6

2.60 ELECTRICAL POWER

2.61 Power Source Review

Review the power source and the motor rating to be sure they agree in voltage, phase, and

frequency. Serious damage may occur to the motor if it is connected to an improper voltage.

All Welch pumps must be grounded. Grounding reduces the risk of electric shock in the event

of an electrical short circuit. The plug must be plugged into a properly grounded outlet. Consult

your local electrical codes if you have doubts.

2.62 Overload Protection

Motor thermal overload protection is made available by the motor manufacturer as an aid to

minimize motor failure. Overload protection is a standard feature on both 50 and 60 Hz single-

phase-motors. The motors have automatic overload protection. Automatic reset protection is

designed to reset itself after a predetermined cooling period. If the fault to the drive remains

unaltered, the motor will cycle on and off until the fault is corrected.

WARNING

The motor is thermally protected and will automatically restart

unexpectedly when the overload device resets. Don’t pump fl ammable

or explosive gases or vapors or operate this pump in an atmosphere

containing fl ammable or explosive gases or vapors.

2.63 Identifi cation Symbols:

Power Off Power On

2.64 Grounding Instructions

This product should be grounded. In the event of an electrical short circuit, grounding reduces

the risk of electric shock by providing an escape wire for the electric current. This product is

equipped with a cord having a grounding wire with a grounding plug. The plug must be plugged

into an outlet that is properly installed and grounded in accordance with all local codes and

ordinances.

DANGER

Improper installation of the grounding plug can result in risk of electrical

shock

- If repair or replacement of the cord or plug is necessary, do not connect the grounding wire to

either fl at blade terminal. The wire with insulation having an outer surface that is green with or

without yellow stripes is the grounding wire.

- Check with a qualifi ed electrician or serviceman if the grounding instructions are not

completely understood, or if in doubt as to whether the product is properly grounded. Do not

modify the plug provided; if it will not fi t the outlet, have the proper outlet installed by a qualifi ed

electrician.

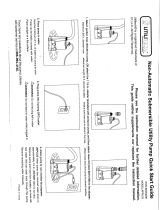

- This product is for use on a nominal 120V circuit, and has a grounding plug that looks like

the plug illustrated in Sketch A in Figure #1. A temporary adapter, which looks like the adapter

illustrated in sketches Band C, may be used to connect this plug to a 2-pole receptacle as

shown in sketch B if a properly grounded outlet is not available.

- The temporary adapter should be used only until a properly grounded outlet (Sketch A) can

be installed by a qualifi ed electrician. The green colored rigid ear, lug, etc. extending from the

adapter must be connected to a permanent ground such as a properly grounded outlet box

cover. Whenever the adapter is used, it must be held in place by a metal screw.