Page is loading ...

SERIES FS FLOWMETER with FLOW LIMIT SWITCH

Specifications - Installation and Operating Instructions

Bulletin F-41-FS

T

he Series FS Flowmeter with Flow Limit Switch combines the proven

t

echnology of direct reading, piston type, variable area flowmeter with a

hermetically sealed, solid state switching module. This combination aids the

machine designer/troubleshooter by providing instantaneous flow rate indication

coupled with an electronic signal module to automatically alert the operator if any

incorrect flow rate is detected.

MECHANICAL INSTALLATION

CAUTION: Do not over tighten the threads on the plastic body. Overtightening the

NPT threads may cause fracturing of the plastic flowmeter body. The flowmeter is

constructed of polysulfone and remains stable to 210˚F (99˚C). Do not expose the

flowmeter to open flames or excessive heat. The meter may melt, crack, or distort.

Some pipe dope formulas will react adversely with polysulfone. Use pipe thread

sealant tape if a sealing material is necessary.

The Series FS Flowmeter can be mounted in any plane of orientation. Horizontal

or vertical mounting does not effect flowmeter accuracy. The inlet and outlet of the

flowmeter should be aligned, particularly when high temperature, high pressure, or

combination of both may be encountered. Install the flowmeter in the direction of

the indicating arrow on the scale. The Series FS FLowmeter does not require

lengths of straight pipe at the inlet, or outlet, to stabilize flow through the meter.

These meters can tolerate particles that normally will jam other flow controls. If

large amounts of particulates are encountered, a 200 mesh or 74 micron filter is

recommended.

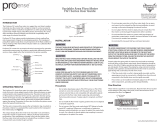

A separate four conductor female connector is supplied with the limit switch

assembly. The connector must be disassembled to solder wires onto it. See Figure

1. The connector has four solder lugs labeled; 1,2,3, and 4. Terminals 3 and 4 are

not used. It should be noted before reassembly, which wire is connected to which

solder plug. Color coding or labeling the wires is advised. Secure wire to solder

lugs and determine the orientation of the connector body. See Figure 2. After

choosing orientation A, B, or C, snap the connector back together, pull excess

wires out of strain relief, and tighten strain nut. Plug into electric housing and

secure with screw.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

S

PECIFICATIONS

S

ervice: Compatible liquids.

Wetted Materials: Polysulfone body, Barium Ferrite, Stainless Steel spring and

retaining rings.

Temperature Limits: 158°F (70°C).

Pressure Limits: 325 psi (22.4 bar).

Accuracy: ±5% full scale.

Repeatability: 1.0%.

Set Point: Adjustable 0 to 100% FS.

Relay Load: 1 A @ 30 VDC; 0.5 A @ 125 VAC (resistive).

Supply Voltage: 115 VAC, ±10%.

Current Consumption: 25 mA max.

Process Connections: 1˝ male NPT Polysulfone or 3/4˝ male NPT brass.

Flow Scale: Calibrated at 1.0 specific gravity @ 70°F (21°C).

Weight:

1˝ male NPT Polysulfone; 0.55 lb (0.25 kg); 3/4˝ male NPT brass: 0.90 lb

(0.41 kg)

.

Agency Approvals: CE.

2

2

4

4

6

6

8

8

1010

55

1010

1515

2020

2525

3030

3535

GPMGPM

LPMLPM

FLOW DIRECTIONFLOW DIRECTION

PAT NO 4389901PAT NO 4389901

1.0 SP. GR.1.0 SP. GR.

DWYER INSTRUMENTS, INC. MICHIGAN CITY IN.DWYER INSTRUMENTS, INC. MICHIGAN CITY IN.

FSXXXXXFSXXXXX

3/4 NPT Brass Inlet

1-1/2 Hex

B

oth Ends

Ø

1-5/16

[33.65]

3

/4 NPT Brass Outlet

1

-3/8

[

35.0]

5

-1/4

[133.35] Polysulfone Body

8-1/4

[209.55]

1-47/64

[43.94]

1-7/8

[47.63]

SERIES FS

F

LOW (GPM)

15.0

12.5

1

0.0

7.5

5.0

2.5

0

.0

0

.0

2

.5

5.0

7

.5 10.0

12.5

1

5.0

17.5

2

0.0

22.5 25.0

27.5

PRESSURE DIFFERENTIAL (PSID)

4 GPM

7 GPM

1

6

G

P

M

2

8

G

P

M

BODY

STRAIN RELIEF NUT

SOLDER LUG

POLARITY PIN

2

1

FIGURE 1

E

LECTRICAL INSTALLATION

The module can only switch loads that consume between 2.5 and 90 watts, or have

5000 Ω to 150 Ω impedence respectively. If the load draws less than 2.5 watts, a

0.47 uF loading capacitor is required. This capacitor will increase the power

consumption and ensure complete conduction over 15-20% of full scale, above or

b

elow the flow rate setpoint. For loads greater than 90 watts, see Figure 4 and 5.

Figure 4 demonstrates a SPDT relay with a 115 VAC coil integrated with the limit

switch module. This combination allows switching of loads up to the rating on the

relay contacts.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 9/14 FR# RV-440909-00 Rev. 2

T

he flow switch can be integrated with latching type relays. See Figure 5. The

m

odule will turn the relay “on” as flow exceeds or falls below the flow rate setpoint.

The relay will remain activated until the reset button is depressed.

OPERATION

The limit switch module is designed to turn on or off a variety of different 115 VAC

loads such as solenoid valves, warning lights, and AC relay coils. 1) Loosen the

cap screw on the flow limit switch. 2) Adjust the assembly so the retaining band

centers approximately at the desired flow alert position. 3) Retighten cap screw

securely.

MAINTENANCE

Periodic check of connections is recommended. The Series FS is not field

serviceable and should be returned if repair is needed (field repair should not be

attempted and may void warranty). Be sure to include a brief description of the

problem plus any relevant application notes. Contact customer service to receive

a return goods authorization number before shipping.

INLET OF FLOWMETER

ELECTRONIC HOUSING

POLARITY PIN

C

B

A

F

IGURE 2

L

OAD

2

1

FLOW

MODULE

100.0

0,1

>200V

.47

µ

F

µF

F

OR USE WITH INDUCTIVE LOADS

C

AP MUST BE RATED >200V

ac LINE

ac LINE

FIGURE 3

DPT

RELAY

COIL

2

1

R

1

FLOW

MODULE

R

1

RELAY CONTACT

LOAD

ac LINE

ac LINE

FIGURE 4

DPDT

RELAY

COIL

2

1

FLOW

MODULE

NC RESET

BUTTON

L

OAD

RELAY CONTACT

R1

R

1

R

ELAY CONTACT

R1

ac LINE

ac LINE

FIGURE 5

/