa30

secondcool-downperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotorand/orfuel

solenoid.

7.Movethethrottletothe“SLOW”(ifin

“MIDWAY”)andlettheenginewarmupafew

minutesbeforemovingthethrottletothe“FAST”

position.

EngagingthePTO

DANGER

Therotatingbladesunderthemowerdeck

aredangerous.Bladecontactcancause

seriousinjuryorkillyou.

DoNotputhandsorfeetunderthemower

ormowerdeckwhenthebladesareengaged.

DANGER

Anuncovereddischargeopeningwillallow

objectstobethrowninanoperator’sor

bystander’sdirection.Also,contactwiththe

bladecouldoccur.Thrownobjectsorblade

contactcancauseseriousinjuryordeath.

Neveroperatethemowerwiththedischarge

deectorraised,removed,oralteredunless

thereisagrasscollectionsystemormulch

kitinplaceandworkingproperly.

ThePTOpush-pullswitchengagesthecuttingblades.

Besurethatallpersonsareclearofthemowerdeck

anddischargeareabeforeengagingPTO.

Important:Operatormustbeinseatbeforethe

PTOcanbeengaged.

1.Setthethrottletothe“MIDWAY”position.

2.PullthePTOswitchoutwardtothe“ROTATE”

position.

3.Placethethrottleinthe“FAST”positiontobegin

mowing.

DisengagingthePTO

1.Setthethrottletothe“MIDWAY”position.

2.PushthePTOswitchintothe“STOP”position

todisengagetheblades.

StoppingtheEngine

1.Bringtheunittoafullstop.

2.DisengagethePTO.

3.Movethemotioncontrolleversouttotheneutral

lockposition.

4.Engagetheparkingbrake.

5.Placethethrottlemidwaybetweenthe“SLOW”

and“FAST”positions.

6.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtothe

“OFF”positiontostoptheengine.

7.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioning

onelevertoomuchaheadoftheother.

Operatormaylosecontrolofthemachine,

whichmaycausedamagetothemachine

orinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Important:Tobeginmovement(forwardor

backward)theoperatormustbeintheseat,the

brakelevermustbedisengaged(pusheddown)

20

/