S.R.LS.R.L CALENDASCO - PIACENZA - ITALYCALENDASCO - PIACENZA - ITALY

MOD./TYPEMOD./TYPE N.N.

DATA/DATEDATA/DATE PEPE

PESO TOTALE VUOTOPESO TOTALE VUOTO

TOTAL WEIGHT EMPTYTOTAL WEIGHT EMPTY

PESO TOTALE PIENOPESO TOTALE PIENO

TOTAL WEIGHT FULLTOTAL WEIGHT FULL

LENGHTLENGHT

LUNG.LUNG.KgKg

KgKg

ST 5ST 5

7

6

47

6

4

18/10/200118/10/2001

100100

340340

HOSEREEL IRRIGATORS

St 4-5-6-7

USER INSTRUCTION BOOK

for

EAM - Rev: 010 - 08/2002

CONDITIONS

Introduction

Page 01

- Thank you for purchasing an IRRIMEC Hose-Reel

- Read This Manual carefully to learn how to operate and service your Hose-Reel properly. Failure

to do so can result in personal injury and-or property damage.

This manual is a permanent part of your Hose-Reel and should always be available for reference

by the operator. This manual should remain with the Hose-Reel when it is sold.

- Measurements in this manual are in metric units unless otherwise noted.

- Right-Hand and Left-Hand sides of the Hose-Reel are determined by the side of the machine

where the fluid enters. The inlet side of the machine is considered the Right-Side.

- The Serial Number of your machine should be written in the space provided in the specification

section of this manual.

- If You Have A Problem of if you do not understand some feature of this equipment, contact your

IRRIMEC dealer.

- Warranty is provided as part of the IRRIMEC product support. Please see specific warranty

statement in this manual.

- The warranty excludes:

- Alterations or modification not previously approved. Neither IRRIMEC dealers or

representatives are authorized to make exceptions to warranty policy. Any deviations from

standard warranty requires written authorization from an officer of IRRIMEC, Irrigation tube

which is longer, larger in diameter, or made from unapproved materials will void the warranty

on the entire machine.

- Damage caused by normal wear, accident, lack of reasonable care and maintenance, neglect

or abuse.

- The replacement cost of normal service items such as belts, gaskets, brake bands, etc. Unless

these parts are know to be defective.

- Transporting, mailing, service call, diagnosis costs. Labor for repairs is also excluded

unless unusual circumstances exist and then only if pre-approved.

INDEX

Page 02

SAFETY

- Owner’s responsibilities.

- Important recommendations.

- Decal positions.

- The serial number.

- Machine description.

- Turbine Powertrain description.

- Handling & loading.

- Assembly specifications

- Trolley Adjustment.

- Position & setup.

- Unwinding PE hose.

- Winding & startup.

- Choosing the winding speed.

- Depth of water.

- The speed.

- Power take off retraction.

- Hose retention bar.

- Hoseguide mechanism.

- Lubrication.

- Dimensions & weigths.

- Guarantee.

- Tightening the chains.

- Hoseguide timing.

- The frame.

- The trolley.

- The trolley lifting device.

1)1)2)2)3)3)4)4)

1)1)2)2)

1)1)2)2)

1)1)2)2)3)3)4)4)5)5)6)6)7)7)8)8)

1)1)2)2)

1)1)2)2)

2)2)

a)a)b)b)

a)a)b)b)c)c)

DESCRIPTION

TRANSPORT

OPERATION

ADJUSTMENT

MAINTENANCE

Page 03

Page 03

Page 05

Page 06

Page 07

Page 09

Page 10

Page 11

Page 12

Page 15

Page 17

Page 18

Page 20

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 29

Page 30

Page 31

Page 32

Page 33

WARRANTY

SAFETY

Owners Responsibilities

SAFETY

Important recommendations

0

1

Km/h

Page 03

1)1)

2)2)

- Owners Responsibilities

-The owner is responsible for the safe operation of this product. The important safeguards and

instructions appearing in this manual are not meant to cover all possible conditions and situations

that may occur. It must be understood that common sense and caution are factors that cannot be built

into any product. These factors must be supplied by the person(s) caring for and operating the product.

- It is the owner’s responsibility to:

- 1)Read and understand these instructions.

- 2)Operate the machine according to prescribed limitations.

- 3)Properly train others who may be permitted to operate the machine.

- 4)Heed rules of safety, including but not limited to those in these instructions.

- 5)Exercise good judgement relating to safe operation and safe conduct by operators and

spectators whether invited or not.

- 6)Always bring the safety decals and placards on the machine to the attention of operators

and spectators.

- 7)Keep All Shields and Guards In Place!

- Use Caution Around Pressurized lines

- Be sure the pressure is relieved from the supply line when disconnecting.

- If the sprinkler plugs, there may be pressure trapped in the

Hose-Reel tube.

- Use Caution When Towing

- Your Hose-Reel is not intended for highway towing.

- Towing Speed:

20 KPH maximum on smooth surfaces.

5 KPH maximum on rough surfaces.

- Never tow the Hose-Reel in excess of 20 KPH.

Page 04

- Warning: It is necessary before each adjustment to execute

the following: Slowly remove tension on the drive

belt to allow hose drum to ret against the anti-return pawl.

- Stay Away From Operating Sprinklers

- Stay away and keep others away from the sprinkler head during

operation. Pressurized fluid from a sprinkler can inflict serious injury

to by-standers.

Stay Away From Power Lines

- Avoid letting water contact power lines.

Be careful not to contact power lines with irrigation pipe or mechanical

equipment.

- Keep Hands and Clothing Away.

- Keep All Guards and Shields In Place.

- Do not under any circumstances reach into

the Hose-Reel while it is in operation.

Never Operate This Machine With Safety Guards Removed!

Never Service Or Make Adjustment While The Water-Reel Is Pressurized.

- Shut the Pump off at the source before attempting to do any service,

maintenance or adjustment.

Never Service Or Make Adjustment While The PET Tube Is in Tension.

SAFETY

Decal positions

Keep away from trolley

when moving machine or turntable

(With IRCO gearbox)

MISTAKE TO AVOID - A FEW WORD OF ADVICE

- If only a few metres of hose are pulled out, be sure to start the hosereel up

gently. This especially applies whenit is empty.

- Never leave the non return pawl in the up position apart from when the hose is being pulled out.

- Do not suddenly stop and start up again while pulling the hose out.

- Do not start the irrigation run if the hose on drum is not wound on

tight nor if there are spaces between the coils left on the drum.

- Never carry out any operation on the hosereel while the hose is under tension.

- Once the hose has been pulled out the irrigation run must begin within 24 hours.

ATTENTION!

It is necessary for the operator, before using the

apliance to be aware of the instructions listed on the

operator’s manual and on the stickers placed on

protection shields.

DANGER

Before carrying out any work on the irrigation machine

make sure that the pet hose is not under tension.

Do not stand in front of irrigation machine on the

hose side when it is use.

I0II

(With BIMA gearbox)

Page 05

3)3)

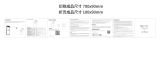

Type of hosereel

S.R.LS.R.L CALENDASCO - PIACENZA - ITALYCALENDASCO - PIACENZA - ITALY

MOD./TYPEMOD./TYPE N.N.

DATA/DATEDATA/DATE PEPE

PESO TOTALE VUOTOPESO TOTALE VUOTO

TOTAL WEIGHT EMPTYTOTAL WEIGHT EMPTY

PESO TOTALE PIENOPESO TOTALE PIENO

TOTAL WEIGHT FULLTOTAL WEIGHT FULL

LENGHTLENGHT

LUNG.LUNG.KgKg

KgKg

ST 5ST 5

7

6

47

6

4

18/10/200118/10/2001

100100

340340

- Serial number and type of hosereel.

- In case of a problem on the reel, you may be

asked the type of Hose-reel, the serial number,

the diameter and the length of the tube.

SAFETY

THE SERIAL NUMBER

Serial number

Ø of PET hose

Length of PET hose

S.R.LS.R.L CALENDASCO - PIACENZA - ITALYCALENDASCO - PIACENZA - ITALY

MOD./TYPEMOD./TYPE N.N.

DATA/DATEDATA/DATE PEPE

PESO TOTALE VUOTOPESO TOTALE VUOTO

TOTAL WEIGHT EMPTYTOTAL WEIGHT EMPTY

PESO TOTALE PIENOPESO TOTALE PIENO

TOTAL WEIGHT FULLTOTAL WEIGHT FULL

LENGHTLENGHT

LUNG.LUNG.KgKg

KgKg

ST 5ST 5

47

647

6

18/10/200118/10/2001

100100

340340

10 Km/h

MAXIMUM SPEED

II

N

I

(With IRCO gearbox)

Page 06

4)4)

DESCRIPTION

Machine Description

AA

Draw bar hook

Jack

Wheel

Axle

Turret bearing

AA

- The frame

AA

CYCLE

PAUSE

CYCLE

PAUSE On

off

On

off

Sede Amministrativa e Operativa: Via Torino, 3 - Z.I. Ponte Trebbia - 29010 CALENDASCO (Piacenza)

Tel. 0523-760441 (4l.r.a.) - Fax 0523-760444 (Amm.ne-vendite) 0523-768324 (Acquisti-Gest.ne merci)

www.irrimec.com - Email: [email protected]

Sede Amministrativa e Operativa: Via Torino, 3 - Z.I. Ponte Trebbia - 29010 CALENDASCO (Piacenza)

Tel. 0523-760441 (4l.r.a.) - Fax 0523-760444 (Amm.ne-vendite) 0523-768324 (Acquisti-Gest.ne merci)

www.irrimec.com - Email: [email protected]

S.R.L.S.R.L.

BB- The reel

CC- The turret

DD- The hose guide mechanism

EE- The retention bar

BB

CC

DD

EE

Swivel seal

Ring gear

Bearing with flange

PET hose

Bearing

turbine

Cabinet

Gearbox

Feet Leg

Electronic speed regulator

Brake

Anti-return pawl

Hose guide fork

Bevel gearbox

Fig. 1Fig. 1

Fig. 2Fig. 2

Fig. 3Fig. 3

Page 07

1)1)

FF- The trolley lifting device

- Manual trolley lifting device

GGtrolley

- Hydraulic trolley lifting device

Automatic trolley lifting device

trolley

Trolley

trolley

Fig. 4Fig. 4

Fig. 5Fig. 5

Fig. 6Fig. 6

Page 08

CYCLE

PAUSE

CYCLE

PAUSE On

off

On

off

Sede Amministrativa e Operativa: Via Torino, 3 - Z.I. Ponte Trebbia - 29010 CALENDASCO (Piacenza)

Tel. 0523-760441 (4l.r.a.) - Fax 0523-760444 (Amm.ne-vendite) 0523-768324 (Acquisti-Gest.ne merci)

www.irrimec.com - Email: [email protected]

Sede Amministrativa e Operativa: Via Torino, 3 - Z.I. Ponte Trebbia - 29010 CALENDASCO (Piacenza)

Tel. 0523-760441 (4l.r.a.) - Fax 0523-760444 (Amm.ne-vendite) 0523-768324 (Acquisti-Gest.ne merci)

www.irrimec.com - Email: [email protected]

S.R.L.S.R.L.

DESCRIPTION

Powertrain

Turbine Flap

Gearbox

Power take off

Clutch lever

Belt

Pulley

Gear lever

- System with two speed IRCO gearbox IRCO (2000-2001-2002)

- System with two speed BIMA gearbox BIMA (2002)

Automatic brake

Belt tightener

(with alternator)

Battery

Actuator

By-pass

Turbine Flap Tachometer

By-pass

Pulley

Gear lever

Clutch lever

Power take off

Automatic brake

Gearbox

Belt Tightener

Winding/Unwinding lever

(Example with Electronic speed Regulator)

(Example with mechanical speed regulator)

Flap control cable

Fig. 7Fig. 7

Fig. 8Fig. 8

Page 09

2)2)

TONN 10

TRANSPORT

Handling & Loading

TONN 10

- In order to facilitate the loading and

transport, the Hosereel can be partially

disassembled, by detaching the wheels

and turret. The manufacturer or one of its

agents will carry out the machine loading

based on measures indicated

on a table. For loading and

assembly, raise the Hosereel only as

indicated on (fig.9)

Fig. 9Fig. 9

Fig. 10Fig. 10

- If the Hosereel is sent

with the turret completely

assembled hang the

turret as (fig.10)

Fig. 11Fig. 11

- Before loading, verify that

the weight and the dimensios of

the components won't be outside

the legal limits of any countries crossed.

Page 10

1)1)

- ATTENTION: To raise the Hosereel always use a slide bridge or a crane

of adequate strength.

- ATTENTION: In order to avoid damaging the Hosereel,

always use a beam to raise it. (fig.11)

The Frame

a)a)

St4: 1810

St5: 1860

St6: 1990

St7: 2150

TRANSPORT

Assembly specifications

- Road-way

St4: 2000

St5: 2000

St6: 2200

St7: 2380

Standard road-way Maximum road-way

- Turret on frame:

Properly tighten the bearing bolts (fig. 12)

- Bolts of wheel:

Properly tighten the wheels bolts (fig. 13)

- Verify the pressure of the tires: - St4: 3.5 bar

- St5: 3.5 bar

- St6: 4 bar

- St7: 4 bar

Repeat this control periodically

- Installation of the jack:

Place the frame at the appropriate heights

Slide the jack in its bracket and

pin the jack in its bracket. Attach

the foot to the jack. (fig. 14)

Axis of fixing

Jack base

Piece of wood

Fig. 12Fig. 12

Fig. 13Fig. 13

Fig. 14Fig. 14

Page 11

2)2)

- Symmetric trolley for St4:

Attach the wheels to their axles

Slide the legs in and attach

them with the u-bolts.

- Automatic symmetric trolley for St4:

Attach the bar for automatic trolley lifting device

- Articulated asymmetric trolley for St5-6-7:

Assembly of the legs

M16

M16×120

installation of the rubber hose

Page 12

The trolleys

2)2)

b)b)

TRANSPORT

Assembly specifications

50

100

- Installation of the hose clamps

Installation of the articulation joint

- Be sure that the hoseclamps

are in the correct position. Leave 50 and

100 mm distance from the weld.

50

100

Self locking nut M12

Screw M12×35

leg assembly on main body

M16

M16×150

Symmetric trolley Asymmetric trolley

Page 13

Installation of the wheels

M10×35

M10

- Assembly for self lifting system

Self locking nut M16

M16×110

M16×50

- Articulated asymmetric trolley for St5-6-7 automatic lift:

Trolley stirrup coupler installation

Page 14

Self lifting trolley bracket assembly

St4-St5-St6

Page 15

The trolley lifting device

2)2)

c)c)

TRANSPORT

a

a: St4: 540

St5: 680

St6: 900

Adjustment

(For more detail see page 25)

Assembly specifications

Page 16

o P

Hse ET

Installation of the hydraulic trolley lifting device St4-St5-St6

Installation of the hydraulic lifting device St7

o PH se ET

670

1050 St4-6

1010 St5

End switch bar

OPERATION

Trolley adjustment

- Gun:

Adjust the gun as indicated by the gun instructions.

- Assembling the trolley to the hosereel:

- With IRCO:

- With hydraulic and manual trolley lifting device:

With the help of the crank provided with the hosereel, raise

the anti-return pawl (fig.27) and loosen

the PET tube. (Fig.15) Pull

on the tube to bring it closer to the flange of the

trolley. (fig.17) Lower the anti-return pawl.

Power take off

Power take off crank

Put the winding/unwinding lever

in the unwinding position. (fig.16) and raise the anti-

return pawl (fig.27)

Pull on the hose by hand or with the help of a rope

to bring the flange closer to the trolley. (fig.17)

Lower the anti-return pawl.

- With B600:

IRCO gearbox

B600 gearbox

Winding/Unwinding lever

Gasket

Assemble the 2 flanges (do not forget the gasket.) (fig.17)

Install the end switch bar (fig.18)

Fig. 15Fig. 15

Fig. 16Fig. 16

Fig. 17Fig. 17

Fig. 18Fig. 18

Page 17

1)1)

- With automatic trolley lifting device:

Assemble the 2 flanges (do not forget the gasket.) (fig.17)

For the automatic trolley lifting device, there isn’t an end switch bar

OPERATION

Position & set up

- 1) place the hosereel on the side of the land that you want to irrigate. Revolve the turret until the

trolley is in the direction of the row that you want to irrigate. Attention, makes sure that the drum is

aligned with the trolley and the row to irrigate. (fig.19)

Fig. 21Fig. 21

- 2) once the hosereel is in place lower the stabilizer legs and

plant them until the wheel lifts itself from the ground (fig.20-21)

hydraulic type:

- With hydraulic lever Manual/automatic type:

- With cranks

Fig. 20Fig. 20

Fig. 19Fig. 19

Hosereel position

Page 18

2)2)

For the hydraulic version, when you plant the stabilizer legs you lower the trolley. (fig. 20)

For the manual version, manipulate the winch. (fig. 21)

For the automatic version proceed as follows:

Anti-return pawl

Power take off wheel

Stop lever

- a) Place the “Power take off wheel” on the power

take off. (fig. 22)

- b) A light counterclockwise rotation will release

the anti-return pawl and the

stop lever. (fig. 22)

Anti-return pawl

Power take off wheel

Stop lever

Fig. 23Fig. 23

Trolley

Trolley

- c) Let the wheel spin while braking it to lower

the trolley. (fig.23)

Fig. 22Fig. 22

Page 19

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

/