2 3A2776D

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Keep Components A and B Separate . . . . . . . . 6

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 6

Components A and B . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . 7

Typical Setup (Front View) . . . . . . . . . . . . . . . . . 7

Typical Setup (Back View) . . . . . . . . . . . . . . . . . 8

Fluid Control Assembly . . . . . . . . . . . . . . . . . . . . 9

Main Power and Heater Controls . . . . . . . . . . . 10

Sprayer and Flush Pump Air Controls . . . . . . . 10

Feed Module Air Controls . . . . . . . . . . . . . . . . 11

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Unboxing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configuration Options . . . . . . . . . . . . . . . . . . . . 14

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . 16

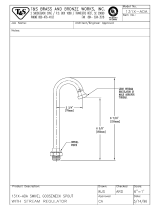

Connect Air Supply . . . . . . . . . . . . . . . . . . . . . . 17

Connect Feed Module Lines to Sprayer Module 18

Install Level Sensor Probe . . . . . . . . . . . . . . . . 19

Check Level Sensor Calibration . . . . . . . . . . . . 19

Connect the Fluid Hose Bundle to the System . 20

Connect the Fluid Hose Bundle to the

Mix Manifold . . . . . . . . . . . . . . . . . . . . . . . . 21

Connect the Mix Manifold to the Gun . . . . . . . . 22

Prime Heated Fluid Circulation System . . . . . . 23

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Prime Solvent Flush Pump . . . . . . . . . . . . . . . . . . 29

Adjust Ratio and System Settings . . . . . . . . . . . . 31

Temperature Settings . . . . . . . . . . . . . . . . . . . . . . 31

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Flush Mixed Material . . . . . . . . . . . . . . . . . . . . . . 36

Park Metering Pump Rods . . . . . . . . . . . . . . . . . . 37

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 38

System Verification . . . . . . . . . . . . . . . . . . . . . . . . 40

Pump and Metering Test . . . . . . . . . . . . . . . . . . 40

Batch Dispense or Ratio Test . . . . . . . . . . . . . . 42

Down Stream Valve Leak Test . . . . . . . . . . . . . 43

Mix and Integration Tests . . . . . . . . . . . . . . . . . 44

Empty and Flush Entire System . . . . . . . . . . . . . . 45

Prepare Level Sensor for Shipping . . . . . . . . . . . 49

Download Data from USB . . . . . . . . . . . . . . . . . . . 50

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Download Setup . . . . . . . . . . . . . . . . . . . . . . . . 50

Download Procedure . . . . . . . . . . . . . . . . . . . . . 50

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Adjust Packing Nuts . . . . . . . . . . . . . . . . . . . . . 52

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Clean the System . . . . . . . . . . . . . . . . . . . . . . . 53

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

General Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Individual Control Module LED Diagnostic

Information . . . . . . . . . . . . . . . . . . . . . . . . . 55

Troubleshooting Table . . . . . . . . . . . . . . . . . . . 55

Appendix A - User Interface Display . . . . . . . . . . 58

Change a Setting . . . . . . . . . . . . . . . . . . . . . . . . 58

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Setup Mode Screens . . . . . . . . . . . . . . . . . . . . . 59

Operator Command Mode Screens . . . . . . . . . . 66

Automatically Displayed Screens . . . . . . . . . . . 73

Appendix B - Alarms . . . . . . . . . . . . . . . . . . . . . . . 75

Alarms Overview . . . . . . . . . . . . . . . . . . . . . . . . 75

Alarm Code Troubleshooting . . . . . . . . . . . . . . . 78

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 88

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 88