• Do not removeor altergroundingpronginany manner.

Inthe eventofa malfunction or breakdown, grounding

providesa pathof leastresistanceforelectricalshock.

WARNING: Do not permitfingers to touchthe termi-

nals of plug when insertingor removingfrom outlet.

• Plug must be plugged into matchingoutlet that is

properly installedand groundedin accordance with

all localcodes and ordinances.Do not modifyplug

provided.If it will not fit in outlet, have proper outlet

installed bya qualified electrician.

• Inspect tool cordsperiodically,and if damaged, have

repaired byan authorized service facility.

• Green (or green and yellow)conductorin cord isthe

groundingwire. If repair or replacement of the elec-

tric cord or plug is necessary,do not connect the

green (or green and yellow)wire to a live terminal.

• A 2-prong wall receptacle mustbe replaced with a

properly grounded3-prong receptacle installedin

accordance with National Electric Code and local

codes and ordinances.

WARNING: Any receptacle replacement shouldbe

performed by a qualified electrician.

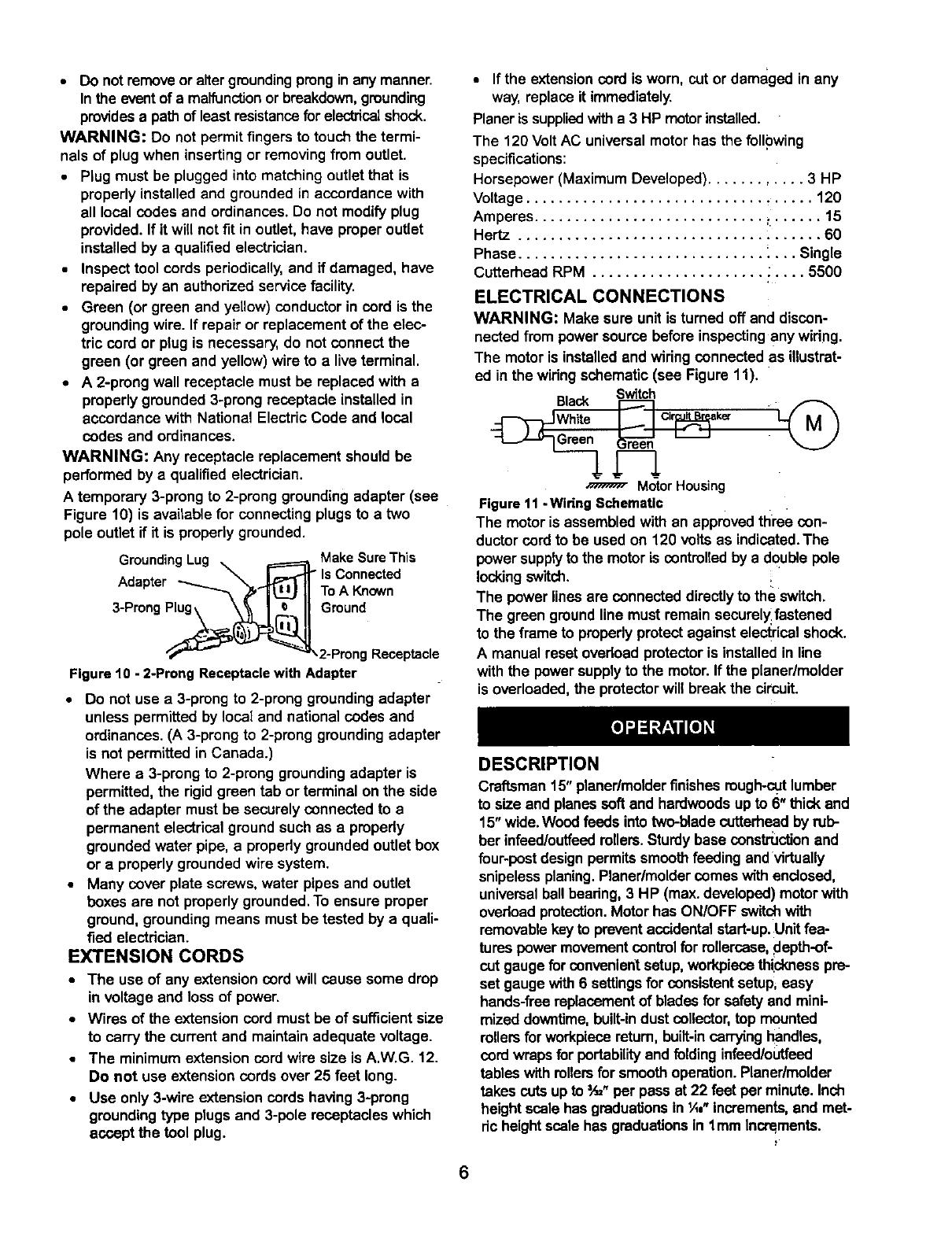

A temporary 3-prong to 2-pronggroundingadapter (see

Figure 10) is available for connecting plugs to a two

pole outlet if it isproperly grounded.

GroundingLug _ r==_MakoeSUrc_e'rhis

Adapter IIToAKnown

3-ProngP__.. Ground

"_"--'- _"_2-Prong Receptacle

Figure10 - 2-ProngReceptaclewith Adapter

• Do not use a 3-prong to 2-prong groundingadapter

unless permitted by local and nationalcodes and

ordinances.(A 3-prong to 2-prong groundingadapter

is not permittedin Canada.)

Where a 3-prongto 2-preng groundingadapter is

permitted, the rigidgreen tab or terminal on the side

of the adapter mustbe securely connected to a

permanent electricalground such as a propedy

groundedwater pipe, a propedy groundedoutletbox

or a properlygroundedwire system.

• Many cover plate screws, water pipes and outlet

boxes are not properlygrounded.To ensure proper

ground, groundingmeans mustbe tested bya quali-

fied electrician.

EXTENSION CORDS

• The use of any extensioncord will cause some drop

in voltage and lossof power.

• Wires of the extension cord mustbe of sufficientsize

to carry the currentand maintainadequate voltage.

• The minimumextension cord wire size isA.W.G. 12.

Do not use extension cords over 25 feet long.

• Use only 3-wire extensioncords having3-prong

groundingtype plugs and 3-pole receptacles which

accept the tool plug.

• If the extensioncord isworn, cutor damaged in any

way, replaceit immediately.

Planeris suppliedwith a 3 HP motor installed.

The 120 Volt AC universalmotorhas the following

specifications:

Horsepower (Maximum Developed)............ 3 HP

Voltage................................... 120

Amperes............................ _...... 15

Hertz ..................................... 60

Phase.............................. _... Single

Cutterhead RPM ..................... : .... 5500

ELECTRICAL CONNECTIONS

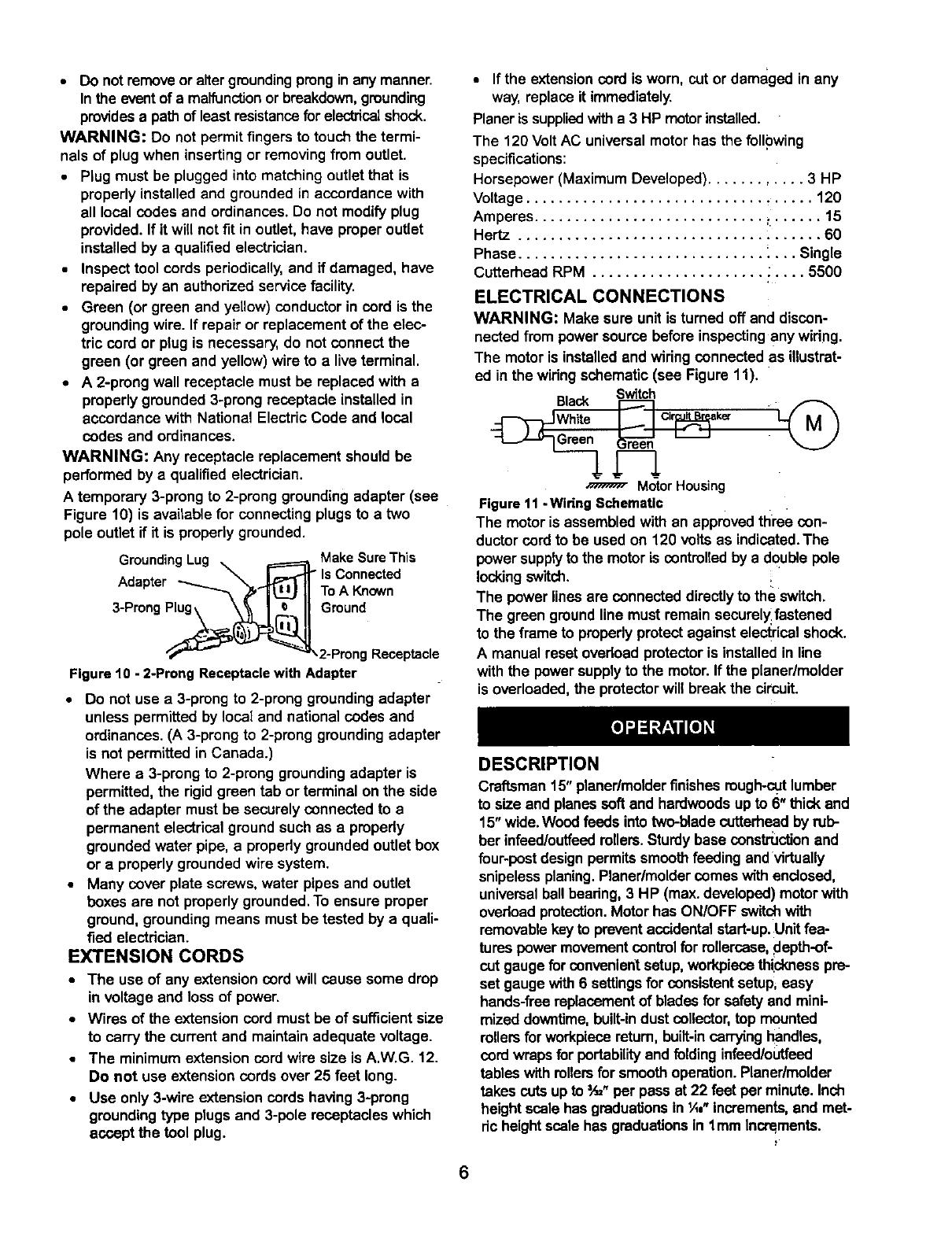

WARNING: Make sure unitisturned off and discon-

nected from powersource beforeinspectinganywidng.

The motorisinstalledand wiringconnected as illustrat-

ed in thewiringschematic (see Figure 11).

Switch

Cir k_"

MotorHousing

Figure11- WiringSchematic

The motoris assembledwith an approvedthree con-

ductorcordto be used on 120 volts as indicated.The

power supplytothe motoris controlledby a double pole

locking switch. !.

The power linesare connecteddirectlyto the switch.

The green groundlinemust remainsecurel_fastened

to the frame to propedyprotectagainst electricalshock.

A manual resetovedoad protectoris installedin line

with the powersupplytothe motor.If the planer/molder

isoverloaded,the protectorwill break the circuit.

DESCRIPTION

Craftsman15" planer/molderfinishesrough-cutlumber

to size and planessoftand hardwoodsup to 6" thickand

15"wide.Woodfeeds intotwo-blade cutterheadbyrub-

ber infead/outfeedrollers.Sturdybase censtmcUon and

four-post designpermitssmoothfeeding andvirtually

snipelessplaning.Planer/moldercomeswithenclosed,

universalballbeadng,3 HP (max.developed)motorwith

ovedoad protection.Motorhas ON/OFF switchwith

removablekeyto preventaccidentalstart-up.Unitfea-

tures power movementcontrolfor rollercase,depth-of-

cut gaugefor convenient setup,workpiecethid(ness pre-

set gaugewith6 settingsfor consistentsetup,easy

hands-flea replacementof bladesfor safetyand mini-

mizeddowntime,built-indust collector, top mounted

rollersfor workpiecareturn, built-incarryinghandles,

cordwraps forportability and folding infeed/outfeed

tables with rollersfor smoothoperation.Planer/molder

takes cutsupto =A_"per pass at 22 feet per minute.Inch

heightscale hasgraduationsin 'A,"increments,and met-

dcheightscalehas graduationsin lmm Incrslments.

6