bt07d109

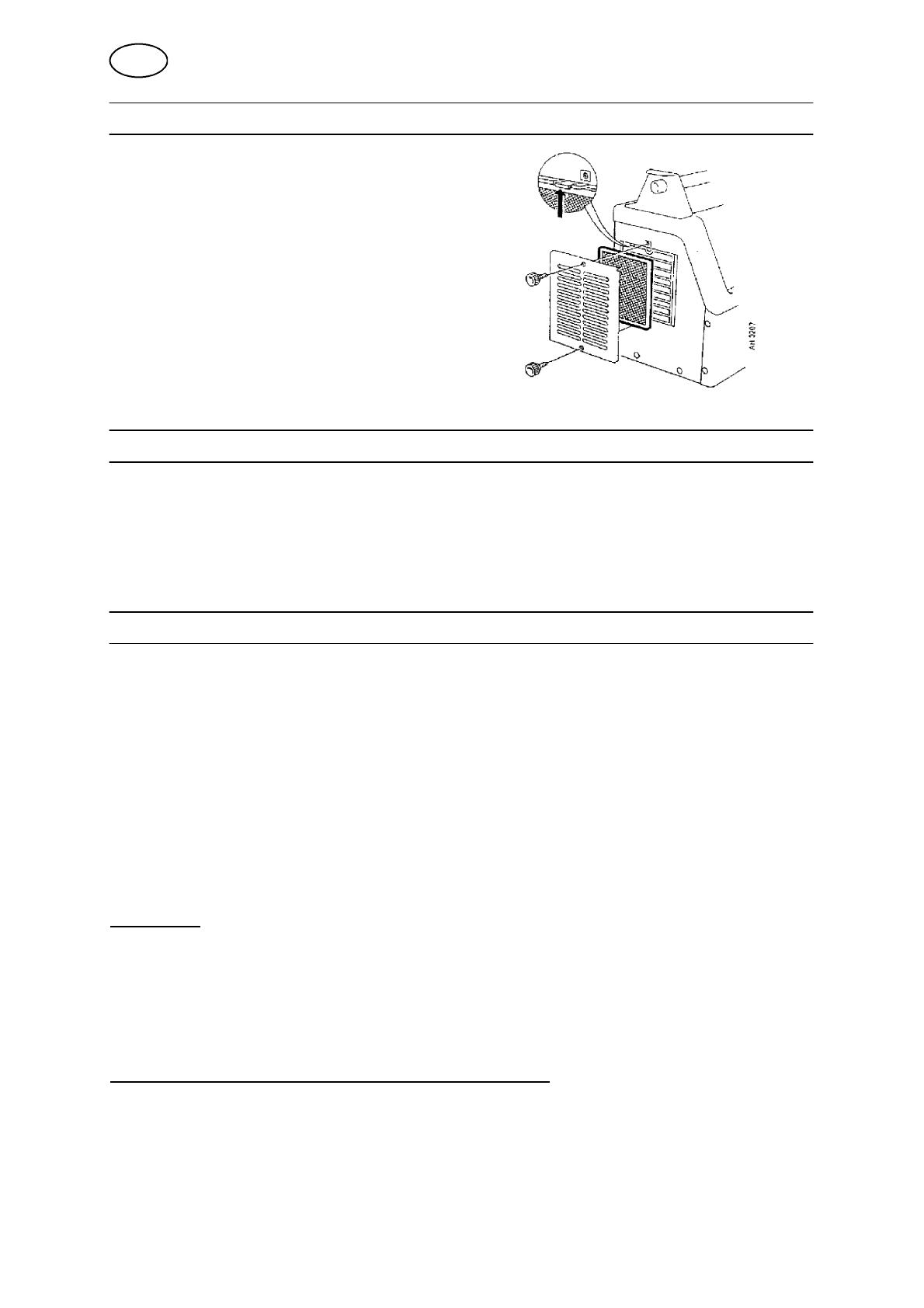

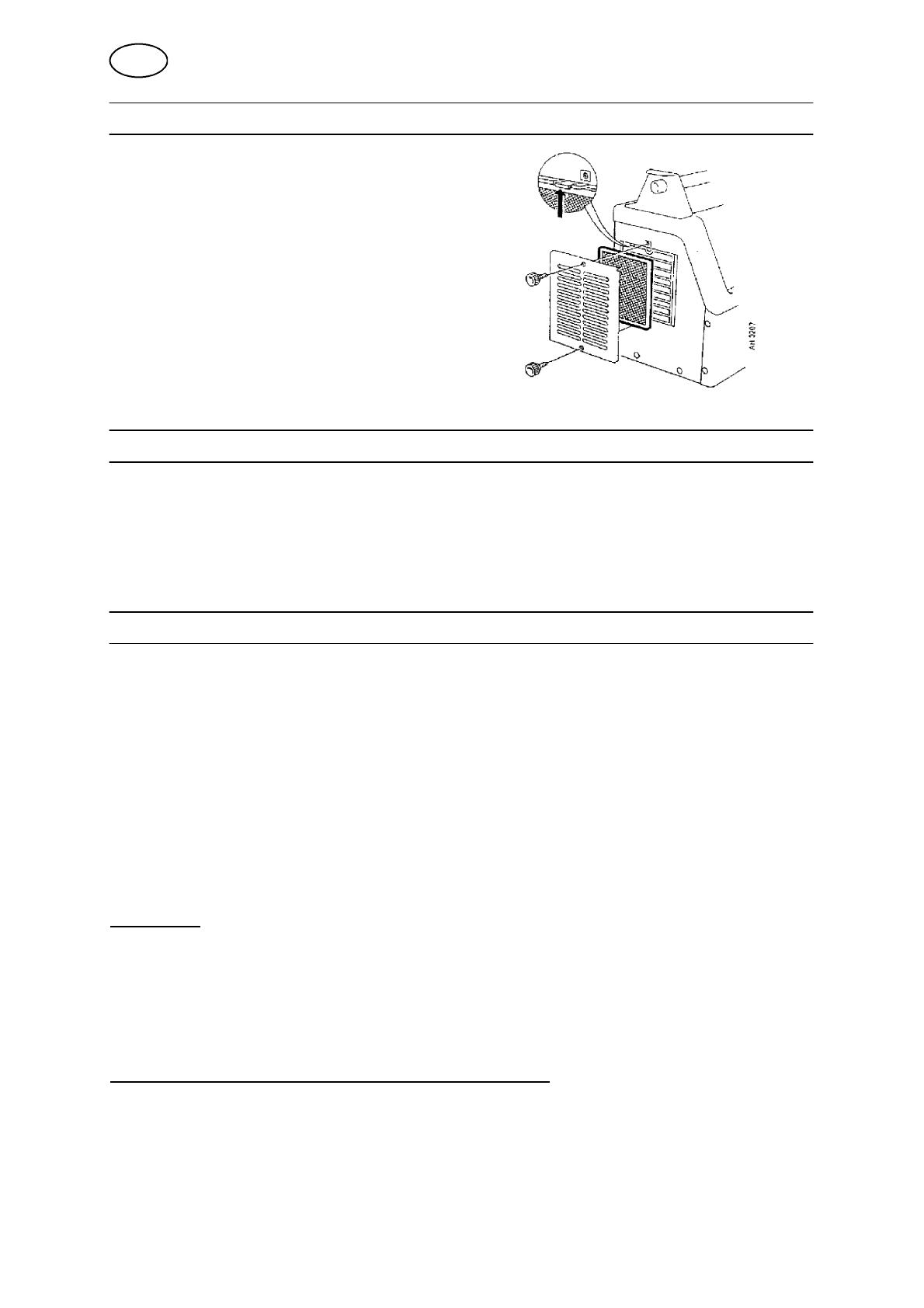

Dismantling the filter

-- 4 6 --

bt16d12e

6 MAINTENANCE

Generally, LTR 160/200 do not

require any maintenance. Normally,

it is sufficient to blow out the

machine using clean, compressed

air annually, and the dust filter

should be cleaned regularly.

If the machine is set up in dusty or

dirty environments the machine and

dust filter should be cleaned more

often. .

7 ORDERING OF SPARE PARTS

A service manual and list of spare parts can be ordered from your nearest ESAB

representative, see the last page of this publication.

When ordering parts please state the machine model, serial number, and the name

and spare part number as shown in the list of spare parts.

This will simplify dispatch and ensure you get the right parts.

8 ACCESSORIES

Order number

Carriage for 5 l gas cylinder 0468 530 880.......................

Carriage for 10--50 l gas cylinder 0456 804 880..................

Protective guard for connections 0468 311 001...................

Handle loop 0468 305 880....................................

Return cable, 25 mm

2

(state the length when ordering) 02626 136 01....... ..........

Return cable clamp 0367 558 880..............................

Foot pedal F S002, incl. cable 0349 090 886.....................

Welding cable, 5 meter 0468 539 880...........................

Return cable, 5 meter 0468 539 881............................

Cooling unit OCF 2L ( to LTR 200) 0457 216 880..................

TIG torch:

HW17R, 4 meter with central connector 0588 000 724.........

HW17R, 4 meter with OKC connector 0588 000 722...........

Information on additional TIG torches and remote control units can be found in

separate brochures.

The following remote controls can be connected:

PHA1,PHA2,PHA5,PHB1,PHB2,PHC2 och F S002.

GB