www.fmiproducts.com

126417-01A2

TABLE OF CONTENTS

Safety .................................................................. 2

Local Codes......................................................... 4

Product identication ........................................... 4

Product Features ................................................. 4

Installation ........................................................... 5

Operation ........................................................... 16

Cleaning and Maintenance ................................ 18

Inspecting Burners............................................. 19

Replacing Light Bulb.......................................... 19

Wiring Diagram .................................................. 20

Troubleshooting ................................................. 21

Parts .................................................................. 24

Specications .................................................... 27

Replacement Parts ............................................ 27

Service Hints ..................................................... 27

Technical Service............................................... 27

Accessories ....................................................... 27

Warranty ..............................................Back Cover

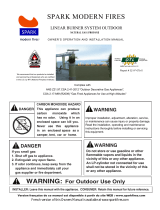

SAFETY

WARNING: Improper

installation, adjustment,

alteration, service or

maintenance can cause

injury or property dam-

age. Refer to this manual

for correct installation

and operational proce-

dures. For assistance or

additional information

consult a qualified in-

staller, service agency or

the gas supplier.

* Aftermarket: Completion of sale, not for

purpose of resale, from the manufacturer

WARNING: This product

contains and/or generates

chemicals known to the State

of California to cause cancer or

birth defects or other reproduc-

tive harm.

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, op-

erate or service this replace.

Improper use of this replace

can cause serious injury or

death from burns, re, explo-

sion, electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs of

carbon monoxide poisoning resemble the u,

with headaches, dizziness or nausea. If you

have these signs, the replace may not be

working properly. Get fresh air at once! Have

heater serviced. Some people are more af-

fected by carbon monoxide than others. These

include pregnant women, people with heart

or lung disease or anemia, those under the

inuence of alcohol and those at high altitudes.

Natural and Propane/LP Gas: Natural and

propane/LP gases are odorless. An odor-

making agent is added to the gas. The odor

helps you detect a gas leak. However, the

odor added to the gas can fade. Gas may be

present even though no odor exists.

Make certain you read and understand all

warnings. Keep this manual for reference. It

is your guide to safe and proper operation of

this

replace

.

WARNING: Any change to

this replace or its controls can

be dangerous.

Due to high temperatures, the

appliance should be located out

of trafc and away from furniture

and draperies.

Do not place clothing or other

ammable material on or near

the appliance. Never place any

objects on the replace.