2.4.2 Connecting the Antenna to

Vehicle Power

The power cable now enters the baseplate through the first liquid-tight

fitting (cable port #2). Interior baseplate wiring is unchanged.

Connecting to Vehicle Power

TracVision SA must be connected to a +12 volt DC,

2.5-3.5 amp power supply to operate. The supplied power cable

should be run up to the antenna unit, through the first liquid-

tight fitting (#2) as pictured in Figure 2-14, and wired to the

terminal connector strip as illustrated in Figure 2-20.

2.4.4 Connecting the Antenna RF Signal

Cable to the IRD

You no longer need to insert RF cables into the baseplate; they now

simply connect to the exterior baseplate connectors.

The RF signal cable is fitted with an F-type connector at only one

end and should be attached to TracVision SA and the IRD as

follows:

1. For a single IRD installation, connect the

F-connector end of the RF signal cable to the

Antenna Unit baseplate connector labeled RF1 (see

Figure 2-14). Once the cable is securely connected,

loosen the sealing nut at the base of the RF1

connector and tighten it onto the end of the RF

cable.

2. Feed the bare end of the RF signal cable through

the cable access hole and into the vehicle.

3. Attach the provided F-connector to the end of the

RF signal cable inside the vehicle as illustrated in

Figure 2-23a-d, using an Augat Snap ‘n Seal

Crimp/Strip tool to lock the connector on the

cable.

A. Slide compression fitting onto raw cable

before beginning connector termination.

4

When shipped from the factory, the

antenna’s RF connectors are

protected with caps. Leave the cap

installed on the RF2 connector

unless you are going to connect a

second RF cable to the

TracVision SA.

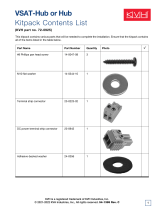

Figure 2-23a-d

Attaching the KVH-provided

F-connector to an RF Cable