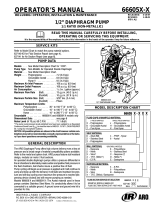

Ingersoll-Rand ARO 66605J- Series

The Ingersoll-Rand ARO 66605J- Series is a non-metallic air operated double diaphragm pump with a 1:1 ratio. It is made of polypropylene and has a maximum air inlet pressure of 100 psig (6.9 bar), a maximum material inlet pressure of 10 psig (0.69 bar), and a maximum outlet pressure of 100 psig (6.9 bar). It has a maximum flow rate of 13 gpm (49.2 lpm) and can handle solids up to 3/32” dia. (2.4 mm). The pump is self-priming and can run dry without damage. It is also stall resistant and can handle a wide range of viscosities.

Ingersoll-Rand ARO 66605J- Series

The Ingersoll-Rand ARO 66605J- Series is a non-metallic air operated double diaphragm pump with a 1:1 ratio. It is made of polypropylene and has a maximum air inlet pressure of 100 psig (6.9 bar), a maximum material inlet pressure of 10 psig (0.69 bar), and a maximum outlet pressure of 100 psig (6.9 bar). It has a maximum flow rate of 13 gpm (49.2 lpm) and can handle solids up to 3/32” dia. (2.4 mm). The pump is self-priming and can run dry without damage. It is also stall resistant and can handle a wide range of viscosities.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

Ingersoll-Rand ARO 66605J- Series User manual

- Type

- User manual

- This manual is also suitable for

Ingersoll-Rand ARO 66605J- Series

The Ingersoll-Rand ARO 66605J- Series is a non-metallic air operated double diaphragm pump with a 1:1 ratio. It is made of polypropylene and has a maximum air inlet pressure of 100 psig (6.9 bar), a maximum material inlet pressure of 10 psig (0.69 bar), and a maximum outlet pressure of 100 psig (6.9 bar). It has a maximum flow rate of 13 gpm (49.2 lpm) and can handle solids up to 3/32” dia. (2.4 mm). The pump is self-priming and can run dry without damage. It is also stall resistant and can handle a wide range of viscosities.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

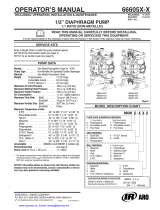

Ingersoll-Rand 66605X-X User manual

-

Ingersoll-Rand ARO 670144-A User manual

-

Ingersoll-Rand 666023 User manual

-

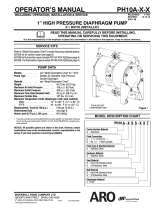

ARO PH10A-X-X User manual

ARO PH10A-X-X User manual

-

Ingersoll-Rand AD25A-X-X User manual

-

Ingersoll-Rand Outboard Motor AF1260-XX User manual

-

Ingersoll-Rand Outboard Motor AF0860-XX User manual

-

Ingersoll-Rand AF1060-XX User manual

-

Ingersoll-Rand PD05P Series User manual

-

Ingersoll-Rand Outboard Motor AF046X-XX User manual

Other documents

-

Ingersoll Rand 666056-622 Owner's manual

-

Dometic M Series Pump Duckbill Valve Installation guide

-

Graco DR2 User manual

-

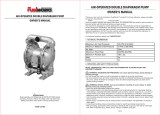

Fuelworks Please see replacement item# 41769. Air Operated Double Diaphragm Pump Owner's manual

Fuelworks Please see replacement item# 41769. Air Operated Double Diaphragm Pump Owner's manual

-

ARO 66605J Series User manual

ARO 66605J Series User manual

-

ARO 66605 series User manual

ARO 66605 series User manual

-

Graco 3A1973B User manual

-

Graymills Diaphragm One Half Inch Kit Split Manifold Owner's manual

-

Graco 3A2714B User manual

-

Graco 308652Y User manual