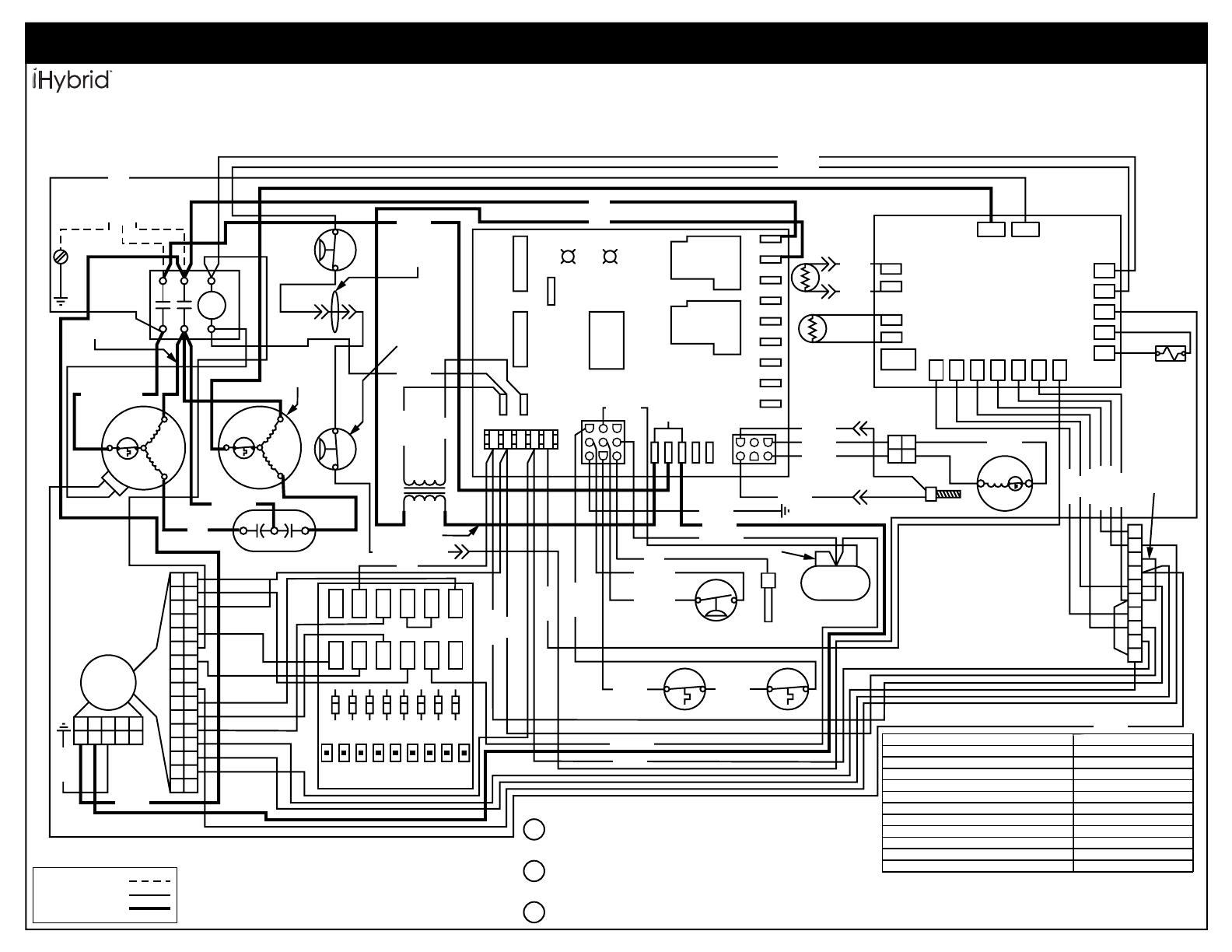

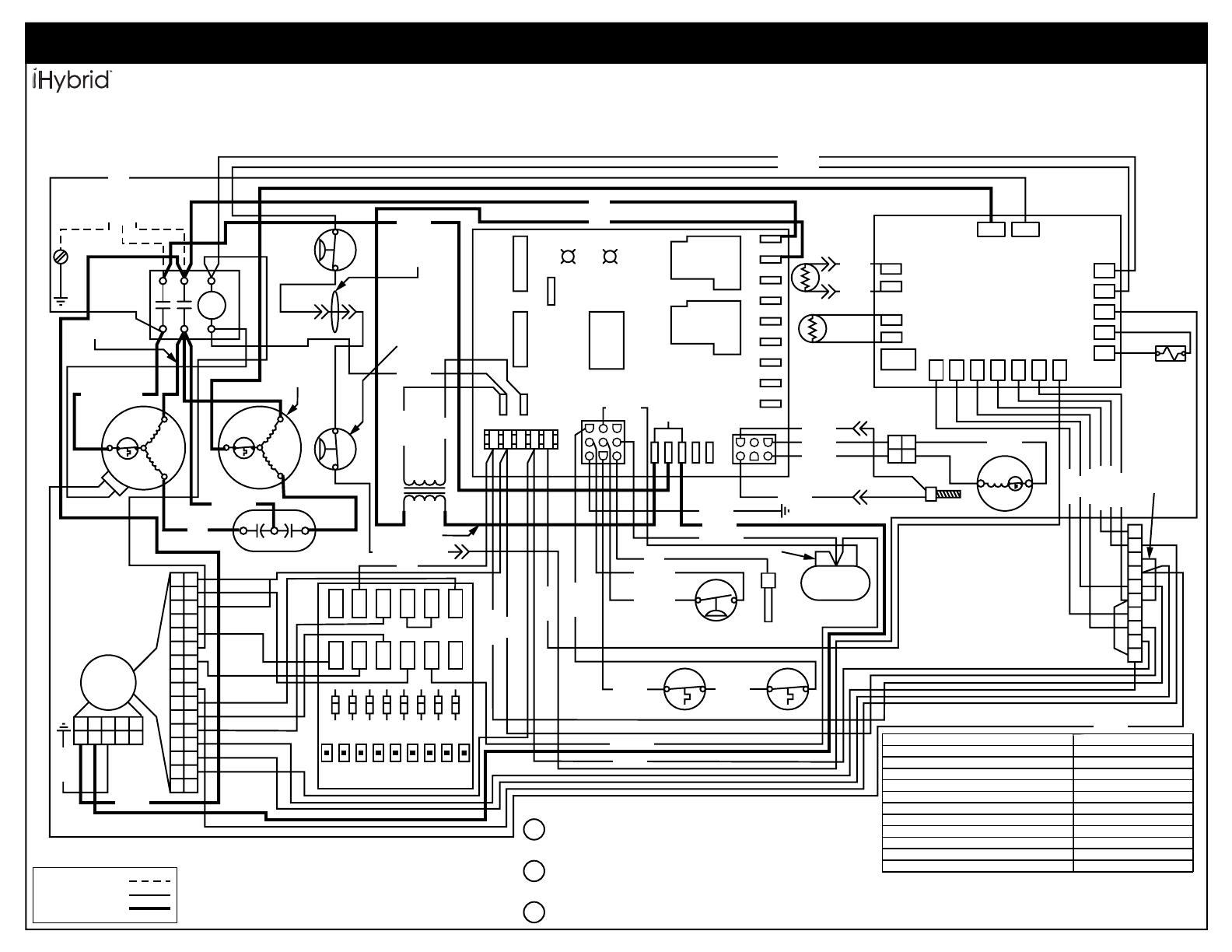

FLAME

TWIN

STATUS

L1

XFMR

EAC

COOL

HEAT

M3

M2

M1

HUM

NEUTRALS

EAC

COM

3 AMP FUSE

BLOWER OFF

24V

HUM

1

2

3

4

5

6

7

8

9

4

5

6

1

2

3

240V 208V

24V

COM

11

22

RC

HI LO

PRIMARY

GAS VALVE

C

54321

54321

VARIABLE

SPEED

BLOWER

MOTOR

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

RC YGW

R

S

C

R

S

C

CHF

TO 208/230 VAC

POWER SUPPLY

FLAME ROLL-OUT SWITCH LIMIT SWITCH

FLAME

SENSOR

PRESSURE

SWITCH

INDUCER MOTOR

IGNITOR

GROUND

HIGH

PRESSURE

SWITCH

DUAL CAPACITOR

CONTACTOR

COMPRESSOR

OUTDOOR

FAN MOTOR

LOW

PRESSURE

SWITCH

L1

L2

T1

T2

AMBIENT

SENSOR

COIL

SENSOR

TEST

LRCYO

W2

IN

W2

OUT

COND FAN

AMBIENT

AMBG

COILG

COIL

DEMAND

DEFROST CONTROL

BOARD

M

PRESS

SW

REV

VALVE

REV. VALVE

SOLENOID

G

C

L

W1

R

Y2

E

O

Y1

TERM.

STRIP

13

R

12

HUM

HUM

10

5

7

11

2

W

4

123456789

D1 D2 D3 D4 D5 D6 D7 D8

VARIABLE SPEED BOARD

YELLOW/BLACK

TRANSFORMER

ORANGE

ORANGE

ORANGE

BLACK

BROWN

BROWN

BROWN

BLACK

BLACK

BLUE

BLUE

BLUE

YELLOW

YELLOW

YELLOW

YELLOW

GRAY

GREEN

WHITE

RED

W2

YELLOW/BLACK

BLUE

BLACK

BLACK

208/230 Volt

Single Phase / 60 Hz.metsySdegakcaPgnilooCdnagnitaeHleuFlauD

WIRING DIAGRAM

NOTES:

1. Disconnect power before servicing.

2. For supply connections use copper conductors only.

3. Not suitable on systems that exceed 150V to ground.

4. If any of the original wire as supplied with the furnace must be replaced,

it must be replaced with wiring material having a temp. rating of at least 105˚C.

5. For supply wire ampacities and overcurrent protection, see unit rating plate.

6. Ensure that wires from the blower remain connected to the board

thermostat terminals after making the field thermostat connections.

710814

0408

FIELD WIRING

LEGEND:

LOW VOLTAGE

HIGH VOLTAGE

NOTES:

1. Couper le courant avant de faire letretien.

2. Employez uniquement des conducteurs en cuivre.

3. Ne convient pas aux installations de plus de 150 V

a la terre.

DEFROST BOARD OPERATION:

Heat Pump operates in heating mode until the combination of outdoor ambient

and outdoor coil temperatures initiate a defrost cycle. The outdoor coil

temperature must be at or below 32˚F before the defrost cycle begins.

There must be a minimum of 20 minutes between defrost cycles. After this

time, temperature conditions must call for defrost continuously for 4 1/2

minutes before a defrost cycle is initiated.

The defrost cycle ends when the outdoor temperature reaches 32˚F or the

defrost terminate time of 13 minutes 39 seconds is reached.

1

2

3

)DER(THG

I

LSUTATSNOITID

N

OC

T

LUAF

Pressure Switch Stuck Open with Inducer On 2 Flashes

Pressure Switch Stuck Open with Inducer Off 3 Flashes

Ignition Failure (Check Ground) 4 Flashes

230 VAC & Neutral Reversed or No Ground 5 Flashes

False Flame or Gas Relay Shorted Continuous Flash

)WOL

L

EY(THGILSUTATSNO

I

T

IDN

O

C

T

L

UAF

Low Flame Sensor Signal Continuous Flash

YELLOW

BLACK

RED

RED

RED

RED

RED

RED

RED

RED

RED

RED

WHITE

WHITE

WHITE

WHITE

WHITE

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

WHITE

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLUE

BLUE

BLUE

YELLOW/BLACK

BLACK/WHITE

ORANGE

ORANGE

GREEN

GREEN

GREEN

BLUE

BROWN

BROWN

BROWN

BROWN

BROWN

ORANGE

BROWN

BLACK

BLACK

7. Wiring shown for single stage operation. For two stage operation, move brown wire from

low side of the gas valve to W2 on the terminal block and remove jumper from W1 to W2.

See installation instructions for an alternate

means of controlling second stage.

8. A heat pump thermostat with fossil fuel back-up heat capability is REQUIRED for this system.

¢710814©¤

(Replaces 710668A