ESAB MXL 201 MXL 271 MXL 341 MXL 411W MXL 511W User manual

- Category

- Power heat guns

- Type

- User manual

ESAB MXL 201 MXL 271 MXL 341 MXL 411W MXL 511W welding torches are designed for industrial and commercial use in MIG/MAG welding processes. They offer precise control, efficient cooling, and reliable performance, making them suitable for various welding applications.

ESAB MXL 201 MXL 271 MXL 341 MXL 411W MXL 511W welding torches are designed for industrial and commercial use in MIG/MAG welding processes. They offer precise control, efficient cooling, and reliable performance, making them suitable for various welding applications.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

ESAB MXL 201 MXL 271 MXL 341 MXL 411W MXL 511W User manual

- Category

- Power heat guns

- Type

- User manual

ESAB MXL 201 MXL 271 MXL 341 MXL 411W MXL 511W welding torches are designed for industrial and commercial use in MIG/MAG welding processes. They offer precise control, efficient cooling, and reliable performance, making them suitable for various welding applications.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

ESAB MXA253 B 3m Torch & MXA254 B 4m Torch Specification

-

ESAB RT Robo Welding Torch System User manual

-

ESAB ESAB MX Torches User manual

-

ESAB EMP 215ic User manual

-

ESAB EM 215ic User manual

-

ESAB MXL™ 200 User manual

-

ESAB MT-350W Cool Grip Water-Cooled Mig Torch User manual

-

ESAB PSF 420w User manual

-

ESAB EMP 235ic User manual

-

ESAB 270 and 340 MXL Torches User manual

Other documents

-

Ammonite LED ONE User manual

Ammonite LED ONE User manual

-

Schneider 131804 Datasheet

-

Parker Suregrip Digi-Pull Mig Series Owner's Handbook Manual

-

Abicor Binzel ERGO 24.1 Operating Instructions Manual

-

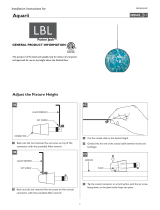

LBL Lighting HS381SC1A50MPT Installation guide

-

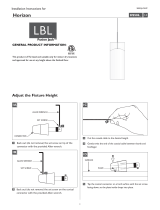

LBL Lighting HS994WHSCLEDS830MPT Installation guide

-

Generation Lighting HS542OPBZLEDS830MPT Installation guide

Generation Lighting HS542OPBZLEDS830MPT Installation guide

-

LBL Lighting HS585BGBZLEDS830MPT Installation guide

-

Generation Lighting HS586OPBZ1BMPT Operating instructions

Generation Lighting HS586OPBZ1BMPT Operating instructions

-

LBL Lighting HS593YPSCLEDS830MPT Installation guide