Cooper Lighting Landscape Lighting 1001 is a one loop Addressable emergency lighting test system. It has provision for a maximum of 250 SCAEL Interfaces. Each SCAEL Interface has its own individual address and can be programmed using an EASICHECK™ hand held programming unit. The EASICHECK™ Panel continually monitors the battery voltage and charge current of each SCAEL Interface and checks for correctness. Any luminaire found to be incorrect will have its Green LED switched to Amber and the Control Panel will display the Address number, location, and a fault description.

Cooper Lighting Landscape Lighting 1001 is a one loop Addressable emergency lighting test system. It has provision for a maximum of 250 SCAEL Interfaces. Each SCAEL Interface has its own individual address and can be programmed using an EASICHECK™ hand held programming unit. The EASICHECK™ Panel continually monitors the battery voltage and charge current of each SCAEL Interface and checks for correctness. Any luminaire found to be incorrect will have its Green LED switched to Amber and the Control Panel will display the Address number, location, and a fault description.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

Cooper Lighting 1001 User manual

- Type

- User manual

- This manual is also suitable for

Cooper Lighting Landscape Lighting 1001 is a one loop Addressable emergency lighting test system. It has provision for a maximum of 250 SCAEL Interfaces. Each SCAEL Interface has its own individual address and can be programmed using an EASICHECK™ hand held programming unit. The EASICHECK™ Panel continually monitors the battery voltage and charge current of each SCAEL Interface and checks for correctness. Any luminaire found to be incorrect will have its Green LED switched to Amber and the Control Panel will display the Address number, location, and a fault description.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Other documents

-

Cooper EASICHECK EC2001 Operating instructions

-

Universal Power Group D1724 User guide

Universal Power Group D1724 User guide

-

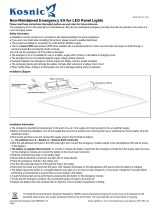

Kosnic EMPAD02 Non Maintained Emergency Kit for LED Panel Lights User manual

Kosnic EMPAD02 Non Maintained Emergency Kit for LED Panel Lights User manual

-

ML Accessories EMTWINST User manual

-

ML Accessories EMXST User manual

-

ML Accessories EMRNST User manual

-

Tridonic em-LINK v3 software Single-Battery Emergency Light User guide

Tridonic em-LINK v3 software Single-Battery Emergency Light User guide

-

Menvier Security TS700 Operating instructions

-

Eaton Aethon Instruction Leaflet

-

ML Accessories T8BLED16HLEM User manual