Page is loading ...

MN902A

Replaces A641−INS

LB7006

Installation Instruction For Baldor Belt Grinder Guard Kit #A641

1MN902a

SAFETY NOTICE:

WARNING statements describe conditions that may lead to personnel injury including potentially fatal injuries if the

machine is not properly used and warnings are not properly followed.

Caution statements describe conditions that may lead to equipment damage.

WARNING: Do not operate this grinder until you are sure that you are completely familiar with the safe operation of the

grinder, all accessories and safety equipment. Improper use can lead to severe injury. This manual defines

proper use of this equipment. Before using this equipment for any other use, please consult Baldor.

Contact Baldor if you do not understand any procedure or operation concerning this grinder or this manual.

WARNING: Prevent electrical shock hazard and accidental machine operation. Always disconnect grinder from the

power source before servicing, changing accessories (such as wheels, tool rest, spark arrestor, etc.) or

before performing maintenance.

WARNING: Avoid accidental starting. Make sure switch is in “OFF” position before connecting to power source.

WARNING: Be sure the system is properly grounded before applying power. Do not apply power before you ensure that

grounds are connected. Electrical shock can cause serious or fatal injury. Follow the National Electrical Code

(NEC) and local codes for the safe installation of this equipment.

WARNING: Check damaged parts. Before further use of the grinder, a guard or other part that is damaged should

be carefully checked to assure that it will operate properly and perform its intended function. Check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions

that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

WARNING: Always use safety glasses with side shields (or full face shield) when operating grinder. Do not use ordinary

eyeglasses. Also use face or dust mask if cutting operation is dusty.

Procedure:

1. Disconnect power source from grinder and accessories.

2. Remove belt.

3. Remove Contact Wheel from motor shaft. Note location of washers.

4. Remove Idler Wheel.

5. Remove motor from the grinder frame (four bolts, washers and nuts secure it to frame).

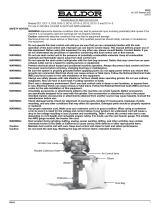

6. Locate Holes “A”, “B” and “C” shown in Figure 1. Use Figure 2 and 3 as templates to locate the holes.

a. Center punch and drill Hole “A” using a #21 tap drill. Tap the hole using a 10−32 tap.

b. Center punch and drill Holes “B” and “C” using a #7 tap drill. Tap the holes using a 1/4−20 tap.

7. Install the motor to the grinder frame (four bolts, washers and nuts secure it to frame).

8. Install the wheel guard B2FH2806A01 at holes B and C using 2 spacers HA6225, 1/4−20 x 2−1/4 screws and

lock washers as shown in Figure 1.

9. Install the Contact Wheel onto the motor shaft. Be sure key is in motor shaft and assemble washers in same

locations as when removed in step 3. Be sure wheel and guard do not contact.

Figure 1 Hole Locations

Hole A

See Figure 2

Hole C

Hole B

See Figure 3

Grinder

Frame

Spacers

HA6225

Wheel Guard

B2FH2806A01

2 MN902a

Procedure: Continued

10. Assemble the Upper Idler onto the frame Hole “A” as shown in Figure 2.

Spacers may be used to adjust the guard position so it does not contact the idler.

Be sure wheel and guard do not contact.

11. Install new Idler Wheel Guard using original screws. See Figure 4.

Figure 2 Hole A Detail Template

Screw

10−32x2−

3

/

4

Frame

Nut

10−32

Nut

10−32

Nut

10−32

Guard

Spacer

Washer

(if needed)

Spacer

Washer

(if needed)

Hole A

Center punch and drill Holes “A”

using a #21 drill.

Tap the holes using a 10−32 tap.

From Motor C

L

see Figure 3

11−3/16

7/8

Upper Idler Assembly

(Hole A)

2 Spacers fit onto the

10−32 screw, the idler

rides on the spacers.

Idler

Spacers

See Figure 4

for more detail

3MN902a

Procedure: Continued

12. Install Grinding Belt on Contact and Idler wheels.

13. Install Idler Wheel Guard Cover using Thumb Screws and Lock Washers.

14. Install Contact Wheel Guard Cover using Thumb Screws and Lock Washers.

15. Install Rear Belt Guard by removing thumbscrew of Contact Wheel Cover.

Place rear belt guard on the outside of the cover and position the upper slot of rear belt guard on the upper idler

axle screw.

16. Secure the Rear Belt Guard to the upper idler axle screw with a at washer, lock washer and nut.

17. Secure the Rear Belt Guard to the Contact Wheel Guard cover with the thumbscrew removed in step 15.

18. Verify that all mounting hardware is tight and secure before applying power and operating the belt grinder.

19. Apply power. Verify that the wheels and belt have proper clearance to move freely without rubbing on the

guards or other parts.

20. Adjust belt tracking manually before operating the belt grinder.

Figure 3 Holes B and C Detail Template

Hole B

Hole C

1/2”

1−7/16”

2−3/16”

9/32

Center punch and drill Holes “B” and “C” using a #7 drill.

Tap the holes using a 1/4−20 tap.

From

Motor C

L

Motor C

L

Baldor Electric Company

P.O. Box 2400, Fort Smith, AR 72902-2400 U.S.A., Ph: (1) 479.646.4711, Fax (1) 479.648.5792, International Fax (1) 479.648.5895

www.baldor.com

© Baldor Electric Company

MN902a

All Rights Reserved. Printed in USA.

6/06

Figure 4 Guard Kit Assembly Diagram

Idler Wheel Guard

B2FH2801A01

Cover

B2FH2808A01

Contact Wheel Guard

B2FH2806A01

Spacers (not shown)

HA6225

(see Figure 1)

Cover

B2FH2807A01

Rear Belt Guard

B2FH2809A01

Spacers (not shown)

HA2001A07

Idler Wheel

(see Figure 2)

Contact Wheel

/