Page is loading ...

Page 1 of 2

Rev. G

Date: 9/23

Document No. BF-720A

Product No. Model 720A

Patent zurn.com/patents

Model 720A

Pressure Vacuum Breaker Assembly

Zurn Industries, LLC | Wilkins

1747 Commerce Way, Paso Robles, CA U.S.A. 93446 Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited

7900 Goreway Drive, Unit 10, Brampton, Ontario L6T 5W6, 877-892-5216

www.zurn.com

Application

Designed for installation on irrigation water lines to protect

against backsiphonage of contaminated water into the po-

table water supply. Assembly shall provide protection where

a potential health hazard exists. For non-potable applications

only.

Standards Compliance

• ASSE® Listed 1020

• UPC® Listed

• CSA® Certified B64.1.2

• Approved by the Foundation for Cross-Connection Control

and Hydraulic Research at the University of Southern

California

Materials

Main valve body Cast Bronze ASTM B584

Fasteners Stainless Steel, 300 Series

Elastomers Silicone

Buna Nitrile

Polymers Polypropylene

POM Acetal (Delrin®)

Springs Stainless Steel, 300 series

Features

Sizes: 1/2", 3/4", 1", 1 1/4", 1 1/2", 2"

Maximum working water pressure 150 PSI

Maximum working water temperature 110°F

Hydrostatic test pressure 300 PSI

End connections threaded ANSI B1.20.1

Accessories

Repair kit (complete)

Water Hammer Arrester (Model 1260XL)

QT-SET Quick Test Fitting Set

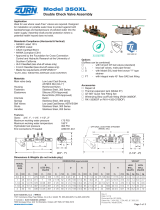

MODEL SIZE DIMENSIONS (approximate) WEIGHT

A B C D LESS BV WITH BV

in. mm in. mm in. mm in. mm in. mm lbs. kg lbs. kg

1/2 15 7 1/8 181 4 1/16 103 4 1/4 108 2 1/4 57 1.8 0.8 3.8 1.4

3/4 20 7 3/16 183 4 5/16 110 4 5/16 110 2 3/8 60 1.8 0.8 3.8 1.4

1 25 7 3/4 197 4 5/8 117 4 3/4 121 2 5/8 67 1.8 0.8 5.1 2.3

1 1/4 32 11 279 7 7/16 189 7 7/16 189 3 1/8 79 14 6.4 20 9

1 1/2 40 10 1/2 267 7 178 7 178 3 1/8 79 14 6.4 20 9

2 50 11 1/16 281 7 9/16 192 7 11/16 195 3 1/8 79 14 6.4 26 10.4

DB

C

A

Dimensions & Weights (do not include pkg.)

Page 2 of 2

⃟ Rated Flow (established by approval agencies)

Flow Characteristics

Zurn Industries, LLC | Wilkins

1747 Commerce Way, Paso Robles, CA U.S.A. 93446 Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited

7900 Goreway Drive, Unit 10, Brampton, Ontario L6T 5W6, 877-892-5216

www.zurn.com

01020304050

0

5

10

04080120 160 200

0

5

10

60

Rated Flow (Established by approval agencies)

FLOW RATES (GPM)

PRESSURE LOSS (PSIG)

69

PRESSURE LOSS (kpa)

FLOW RATES (l/s)

MODEL 720A 1/2", 3/4", 1", 1 1/4", 1 1/2" & 2" (STANDARD & METRIC)

35

1/2" (15mm) 3/4" (20mm)

1" (25mm)

1 1/4" (32mm) 1 1/2" (40mm)

2" (50mm)

12.6

10.1

7.6

5.0

2.52

3.8

3.22.52

1.89

1.26

0.63

Typical Installation

Local codes shall govern installation requirements. Unless

otherwise specified, the assembly shall be mounted at a

minimum of 12" (305mm) above the highest piping or outlet

downstream of the device. Install with adequate drain and

sufficient side clearance for testing and maintenance. The

installation shall be made so that no part of the unit can be

submerged. A pressure vacuum breaker cannot be installed

where back-pressure could occur or where spillage of water

from vent could cause damage.

Specifications

The Pressure Vacuum Breaker shall be ASSE 1020 approved, and supplied with full port ball valves. The main body and bon-

net shall be bronze (ASTM B584), the loaded-air inlet shall use an silicone elastomer spring and seat disc. The entire assem-

bly shall be accessible for maintenance and testing without removing the device from the line. For non-potable applications

only. The Pressure Vacuum Breaker shall be a Zurn Wilkins Model 720A.

INDOOR INSTALLATION

TYPICAL OUTDOOR INSTALLATION

For warm climates with no winterization

Capacity thru Schedule 40 Pipe

Pipe size 5 ft/sec 7.5 ft/sec 10 ft/sec 15 ft/sec

1/8" 1 1 2 3

1/4" 2 2 3 5

3/8" 3 4 6 9

1/2 5 7 9 14

3/4" 8 12 17 25

1" 13 20 27 40

1 1/4" 23 35 47 70

1 1/2" 32 48 63 95

2" 52 78 105 167

12" MIN. ABOVE

HIGHEST OUTLET

DIRECTION OF FLOW

12" MIN. ABOVE

HIGHEST PIPING

DIRECTION OF FLOW

TESTCOCKS (4)

1” 720A PVB

(25MM)

OUTLET SHUT OFF

VALVE (5)

OUTLET DRAIN

VALVE (6)

MAIN SHUT-OFF

VALVE (1)

INLET DRAIN

VALVE (2)

(If allowed by

local codes)

TO IRRIGATION

SYSTEM

DRAIN

DIRECTION OF FLOW

INLET

SHUT OFF

VALVE (3)

TYPICAL OUTDOOR INSTALLATION

For cold climates which require winterization

/