Powr-Flite PFX5. PFX10, PFX15 Owner's manual

- Category

- Scrubber

- Type

- Owner's manual

Powr-Flite PFX5. PFX10, PFX15 are commercial carpet extractors designed for heavy-duty cleaning in various commercial settings. These machines offer a range of capabilities to effectively remove dirt, stains, and allergens from carpets, leaving them refreshed and revitalized.

With their powerful vacuum motors, these extractors deliver exceptional suction power to extract deeply embedded dirt and debris from carpet fibers. The adjustable spray pressure allows for customized cleaning, ensuring optimal results on different carpet types. The large solution and recovery tanks enable extended cleaning sessions without frequent interruptions for emptying or refilling.

Powr-Flite PFX5. PFX10, PFX15 are commercial carpet extractors designed for heavy-duty cleaning in various commercial settings. These machines offer a range of capabilities to effectively remove dirt, stains, and allergens from carpets, leaving them refreshed and revitalized.

With their powerful vacuum motors, these extractors deliver exceptional suction power to extract deeply embedded dirt and debris from carpet fibers. The adjustable spray pressure allows for customized cleaning, ensuring optimal results on different carpet types. The large solution and recovery tanks enable extended cleaning sessions without frequent interruptions for emptying or refilling.

-

1

1

-

2

2

-

3

3

-

4

4

Powr-Flite PFX5. PFX10, PFX15 Owner's manual

- Category

- Scrubber

- Type

- Owner's manual

Powr-Flite PFX5. PFX10, PFX15 are commercial carpet extractors designed for heavy-duty cleaning in various commercial settings. These machines offer a range of capabilities to effectively remove dirt, stains, and allergens from carpets, leaving them refreshed and revitalized.

With their powerful vacuum motors, these extractors deliver exceptional suction power to extract deeply embedded dirt and debris from carpet fibers. The adjustable spray pressure allows for customized cleaning, ensuring optimal results on different carpet types. The large solution and recovery tanks enable extended cleaning sessions without frequent interruptions for emptying or refilling.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Powr-Flite PFX1380E Owner's manual

-

Powr-Flite PFX1350 Owner's manual

-

Powr-Flite PFX1385MAX Owner's manual

-

Powr-Flite PFX1380E Owner's manual

-

Powr-Flite PFX1080E User manual

-

Powr-Flite PFX1085MAX Owner's manual

-

Powr-Flite PFX1080E Owner's manual

-

Powr-Flite PFX900S Owner's manual

-

Powr-Flite PFX3S User guide

-

Powr-Flite 98150-PF 4 Gallon Owner's manual

Other documents

-

MasterCraft MX-1408 Owner's manual

-

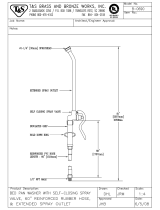

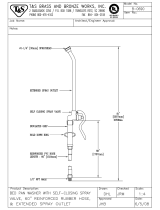

T & S Brass & Bronze Works B-0690 Datasheet

T & S Brass & Bronze Works B-0690 Datasheet

-

Windsor CMPS2 User manual

-

Sanitaire SC6085 Owner's manual

-

Resolve 19200-89973 User manual

Resolve 19200-89973 User manual

-

Windsor BRC 46/76 W Owner's manual

-

Windsor Clipper DUO Owner's manual

-

eMachines E 600 Owner's manual

-

Prochem Comanche CM2EC 10075300 Operating instructions

-

Dustbane Power Clean 1000 XT Operations Manual