Toro HoverPro 450 Machine User manual

- Category

- Lawnmowers

- Type

- User manual

This manual is also suitable for

FormNo.3425-134RevA

HoverPro

®

450and550Machines

ModelNo.02610—SerialNo.403230000andUp

ModelNo.02611—SerialNo.402000000andUp

Operator'sManual

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g017365

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Thismachinedoesnotcomeequippedwitha

sparkarresterstandard.Youmustinstallthe

sparkarresterkitbeforeoperatingthismachinein

California.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1349.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginehorsepoweronthis

classmachinewillbesignicantlylower.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUK

AllRightsReserved

*3425-134*A

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Contents

Introduction...............................................................1

Safety.......................................................................2

GeneralSafety...................................................2

SafetyandInstructionalDecals..........................3

Setup........................................................................4

1AssemblingtheHandle....................................4

2InstallingtheFootstop......................................6

3FillingtheEnginewithOil.................................6

ProductOverview.....................................................7

Specications....................................................8

Operation..................................................................8

BeforeOperation...................................................8

BeforeOperationSafety.....................................8

FillingtheFuelTank............................................8

CheckingtheEngine-OilLevel............................9

AdjustingtheCuttingHeight.............................10

DuringOperation.................................................10

DuringOperatingSafety...................................10

StartingtheEngine............................................11

AdjustingtheChoke..........................................12

ShuttingOfftheEngine.....................................12

OperatingTips.................................................13

AfterOperation....................................................14

AfterOperatingSafety......................................14

CleaningtheMachine.......................................14

Maintenance...........................................................15

RecommendedMaintenanceSchedule(s)...........15

MaintenanceSafety..........................................15

PreparingforMaintenance...............................16

ServicingtheAirFilter.......................................16

ChangingtheEngineOil...................................17

ServicingtheSparkPlug...................................17

ReplacingtheBlade..........................................18

Storage...................................................................19

PreparingtheMachineforStorage...................19

Troubleshooting......................................................20

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersasafedistanceawayfromthe

machine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

2

SafetyandInstructionalDecals

Safetyandinstructionaldecalsareeasilyvisibleandarelocatednearareasofpotential

danger.Replaceanydamagedormissingdecal.

decal130-8322

130-8322

1.Useonlyfuelwithan

alcoholcontentbyvolume

under10%.

3.Donotusefuelwithan

alcoholcontentbyvolume

greaterthan10%.

2.ReadtheOperator's

Manualformore

informationonfuel.

decal111-9826

111–9826

1.Cutting/dismemberment

hazardofhandorfoot,

cuttingunit—keepyour

handsandfeetawayfrom

movingparts.

2.ReadtheOperator’s

Manual.

decal111-5393

111-5393

1.Warning—Receivetrainingontheproduct;readthe

Operator’sManual.

4.Thrownobjecthazard;keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhandorfoot,mowerblade;

disconnectthewirefromthesparkplugbeforeworkingonthe

machine;nevertmetalcuttingparts.

5.Warning—donottouchhotsurfaces;keepguardsinplace;

Stayawayfrommovingparts;keepguardsinplace.

3.Warning—weareyeandhearingprotection.

3

decal94-8072

94-8072

1.Warning—cutting/dismembermenthazardofhandorfoot,

cuttingmechanism.

g017410

H295159

1.Enginestop(shutoff)

decal133-8062

133-8062

Setup

1

AssemblingtheHandle

NoPartsRequired

Procedure

1.Slide2bushingsintotheframe.

g017333

Figure3

1.Lowerhandle4.Frame

2.Bushings5.Bolt

3.Nut6.Washers

2.Placethelowerhandlebetweenthebushings

andsecureitwith1handlebarbolt,2washers,

and1nut.

4

Note:Placethelowerhandlebetweenthe

bushingswiththekickstopassemblyattheright

side.

3.Repeatfortheoppositeside.

4.Aligntheholesontheupperhandlewiththe

lowerhandle.

g209291

Figure4

1.Upperhandle4.U-bolt

2.Handwheel5.Lowerhandle

3.Washer

5.FittheU-boltthroughtheupperandlower

handleandsecureitwithawasherandahand

wheel.

6.Attachthethrottleassemblytotheoutsideofthe

handlebarandsecureitwithanutandapan

screw.

g209280

Figure5

1.Nut2.Panscrew

5

2

InstallingtheFootstop

NoPartsRequired

Procedure

Securethefootstoptotheboltontherightsideofthe

lowerhandleusinganutand2washers(Figure6).

Note:Installthefootstopusingthelowerholeinthe

footstopasshowninFigure6.

g027774

Figure6

1.Footstop4.Bolt

2.Nut5.Lowerhandle

3.Washer

3

FillingtheEnginewithOil

NoPartsRequired

Procedure

Important:Yourmachinedoesnotcomewithoil

intheengine.Beforestartingtheengine,llthe

enginewithoil.

EngineOilSpecications

Engineoilcapacity

0.59L(20oz)

OilviscositySAE10W-30multigrade

mineraloil

APIserviceclassicationSJorhigher

1.Movethemachinetoalevelsurface.

2.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout(Figure7).

g017332

Figure7

1.Full3.Low

2.High

3.Carefullypourabout3/4oftheenginecapacity

ofoilintotheoil-lltube(Figure8).

6

g017338

Figure8

4.Wait3minutesfortheoiltosettleintheengine.

5.Wipethedipstickcleanwithacleancloth.

6.Insertthedipstickintotheoil-lltube,butdonot

screwitin,thenremovethedipstick.

7.Readtheoillevelonthedipstick(Figure7).

•Iftheoillevelonthedipstickistoolow,

carefullypourasmallamountofoilintothe

oil-lltube,wait3minutes,andrepeatsteps

5through7untiltheoilonthedipstickisat

thecorrectlevel.

•Iftheoillevelonthedipstickistoohigh,drain

theexcessoiluntiltheoilonthedipstickis

atthecorrectlevel;refertoChangingthe

EngineOil(page17).

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,you

maydamagetheengine.

8.Installthedipstickandhandtightenitsecurely.

Important:Changetheengineoilafterthe

rst5operatinghours;changeityearly

thereafter.RefertoChangingtheEngineOil

(page17).

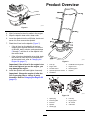

ProductOverview

g017341

Figure9

1.Fuelcap6.Handlebarsecuringknob

2.Enginestart7.Enginecover

3.Throttlecontrol8.Exhaustguard

4.Operator-presencecontrol

9.Dipstick

5.Handlebar

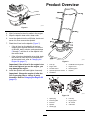

g017335

Figure10

1.Sparkplug

6.Fuelcap

2.Exhaustguard7.Fingerguard

3.Exhaust8.Aircleaner

4.Dipstick

9.Carburetor

5.Startergrip

7

Specications

Model

Cuttingwidth

Productwidth

02610

46.5cm(18-1/2

inches)

57.5cm(22-1/2

inches)

02611

53.5cm(21inches)63.5cm(25inches)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Checkthatallguardsandsafetydevicesarein

placeandworkingproperly.

•Alwaysinspectthemachinetoensurethatthe

blades,bladebolts,andcuttingassemblyarenot

wornordamaged.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Adjustingthecuttingheightmaybringyouinto

contactwiththemovingblade,causingserious

injury.

–Shutofftheengineandwaitforallmoving

partstostop.

–Disconnectthespark-plugwirefromthespark

plugbeforeadjustingthecuttingheight.

FuelSafety

DANGER

Fuelisextremelyammableandhighly

explosive.Areorexplosionfromfuel

canburnyouandothersandcandamage

property.

•Topreventastaticchargefromignitingthe

fuel,placethecontainerand/ormachine

directlyonthegroundbeforelling,notin

avehicleoronanobject.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Donothandlefuelwhensmokingor

aroundanopenameorsparks.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•Donotuseethanolblendsofgasoline,such

asE15orE85,withmorethan10%ethanolby

volume.Performanceproblemsand/orengine

damagemayresult,whichmaynotbecovered

underwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorinfuel

containersoverthewinterunlessfuelstabilizer

hasbeenaddedtothefuel.

•Donotaddoiltogasoline.

Fillthefueltankwithfreshunleadedregulargasoline

fromamajorname-brandservicestation(Figure11).

Important:Toreducestartingproblems,addfuel

stabilizer/conditionertofreshfuelasdirectedby

thefuel-stabilizermanufacturer.

8

Refertoyourengineowner’smanualforadditional

information.

g017340

Figure11

CheckingtheEngine-Oil

Level

1.Movethemachinetoalevelsurface.

2.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout(Figure12).

g017332

Figure12

1.Full3.Low

2.High

3.Wipethedipstickcleanwithacleancloth.

4.Insertthedipstickintotheoil-lltube,butdonot

screwitin,thenremovethedipstick.

5.Readtheoillevelonthedipstick(Figure12).

•Iftheoillevelonthedipstickistoolow

(Figure12),carefullypourasmallamountof

multigrademineralSAE10W-30oilwithan

APIseriesclassicationofSJorhigherinto

theoil-lltube,wait3minutes,andrepeat

steps3through5untiltheoilonthedipstick

isatthecorrectlevel.

•Iftheoillevelonthedipstickistoohigh

(Figure12),draintheexcessoiluntiltheoil

onthedipstickisatthecorrectlevel;referto

ChangingtheEngineOil(page17).

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,you

maydamagetheengine.

6.Installthedipstickintotheoil-lltubesecurely.

Important:Changetheengineoilafterthe

rst5operatinghours;changeityearly

thereafter.RefertoChangingtheEngineOil

(page17).

9

AdjustingtheCutting

Height

WARNING

Adjustingthecuttingheightmaybringyou

intocontactwiththemovingblade,causing

seriousinjury.

•Shutofftheengineandwaitforallmoving

partstostop.

•Weargloveswhilehandlingthecutting

unit.

CAUTION

Iftheenginehasbeenrunning,themufer

willbehotandcanseverelyburnyou.

Keepawayfromthehotmufer.

Adjustthecuttingheightasdesired.

1.TurnthefuelswitchtotheOFFposition.

2.Disconnectthewirefromthesparkplug.

3.Tipthemachineonitssidewiththedipstick

down.

4.Wearingprotectivegloves,removetheblade

boltandcuttingunit.

5.Positionthespacerstothedesiredheight,then

installthecuttingunitasshowninFigure13.

g017336

Figure13

1.Cutterbar

4.Bladebolt

2.Spacers

5.Largespacer

3.Bladeretainer

Note:Thelargespacermustbedirectlybelow

theimpelleratalltimes.

6.Torquethebladeboltto25N∙m(18ft-lb).

DuringOperation

DuringOperatingSafety

GeneralSafety

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Thebladeissharp;contactingthebladecanresult

inseriouspersonalinjury.Shutofftheengine,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

•Whenyoureleasetheoperator-presencecontrol,

theengineshouldshutoffandthebladeshould

stopwithin3seconds.Ifnot,stopusingyour

machineimmediatelyandcontactanAuthorized

ServiceDealer.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflighting.

•Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.Avoidmowingin

wetconditionsifpossible.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayblockyourview.

•Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldcausea

slip-and-fallaccident.

•Stopthemachineandinspectthebladesafter

strikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Beforeleavingtheoperatingposition,shutoffthe

engine,andwaitforallmovingpartstostop.

•Iftheenginehasbeenrunning,themuferwillbe

hotandcanseverelyburnyou.Keepawayfrom

thehotmufer.

•Useaccessoriesandattachmentsapprovedby

TheToro®Companyonly.

10

SlopeSafety

•Beforeoperatingonanyslope,completeasite

surveytodeterminetheactualslopewhereyou

willoperatethemachine.

•Avoidmowingonwetgrass.Poorfootingcould

causeaslip-and-fallaccident.

•Mowwithcautionneardrop-offs,ditches,or

embankments.

•Whenusingthemachine,alwayskeepbothhands

onthehandle.

•Whencuttingfromthetopofasteepslopeand

youneedlongerreach,useanapprovedextended

handleifyouneedalongerreach.

StartingtheEngine

1.Placethethrottlecontroltothechokeposition,

ensurethatthefuelswitchisintheONposition.

g017346

Figure14

2.Holdtheoperator-presencecontrolagainstthe

handle.

g017334

Figure15

1.Handle

2.Operator-presencecontrol

3.Placeyourfootonthedeckandtiltthemachine

towardyou(Figure16).

g017329

Figure16

4.Pulltherecoil-starthandle.

Note:Ifthemachinedoesnotstartafterseveral

attempts,contactanAuthorizedServiceDealer.

11

AdjustingtheChoke

Usethethrottleassemblytoadjustthechoke(Figure

17).

g017367

Figure17

1.Chokeon2.Chokeoff

ShuttingOfftheEngine

ServiceInterval:Beforeeachuseordaily

Toshutofftheengine,releasetheoperator-presence

control(Figure18).

Important:Whenyoureleasethe

operator-presencecontrol,boththeengine

andbladeshouldstopwithin3seconds.Ifthey

donotstopproperly,stopusingyourmachine

immediatelyandcontactanAuthorizedService

Dealer.

g017366

Figure18

12

OperatingTips

GeneralMowingTips

Important:Operatingthemachineonslopesof

morethan45°willcausesevereenginedamage

duetoalackoflubrication.Donotoperatethe

machineonslopesgreaterthan45°.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Avoidstrikingsolidobjectswiththeblade.Never

deliberatelymowoveranyobject.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelyshutofftheengine,disconnect

thewirefromthesparkplug,andexaminethe

machinefordamage.

•Forbestperformance,installanewbladebefore

thecuttingseasonbegins.

•ReplacethebladewhennecessarywithaToro

replacementblade.

CuttingGrass

•Cutonlyaboutathirdofthegrassbladeata

time.Donotcutbelowthehighestsettingunless

thegrassissparseoritislatefallwhengrass

growthbeginstoslowdown.RefertoAdjusting

theCuttingHeight(page10).

•Mowinggrassover15cm(6inches)inlengthis

notrecommended.Ifthegrassistoolong,the

machinemayplugandcausetheenginetostall.

•Wetgrassandleavestendtoclumpontheyard

andcancausethemachinetoplugortheengine

tostall.Avoidmowinginwetconditions.

WARNING

Wetgrassorleavescancauseserious

injuryifyouslipandcontacttheblade.

Mowonlyindryconditions,ifpossible.

•Beawareofapotentialrehazardinverydry

conditions,followalllocalrewarnings,andkeep

themachinefreeofdrygrassandleafdebris.

•Ifthenishedlawnappearanceisunsatisfactory,

try1ormoreofthefollowing:

–Replacethebladeorhaveitsharpened.

–Walkataslowerpacewhilemowing.

–Raisethecuttingheightonyourmachine.

–Cutthegrassmorefrequently.

–Overlapcuttingswathsinsteadofcuttingafull

swathwitheachpass.

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthelawn

showsthroughthecutleafcover.Youmayneed

tomakemorethanasinglepassovertheleaves.

•Mowinggrassover15cm(6inches)inlengthis

notrecommended.Iftheleafcoveristoothick,the

machinemayplugandcausetheenginetostall.

•Slowdownyourmowingspeedifthemachine

doesnotcuttheleavesnelyenough.

13

AfterOperation

AfterOperatingSafety

GeneralSafety

•Cleangrassanddebrisfromthemachinetohelp

preventres.Cleanupoilorfuelspills.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

HaulingSafety

•Usecarewhenloadingorunloadingthemachine.

•Securethemachine.

•Usecarewhenloadingandunloadingthemachine

toavoidsharpedges.

CleaningtheMachine

ServiceInterval:Beforeeachuseordaily

Aftereachuse

WARNING

Themachinemaydislodgematerialfrom

underthemachinehousing.

•Weareyeprotection.

•Stayintheoperatingposition(behindthe

handle).

•Donotallowbystandersinthearea.

1.Tipthemachineonitssidewiththedipstick

down.

2.Useabrushorcompressedairtoremovegrass

anddebrisfromtheexhaustguard,thetopcowl,

andthesurroundingdeckareas.

14

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Beforeeachuseordaily

•Ensurethattheengineshutsoffwithin3secondsafterreleasingthe

operator-presencecontrol.

•Cleangrassclippingsanddirtfromtheentiremachine.

Aftereachuse

•Cleangrassclippingsanddirtfromtheentiremachine.

Beforestorage

•Emptythefueltankbeforerepairsasdirectedandbeforeannualstorage.

•Cleanthecoolingsystem;removegrassclippings,debris,ordirtfromtheengine

aircoolingnsandstarter.Cleanthesystemmorefrequentlyindirtyorhigh-chaff

conditions.

Yearly

•Servicetheairlter;serviceitmorefrequentlyindustyoperatingconditions.

•Changetheengineoil.

•Servicethesparkplugandreplaceitifnecessary.

•Replacethebladeorhaveitsharpened(morefrequentlyiftheedgedullsquickly).

MaintenanceSafety

•Disconnectthespark-plugwirefromthesparkplug

beforeperforminganymaintenanceprocedure.

•Wearglovesandeyeprotectionwhenservicing

themachine.

•Thebladeissharp;contactingthebladecanresult

inseriouspersonalinjury.Weargloveswhen

servicingtheblade.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Tippingthemachinemaycausethefueltoleak.

Fuelisammableandexplosive,andcancause

personalinjury.Runtheenginedryorremovethe

fuelwithahandpump;neversiphonthefuel.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

15

PreparingforMaintenance

WARNING

Tippingthemachinemaycausethefuelto

leak.Fuelisammable,explosiveandcan

causepersonalinjury.

Runtheenginedryorremovethefuelwitha

handpump;neversiphon.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthespark-plugwirefromthe

sparkplug(Figure19)beforeperformingany

maintenanceprocedure.

Important:Alwaystipthemachineontoits

side,withthedipstickdown.Ifthemachine

istippedinanotherdirection,oilmayllthe

valvetrain,requiringatleast30minutesto

drain.

g017342

Figure19

1.Spark-plugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthespark-plugwiretothesparkplug.

ServicingtheAirFilter

ServiceInterval:Yearly

1.Pressdownonthelatchtabsontopofthe

air-ltercover(Figure20).

g017339

Figure20

1.Cover

3.Filter

2.Latchtabs

2.Openthecover.

3.Removetheair-lterelements(Figure20).

4.Inspecttheairlterandreplaceitifitisdamaged

orexcessivelydirty.

5.Inspectthepaperairlter.

A.Ifthelterisdamagedoriswetwithoilor

fuel,replaceit.

B.Ifthelterisdirty,tapitonahardsurface

severaltimesorblowcompressedairless

than207kPa(30psi)throughthesideof

thelterthatfacestheengine.

Note:Donotbrushthedirtoffthelter;

brushingforcesdirtintothebers.

6.Removedirtfromtheair-lterbodyandcover

usingamoistrag.

Important:Donotwipedirtintotheairduct.

7.Inserttheair-lterelementsintotheair-lter

body.

8.Installthecover.

16

ChangingtheEngineOil

ServiceInterval:Yearly

Note:Runtheengineafewminutesbeforechanging

theoiltowarmit.Warmoilowsbetterandcarries

morecontaminants.

EngineOilSpecications

Engineoilcapacity

0.59L(20oz)

OilviscositySAE10W-30multigrade

mineraloil

APIserviceclassicationSJorhigher

1.Ensurethatthefueltankcontainslittleornofuel

sothatthefueldoesnotleakwhenyoutipthe

engineontoitsside.

2.RefertoCheckingtheEngine-OilLevel(page9).

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout(Figure21).

g017332

Figure21

1.Full3.Low

2.High

4.Tipthemachineontoitsside(sothattheairlter

isup)todraintheusedoilfromtheoil-lltube.

5.Afterdrainingtheusedoil,returnthemachineto

theoperatingposition.

6.Carefullypourabout3/4oftheenginecapacity

ofoilintotheoil-lltube.

7.Wait3minutesfortheoiltosettleintheengine.

8.Wipethedipstickcleanwithacleancloth.

9.Insertthedipstickintotheoil-lltube,butdonot

screwitin,thenremovethedipstick.

10.Readtheoillevelonthedipstick(Figure21).

•Iftheoillevelonthedipstickistoolow,

carefullypourasmallamountofoilintothe

oil-lltube,wait3minutes,andrepeatsteps

8through10untiltheoillevelonthedipstick

iscorrect.

•Iftheoillevelonthedipstickistoohigh,

draintheexcessoiluntiltheoillevelonthe

dipstickiscorrect.

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,you

maydamagetheengine.

11.Installthedipstickintotheoil-lltubesecurely.

12.Recycletheusedoilproperly.

ServicingtheSparkPlug

ServiceInterval:Yearly—Servicethesparkplugand

replaceitifnecessary.

UseaT orosparkplug;contactanAuthorizedService

Dealer.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug(Figure

19).

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercan

damagetheengine.

5.Setthegapontheplugto0.76mm(0.030inch)

asshowninFigure22.

g000533

Figure22

1.Center-electrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

6.Installthesparkplug.

7.T orquetheplugto27to30N∙m(20to22ft-lb).

8.Connectthewiretothesparkplug.

17

ReplacingtheBlade

ServiceInterval:Yearly

Important:Youwillneedatorquewrenchto

installthebladeproperly.Ifyoudonothavea

torquewrenchorareuncomfortableperforming

thisprocedure,contactanAuthorizedService

Dealer.

Examinethebladewheneveryourunoutoffuel.Ifthe

bladeisdamagedorcracked,replaceitimmediately.

Ifthebladeedgeisdullornicked,haveitsharpened

andbalanced,orreplaceit.

WARNING

Thebladeissharp;contactingthebladecan

resultinseriouspersonalinjury.

•Disconnectthewirefromthesparkplug.

•Weargloveswhenservicingtheblade.

1.RefertoPreparingforMaintenance(page16).

2.Tipthemachineontoitsside,withthedipstick

down.

3.Useablockofwoodtoholdthebladesteady.

g209201

Figure23

4.Removetheblade(turnthebladebolt

counterclockwise),savingallthemounting

hardware.

5.Installthenewblade(turnthebladebolt

clockwise)andallmountinghardware.

Important:Positionthecurvedendsofthe

bladetopointtowardthemachinehousing.

6.Useatorquewrenchtotightenthebladebolt

to25N∙m(18ft-lb).

Important:Whileholdingthebladewith

ablockofwood,putyourweightbehind

theratchetorwrenchandtightenthe

boltsecurely.Thisboltisverydifcultto

overtighten.

18

Storage

Storethemachineinacool,clean,dryplace.

PreparingtheMachinefor

Storage

WARNING

Fuelvaporscanexplode.

•Donotstorefuelmorethan30days.

•Donotstorethemachineinanenclosure

nearanopename.

•Allowtheenginetocoolbeforestoringit.

1.Onthelastrefuelingoftheyear,addfuel

stabilizertothefuelasdirectedbytheengine

manufacturer.

2.Runthemachineuntiltheengineshutsofffrom

runningoutoffuel.

3.Primetheengineandstartitagain.

4.Allowtheenginetorununtilitshutsoff.

Whenyoucannolongerstarttheengine,itis

sufcientlydry.

5.Disconnectthewirefromthesparkplug.

6.Removethesparkplug,add30ml(1oz)of

oilthroughthespark-plughole,andpullthe

starterropeslowlyseveraltimestodistribute

oilthroughoutthecylindertopreventcylinder

corrosionduringtheoff-season.

7.Installthesparkplugandtightenitwithatorque

wrenchto20N∙m(15ft-lb).

8.Tightenallnuts,bolts,andscrews.

19

Troubleshooting

Problem

PossibleCauseCorrectiveAction

1.Thewireisnotconnectedtothespark

plug.

1.Connectthewiretothesparkplug.

2.Theholeinthefuel-capventis

plugged.

2.Cleantheholeinthefuel-capventor

replacethefuelcap.

3.Thesparkplugispitted,fouled,orthe

gapisincorrect.

3.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

Theenginedoesnotstart.

4.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

4.Drainand/orllthefueltankwithfresh

fuel.Iftheproblempersists,contactan

AuthorizedServiceDealer.

1.Theholeinthefuel-capventis

plugged.

1.Cleantheholeinthefuel-capventor

replacethefuelcap.

2.Theairlterelementisdirtyandis

restrictingtheairow.

2.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

3.Theundersideofthemachinehousing

containsclippingsanddebris.

3.Cleanunderthemachinehousing.

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

4.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

5.Theengineoil-levelistoolow,too

high,orexcessivelydirty.

5.Checktheengineoil.Changetheoilif

itisdirty;addordraintheoiltoadjust

theoilleveltotheFullmarkonthe

dipstick.

Theenginestartshardorlosespower.

6.Thefueltankcontainsstalefuel.

6.Drainandllthefueltankwithfresh

fuel.

1.Thewireisnotconnectedtothespark

plug.

1.Connectthewiretothesparkplug.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

2.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

Theenginerunsrough.

3.Theairlterelementisdirtyandis

restrictingtheairow.

3.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

1.Theundersideofthemachinehousing

containsclippingsanddebris.

1.Cleanunderthemachinehousing.

2.Theenginemountingboltsareloose.2.Tightentheenginemountingbolts.

3.Theblademountingboltloose.3.Tightentheblademountingbolt.

Themachineorenginevibrates

excessively.

4.Thebladeisbentorisoutofbalance.

4.Balancetheblade.Ifthebladeisbent,

replaceit.

1.Youaremowinginthesamepattern

repeatedly.

1.Changethemowingpattern.

2.Theundersideofthemachinehousing

containsclippingsanddebris.

2.Cleanunderthemachinehousing.

Thereisanunevencuttingpattern.

3.Thebladeisdull.

3.Sharpenandbalancetheblade.

20

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

Toro HoverPro 450 Machine User manual

- Category

- Lawnmowers

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Toro HoverPro Series User manual

-

Toro HoverPro 550 Machine User manual

-

Toro HoverPro Series – 40 to 53 cm Cutting Width User manual

-

Toro HoverPro 550 Machine User manual

-

Toro HoverPro 450 Machine User manual

-

Toro HoverPro Series – 40 to 53 cm Cutting Width User manual

-

Toro HoverPro 550 Machine User manual

-

Toro HoverPro 550 Machine User manual

-

Toro HoverPro 550 Machine User manual

-

Toro HoverPro 550 Machine User manual