Page 6

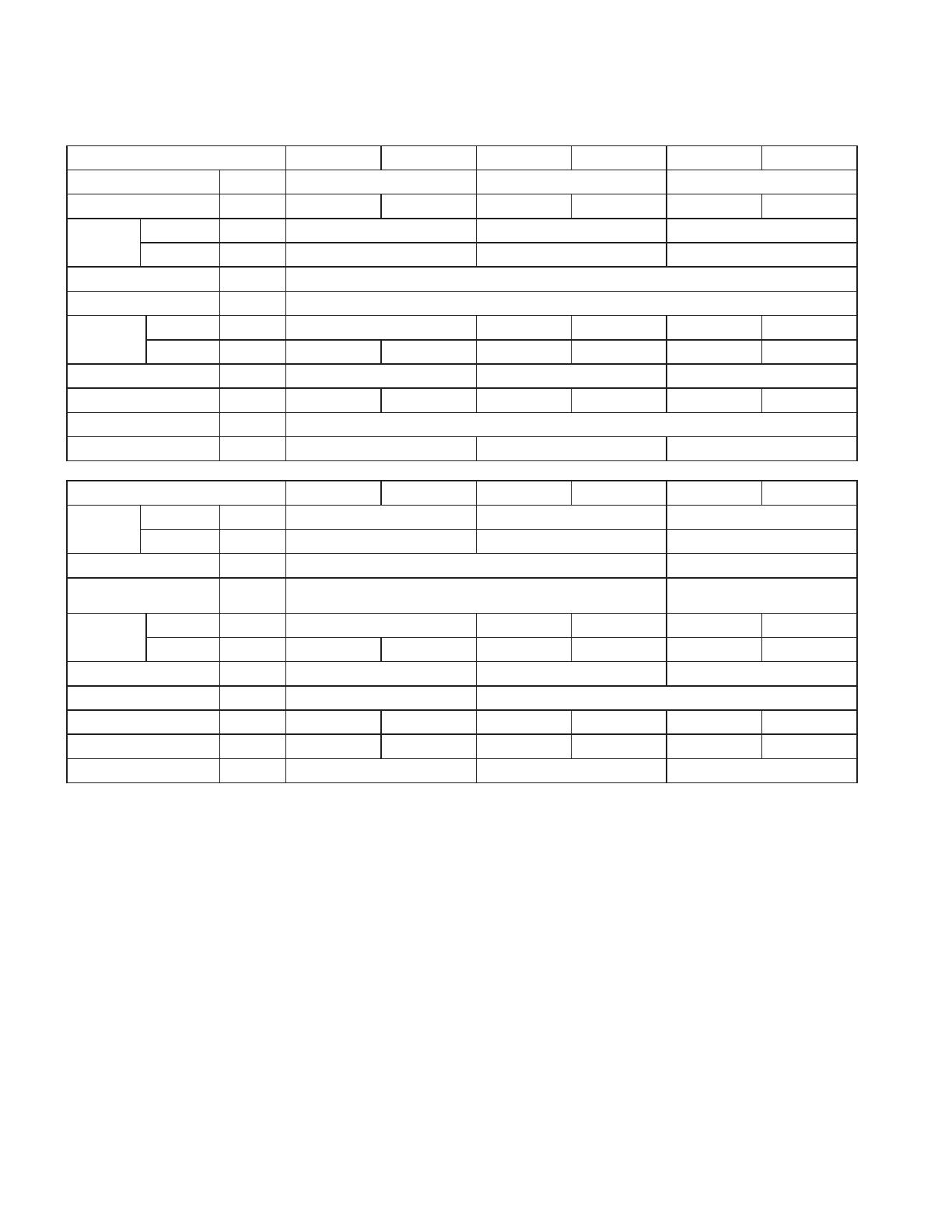

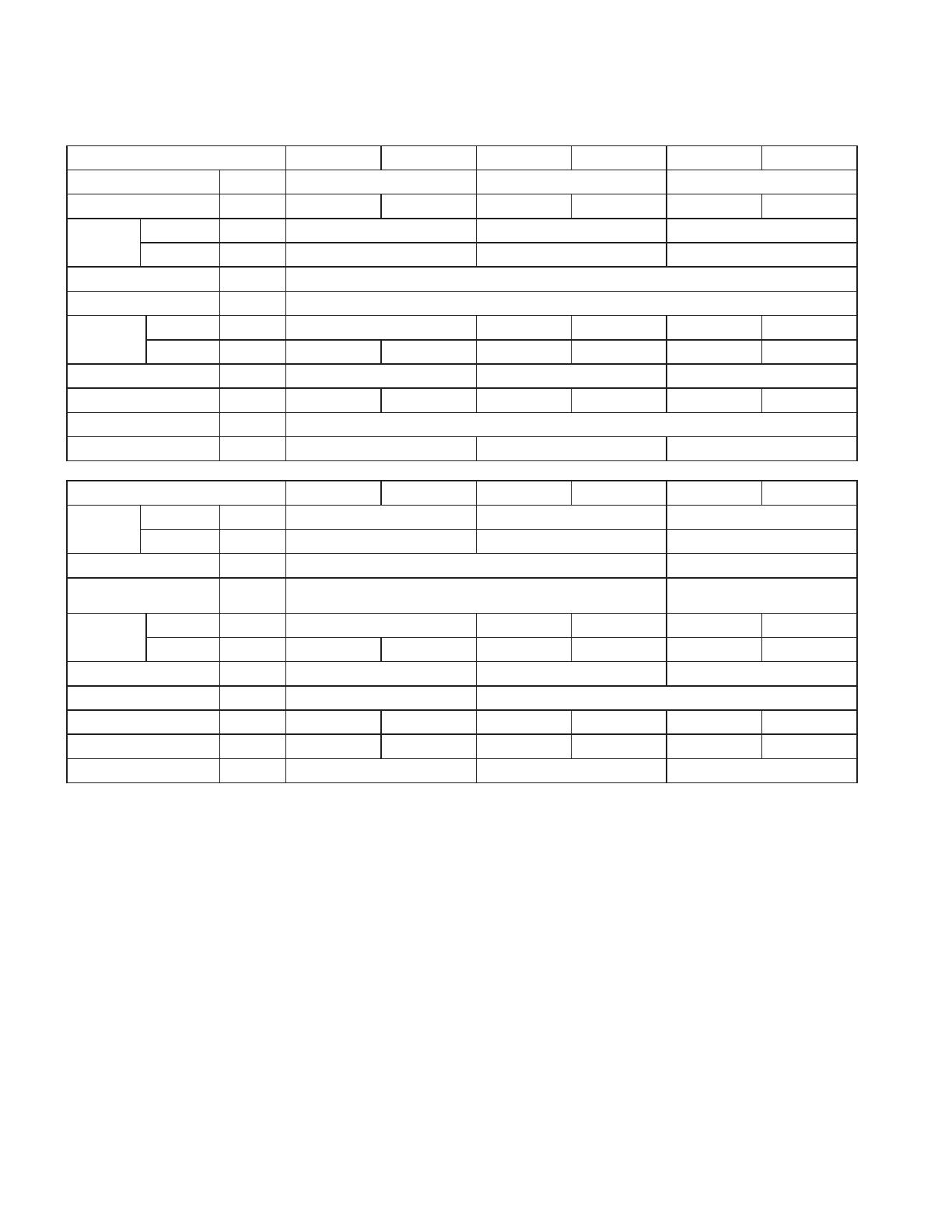

Ceiling Cassette Heat Pump Models

Indoor Unit MCK 020A MCK 020AR MCK 030A MCK 030AR MCK 050A MCK 050AR

Cooling Capacity W 5,600 8,200 12,300

Heating Capacity W —5,600—10,500 — 14,500

Piping Size

Liquid Pipe Φmm(in) 6.35 (1/4") 9.52 (3/8") 9.52 (3/8")

Gas Pipe Φmm(in) 15.88 (5/8") 15.88 (5/8") 19.05 (3/4")

Refrigerant R22

Power Source 220V~/50Hz

Power Input

Cooling W 1,400 2,370 2,370 3,060 3,060

Heating W — 1,480 — 2,490 — 3,290

Air Flow m³/h 1,100 1,300 1,850

Weight(Indoor Unit) kg 37.5 37.5 39.5 39.5 39.5 39.5

ESP Pa 0

Sound Level dB(A) 41 45 49

Outdoor Unit MWSC 020B MWSC 020BR MWSC 030B MWSC 030BR MWSC 050B MWSC 050BR

Piping Size

Liquid Pipe Φmm(in) 6.35 (1/4") 9.52 (3/8") 9.52 (3/8")

Gas Pipe Φmm(in) 15.88 (5/8") 15.88 (5/8") 19.05 (3/4")

Power Source 220V~/50Hz 380V/3N~/50Hz

Protection Device Pressure Protector

Overload. Phase and Pressure

Protector

Rated

Current

Cooling A 6.5 11.4 11.4 5.6 7.0

Heating A —7.1—12.1— 7.3

Water Flow m

3

/h 1.15 1.5 2.37

Water Pipe Size in Rc1/2 Rc3/4

Weight(Outdoor Unit) kg 62 63 91 92 84 85

Charge(R22) kg 1.1 1.13 2.85 2.8 3.3 2.8

Sound Level dB(A) 41 41 42

Note: 1 specifi cation will be subjected to change by manufacturer without prior notice.

2 cooling capacity is based on 26.7

°C(DB),19.4°C(WB) entering air temperature and 29.4°C entering water

temperature,35

°C leaving water temperature.

3 heating capacity is based on 21.1

°C(DB),15.6°C(WB) entering air temperature and 21.1°C entering water

temperature.