Section 2: Installation

Section 2: Installation

2.1 Before installing the equipment

Ensure your package includes the following items:

l Installation and user guides

l HS3032/HS3128/HS3248 alarm controller

l Power supply

Select a location that is

l within an environment that provides a pollution degree max 2, over voltages category II.

l non-hazardous, indoor locations only.

l near a telephone socket and power outlet.

l free from vibration and shock.

l free from exposure to direct sunlight, excessive heat, moisture, vapors, chemicals or dust.

l flat and stable that allows adequate working room for external wiring.

Do not

l Connect the alarm controller to the same circuit as large appliances.

l Install this equipment near water. (e.g. bathtub, sink, wet basement, swimming pool).

l Install this equipment and accessories in areas where risk of explosion exists.

l Connect this equipment to electrical outlets controlled by wall switches or automatic timers.

Avoid

l Interference sources.

l Installing equipment near heaters, air conditioners, ventilators, and refrigerators.

l Locating equipment close to or on top of large metal objects.

2.2 Overview of installation process

The steps below are provided to assist with the installation of the alarm system. Read over this section to get an overall

understanding of the order of installation. Working from this plan can help reduce problems and reduce the overall time required for

installation.

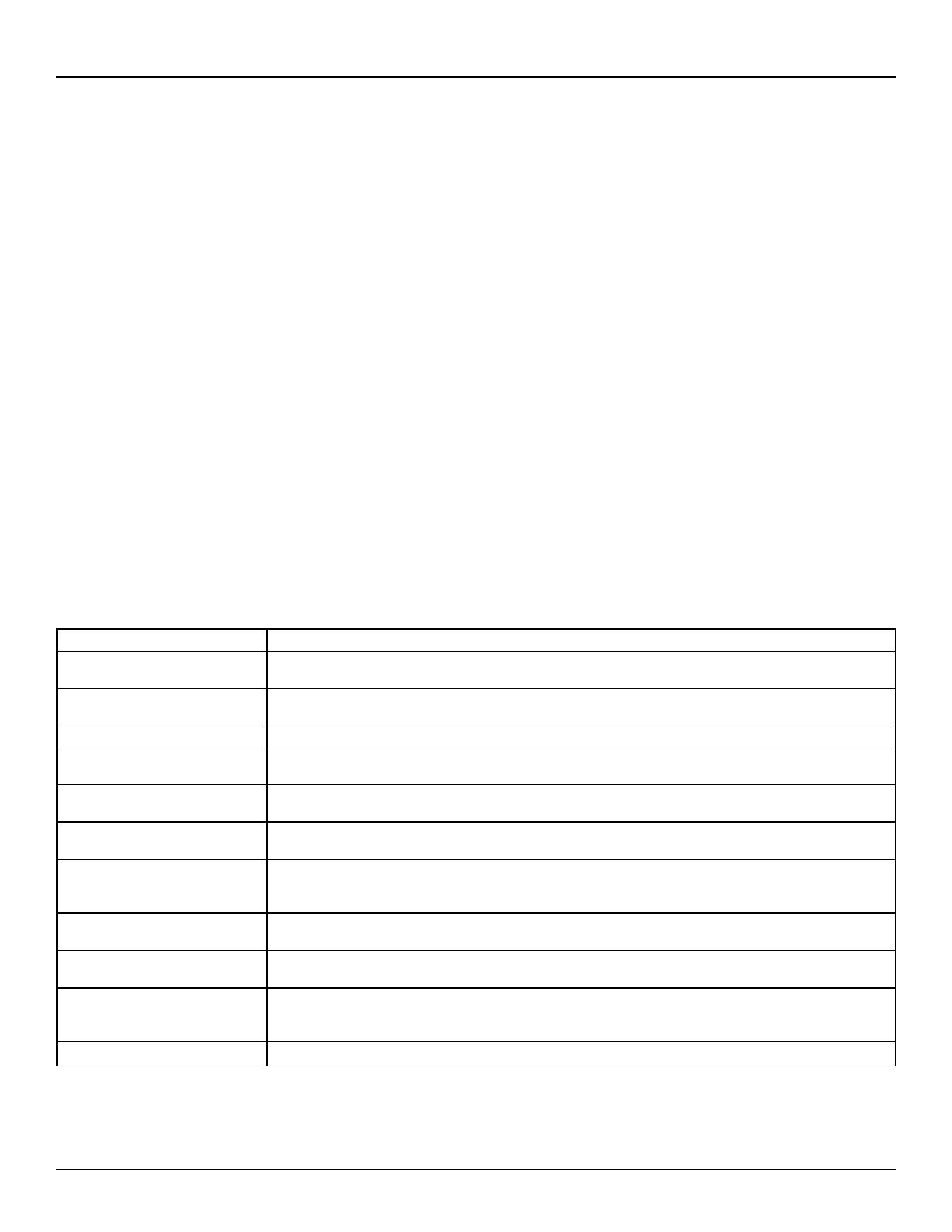

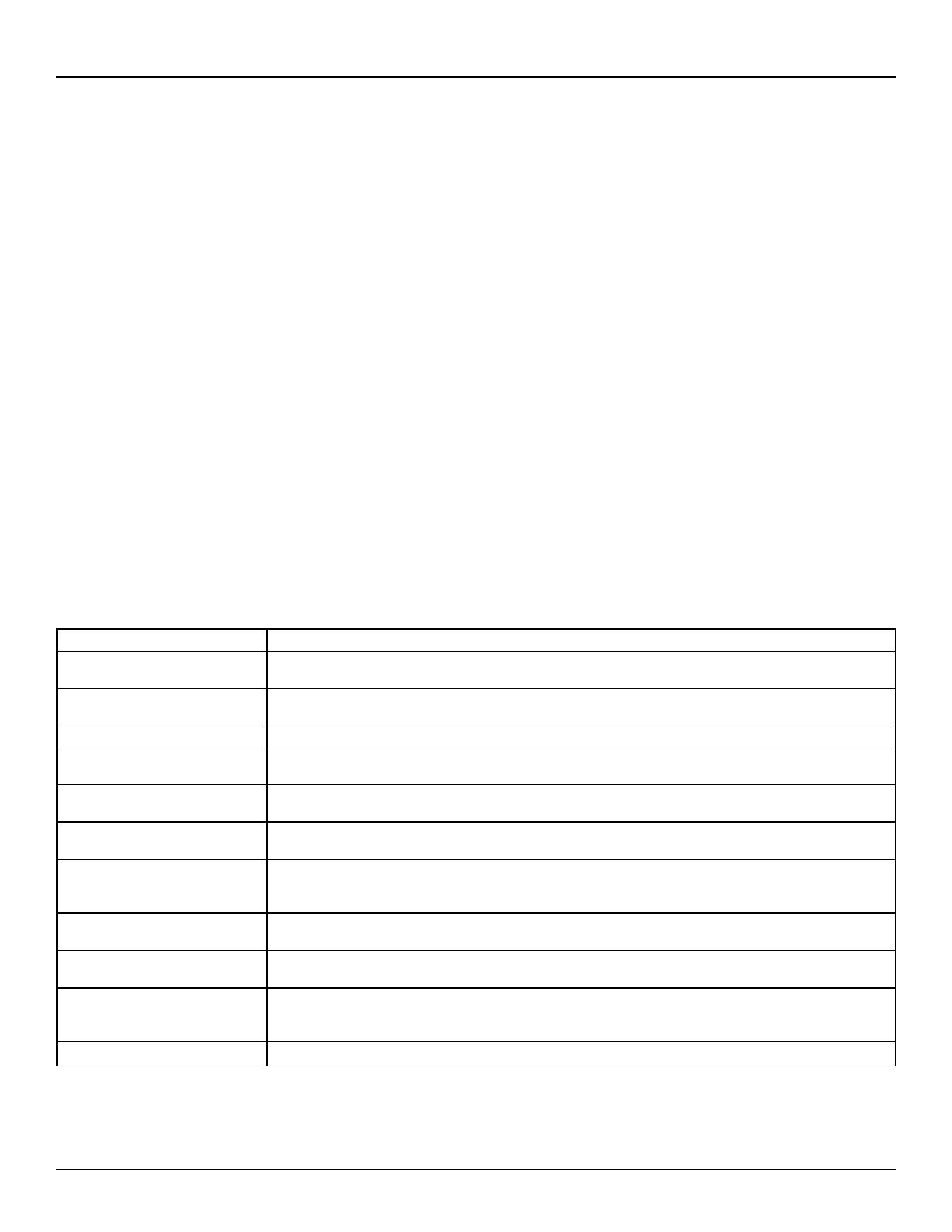

Step Description

Create a layout Draw a rough sketch of the site and include all alarm detection devices, zone expanders, keypads and other required

modules.

Mount the panel Decide on a location for the alarm panel and secure it to the wall using suitable mounting hardware. See Mounting

the enclosure on page 12

Wire the alarm controller Wire each of the modules to the alarm controller following the guidelines provided in Corbus wiring on page 33

Wire zones Complete all zone wiring. Follow the guidelines provided in Zone wiring on page 42 to connect zones using normally

closed loops, single EOL resistor, double EOL resistors, triple EOL resistors, fire zones, and keyswitch arming zones.

Complete wiring Complete all other wiring including bells or sirens, telephone line connections, ground connections, Ethernet con-

nection or any other wiring necessary. Follow the guidelines provided in Terminal descriptions on page 33.

Power up the control panel Once all zone and alarm controller wiring is complete, connect the battery before applying AC, and power up the sys-

tem. The alarm controller will not power up if onlythe battery is connected.

Enrollkeypads and modules All keypads must be enrolled in order to operate on the system. To enroll the first keypad. See Enrolling the first

keypad on page 55. To enroll optional keypads, enter installer's programming section [902][000]. For more inform-

ation, see Module Programming.

Confirm module supervision By default, all modulesare supervised upon installation. Supervision is enabled at all times. To confirm that each mod-

ule is properly supervised, see [903] Confirm Module on page 157.

Enrollwireless devices Wireless devices are enrolled via the wireless transceiver module (HSM2HOSTx) or RF keypad and Installer pro-

gramming section [804]. To enroll wireless devices, see[804] Wireless Programming.

Program the system Section 5 "Programming" on page 81 provides a complete description of how to program the alarm controller. It con-

tains complete descriptions of the various programmable features and options. Fill out the programming worksheets

starting at "Programming Worksheets" on page 161 completely before attempting to program the system.

Test the system

Test the panel completely to ensure that all features and functions operate as programmed.

2.3 Alarm controller installation

Begin the installation by mounting the alarm controller in the metal enclosure using the stand-offs provided. Optional modules, such

as the HSM3408, can also be mounted in the enclosure. Install hardware in the sequence indicated on the following pages.

- 11 -