Page is loading ...

ba75817e01 05/2009

Operating instructions

Water sampler

PB 150/2 & PB150-SE

Remarks

ba75817e01 05/2009 - 2 - PB 150/2 & PB 150-SE

MAXX GmbH is not liable for possible faults in this documentation. Any liability for

direct or consequential damages in connection with the delivery or the use of this

device is excluded as far as it is legal.

All rights, especially the rights for duplication, distribution and/or translation, are

reserved to MAXX GmbH. Any reproduction, use or duplication of this manual, also in

extracts, is prohibited by law without the previous written agreement of MAXX GmbH.

Subject to changes!

Access code for programming, system settings, key lock

Password:

Your password:

6299

General Information

ba75817e01 05/2009 - 3 - PB 150/2 & PB 150-SE

Table of contents

Table of contents .................................................................................................................................4

General information .............................................................................................................................6

Safety remarks.....................................................................................................................................6

Before putting into service ...................................................................................................................6

Permissible application ........................................................................................................................6

Permissible operating and ambient conditions ....................................................................................6

Redelivery for repair.............................................................................................................................7

Use of Hazard Information...................................................................................................................8

Precautionary labels ............................................................................................................................8

Characteristics: sampler PB 150/2 ....................................................................................................12

haracteristics: sampler PB 150-SE ....................................................................................................13

Dimensions of device PB 150-SE depending on the bottle variant ...................................................14

(see technical specifications).............................................................................................................14

Installing the apparatus......................................................................................................................15

Troubleshooting .................................................................................................................................17

Connections .......................................................................................................................................18

Connector pin assignment – RS 232 .................................................................................................18

Terminal assignment – input signals .................................................................................................18

Sampling modes ..............................................................................................................................20

Troubleshooting – vacuum sampling system ..............................................................................25

Flow-proportional sampling system ..............................................................................................26

Troubleshooting – flow-proportional sampling system ..............................................................28

Bypass sampling system................................................................................................................29

Troubleshooting – bypass sampling system................................................................................30

Sample distribution at PB 150/2-F-MS ..............................................................................................31

Troubleshooting – distributor PB 150/2-F-MS ...................................................................................32

Sample distribution at PB 150-SE – variants: 12 / 24 bottles............................................................33

Sample distribution at PB 150-SE – variants: 2 / 4 bottles ...............................................................35

Troubleshooting – distributor PB 150-SE ..........................................................................................36

Programming .....................................................................................................................................37

CHANGE PROGRAM .......................................................................................................................46

START PROGRAM ...........................................................................................................................50

MODEM SETTINGS .......................................................................................................................... 55

CHANGE SYSTEM SETTINGS.........................................................................................................58

EXTENDED PROGRAM SETTINGS ................................................................................................ 60

SPECIAL DISPLAY/MALFUNCTION MESSAGES ...........................................................................72

EXTENDED MALFUNCTION MESSAGES.......................................................................................73

MESSAGES.......................................................................................................................................73

DIGITAL INPUTS / OUTPUTS ..........................................................................................................74

Spare parts / accessories PB 150/2 ..................................................................................................88

Circuit diagram mains connection PB 150/2 & PB150-SE ................................................................89

Circuit diagram vacuum system.........................................................................................................90

Circuit diagram bypass system..........................................................................................................91

Circuit diagram flow-proportional system...........................................................................................92

Circuit diagram terminal connections.................................................................................................93

Circuit diagram self-emptying PB 150/2-A 12 x 1,6...........................................................................94

Circuit diagram self-emptying PB 150/2-A 24 x 2 L..........................................................................95

Circuit diagram PB 150/2-A 12 x 1,6 Bypass ....................................................................................96

Circuit diagram PB 150/2-A 24 x 2,0 Bypass ....................................................................................97

EXAMPLES FOR STANDARD PROGRAMS .......................................................................................38

MAIN MENU (root): ...............................................................................................................................45

MANUAL MODE ...................................................................................................................................53

SETUP ..................................................................................................................................................54

MEMORY ..............................................................................................................................................64

SERVICE MENU ...................................................................................................................................65

APPENDIX A - Special programming ...................................................................................................68

General Information

ba75817e01 05/2009 - 4 - PB 150/2 & PB 150-SE

Circuit diagram PB 150/2-A 12 x 1,6 L flow-proportional ..................................................................98

Circuit diagram PB 150/2-A 12 x 1,6 L flow-proportional .................................................................99

Circuit diagram PB 150-SE 2 x 10 L vacuum ................................................................................100

Circuit diagram optional inlet / additional valve 900276 ..................................................................101

Circuit diagram optional inlet / additional valve 900276 ..................................................................102

Warranty and liability........................................................................................................................103

General Information

ba75817e01 05/2009 - 5 - PB 150/2 & PB 150-SE

General information

We are glad that you have chosen this product.

When developing this device, we combined approved technique with innovative detail solutions.

Greatest importance has also been attached to the design of an apparatus which provides easy

access for connection and maintenance works.

Safety remarks

Disconnect the mains power connections before carrying out any connection, maintenance or

repair works.

Before putting into service

- Please read these operating instructions and special remarks thoroughly before putting the

device into service.

- Familiarize yourself with the safety and operating requirements in order to safeguard

personnel and equipment.

- The apparatus has been subjected to exhaustive quality inspections before dispatch.

- Any service and maintenance works required may only be carried out by trained service

personnel.

- Observe the local safety regulations and the rules for prevention of accidents.

- Observe the rules concerning the handling of hazardous substances.

- Do only use original spare parts or spare parts authorised by the manufacturer.

- No liability or claims under guarantee will be accepted in respect of any modifications or

conversions of the apparatus, other than those carried out by us or by persons authorised by

us or for which we have given express permission (in a written form)! This also refers to any

damage due to incorrect operation and/or improper use of the equipment.

Permissible application

The permissible application of the water sampler consists in the extraction of liquid, aqueous

substances, temperature range 0°C to 40°C. The device must only be installed in areas free from

explosion hazard and must only be used for sampling of non-explosive substances. Please refer to

the technical specifications in chapter “Specifications”. Other applications are not allowed!

Permissible operating and ambient conditions

- Sample extraction of liquid aqueous substances, temperature range: 0°C to 40°C.

- The sampler is designed for operation in non-hazardous areas (no explosion risk).

- The sampler can be operated at ambient temperatures from -20°C to +43°C.

- Sampling from pressurised lines is not possible without optional accessories.

- The device is weather-proof and suitable for outside operation.

General Information

ba75817e01 05/2009 - 6 - PB 150/2 & PB 150-SE

Redelivery for repair

Before returning any appliances to us, please pay attention to the following to avoid unnecessary cost

and repair delays:

- Redeliveries only after agreement by the supplier

- All appliances or parts returned to us for repair must be cleaned and free of any hazardous

substances whatsoever (acids, alkaline solutions, solvents, etc.) as in Germany official

regulations regarding waste stipulate that persons in possession of hazardous waste are

responsible for its disposal and that, at the same time, employers are responsible for

protecting their employees against hazardous materials.

- Any cleaning or disposal required to be carried out by us will be charged for accordingly.

All packing materials can be disposed of as usual.

Packing materials are: cardboard, wood, PS and PE.

If the packing is returned free of cost, we will take care of its disposal.

General Information

ba75817e01 05/2009 - 7 - PB 150/2 & PB 150-SE

Safety information

Please read this entire manual before unpacking, setting up

or operating this equipment. Pay attention to all danger and

caution statements. Failure to do so could result in serious

injury to the operator or damage to the equipment.

To ensure that the protection provided by this equipment is

not impaired, do not use or install this equipment in any

manner other than that specified in this manual.

Use of Hazard Information

DANGER

Indicates a potentially or imminently hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in

minor or moderate injury.

Important Note: Information that requires special

emphasis.

Note: Information that supplements points in the main text.

Precautionary labels

Read all labels and tags attached to the instrument.

Personal injury or damage to the instrument could occur if

not observed.

This symbol, if noted on the instrument, references the instruction manual for operation

and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of

electrical shock and/or electrocution exists.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for

Protective Earth (ground).

This symbol, when noted on the product, identifies the location of a fuse or current

limiting device.

Electrical equipment marked with this symbol may not be disposed of in European public

disposal systems after 12 August 2005. In conformity with European local and national

regulations (EU Directive 2002/96/EC), European electrical equipment users must now

return old or end-of life equipment to the Producer for disposal at no charge to the user.

Note: For all electrical products (marked or unmarked) which are supplied or produced

by MAXX, please contact the local MAXX sales office for instructions for proper disposal.

General Information

ba75817e01 05/2009 - 8 - PB 150/2 & PB 150-SE

Device designation

PB 150/2

Housing Stainless steel with 40 mm insulation,

(material 1.4301/ SS304) / PS / PC (GF10)

Option:

(material 1.4571/ SS316Ti; SS304 EPOXY-coated;

SS316Ti EPOXY-coated)

Thermostatic control Self-contained cooling / heating with 4 settings, no-frost.

Temperature in sample compartment: 4°C (setting range: 0,0-9,9°C)

Control Microprocessor control, foil keyboard, back lit four-line LC-display

Data memory Non-volatile data memory: storage of sampling and malfunction data

like sample extractions, bottle changes, messages, external signals

Programming 6 user programs (can be edited freely)

Program start options Immediately, at a certain time, by an external signal

Program stop options End of sampling program after one program run, continuous operation

Pause mode Interruption of program at any time

Overfilling protection Adjustable from 1–999 samples/bottle

Interval setting 1 min. to 99 h 59 min. in steps of 1 minute

Pulse setting 1 to 255 pulses/sample

Manual sample extraction Possible at any time without interrupting the current program run

Program protection Up to 5 years after voltage loss

Interface RS 232

Communication Modbus, connection via DP PROFIBUS optional

GSM modem / wireless

communication

Optional (in combination with PC software)

Languages Multi-language, selectable

Signal inputs • 1 x analogue: 4-20 mA, optional 0-20 mA, minimum voltage: 3,3 V

(optocoupler)

• 5 x digital: flow, event, 3 inputs can be programmed freely

Signal outputs / status

messages

Max. 8 digital outputs, depending on device version;

freely programmable

Sampling method -Vacuum system 20-350 ml, plastic vessel

-Vacuum system 20-500 ml, optional

-Vacuum flow-proportional 20-400 ml, optional

-Bypass system 20-250 ml optional

Single sample volume

accuracy

< 2,8 % at standard vacuum system

Suction height Max. 8 m (at 1013 hPa and stagnant medium)

Pumping speed >0,5 m/s at a suction height up to at least 7,8 m (at 1013 hPa); pump

capacity can be adjusted electronically.

Suction hose PVC, L=7,5 m, ID=12 mm (ID 16 mm at flow-proportional option)

Max. hose length 30 m

Sampling modes Time-related, flow-dependent, flow-proportional (option), event-related,

manual sample extraction

Bottle variants Plastic

1 x 25 L, 1 x 50 L, 2 x 10 L

4 x 6,0 L, 4 x 10 L, 4 x 14 L, 4 x 20 L, 4 x 25 L

12 x 2,9 L, 24 x 1,0 L, 24 x 2,9 L

Glass

12 x 2,0 L, 24 x 1,0 L, 24 x 2 L

Overall dimensions (Hxwxd)

1.290 (1.890*)x 690 x 645 mm

for bottle variants: 1x25 L, 1x50 L, 2x10 L, 2x22 L, 4x6 L, 4x10 L,

4x14 L, 12x2 L, 12x2,9 L, 24x1 L

1400 (2015*) x 930 x 850 mm

for bottle variants: 4x20 L, 4x25 L, 24x2,9 L, 24x2 L, 36x1 L

*) with opened top

Weight 100 kg with composite container; higher weight when using several

General Information

ba75817e01 05/2009 - 9 - PB 150/2 & PB 150-SE

bottles and/or glass bottles

Power supply 230 V 50Hz

optional 115 V 50/60Hz

Power requirement Approx. 350 VA (with cooling)

Ambient temperature -20 - +43°C

Sample temperature 0 – 40°C

Standards Device meets ISO 5667 standard

Test marks CE

Wetted materials PVC, Silicone, PS, PE, EPDM (optional: glass (Duran50) metering

vessel, sinker weight SS304)

Device designation PB 150/2-M (with measurin rack) (like PB 150/2, with the following

modifications)

Device type Fixed site sampler with measuring rack for measuring transducers

(controller sc100)

Bottle variants Plastic

1 x 25 L, 1 x 50 L, 2 x 10 L

4 x 6,0 L, 4 x 10 L, 4 x 14 L,

12 x 2,9 L, 24 x 1,0 L

Glass

12 x 2,0 L, 24 x 1,0 L

Overall dimensions (Hxwxd)

1.470 (2.070*) x 690 x 645 mm

for bottle variants: 1x25 L, 1x50 L, 2x10 L, 2x22 L, 4x6 L, 4x10 L,

4x14 L, 12x2 L, 12x2,9 L, 24x1 L

*) with opened top

Power requirement Approx. 350 VA (with cooling) + power requirement of controller

Weight 105 kg with composite container; higher weight when using several

bottles and/or glass bottles

General Information

ba75817e01 05/2009 - 10 - PB 150/2 & PB 150-SE

Device designation PB 150-SE (like PB 150/2, with the following modifications)

Device type Self-emptying fixed site sampler for continuous operation without the

need of personnel (monitoring applications)

Emptying/rinsing Bottles are emptied, rinsed and re-filled on the same bottle position.

The rinsing head is installed above the bottle.

Bottle emptying for sample

collection

According to the device version: manual bottle emptying at 12 and 24-

bottle version or menu-driven emptying at 2 and 4-bottle version

Hose inlet Hose connection at dosing unit (top)

Union nut R 3/4", hose ID 12 mm

Hose outlet Hose connection at dosing unit

Silicone hose 12x2, is only slipped over

Rinsing water inlet Union nut R 3/4" (max. 2 bar)

Rinsing water outlet Union nut R 1 1/4". When using the rinsing function, the customer has

to make sure that the rinsing water can drain off freely

Bottle variants Plastic

2 x 10 L, 4 x 5 L, 4 x 10 L, 24 x 2 L (PPH)

Glass

12 x 1,6 L, 24 x 1,0 L, 24 x 2 L

Overall dimensions (Hxwxd)

• 1.290 (1930*) x 690 x 645 mm

for bottle variants: 2 x 10 L, 4 x 5 L, 12 x 1,6 L

• 1400 (2175*) x 800 x 850 mm

for bottle variants: 4 x 10 L, 24 x 1 L, 24 x 2 L

*) with opened top

Weight 115 kg with bottle option 2x10 L PE; higher weight when using other

bottle or glass bottle options

General Information

ba75817e01 05/2009 - 11 - PB 150/2 & PB 150-SE

Characteristics: sampler PB 150/2

The device consists of the following component parts:

1. Protective top (can be

opened)

2. Upper part of housing

3. Back lit LC-display

4. Keyboard

5. Lower part of housing (cooled

sample compartment)

6. Motor-driven distributor

7. Distributor plate

8. Sample bottles

9. Carrying tray for bottles

10. Fixing bar

11. Fixing bar

12. Dosing unit

13. Pinch valve

14. Type plate

Remark: The illustrated sampler corresponds to a standard version with 12 bottles and

distributor plate.

According to the sampler version, some components such as dosing unit or

distributor/bottles can be different!

General Information

ba75817e01 05/2009 - 12 - PB 150/2 & PB 150-SE

haracteristics: sampler PB 150-SE

1

. Protective top (can be

opened)

2. Upper part of housing

3. Back lit LC-display

4. Keyboard

5. Lower part of housing

(cooled sample compart-ment)

6. Type plate

7. Glass sample bottles

8. Distributor drive

9. Fixing bar

10. Dosing unit

11. Pinch valve

12. Combined dosing and rinsing head

13. Automatic discharge valve

14. Swivelling sample discharge tube

Remark:

The illustrated sampler corresponds to a standard version with 24 bottles.

According to the sampler version, some components such as dosing unit or

distributor/bottles can be different!

General Information

ba75817e01 05/2009 - 13 - PB 150/2 & PB 150-SE

Dimensions of device PB 150-SE depending on the bottle variant

(see technical specifications)

General Information

ba75817e01 05/2009 - 14 - PB 150/2 & PB 150-SE

Installing the apparatus

- We recommend to install the apparatus as near as possible to the point of extraction. If installed

outside, the device should be fixed on a solid flat base (e.g. plinth). The fixing bars do already

have the necessary fixing holes.

- If the device is equipped with castors (mobile version), please make sure that the two lock-type

castors are locked during operation.

- For better deaeration / ventilation install the apparatus with a distance of approx. 10 cm to the wall.

- The hose has to be laid with a continuous fall from the apparatus to the point of extraction, without

fail. Lower lying points can lead to deposits in the hose which may freeze up in winter.

- To fix the suction hose, we recommend to use the extraction unit available as accessory.

- Fix the hose in such a way that the suction aperture lies in the direction of flow, so that coarse

matter and fibres cannot be forced into the suction aperture.

Remark: To open the top cover both front screws

(left + right) have to be removed. Then the

top cover can be lifted up to the point

where the retention bars snap-in. To close

the cover again, the two retention bars

have to be lifted slightly.

After having closed the cover, the two

screws (left + right) have to be screwed in

again.

Mains connection The device is equipped with a power supply lead.

The connecting data can be found in chapter “Technical Data”.

Connect/disconnect The device is connected/disconnected by means of the mains plug (except

devices with main switch).

Hose routing The apertures for the suction hose are on the left and on the right at the front.

Signal inputs The signal inputs (e.g. for flow meter) are located on the „fold-out“ plate and can

be connected according to the plan of terminal connections shown there.

Messages The relays required for messages (up to 4) can be fixed on the top hat rail. For

details please see the circuit diagram

General Information

ba75817e01 05/2009 - 15 - PB 150/2 & PB 150-SE

Terminal box

Shall the device be connected directly by means of an existing underground cable, a terminal box

(BM900015) is available as accessory.

As standard the terminal box is equipped with a shock-proof socket and a flow signal input (option:

lightning protector). Thus a separate main switch is not needed as the device can be disconnected from

the mains at any time by pulling the plug.

According to the installation site, the whole unit can be screwed to the side of the sampler or to a wall.

1. V2A stainless steel protective cover

2. Terminal box

3. PG screw connections

4. Earth cable

5. Shock-proof socket

6. Flow signal input

Replacement of fuses

1. Main fuse of device

(is installed on fold-out plate)

Fine-wire fuse 230V/T8A 5x20

To replace the fuse, pull out fuse holder,

open the cover and remove the fuse.

2. Fuse protection of CPU board

by an automatic fuse. The fuse is

reactivated by disconnecting the device

from the mains.

General Information

ba75817e01 05/2009 - 16 - PB 150/2 & PB 150-SE

Troubleshooting

If a fault develops in your sampler, we can only provide prompt assistance if you give us the type and

serial number of the apparatus concerned. You will find these data on the type plate.

The more precise your description of the fault is, the better our fault diagnosis will be.

Symptom Possible cause Action

Sampler does not

function at all

- Mains connection

- Fuse defective

-Check mains cable

-Check all fuses and replace them

if necessary

Cooling system does

not function

- Power supply

- Cooling system leaking

-Check mains connection of

cooling machine

-Contact service department

General Information

ba75817e01 05/2009 - 17 - PB 150/2 & PB 150-SE

Connections

Connector pin assignment – RS 232

1 = Rx

2 = free

3 = Tx

4 = free

5 = Gnd

Terminal assignment – input signals

Remark: Terminals K2 to K4 are optional depending on the device version.

General Information

ba75817e01 05/2009 - 18 - PB 150/2 & PB 150-SE

Technical information on inputs and outputs

The numbering in the test display of the service menu is not identical with the numbering when

programming the inputs and outputs.

In the following tables the numbering of the inputs and outputs on the adapter board, the numbering in the

test display as well as when programming are listed.

Please note that only inputs 1 - 3 are freely programmable. At the outputs the malfunction message is

always assigned to terminal 39 (test display 5). The number of freely programmable outputs may vary

according to the type of device.

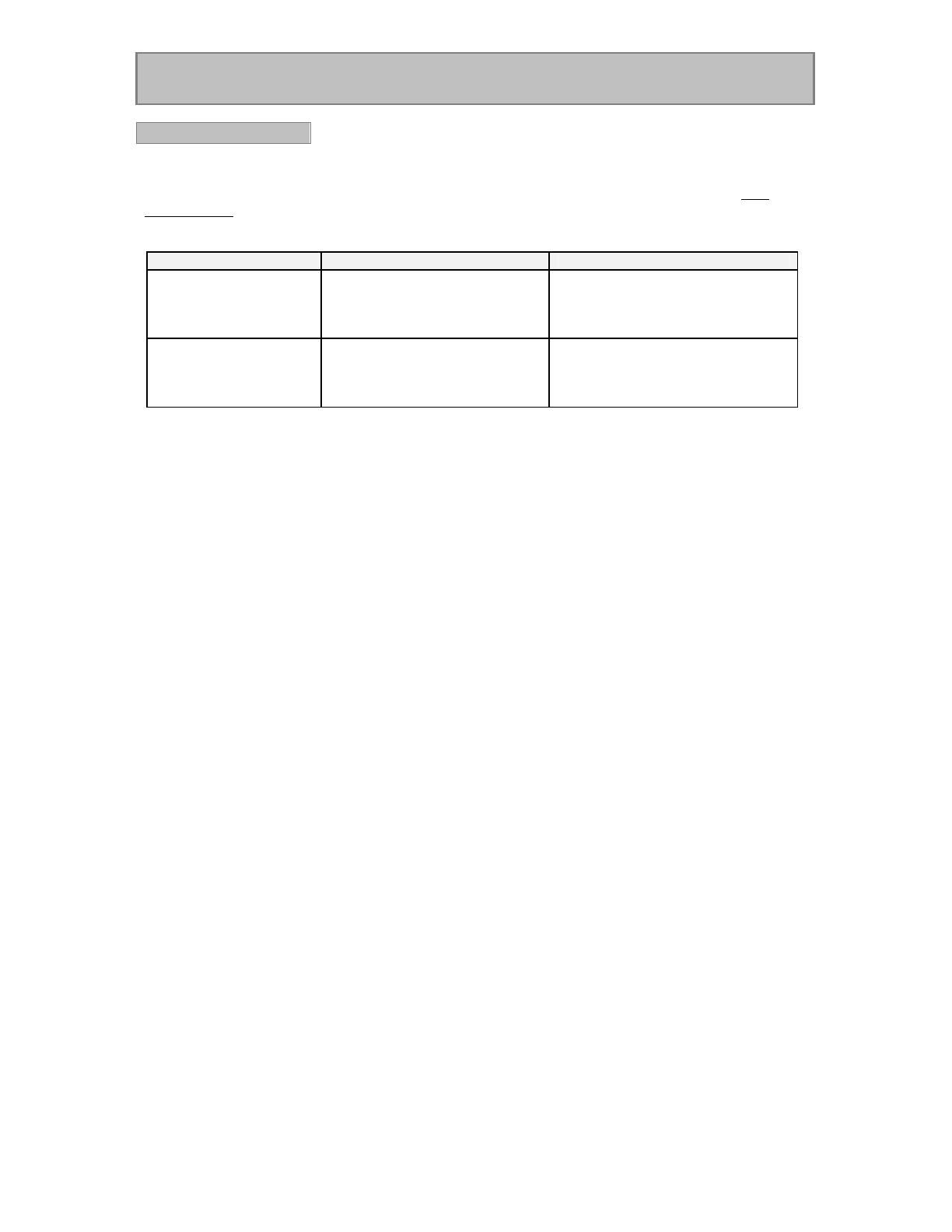

Inputs

No. of terminal on adapter board

1

2

3

4

5

6

7

Numbering in test display

(service menu)

7

6

5

4

3

2

1

Numbering when programming

1

2

3

Not

freely

prog.

Not

freely

prog.

Not

freely

prog.

Not

freely

prog.

To trigger these inputs by means of a relay the make contact of the relay has to be connected

to the respective terminal on the adapter board (1 - 7) and to terminal 16, 17 or 18 (+12V).

Outputs

No. of terminal on adapter

board

35

36

37

38

39

40

41

42

43

44

45

Numbering in test display

(service menu)

1

2

3

4

5

6

7

8

9

10

11

Numbering when

programming

5

6

7

8

error

mess

1

2

3

4

not

free

not

free

To connect a relay, it has to be connected to the respective terminal on the adapter board

(GND (-)) and to terminal 34 (+).

In the future software version V3_51 the numbering of the inputs and outputs of the control unit when

programming and in the test display will be identical with the terminal numbers on the adapter board.

Operation

ba75817e01 05/2009 - 19 - PB 150/2 & PB 150-SE

Graphical representation of sampling modes TIME-FLOW-EVENT

Flow graph

Time-

proportional

Flow-

dependent

Flow-

proportional

Event signal

Event-

proportional

A sample is extracted in

fixed time intervals (e.g.

every 10 minutes) with a

fixed sample volume (e.g. 50

ml).

A sample is extracted in

variable time intervals

(depending on the flow (Q))

with a fixed sample volume

A sample is extracted in

fixed time intervals (e.g.

every 10 min.), however, with

a variable sample volume

(the sample

volume is directly de-pending

on the flow (Q) = mA signal).

The sampler is waiting for an

event (e.g. the exceeding of a

pH limit value). A sample is

extracted in fixed time

intervals (e.g. every 10 min.)

with a fixed

volume (e.g. 50 ml) as long

as an event is present.

Sampling modes

Operation

ba75817e01 05/2009 - 20 - PB 150/2 & PB 150-SE

The following sampling modes can be programmed:

Sampling mode Description Example

Time-proportional In this sampling mode, the single

sample extractions as well as the

bottle change are effected in fixed

time intervals.

Values to program:

sampling interval

e.g. 00:05 hh:mm

Bottle filling time

e.g. 02:00 hh:mm

Flow-dependent

- digital

In this sampling mode the sample

extraction is triggered by flow pulses.

The bottle change is effected in fixed

time intervals or after a certain

number of sample extractions.

Values to program:

pulse divider

e.g. 100

(that means that a sample is

extracted after each 100th pulse).

Bottle filling time

e.g. 02:00 hh:mm

or

bottle change after X sample

extractions e.g. 100

Flow-dependent

- analogue

In this sampling mode samples are

extracted according to the analogue

flow signal (0-20 mA or 4-20 mA). The

sample extraction is started when the

programmed flow is reached. Thus

the interval between the sample

extractions varies according to the

flow signal. The bottle change is

effected in fixed time intervals or after

a certain number of sample

extractions.

Values to program:

Flow per sample extraction

e.g. 1 m³

Bottle filling time

e.g. 02:00 hh:mm

or

bottle change after X sample

extractions e.g. 100

Flow-proportional Samples are not extracted with a

fixed volume but within a fixed time

interval (e.g. every 10 minutes).For

this kind of sampling, the variable

automatic dosing system (available as

option) is required. This system is

only working with an analogue flow

signal!

The sample volume adapts itself

automatically proportionally to the

flow. This is achieved by

proportionally scaling the mA signal

and the maximum sample volume.

That means, the sample volume is

automatically adjusted to the mA

signal.

•Analogue signal (4-20 mA or

optional 0-20 mA)

•The max. sample volume at 20 mA

is fixed to 200 ml.

At an analogue signal of e.g. 10 mA,

a 100 ml sample would be extracted

accordingly. Sampling is effected in a

fixed time interval of e.g. 10 minutes.

Thus the sample extraction is always

proportional to the flow, that means:

high flow = big sample volume

low flow = small sample volume.

/