Page is loading ...

Öhlins Radial Caliper Bracket Kit is designed for

Brembo radial calipers. The Kit contains left and right

caliper brackets and fork bottom pieces. Spacers

for larger diameter brake disks are provided

Kit 4791-01 includes caliper brackets with 100

mm c-c screw holes.

Kit 4791-02 includes caliper brackets with 108

mm c-c screw holes.

No wheel spacers or fender brackets are included

in this kit.

The brackets have a side offset of 13.3 mm. The

brake discs must have an offset corresponding

to this measure.

CAUTION!

It is of vital importance that brake discs with correct

offset are used

Bracket without spacers fits brake discs with a

diameter of 290 mm.

When spacers are used discs with a diameter of

320 mm can be fitted.

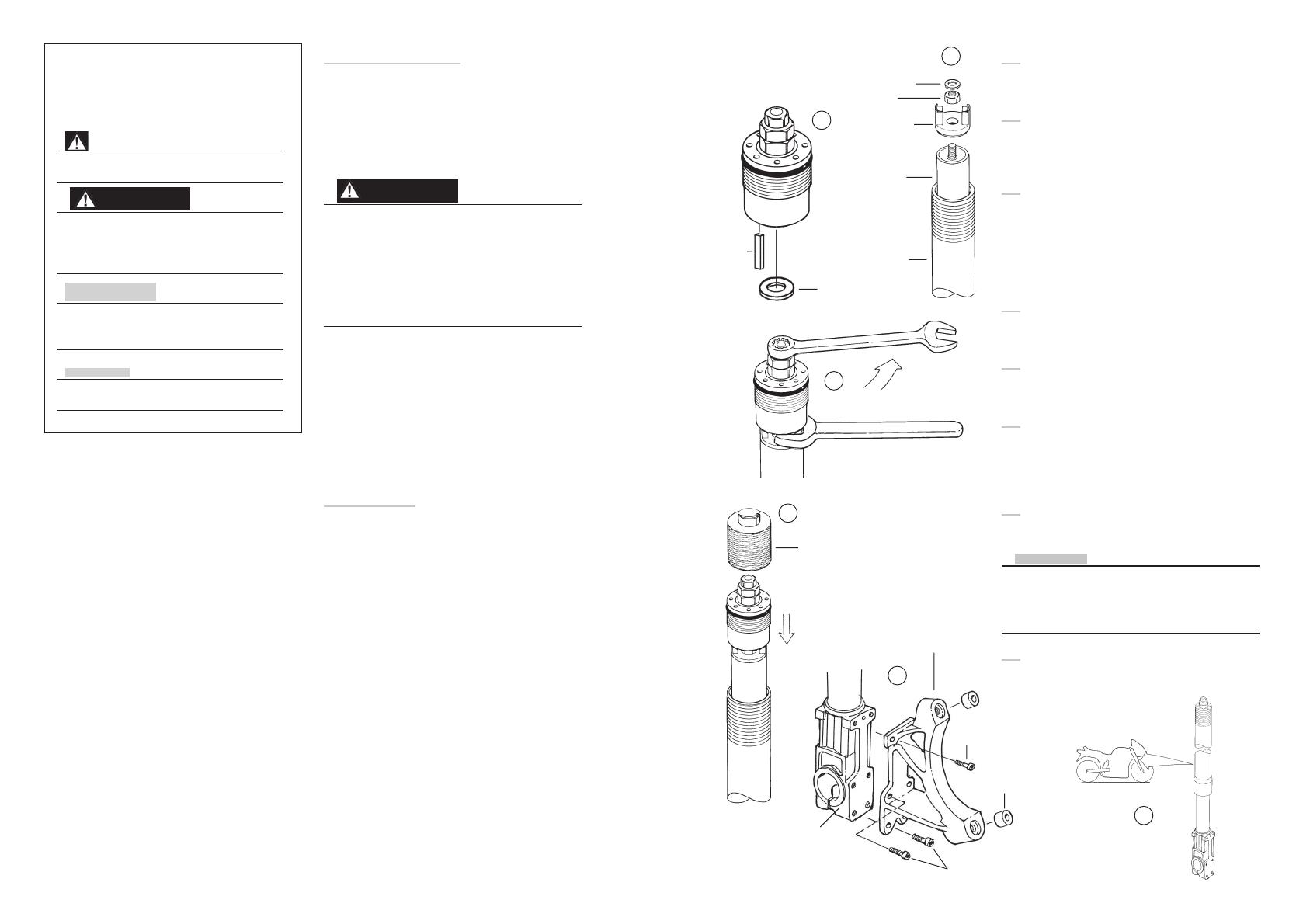

WARNING!

When radial brake calipers are mounted to earlier

Front Forks 43 the fork bottoms must be changed.

New fork bottoms are provided with the kit. Chang-

ing fork bottoms demands good mechanical skills

and special tools. This kit must be changed by an

authorized Öhlins Service Centre

Mounting Instructions

Öhlins Radial Caliper Bracket Kit

04791-01 and 04791-02

© Öhlins Racing AB. All rights reserved. Any reprinting or unauthorized use without the

written permission of Öhlins Racing AB is prohibited. Printed in Sweden.

NOTE!

Before dismantling the front fork check the

settings and make a note on rebound and com-

pression clicks and spring pre-load setting.

Öhlins Racing AB, Box 722, S-194 27 Upplands Väsby, Sweden.

Phone +46 8 590 025 00. Fax +46 8 590 025 80.

www.ohlins.com

Part No. 04791-01. Issued 03 05 12

Checking sag and ride height

Front suspension

F1. Bike on a stand with the

suspension fully extended = ............

F2. Bike on the ground without rider = ............

F3. Bike on the ground with rider = ............

Free sag

F1 - F2 = ............

Ride height

F1 - F3 = ............

Bike on a stand.

F1

R1

Bike on the ground.

F2

R2

Bike with rider on.

F3

R3

Rear suspension

R1.Bike on a stand with the

suspension fully extended = ............

R2.Bike on the ground without rider = ........... .

R3.Bike on the ground with rider = ............

Free sag

R1 - R2 = ............

Ride height

R1 - R3 = ............

Safety signals

Important information concerning safety is

distinguished in this manual by the

following notations:

The Safety alert symbol means:

Caution! Your safety is involved.

WARNING!

Failure to follow warning instructions

could result in severe or fatal injury

to anyone working with, inspecting or

using the suspension, or to bystanders.

CAUTION!

Caution indicates that special pre-

cautions must be taken to avoid dam-

age to the suspension.

NOTE!

This indicates information that is of

importance with regard to procedures.

Before installation

Öhlins Racing AB can not be held responsible for

any damage whatsoever to suspension or vehicle,

or injury to persons, if the instructions for fitting

and maintenance are not followed exactly.

Similarly, the warranty will become null and void

if the instructions are not adhered to.

WARNING!

Installing a suspension, that is not approved

by the vehicle manufacturer, may affect the

stability of your vehicle. Öhlins Racing AB

cannot be held responsible for any personal

injury or damage whatsoever that may occur

after fitting the suspension. Contact an

Öhlins dealer or other qualified person for

advice.

Öhlins products are subject to continual improve-

ment and development. Consequently, although

these instructions include the most up-to-date

information available at the time of printing, there

may be minor differences between your front fork

and this mounting instruction. Please consult your

Öhlins dealer if you have any questions with re-

gard to the contents of the mounting instruction.

Kit contents

Before installing the Caliper Bracket Kit, please

check the contents of the kit. If anything is

missing, contact your Öhlins dealer.

Description Pcs. Part No.

04791-01

Caliper bracket LH 1 01593-13

Caliper bracket RH 1 01593-14

04791-02

Caliper bracket LH 1 01593-11

Caliper bracket RH 1 01593-12

Caliper spacer 4 01669-03

Caliper sleeve 4 01669-02

Fork bottom assy 2 04742-05

O-ring 2 04722-08

Sticker Öhlins 2 00194-10

21

Reinstall the pre load tube, the upper spring seat

and the nut of the piston rod..

22

Apply red grease (146-01) to the washer and the

key and fit them to the top nut assy. (Top nut A/B

assy only)

23

Pull the piston rod upwards and screw it into the

top nut assy. Use Top nut holder (4705-01) or a

17 mm wrench to keep a firm hold of the cartridge

nut, use a 12 mm wrench on top nut assy “A/B”

and a 17 mm wrench on top nut assy “C/D” and

tighten to a torque of 30 Nm.

24

Pull the outer tube up and reinstall the top nut. Use

top nut tool (797-04) and tighten it gently by hand.

25

Fit the radial caliper brackets.

Torque: M8=25Nm, M6=12 Nm.

26

Adjust compression and rebound by first turning

the adjusters clock vise to 0-position. Then turn

them counter clock vise to correct number of

clicks according to your notes. Set the pre-load.

27

Reinstall the fork legs to the motorcycle.

NOTE!

The shaft hole of the fork bottom has a diameter of

32 +0,05 -0 mm. We recommend a sleeve with the

following valves: 32 h9 +0 -0,052. Max. radial play

between the sleeves and the wheel shaft is 0,1 mm.

21

22

23

24

27

25

Washer

Nut

Spring

seat

Pre-load

tube

Outer

tube

Key

Washer

12 mm wrench

17 mm wrench

Top nut assy tool 797-04

Front fork

bottom

Spacer

Caliper bracket

30 Nm

M6 screw

M8 screws

28

The sleeve 01669-02 shall be mounted with the

chamfer inside the caliper bracket, not inside the

brake caliper.

4

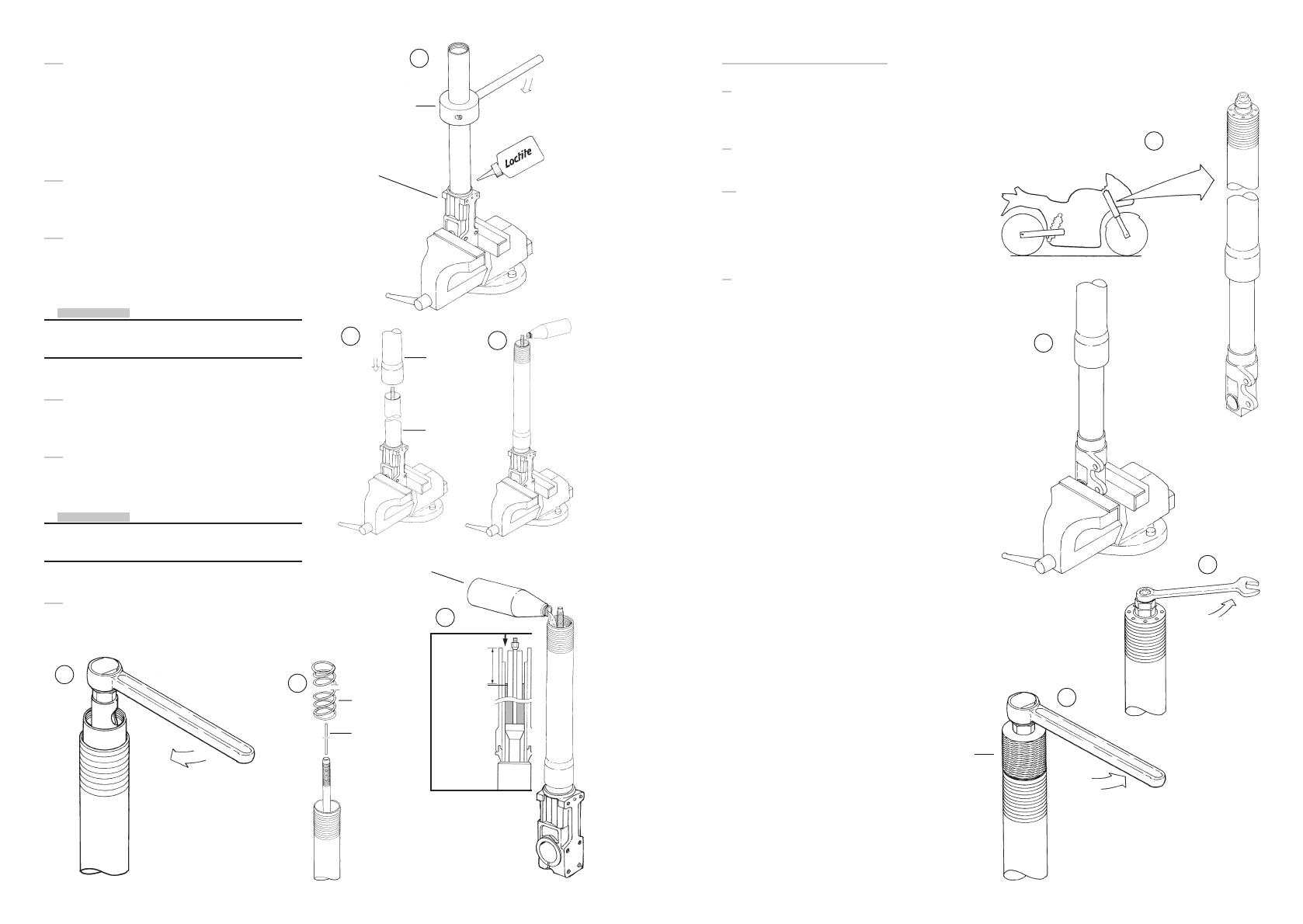

Mounting instructions

1

Remove the front fork legs from the motorcycle.

2

Fasten the fork leg in a vice. Use soft jaws.

3.

Loosen the spring pre load by turning the upper

adjustment nut counter clock vise. Use a 12 mm

wrench to Top nut type “A/B” and a 17 mm

wrench to Top Nut type “C/D”

4

Loosen the top nut assembly. Use Top nut tool

(797-04).

1

2

3

Top nut tool 797-04

15

Make sure that the thread of the inner tube is clean

and free form oil, grease and loctite. Position the

o-ring (04722-08) provided into the bottom piece.

When reinstalling the inner tube to the new fork

bottom piece, locking fluid Loctite 270 or similar

must be used. Tighten to a torque of 110 Nm.

16

Install the outer tube. Fill 500 ml Öhlins front fork

oil (1309-01).

17

Insert the piston rod assy into the cylinder. Apply

some red grease (146-01) to the tread and tighten

to a torque of 40 Nm. Use a torque wrench

NOTE!

Open the compression adjuster fully before

pumping procedure. Use a 3 mm allen tool

18

Push the piston rod up and down until the

cartridge is completely filled with oil.

19

Reinstall the adjustment rod and put the spring

back into the fork leg.

NOTE!

The spring is to be positioned with the marking

number upwards.

20

Measure the oil level and adjust to correct level

(see spec. card for correct data)

17

15

16

16

20

Oil level

See

spec. card for

correct fluid level

Tool 786-05

New bottom piece

Loctite 270

Outer

tube

Inner

tube

Spring

Öhlins front fork oil

1309-01

19

Adjustment

rod

110 Nm

5

Let the outer tube drop down. Use Top nut holder

(4705-01) or a 17 mm wrench to keep a firm hold

of the piston rod nut.

CAUTION!

Beware not to damage the O-ring.

NOTE!

When a standard 17 mm wrench is used, the

upper spring seat must be pressed down, to make

access to the nut.

6

Remove the top nut assy from the piston rod.

Use a 12 mm wrench. On top nut type “A/B” the

washer and the key should be removed.

7

Unscrew and remove the upper nut from the

piston rod to release the upper spring seat and

the pre-load tube.

8

Use a steel wire shaped to a hook in one end to

grip the spring and pull the spring out.

9

Free the front fork from the vice and pour the

front fork fluid out.

NOTE!

The adjustment rod must be held in position not

to fall out.

10

Put the front fork leg back into the vice and care-

fully slide the outer tube upwards to remove it.

NOTE!

Use a cloth to avoid excess oil to trickle out from

the tube

5

7

8

9

Top nut assy

Spring seat

Pre-load tube

Inner tube

Outer tube

Spring

6

12 mm wrench

17 mm wrench

Outer tube

11

Loosen the piston rod assy and pull it out. Use

Cartridge tool (4702-01).

12

Free the fork bottom and inner tube from the vice

and pour the remaining oil out.

13

Fasten the fork bottom to the vice again.

14

Remove the inner tube from the fork bottom. Use

of clamp tool (786-05) and a heat air gun to

release the fork bottom from locking fluid.

12

11

14

Cartridge tool

4702-01

Piston rod

assy

Inner tube

Fork bottom

Heat air gun

Clamp tool

786-05

15

Make sure that the serial number on the old fork

bottom will be printed/punched on the new

NOTE!

This must be done to be able to identify the front

fork in the future!

fork bottom.

/