Page is loading ...

WHOLE HOUSE CARBON FILTRATION SYSTEMS

1.0, 1.5, 2.0

SERVICE MANUAL

TABLE OF CONTENTS

2

System Information ......................................................................................................................................3

Annual Maintenance Requirements..............................................................................................................4

Pre-Installation Instructions ..........................................................................................................................4

Installation Instructions ..............................................................................................................................5-7

Control Information ......................................................................................................................................8

Programming the Control ........................................................................................................................8-12

Understanding the Diagnostic Level ..........................................................................................................13

Start Up Instructions ..................................................................................................................................14

Exploded Views and Parts Lists ............................................................................................................15-21

Troubleshooting Guide ..........................................................................................................................22-23

Warranty Information ..................................................................................................................................24

SYSTEM INFORMATION

POWER REQUIREMENTS

The computer board receives power from an external wall-mount transformer, supplied with each

system.

Voltage: The voltage supplied to the computer board is 24V AC.

Frequency: The line frequency is 50 Hz or 60 Hz.

WATER PRESSURE

A minimum of 20 pounds of water pressure is required for proper operation of the system. The stated

operating pressure range is 20 psi - 120 psi (138 kPa - 828 kPa).

BYPASS VALVE

The bypass valve enables the customer to bypass the system in situations of: emergency leaks in the

equipment, service calls and/or outdoor water use.

TEMPERATURE OPERATING RANGES

Operating Temperature Range: 40° F - 100° F (4.4° C - 38° C)

Storage Range: The computer board can be stored at temperatures from -20°C (-4°F) to 70°C (158°F).

Humidity: The computer board operates properly with relative humidity from 10% to 95%, non-

condensing.

ENVIRONMENTAL REQUIREMENTS

Location: The water filter and control cannot be exposed to outdoor elements, such as direct sunlight

or atmospheric precipitation. The system may be installed in a covered, open-air structure such as a

carport, residential or commercial building. Weather covers are also available through the Order

Department ( part number 72370 or 71345).

OPERATIONAL SPECIFICATIONS

3

MODEL

MEDIA AMOUNT

(CU.FT)

SERVICE FLOW

RATE

(GAL/MIN)

CHLORINE CAPACITY

((GAL)

PSI DROP AT

SERVICE FLOW

RATE

DRAIN FLOW RATE

(GAL/MIN)

PENTAIR CARBON FILTRATION

SYSTEM 1.0

1.0 CARBON 11.6 400,000 10 5.0

PENTAIR CARBON FILTRATION

SYSTEM 1.5

1.5 CARBON 11.9 600,000 15 5.0

PENTAIR CARBON FILTRATION

SYSTEM 2.0

2.0 CARBON 13.2 800,000 14 7.0

SYSTEMS TESTED AND CERTIFIED BY WQA UNDER NSF/ANSI/CAN 61 FOR MATERIAL SAFETY AND NSF/ANSI 372

FOR LEAD FREE COMPLIANCE ONLY. NOT CERTIFIED FOR CONTAMINANT REDUCTION OR STRUCTURAL

INTEGRITY.

PRE-INSTALLATION INSTRUCTIONS

• Do not install this system where water is microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

• This system must be installed in an area that is not affected by extreme heat, cold or the elements.

The selected installation area must be adequate for easy service of all parts.

• This system must be installed in accordance with all applicable state and local laws and regulations.

• This system is designed to treat cold water only and can be installed on any cold water supply.

ANNUAL MAINTENANCE REQUIREMENTS

• Clean the backwash flow control.

• Verify that the flow meter is functioning correctly. Clean the impeller, if necessary.

• Verify the programming of the control. Reprogram, if necessary.

• Verify the minimum and maximum water pressure. Install a pressure reducer, if necessary.

4

INSTALLATION INSTRUCTIONS

1. SAFETY PRECAUTIONS

• To prevent accident or injury, do not hoist the unit over your shoulder. Use a hand truck to transport

the unit. Note: Do not lay the unit on its side during transportation and/or installation.

• Wear safety glasses and work gloves during installation and service.

2. TEST THE RAW WATER

• If water contains iron, manganese or hydrogen sulfide, a seperate iron removal system is suggested

to be installed prior to the system, consulting with your local dealer.

3. CHECK WATER PRESSURE

• Use a pressure gauge to confirm that the water pressure does not exceed 120 psi. If the water

pressure does exceed this limit, install a pressure regulator on the inlet pipe of the unit. The minimum

pressure for a filter is 20 psi. 60 psi is the optimum operating pressure.

4. LOCATE A SITE FOR THE UNIT

• There are three primary requirements needed for a site: the main water source, a drain (the drain may

be a floor drain, a sewer trap, utility sink, vent stack, dry well, etc., depending on local plumbing

codes) and an electrical connection. Locate the system as close to these items as practical. Avoid

drain lines over 25 feet long. In most applications, bypass any outside faucets.

• Place the unit in the desired location. The location must have a level, smooth surface.

• If the system is located outdoors, protect the unit from direct sunlight. (Direct sunlight can damage

the fiberglass and other system components.) If necessary, build a box or shed. Note: The system can

only be installed outdoors in climates that do not reach freezing levels.

5. TURN OFF THE WATER AND DRAIN THE PLUMBING

• Turn off the water at the meter or the pressure tank.

• Drain all the pipes. Do not sweat the pipes with water in them; steam will damage plastic parts in the

valve.

• To drain the plumbing system, open all the faucets in the house and flush the toilets. This procedure

will allow air to enter the plumbing system. The water will drain out of the lowest faucet or outlet.

6. BYPASS THE OUTSIDE FAUCETS

•When possible it is best to bypass the outside faucets. However in some cases the outside faucets

can not be accessed. In this situation the bypass valve should be used whenever watering outside

for extended periods of time. If the installation is outside or in a garage a faucet can be installed on

the inlet water side to provide an option for untreated water.

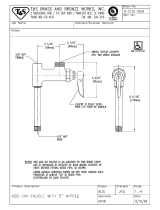

7. CONNECT THE PLUMBING TO THE BYPASS VALVE

• Do not point the soldering torch directly at the system. The thermo-plastic material will last a lifetime,

within normal operating temperatures, but will melt in a torch flame.

• To prevent hot water from backing up into the conditioner,

avoid short connections of pipe between the conditioner

and the hot water heater. If you can’t avoid a short connec-

tion, move the equipment to another location. As a last

resort, install a check valve. If the check valve causes

“water hammer”, install a water hammer suppressor.

5

OUTLET

INLET

• Connect the raw water pipe to the INLET pipe connection of the bypass valve. When looking at the

front of the unit, the inlet is the pipe connection on the LEFT side of the valve.

• Connect the treated water pipe to the OUTLET pipe connection of the bypass valve. When looking at

the front of the unit, the outlet is the pipe connection on the RIGHT side of the valve.

8. PLUMBING GROUND CONNECTION

• In some homes, metal piping may serve as a ground connection for the home electrical system.

Installing a Pentair Filter with its nonmetallic valve body will interrupt the ground connection.

Whenever a system is installed on metallic plumbing, we recommend you use grounding pipe clamps

and a ground cable to maintain continuity of the ground connection from the inlet to the outlet pipe.

¼” bare stranded wire is recommended for the ground cable. Check electrical continuity of the

connection after installation.

9. INSTALL THE DRAIN LINE AND AIR GAP (AIR GAP NOT INCLUDED WITH THE UNIT)

• Using the supplied drain line fitting use Teflon tape on the threads and attach to the top of the valve.

Run 1/2 inch ID flexible drain line tubing ( not supplied) to an appropriate drain. Most local codes

require an air gap. See pictures below.

•If you wish to use an air gap device (not included) you may purchase one from the Order Department.

6

Air Gap_Floor Drain

Part Number: 13142

Air Gap_Mr. Drain,

Part Number: 14199

Option for non-freezing climate only

Note: Drain line may be plumbed with rigid pipe or PEX, if required by local code. The drain

connection on the valve will accommodate any standard 3/4 inch NPT fitting.

Note: For whole house carbon filters and acid neutralizers, the regeneration cycle is a simple

backwash to refresh the filter bed. Since no regeneration chemicals are added, the discharge

water may be drained to the outside and used for irrigation in climates where freezing is not a

concern. See drawing below.

Special Attention for situations where a Filter and a Softener are installed

together:

When a whole house filter and a softener are installed side by side, the preferred approach is to run a

separate drain line from each unit all the way to the point of termination. If this is not done, there is

the potential for drain water from the filter to back feed through the softener and overfill the brine

tank, especially when drain lines are run overhead. (Please note that back feed goes only into the

brine tank, not the service line.)

If circumstances require you to tie the drain lines together, please use one of the following methods

to avoid back feed issues:

Option 1: Run the drain lines from both systems to the point of termination, and tee them together

before the air gap. (See figures below)

Option 2: Install a PVC check valve with a light spring on the Softener side to prevent back flow to

the Softener. (See figure below)

7

WATER IN

TREATED

WATER OUT

2 SEPARATE DRAIN LINES

TO APPROVED DRAIN

LOCATION WITH AIR GAP

FILTER

SOFTENER

2 SEPARATE

DRAIN LINES

AIR GAP

APPROVED FLOOR DRAIN

TEE

FILTER

SOFTENER

SPRING CHECK ON DRAIN

LINE AFTER SOFTENER

WATER IN

TREATED

WATER OUT

TO APPROVED DRAIN

LOCATION WITH AIR GAP

8

CONTROL INFORMATION

POWER ON LED

A green LED is ON when power is applied to the control and the microprocessor is operating properly.

SERVICE REQUIRED

If the message “For Service Call” or “Service Required” displays in the window of the control without

showing the time of day, the control valve has encountered a problem, such as failure to reach the

proper position during regeneration. The valve, the motor assembly, and board must be checked to

diagnose and fix this problem.

Note: It is normal for the message ‘For Service Call’ followed by a phone number to scroll across

the second line of the display. The time of day & capacity remaining will appear on line 1 during

normal operation.

TIME CLOCK

The time clock maintains the time of day for an extended period of time in the event of power loss. A

super capacitor provides this function and eliminates the need of a battery. In the event the power is off

past the charge of the capacitor only the time of day is lost. The rest of the programming is stored in

the memory and will not need to be reprogrammed. When the power is restored the clock will restart

at 8 AM and will need to be reset.

REGENERATION

Once an immediate regeneration is requested, a complete regeneration must occur to clear the

request. Once the regeneration starts, it must finish or the computer board will not clear. Manually walk

(scroll) the control through regeneration to clear the computer board. If the regeneration is aborted and

the request is not cleared, another immediate regeneration will occur.

HIGH-SPEED MOTOR OPERATION IN THE REGENERATION MODE

High-speed motor operation is achieved while stepping the control through the regeneration cycle.

Pressing the scroll button a second time, while in regeneration, activates the higher speed.

PROGRAM LEVELS

To enter any of the program levels, the control must display the time of day and gallons of capacity

remaining (Service Mode).

The system have three program levels available:

1. The Installer’s Level: To access the Installer’s Level, you must enter the five key sequence code

located on page 9. Please refer to pages 9-12 for programming information.

2. The End User’s Level: The End User’s Level does not require a special code to access. Please refer

to page 12 for programming information.

3. The Diagnostic Level: Please refer to page 13 for information.

9

HOW TO PROGRAM THE INSTALLER’S LEVEL

To begin, verify that the control is in the Service Mode.

• Press the DOWN ARROW and hold it for 5 seconds; the control will display:

• Within 10 seconds, enter the following key sequence:

DOWN ARROW

DOWN ARROW

SCROLL BUTTON

DOWN ARROW

The control is now in the Installer’s Level. Use the SCROLL BUTTON to advance through the different

settings.

The following settings are available in the Installer’s Level:

1. CAPACITY

The control will display:

• Press the UP or DOWN ARROW to change the volume of treated water between regenerations. The

gallons are in increments of 100. The setting range is 100 to 999,999 gallons (maximum limit).

Press the SCROLL BUTTON to advance to the next setting.

2. SERVICE PHONE NUMBER

The control will display:

Time of Day GL Remaining

System Check

POWER

POWER

KEY BUTTONS:

SCROLL BUTTON

UP ARROW

DOWN ARROW

Capacity: 1200 GL

Change Phone? No

000-000-0000

• If you do not want to change the phone number, leave this setting at NO. Press SCROLL to advance

to the next setting.

• To change the number, select YES; Press the UP or DOWN ARROW and then enter the service phone

number. Press SCROLL to advance through the digits. After setting the number, press SCROLL to

advance to the next settings.

3. TIME OF DAY

The control will display:

• Press the UP or DOWN ARROW to program the time of day.

Press the SCROLL BUTTON to advance to the next setting.

The control will display:

If you want to go to advanced setting, press the UP or DOWN ARROW, change to YES and press the

SCROLL BUTTON. (see ADVANCED MENU below)

If you do not want to access advance setting, leave this at NO. Press Scroll to advance to Exit screen.

Press the DOWN ARROW to exit the Installer’s Level.

Note: If you need to recheck settings or make a change, pressing SCROLL when “EXIT” is

displayed will take you back to the start of Installer Settings.

IMPORTANT NOTE: TO ACTIVATE THE NEW SETTINGS, YOU MUST EXECUTE A COMPLETE

REGENERATION. IF YOU DO NOT MANUALLY REGENERATE THE SYSTEM, THE SETTINGS WILL

NOT BECOME ACTIVE UNTIL THE UNIT HAS COMPLETED THE NEXT SCHEDULED REGENERA-

TION.

ADVANCED MENU

1. RESET AVERAGE

The control will display:

• If you want to reset the average daily volume, press the UP or DOWN ARROW to select YES.

• If YES is selected, the control will reset the average volume per day to 25% of the capacity.

Press the SCROLL BUTTON to advance to the next setting.

2. RESERVE CAPACITY

The control will display:

• The reserve capacity will be calculated automatically, based on the daily water consumption. The

initial setting is 25% of the capacity, which will adjust over time to accurately reflect daily water use.

•If you prefer, you can select a Fixed Reserve. While at the Reserve screen when “Variable” is

flashing, press the UP or DOWN ARROW. The control will display:

10

Rsrv: Variable

Set Time of Day

Go to ADVANCED menu ? No

To Exit Press Down Arrow

Reset Average No

Rsrv: 200 GL FXd

11

• To adjust the resreve, press the SCROLL BUTTON. Use the UP OR DOWN ARROW to set the reserve

capacity in increments to 10 gallons, upto 70% capacity of the bed.

• To calculate the reserve capacity, take the number of people in the home and multiply it by 70 gallons

per day. The reserve capacity will equal one day of water use.

Example: 3 people X 70 gallons per day = 210 gallons (suggested reserve capacity)

Press the SCROLL BUTTON to advance to the next setting.

3. TIME OF REGENERATION

The control will display:

• Press the UP or DOWN ARROW to adjust the time of regeneration.

Regeneration should be set for a time when water use is minimal.1:00 AM is good for most households.

Note: The system diverts untreated water to the home during regeneration. If any water is drawn

during regeneration, some untreated water will enter the plumbing system and possibly the hot

water tank.

Press the SCROLL BUTTON to advance to the next setting.

4. DAYS OVERRIDE

The control will display:

• Press the UP or DOWN ARROW to set the number of days between regenerations. The setting range

is OFF to 30 days.

Note: In most situations with carbon filter, override can remain “OFF”. Set a number of days if you

wish to have the filter be refreshed periodially regardless of water use.

Press the SCROLL BUTTON to advance to the next setting.

5. CYCLE 1 - BACKWASH

The control will display:

• Press the UP or DOWN ARROW to change the length of the backwash cycle. The setting range is 0

to 99 minutes.

Press the SCROLL BUTTON to advance to the next setting.

6. CYCLE 2 - BRINE/SLOW RINSE

The control will display:

• Press the UP or DOWN ARROW to change the length of the brine/slow rinse cycle. The setting range

is 0 to 99 minutes (maximum limit). Note: In most applications, this setting will not need adjusting.

Press the SCROLL BUTTON to advance the next setting.

7. CYCLE 3 - FAST RINSE/BRINE REFILL

The control will display:

Regen @ 1:00 am

Override: OFF

Backwash: 10 min

BRN/RNS: 0 min

FILL/RNS: 3 min

• Press the UP or DOWN ARROW to change the length of the fast rinse. The setting range is 0 to 99

minutes (maximum limit). Note: In most applications, this setting will not need adjusting.

Press the SCROLL BUTTON to advance to the next setting.

Press the DOWN ARROW to exit the Installer’s Level.

Note: If you need to recheck settings or make a change, pressing SCROLL when “EXIT” is

displayed will take you back to the start of Installer Settings.

IMPORTANT NOTE: TO ACTIVATE THE NEW SETTINGS, YOU MUST EXECUTE A COMPLETE

REGENERATION. IF YOU DO NOT MANUALLY REGENERATE THE SYSTEM, THE SETTINGS WILL

NOT BECOME ACTIVE UNTIL THE UNIT HAS COMPLETED THE NEXT SCHEDULED REGENERA-

TION.

HOW TO PROGRAM THE END USER’S LEVEL

To begin, verify that the control is in the Service Mode.

Press the SCROLL BUTTON to advance to the next setting.

The following settings are available in the End User’s Level:

1. TIME OF DAY

The control will display:

• Press the UP or DOWN ARROW to program the time of day.

Press the SCROLL BUTTON to advance to the next setting.

2. IMMEDIATE REGENERATION MODE

The control will display:

• If the control is left in this position, the timer will countdown from 10 to 0, initiating a regeneration at

0.

• To avoid an immediate regeneration, press the SCROLL BUTTON before the timer reaches 0.

Press the SCROLL BUTTON to advance to the next setting.

3. DELAYED REGENERATION MODE

The control will display:

• If the control is left in this position, the unit will regenerate at the programmed time. The display will

remain in the Delayed Regeneration Mode until the regeneration has begun.

• To cancel the Delayed Regeneration Mode, press the SCROLL BUTTON.

Press the SCROLL BUTTON to return to the Service Mode.

12

To Exit Press Down Arrow

Time of Day GL Remaining

Set Time of Day

Regen in 10 sec

Regen @ (1 am)

13

UNDERSTANDING THE DIAGNOSTIC LEVEL

To begin, verify that the control is in the Service Mode.

• Press the UP ARROW and hold it for 5 seconds; the control will display:

The control is now in the Diagnostic Level. Use the SCROLL BUTTON to advance to each diagnostic.

If no button is pressed within 5 minutes, the display will return to the Service Mode.

The following items are available in the Diagnostic Level (Read Only):

• Regen _ Days Ago: Displays how many days ago the unit last regenerated.

• In Srvc: Displays how many days the control has been in service.

• # of Regens: Displays the number of regenerations that have taken place since the control was first

installed.

• Tot Vol: Displays the total volume of water used since installation.

• Last Rgn @: Displays the amount of water used before the last regeneration.

• Flow Rate: Displays the current flow rate.

• Avg Vol: Displays the average daily water consumption.

• Capacity: The control is programmed for a volume setting. The display will read capacity

along with maximum water to be used before regeneration.

• Rsrv: Displays whether the control is programmed for a Fixed or Variable Reserve.

• Regen @: Displays the time of day the unit will regenerate.

• Override: Displays the override mode by reading “OFF” or the number of days programmed into the

control.

• Backwash: Displays the minutes of backwash programmed into the control.

• BRN/RNS: Displays the minutes of brine and slow rinse programmed into the control.

• FILL/RNS: Displays the minutes of fast rinse and brine refill programmed into the control.

• Units: English - US

• M P Resets: Displays how many times the control has lost power.

• Memory Reset: Displays how many times the control lost power long enough to lose the time of day.

• SP1Fc PlumbR21: Displays the current program.

To exit the Diagnostic Level, press the DOWN ARROW at the EXIT display.

Time of Day GL Remaining

Regen _ Days Ago

SYSTEM START UP INSTRUCTIONS

1. Confirm the system is plumbed in correctly: inlet on left, outlet on right.

2. If you made any mistakes, make the necessary corrections before continuing with startup procedure.

3. When turning the water back on to the house, leave system in bypass mode. Then turn the water on

to the house and check for leaks. Run the cold water in bathtub to flush debris and air from lines.

(Bathtubs do not have aerators that may plug with debris.)

4. Press the SCROLL button 2 times. The display will start a 10 second count down. At zero the motor

will start and advance valve to cycle 1 (backwash). SLOWLY open the INLET VALVE PARTIALLY to

purge the air from the tank without stressing the fresh carbon.

5. Allow to run until there is a steady flow of water at the drain. Once this occurs you may advance valve

to next cycle by pressing and holding briefly the SCROLL button.

6. Once the motor starts, release the SCROLL button. The valve will advance to cycle 3 (fast rinse).

Open the inlet valve fully and allow to run the full 3 minutes of cycle. Once regeneration is complete,

open the outlet valve.

7. Go to a faucet. Run the cold water 5-10 minutes and test for chlorine. Run cold water till 0ppm of

chlorine is achieved. While the water is running, check the gallons remaining on the home screen

and verify that the number is decreasing. This will confirm that the system is counting gallons.

8. Run a faucet on the hot water side until it runs cold to drain hot water tank. If you do not want to

waste water and skip this step, it will take some time to exchange all the untreated water in the

plumbing and hot water tank.

9. The installation is now complete.

14

15

VALVE EXPLODED VIEW

36

36

25

25

34

34

33

33

28

28

29

29

27

27

26

26

32

32

30

30

38

38

23

23

18

18

24

24

31

31

21

21

14

14

20

20

19

19

16

16

17

17

15

15

13

13

12

12

39

39

11

11

10

10

9

9

8

8

37

37

6

6

7

7

5

5

2

2

4

4

3

3

1

1

35

35

40

41

42

43

16

VALVE PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 1

70793 3/4 NPTF TO 1/2 ID HOSE MALE ELBOW (OPTIONAL)

2 1

75074

75075

75076

BACKWASH FLOW CONTROL 5.0 GPM ( SIZE 1.0 & 1.5 CARBON)

BACKWASH FLOW CONTROL 6.0 GPM (SIZE 1.0 ACID NEUTRALIZER)

BACKWASH FLOW CONTROL 7.0 GPM (SIZE 2.0 CARBON)

3 6 72678 SCREW 1/4-20 X 1-1/4 LG HEX WASHER HD

4

1

71083 VALVE BODY COVER

5

1

70658 VALVE COVER O-RING

6

1

72327 TEFLON WASHER

7

1

70665 TEFLON O-RING

8

1

71089 GEAR

9

1

71087 CAM SHAFT

10

1

70656 ROTOR PLATE O-RING

11

1

71132 ROTOR PLATE, COATED

12

1

71084 SEAL DISC, COATED

13

1

71182 INSERT PLATE

14

1

71183 GASKET

15

1

71006 FLOAT VALVE SPRING

16

1

71127 FLOAT VALVE

17

1

70660 FLOAT VALVE O-RING

18

1

72770 VALVE BODY ROTARY GEN-3 W/INSERTS

19

1

71063 INJECTOR #1 RED

20

1

70655 INJECTOR O-RING, LOWER

21

1

70664 INJECTOR O-RING, UPPER

23

1

71947 SPRING CLIP

24

1

71344 RISER INSERT GASKET

25

1

71118 RISER INSERT

26

1

70662 RISER INSERT O-RING

27

1

70663 TANK O-RING

28

1

71010 UPPER BASKET ADAPTER RING

29 2 70630 SCREW #6-19 X 3/4 LG SS

30 1 71060 WORM DRIVE SHAFT

31

1

70616 WORM DRIVE SHAFT TEFLON WASHER

32 2 70666 WORM DRIVE SHAFT O-RING

33 1 70661 PACKING GLAND O-RING

34

1

72772 PLASTIC PACKING GLAND ROTARY

35

1

70667 O-RING

36

1

70659 O-RING

37

1

70932 UMBRELLA CHECK (OPTIONAL)

38

1

71958 BRINE LINE PLUG

39

1 70791 BRINE LINE PLUG THREADED

40 1 72458 FLOW METER DIFFUSER

41 1 72544 IMPELLER ASSY L W/BUSHING

42 1 72545 HUB FLOWMETER ASSY

43 1 72519 FLOW METER SENSOR CABLE

17

CONTROL EXPLODED VIEW

1

2

3

4

6

5

10

7

8

9

12

20

17

18

19

16

13

14

11

3

21

15

22

18

CONTROL PARTS LIST

ITEM QUANTITY PART NUMBER DESCRIPTION

1 1 39497 FRONT COVER ASSY, PENTAIR ROTARY

2 1 38752 BOARD ASSY FILTER WITH 2 LINE DISPLAY

3 3 70618 SCREW #4-24 X 3/8 LG SELF-THREADING

4 1 72519 FLOW METER SENSOR CABLE NGC

5 1 72134 HEYCO BUSHING, SR 5P-4

6 1 70971 POWER LEAD

7 1 70312 HEYCO BUSHING, SR 2P-4

8 1 70962 ELECTRONIC CONTROL BACKPLATE

9 3 71502 SCREW #8-18 X 3/8 LG, SELF-THREADING

10 4 71497 SCREW #10-16 X 1 LG, TYPE BT SS, SELF-THREADING

11 1 75156 ROTARY WORM DRIVE GEAR

12 1 71656 MOTOR, 24VCD WITH INTERNAL CAPACITORS

13 1 75158 1/4IN E RETAINING RING STAINLESS STEEL

14 1 75157 ROTARY WORM COUPLING

15 1 72451 MICROSWITCHES SUBASSY 2401

16 2 70622 SCREW #2-28 X 3/4 LG, SELF-THREADING

17 1 71185 BRACKET

18 1 71106 HUB AND GEAR

19 1 70625 SCREW #6-32 X 7/16 LG

20 1 70965 CAM SHAFT

21 1 71679 MOTOR LEAD

22 1 72138 TRANSFORMER 120VAC .5 A

19

BYPASS VALVE EXPLODED VIEW AND PARTS LIST

BYPASS VALVE ASSEMBLY PART NUMBER 72668

ITEM QUANTITY PART NUMBER DESCRIPTION

1 2 72599 SCREW 6X32X1/2 TYPE

2 1 72580 BYPASS END CAP 541

3 1 13328 017 O-RING 8730

4 2 72584 RETAINING RING VS-15

5 2 71161 568-363 NUT, BYPASS VALVE

6 2 71162 568-364 RING, NUT RETAINER

7 2 71110 568-320 GASKET

8 1 72669 BYPASS BODY ROTARY

9 2 72585 O-RING 220 EPC 70 DURO

10 2 72586 O-RING 222 EPC 70 DURO

11 2 72583 SEAL BYPASS VALVE

12 2 72670 BYPASS HANDLE ROTARY

20

1

2

4

5

3

3

SYSTEM EXPLODED VIEW AND PART LIST

ITEM QUANTITY PART NUMBER DESCRIPTION

1 1

38946 10” PENTAIR PRINTED TANK COLLAR 1.0 & 1.5

38947 12” PENTAIR PRINTED TANK COLLAR 2.0

2 1

38256 10 X 44 TANK BLACK W/BASE 1.0

38257 10 X 54 TANK BLACK W/BASE 1.5

38258 12 X 48 TANK BLACK W/BASE 2.0

3 1

83489 PENTAIR ROTARY VALVE CARBON FLT 1.0 & 1.5 WITH BYPASS

83490 PENTAIR ROTARY VALVE CARBON FLT 2.0 WITH BYPASS

4 1

18961 RISER PIPE ASSY 1.0

18962 RISER PIPE ASSY 1.5

38013 RISER PIPE ASSY 2.0

5 1 70793 3/4" NPT TO 1/2 ID ELBOW

/