– 3 –

TABLE OF CONTENTS

GENERAL .............................................................................................................................................................. 5

Specifications ........................................................................................................................................... 5

Options and Features ............................................................................................................................... 6

Battery Configurations .............................................................................................................................. 6

Field-Installed Accessories ...................................................................................................................... 7

Factory-Installed Accessories.................................................................................................................. 7

HGF Series Frymate (Dump Station) ....................................................................................................... 7

HGFO Series Frymate - Finish Options ............................................................................................ 7

HGFO Series Frymate - Features ...................................................................................................... 7

INSTALLATION ..................................................................................................................................................... 8

Unpacking ................................................................................................................................................. 8

Location..................................................................................................................................................... 9

Installation Codes and Standards ............................................................................................................ 9

In the United States of America ........................................................................................................ 9

In Canada ........................................................................................................................................... 9

Assembly .................................................................................................................................................10

Fryers Mounted on Legs (Non-Batteried Fryers) ..............................................................................10

Fryers Mounted on Casters...............................................................................................................10

Gas Connections .....................................................................................................................................11

Gas Pressures and Orifices ....................................................................................................................11

Testing the Gas Supply Piping System ..................................................................................................11

Leveling Fryer ..........................................................................................................................................12

Flue Connections .....................................................................................................................................12

Electrical Connections .............................................................................................................................12

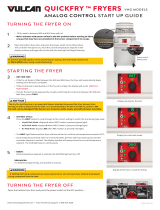

OPERATION .........................................................................................................................................................13

Before First Use.......................................................................................................................................13

Seasoning ..........................................................................................................................................13

Filling Fry Tank With Shortening .............................................................................................................13

Startup With Manual Pilot........................................................................................................................14

Startup With Electronic Igniter ................................................................................................................15

HGS Series ....................................................................................................................................................16

Controls ....................................................................................................................................................16

Using the Fryer (After Startup) ................................................................................................................16

Shutdown .................................................................................................................................................16

Extended Shutdown .................................................................................................................................16

HGD Series ....................................................................................................................................................17

Controls ....................................................................................................................................................17

Control Guide .....................................................................................................................................17

Programming ............................................................................................................................................18

Programming Guide ...........................................................................................................................18

Melt Options (HGD Series) ...............................................................................................................19

Using the Fryer (After Startup) ................................................................................................................20

Models Without Basket Lift Option ...................................................................................................20

Models With Basket Lift Option ........................................................................................................20

Shutdown .................................................................................................................................................20

Extended Shutdown .................................................................................................................................20