Page 6

EDFPB117C, EDFPBM117C, EDFPB117RAC, EDFPBM117RAC, EDFPBV117C,

EDFPBMV117C, EDFPBV117RAC, EBFPBMV117RAC

97922C (Rev. H - 01/18)

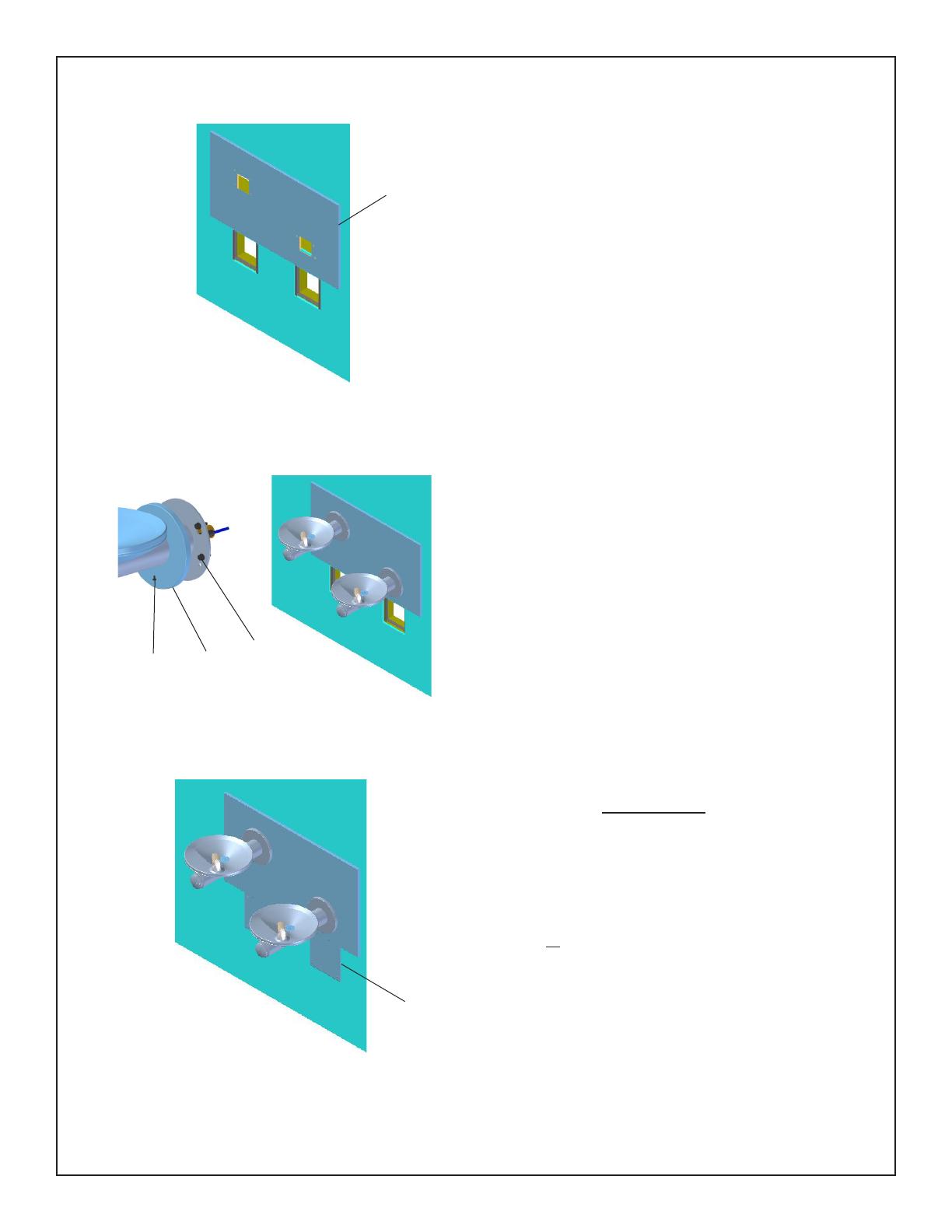

Figure 9 -Panel Installation

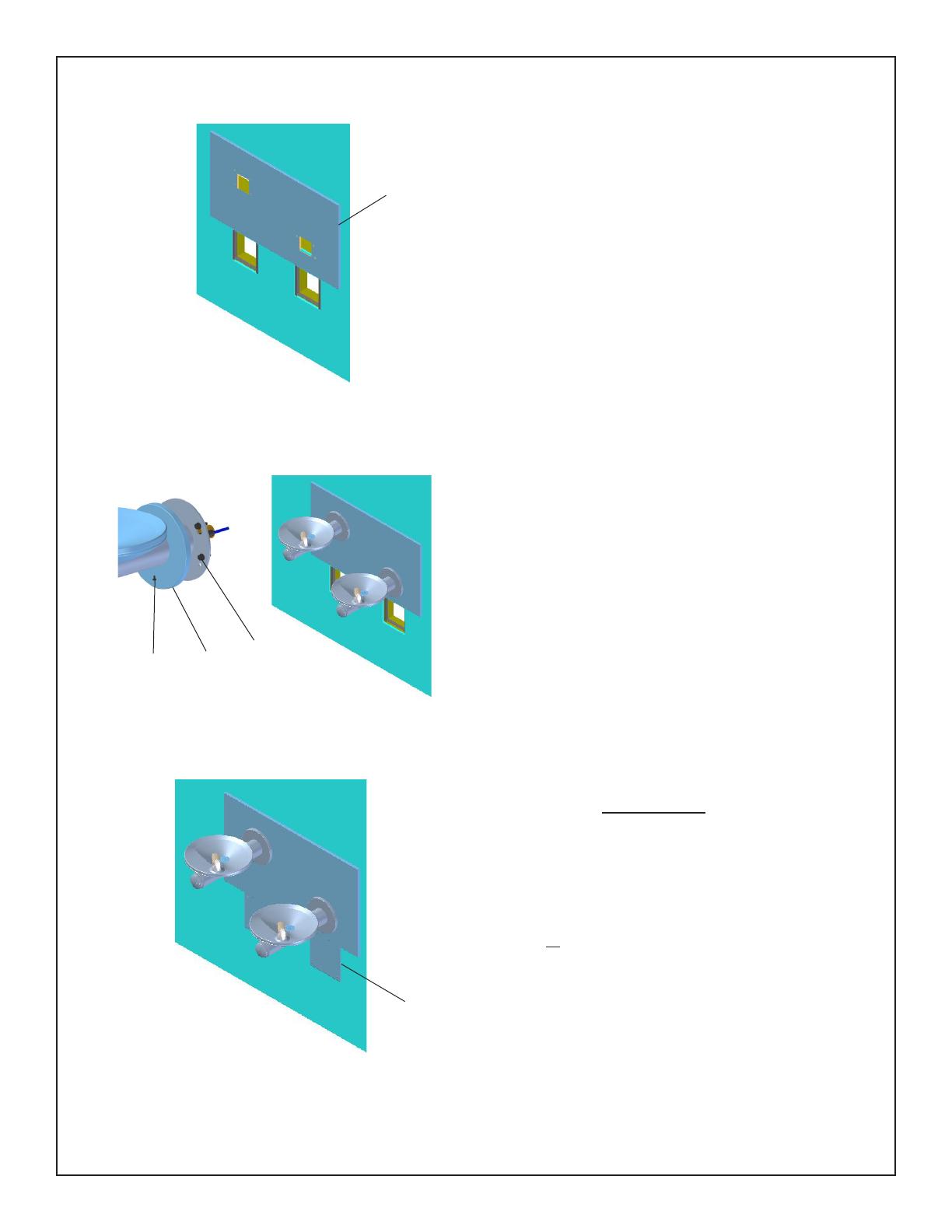

Figure 10 - Fountain Installation

Figure 11 - AP-99 Panel (Optional)

6

9

Installation Instructions:

1. Fountains using the MPW Mounting Plate refer to Figures

5 or 7 for hanger bracket location and rough-in dimensions.

NOTE: Review separate installation instructions for details of the

MPW Mounting Plate.

Fountains using the Wall Plate Assy. refer to Fig’s. 1 or 3

for rough-in dimensions.

2. Shown dimensions pertain to installation location (framing must

support up to 300 lbs. weight). These dimensions are required for

compliance with ANSI Standard A117.0.

3. Install rough-in plumbing as shown in Fig’s. 1, 3, 5, or 7. Run

supply water inlet line through the back panel. Install a service

stop (not provided). Turn on supply water and ush thoroughly.

4. Installing back panel.

Ftn. w/MPW Mounting Plate: Refer to Fig. 16 for placement

of braces onto back panel. Place the upper edge of the panel

above the hanger bracket. Slide the panel down until it engages

the hanger bracket. Be sure back panel is rmly engaged before

releasing it.

Ftn. w/Wall Plate Assy.: Place the upper edge of the panel

above mounting plate on the wall. Slide the panel down until it

engages the mounting plate. Be sure back panel is rmly engaged

before releasing it. (See Figure 9)

5. Install fountain. Remove screw (Item 9) from cover

plate and slide cover plate (Item 14) toward basin. (See Figure 10)

Ftn. w/MPW Mounting Plate: Mount the fountain to the back

panel and wall using (4) 5/16” x 6” long threaded rods, washers,

and nuts (provided). Tighten securely.

Ftn. w/Wall Plate Assy.: Mount the fountain to the back panel

and wall plate assy. with (4) 5/16” x 1” (25mm) long screws

(Item 6 - provided). Tighten securely.

6. Determine required length of waste line and cut to

appropriate length. 1-1/4” O.D. waste tube furnished.

1-1/4” slip trap, waste elbow and extension not provided.

7. Make water supply connections from service stop to the

3/8” O.D. unplated copper tube coming out of the strainer. Turn on

water supply and check for leaks (See Figure 17). Newly installed

water supply line should be insulated after leak check is

completed.

CAUTION: DO NOT SOLDER tubes inserted

into the strainer as damage to the

o-rings may result.

8. These products are designed to operate on 20-105 PSI supply

line pressure. If the inlet pressure is above 105 PSI, a pressure

regulator must be installed in the supply line. Any damage caused

by reason of connecting these products to supply line pressures

lower than 20 PSI or higher than 105 PSI is not covered by

warranty.

9. Check stream height from bubbler. Stream height is factory set at

35 PSI. If supply pressure varies greatly from this, remove push

button (Item 17 - Figure 14) and adjust the screw on the regulator

(Item 19 - Figure 14). To remove push button, remove setscrew

from bottom of sleeve (Item 15). Insert a small punch in screw

hole and push up while grasping the push button and pull forward

removing the push button. Clockwise adjustment will raise stream

height and counterclockwise movement will lower stream height.

For best adjustment stream should hit basin approximately 6-1/2”

from the bubbler. Reassemble the push button by pushing in on

button until the push button catches in the sleeve. Reinstall the

setscrew (Item 5) in the sleeve (Item 15).

19

17

14