Page is loading ...

1

Operating and installation guide

motoscope Classic, Chronoclassic, Classic speedo

starting at serial no. 00030961

Suchen Sie die deutsche Bedienungsanleitung?

http://motogadget.com

ABE

KBA 91262

________________________________________________________________

HW 2.1 SW 4.03 Manual 4.9_k

2

CAUTION FOR ALL U.S. CUSTOMERS

THIS PRODUCT IS NOT D.O.T. APPROVED AND INTENDED FOR

SHOW USE ONLY!

CAUTION: IF YOU ARE NOT A CERTIFIED MOTORCYCLE

TECHNICIAN PLEASE STOP HERE AND ASK YOUR LOCAL

MOTORCYCLE SHOP FOR PROFESSIONAL INSTALLATION!

Thank you very much for purchasing a high quality product from motogadget.

Please read the following information and recommendations carefully and

follow these instructions for installation and usage of the instrument. No liability

is assumed by motogadget for damage or defects resulting from negligence or

failure due to following the operating manual.

For further product information e.g. measurements, 2D or 3D drawings,

surveys, TÜV approval, etc. visit:

www.motogadget.com

Contact:

motogadget GmbH

Köpenicker Str. 145

D-10997 Berlin

Germany

Fon +49 (0)30 - 69 00 410 - 0

Fax +49 (0)30 - 69 00 410 - 22

www.motogadget.com

info@motogadget.de

© Copyright and all further rights by motogadget, Berlin 2006-2017

motoscope and motogadget are registrated trademarks of motogadget GmbH, Berlin, Germany

3

1 Review of delivery

All products from motogadget are thoroughly checked to ensure they are completely fault free

when dispatched. Please check the received goods immediately for possible transport damage. If

you find any damage or other deficiencies, please contact us immediately.

In this regard we refer to our general terms of business and delivery, which are published under

www.motogadget.com. Should a return of the received delivery be agreed, please note that we

only take back goods in their original packaging. The instrument and its accessories must be

returned within the legal period of time and without any traces of use. We do not assume any

liability for returns which are insufficiently insured or packed.

2 Exclusion of liability

INSTRUMENT HOUSINGS AND ALL OTHER DELIVERED PARTS MUST NOT BE OPENED OR

DISMANTLED. IN CASE OF NON-COMPLIANCE ALL GUARANTEE CLAIMS BECOME

INVALID. THE USE OF THE DELIVERED INSTRUMENTS, SENSORS AND ACCESSORY

PARTS FOR RACING OR OTHER COMPETITIONS, AS WELL AS ALL USES THAT DO NOT

CORRESPOND TO THE RECOMMENDED APPLICATION RENDER ALL GUARANTEE

CLAIMS INVALID. MOTOGADGET ACCEPTS NO LIABILITY FOR DIRECT OR INDIRECT

DAMAGE OR SUBSEQUENT DAMAGE OF ANY KIND RESULTING FROM THE USE,

INSTALLATION OR CONNECTION OF INSTRUMENTS, THE SENSORS OR OTHER

DELIVERED EQUIPMENT. THIS EXCLUSION OF LIABILITY PARTICULARLY INCLUDES

DAMAGE TO PERSONS, MATERIAL LOSSES AND FINANCIAL DAMAGES. THE USE IN

AREAS OF PUBLIC TRAFFIC IS UNDERTAKEN AT THE USER'S OWN RISK.

THE INSTRUMENT CONTAIN MOVABLE, MECHANICAL PARTS. THE DEVICE IS NOT

SUITABLE TO MOUNT ON EXTREM HOT OR VIBRATING PARTS LIKE INSIDE HEADLIGHT

HOUSINGS OR ON A ENGINE ROCKERBOX. DAMAGES RESULTING FROM HEAT

(HUMIDITY INSIDE INSTRUMENT) OR EXTREME VIBRATIONS RENDER ALL GUARANTEE

CLAIMS INVALID.

2.1 Duty of registration

The motoscope has a General Operating Permit (ABE) and therefore does not have to be entered

into the vehicle documents. The device is identifiable as having a General Operating Permit by a

special label with the code "KBA 91260" on the back side of the device.

THE GENERAL OPERATING PERMIT (ABE) IS ONLY VALID WHEN THE DEVICE IS

INSTALLED IN TWO- OR THREE-WHEELED VEHICLES AND THE WHEEL CIRCUMFERENCE

WHICH HAS BEEN ENTERED INTO SETUP CORRESPONDS TO THE ROLLING TIRE

CIRCUMFERENCE GIVEN (TABLE IN APPENDIX).

THE USER IS PERSONALLY RESPONSIBLE FOR CORRECT CALCULATIONS AND

ADJUSTMENTS CONCERNING TIRE CIRCUMFERENCE, IMPULSES PER WHEEL ROTATION

AND CORRECT INSTALLATION OF THE SPEEDOMETER SENSOR.

2.2 Advice

The motoscope is equipped with a Gore membrane to prevent of moisture entry. Nevertheless

extreme outside temperature or pressure changes in a short time duration may lead to a fogging

inside which will disappear after some minutes. This will not affect product functionality or life time.

4

3 Technical Data

Mounting diameter / Total diameter 80 mm / 85 mm

Depth (without cable fitting) 34 mm

Weight without cable ca. 230 g (without instrument)

Mounting holes 3 x M4 thread

Power consumption ca. 150 mA (load depending)

Operating voltage 9–18 V

Operating temperature -20°C... +80 °C

3.1 Feature Overview

Features Measuring Range

Analog display (indicator) for rpm or road speed, depending

on model 0–8 krpm / 10 krpm / 14 krpm

0–200 km/h or mph

Speedometer 0–350 km/h or mph

Day trip meter up to 999.99 km or mi

Total distance (adjustable) up to 250.000 km or mi

Trip time (stop watch) 0–99:59:59 h:m:s

Digital rpm meter on LCD 0–20 krpm

Setup internal rpm alert LED, external gear shift flash 0–20 krpm

On-board voltage 9.0–18.0 V

Air temperature* (optional, instead of water temperature) -20–80 °C or -4–176 °F

Air temperature* (optional, instead of water temperature) 40–120 °C or 104–248 °F

Oil temperature* 40–160 °C or 104–320 °F

Oil pressure* 0–8 bar or 0–116 psi

Actual acceleration (-20,0)–20,0 m/s

2

Average speed (memory value) 0–350 km/h or mph

Maximum speed (memory value) 0–350 km/h or mph

Maximum speed (memory value) 0–20 krpm

Time keeping from 0–100 km/h resp. 0–60 mph 0,0–99.9 s

Max. positive acceleration (memory value) 0.0–20.0 m/s

2

Max. negative acceleration (memory value) 0.0–20.0 m/s

2

Gear indicator N, Gear 1–6

Green indicator light Neutral

Green indicator light Turn indicator, right

Blue indicator light High beam

Red indicator light Miscellaneous warning features

External gear shift flash (adjustable rpm value) Switching capacity max. 1 A

* Adjustable minimal and maximal values for temperature and pressure alert

5

4 Preparing Installation and Connection of the Instrument

4.1 Essential Knowledge and Skills

Installation and Connection of the motoscope classic requires basic knowledge in vehicle electrics.

Since the motoscope classic can be installed on many different vehicle platforms with different

specifications and accessories, not every particular case is covered in this manual. If in doubt,

please refer to the information offered on our web site. Another possibility would be to have the

motoscope classic installed in an authorized service center.

4.2 Required Materials and Tools

The motoscope classic is universally applicable and thus suited for many different vehicle

platforms. Thus, depending on the vehicle and mounting options chosen, some customisation and

additional hardware may be required, e. g.:

• Instrument holder and mounting screws

• Brackets for the speedometer sensor and the menu push-button

• Input cables for power, ignition signal, and push-button

• Mounting hardware such as cable ties, connectors, heat shrink tubing, soldering iron

We recommend use of wiring diagrams for electrical connection.

If you don’t use the motogadget all-purpose bracket you will need a stable mounting bracket for the

instrument. The speedometer sensor is already equipped with a connecting cable (length

1.5 meters) so that the sensor can be connected to the front or rear wheel. For positioning of the

speedometer sensor you might – depending on the position – also require a self-made holding

bracket.

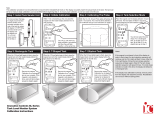

5 Quick Start

This section covers installation and connection – briefly but clearly:

a) Prepare all required materials and hardware like brackets (resp. the sheet metal for

constructing them), screws, thread seal, cable/wire, connectors etc.

b) Put all tools required for the mechanical and electrical mounting of your device at the ready:

screw drivers, wrenches, soldering iron, brazing solder, multimeter etc.

c) Keep documents like the wiring diagrams for your vehicle and the motoscope classic etc. at

hand.

d) Ensure a safe and secure position of your vehicle and disconnect the ground cable from

the battery.

e) Choose adequate locations for the instrument and the speedometer sensor. Decide where

the connecting cables of instrument, indicator lights, sensors and push-buttons will join.

Allow for sufficient space for the connectors. Customise the included brackets or

manufacture your own. Mount the brackets.

f) Install the instrument, the speedometer sensor, the push-button, and the optional sensors.

g) Lead all cables (power supply, push-button, sensors, rpm input, speedometer sensor and

indicator lights) to this terminal as well and connect them to the connectors following the

wiring diagram (see appendix).

h) Reconnect the battery to the on-board system and activate the ignition.

i) Adjust the apropriate parameters for rpm meter, scale, speedometer, sensors, etc. in setup

(see respective chapter).

j) Start the engine and check the rpm meter. Carefully and slowly drive several meters and

watch the speedometer. If nothing suspicious and no mechanical or electrical problems or

peculiarities occur, you can continue your test drive.

6

6 Safety Instructions for Installation and Connection

• Ensure your vehicle is standing firmly on the ground before beginning installation works.

• Disconnect the connector cable from battery minus to the on-board electrical system.

• In your own interest and in the safety interest of third persons, ensure a good and solid mount

for all mounting parts.

• Make sure that your vehicle is equipped with a interference suppressing ignition system.

Absence of an interference suppression may result in damage to or malfunction of the

instrument!

7 Installation of the Instrument

Mount your device to vehicle parts that are as little as possible exposed to vibrations. Dimension

your bracket suitably sturdy. For exemplary installations please refer to our website.

A plane and tension free mounting with all 3 of the provided M4 screws is absolutely essential. For

a secure installation and to avoid ruptures to the mounting bores, the mounting screws have to be

screwed into the casing for at least 4 mm.

The maximum screw-in depth shall not be exceeded. Choose your screw length according to the

bracket. We recommend using additional washers and thread locker (medium strength). It is also

critical to adhere to the maximum torque of 2 Nm.

8 Connecting the Instrument

8.1 Notes to Cable Placement

Before placing your cables you will want to find a suitable route for them. It should stay away from

hot motor parts. Find a suitable spot for connecting cables and plugs. In most cases, similar

connecting points in the wiring harness already exist in the headlight, under the tank or in the

cockpit. Please ensure sufficient length remaining before shortening them. Keep in mind that

additional cable length will be needed to account for steering and suspension of your vehicle. All

connector cables have to be routed without kinks, tension and properly insulated. Deploy additional

insulation protection in areas of high mechanical wear. We recommend plastic cable ties for routing

and fastening your cables.

7

8.1.1 Assignment and Color Code

also refer to chapter 15.1

6-pin Connector for the motoscope classic

Cable Color Function Connector

Red Power supply Plus of the switched on-board power

supply, protected by a 1A fuse.

Black Power supply Ground

Yellow RPM meter signal cable

NEVER CONNECT TO IGNITION

HIGH VOLTAGE CIRCUIT!

leads to the ignition coil, terminal 1

(switched ground of ignition unit)

In case of a CDI ignition, please use the

motogadget ignition

signal sensor (order no.

9000001)

Orange Input for speedometer signal

leads to the signal cable of the OEM

speedometer sensor or of the motogadget

speedometer sensor which again switches

to ground

Green signal cable of the menu push-

button connects to the menu push-button which

again switches to ground

Brown output for external gear shift

flasher

connects to the gear shift flash bulb

connected to +12V (max. 1A switched

power)

9-pin Connector for the motoscope classic

Cable Color Function Connector

Purple Signal Cable for Air and Water

Temperature leads to connector cable to the air and

water temperature sensor

white/black signal cable oil temperature

sensor leads to the connector cable of the oil

temperature sensor

white signal cable for oil pressure

sensor leads to the motogadget oil pressure sensor

blue blue indicator light / high beam leads to high beam / +12V

white/yellow red indicator light / +12V

white/green red indicator light / ground

customisable (chapter 15.1 shows usage as

oil pressure warning light)

grey green indicator light / neutral leads to the neutral switch

white/orange yellow control light / turn indicator

connects to left flasher plus

white/brown yellow control light / turn indicator

connects to right flasher plus

Motogadget Speedometer Sensor

Black gear switch input (no polarity) Ground

Black gear switch input (no polarity) connects to the orange cable motoscope

8

8.2 Notes to the Connector

Route the necessary cables to the connector interface of the instrument. Decide in advance, if

possibly multiple wires have to be unified before being connected to a contact pin. Therefor we

recommend to create the crimp connections at the end of your installation work.

With a crimping tool, crimp the contact pin to the wire(s). Now insert the pin from the backside into

the appropriate connector opening (refer to the connection diagram). Mind the correct positioning

of the latching hooks of the pin. It has to latch onto the connector body.

8.3 Battery and Power Supply

The instrument needs a "switched plus" power supply. This refers to the +12V potential only being

present when the ignition switch is activated. Before beginning installation work, the ground cable

has to be disconnected from the battery. The motoscope classic works on on-board power supplies

with 9-18VDC. Operating the device on a on-board power supply without a battery connected is not

intended by design and is not recommended. Please mind the correct polarisation of the power

supply.

CAUTION!

THE MINIMUM DIAMETER OF THE CONNECTOR CABLE IS 0.5 MM². THE DEVICE

HAS TO BE PROTECTED BY A 1A FUSE. OPERATING THE DEVICE WITHOUT FUSE MAY LEAD

TO DAMAGE OF THE CONNECTOR CABLE OR THE INSTRUMENT OR CREATE SHORTS AND

CABLE FIRES. CAUTION: MORTAL DANGER! MAKE PROPER AND SOUND ELECTRICAL

CONNECTIONS! IF YOU ARE LACKING SUFFICIENT KNOW-HOW, LET AN AUTHORIZED SERVICE

CENTER MAKE THESE CONNECTIONS FOR YOU.

9 Installation and Connection of Sensors and Menu Push-Buttons

9.1 The Menu Push-Button

You need a menu push-button to use the instrument. The button is not included.

Via the menu push-button, the display can be toggled while driving. All settings of the instrument

are selected with this push-button (see respective chapter). One terminal of the push-button si

connected to the green cable of the instrument, the other one to the vehicle ground. Polarity of the

push-button is irrelevant.

9.2 RPM Counter Sensor Cable

The instrument can be connected to all conventional ignition systems that work with ignition coils.

Connect the yellow cable to the terminal 1 (switched ground from the ignition box) of one of the

ignition coils.

In case of a CDI ignition (Capacitor Discharge Ignition - used in squads, scooters, trail bikes) you

must use the motogadget ignition signal pickup unit (article no. 9000001).

We assume that your vehicle is equipped with an interference suppressing ignition system .

For accurate functioning of the instrument preferences in the setup menu of the instrument have to

be changed. Please see directions in the relevant chapter.

Caution! The rev counter connection should never be connected to the high voltage output

of the ignition.

9

9.3 Installation and Connection of the Speedometer Sensor

9.3.1 Use of OEM Speedometer Sensor

If a speedometer sensor with three connector cables (and able to output a ground signal) is

present in the vehicle, it may be used. Two wire hall sensors are not compatible to the motoscope .

Connect the orange cable of the motoscope directly to the speed sensor signal cable. You will

have to use the (included) motogadget speedometer sensor if no speedometer signal can be

detected.

9.3.2 Use of the motogadget Speedometer Sensor

The included speedometer sensor is a dry reed contact, which is triggered by a magnetic field. To

sense the signals, the included magnet has to be attached to one of the wheels with two-

component epoxy glue. The distance between the magnet and the wheel centre is irrelevant. The

speedometer sensor has to be attached to the vehicle by using a self-made holding bracket. The

sensor tip has to be fastened parallel to the magnet. The distance between magnet and sensor

should not exceed 4 mm and the sensor should not touch the magnet or any other moving parts.

The sensor holding bracket has to be sufficiently stable in order to prevent shifting of the sensor

while driving. The maximum mounting torque of the sensor nuts is 1.6 Nm. We recommend Loctite

(medium strength) for secure mounting. Connect one cable of the speedometer sensor to vehicle

ground and the other one to the orange cable of the motoscope.

CAUTION!

IF THE MAGNET IS EXPOSED TO TEMPERATURES ABOVE 100 °C (E. G. HOT

BRAKING SYSTEM), IT MIGHT BECOME DE-MAGNITISED. THE MAGNET WILL BECOME

UNUSABLE.

9.4 Output for External Gear Shift Flash

The output for the external gear shift flash can be connected to a gear shift indicator flasher. The

maximum switchable continuous power is 1A. The output switches to ground. Please ensure the

right polarity when connecting LED lamps.

9.5 Connecting Optional Temperature and Pressure Sensors

We can only vouch for sensors and transmitters from our own optional accessories to be

compatible to our instrument and to provide exact measurements. When using third-party sensors,

we can not guarantee sound operation of the device and will reject any warranty or liability.

Please check, if the type of sensor, its bore size, thread length, type and pitch match your vehicle

before mounting screw-in type sensors (resp. their threaded adapter). Ensure clean sealing faces,

right torque and good connectivity of the terminals.

All our sensors, as a general rule, get their minus from the vehicle ground. Thus, per temperature

or pressure sensor only one signal wire from the sensor to the connecting plug of the instrument is

necessary.

9.6 Connecting Indicator and Warning Lights

Since all four indicator lights are LED, ensuring the right polarity is critical.

9.6.1 Green Indicator Light for Turn Indicator Left and Right

The indicator light for the turn indicator has two terminals on the connector plug. They are pre-

made for left or right side connections (+12V). If a turn indicator indicator light is present, just

connect its leads. If no indicator light is present, please adhere to the connection diagram in the

appendix.

10

9.6.2 Blue Indicator Light for High Beam

High beam indicator light (+12V). Generally, the layout of the OEM indicator light should be the

same. If your vehicle differs, use the direct input line (plus) from your high beam switch or light.

9.6.3 Green Indicator Light for Neutral

The neutral indicator light is pre-made for connection to ground.

Generally, the layout of the OEM indicator light should be the same. If your vehicle differs, use the

direct input line from the neutral switch that is switching to ground.

9.6.4 Red Indicator and Warning Light

The red warning light can be triggered internally or externally.

It warns by flashing quickly when limits for the values of rpm, temperatures or pressures are either

exceeded or underrun. These functions are controlled internally.

Additional sensors (e. g. oil pressure sensor) can be connected to the terminals with white/yellow

and white/green wire. It is critical that these transmitters are of the "switching" type (on/off) and that

the polarity of all connected transmitters is set correctly.

Connection of a oil pressure switch: white/yellow = switched 12V AND white/green = oil

pressure switch

10 First Use of the Instrument

When all parts are securely mounted and connected properly, you can assemble the connector

halves and connect the battery.

Activate the on-board power suply. The display should light up and show the startup display

(motogadget logo). If this is not the case, please deactivate the ignition and systematically recheck

all connections of the instrument and the sensor connector cables.

Start the motor and watch the rpm meter display. The value displayed should change according to

the actual motor rpm. To get the display to show the proper rpm value, the corresponding settings

have to be made in the setup.

If everything worked as planned up to this point, you can continue with adjusting the settings in the

setup.

11 Operation and Display of Features

11.1 General Notes on Operation with the Menu Push-Button

The device is operated via the menu push-button. To toggle between the different display and

setup levels, the switching time of the push-button is varied.

The device discriminates between 3 switching times which are visually referred to by the three lines

in the first line of the display.

• Level 1: < 1s (one line is displayed top-left on the display)

Function: Select the next option or increment a digit

• Level 2: 1–3 s (two lines are displayed top-left on the display)

Function: Selection of the next/subordinated level or the next digit. Deleting saved

values.

• Level 3: > 3 s (three lines are displayed on the display)

Function: Selection of the previous/superordinate level or exiting the menu point.

For the exact order of the setup please refer to the flow chart in the appendix.

11

11.2 The analog Display with pointer

Depending on the model, the device shows rpm or ground speed. The models with the ground

speed scale have to have the value of Damp at 9 in the MOTOR setup parameter. The value of

SCL has to be 10K.

Models with rpm meter have to have their scale set to 0–8.000 rpm, 0–10.000 rpm, or 0-14.000

rpm resp., this has to be preset at the SCL value in the setup. Additionally, the vehicle-specific

parameter InpE has to be set.

If your analogue indicator is oscillating strongly, another rpm input filter InpF and or a different

indicator dampening factor DAMP should be chosen in the setup.

At start-up, the indicator moves to the stop pin. This calibrates the needle. Turning off the on-board

power supply while the engine is running (key switch), the indicator freezes at the rpm value last

displayed. This is perfectly normal for an instrument driven by a stepping motor and not a

malfunction. If this is an optical nuisance to you, you could turn off the engine with the kill switch

and interrupt the on-board power supply only afterwards.

11.2.1 RPM Limit Display by the Red Warning LED

The red LED (right side triangular symbol) blinks when a rpm value preset in the setup is reached

(refer to FLASH). The preset rpm value also controls the external gear shift flash output. The

flashing can be set to continuous light (refer to FIM).

11.3 Read-out on the LC-Display

11.3.1 Selecting Readouts on the LC-Display

The LC-Display has two lines. The display value of the first line can not be altered.

Push-button level 1 toggles between sensor values on the second line. Available display values are

determined by the preset chosen in the (SCREEN) setup.

11.3.2 The Ground Speed Display (km/h or mph)

Models with rpm scale permanently show the actual ground speed in the top line of the LCD. The

measuring range ranges from 0-350 km/h. Ground speed can also be displayed im miles (mph).

These settings can be changed in the setup (refer to SEL).

Models with ground speed scale show the current speed on the dial. Above a speed of 190 km/h

the speed value is shown on the first line of the of the LC display (instead of the day trip value). If

ground speed drops below 180 km/h or mph, the display switches back to the day trip meter.

11.3.3 The Day Trip Meter (km oder mi)

After start-up, the rpm scale model shows the day trip value in the second line. This value displays

the day trip total in the range from 0 to 999.99 km or mi (delete by push-button level 2).

11.3.3 The Total Distance Meter (km oder mi)

The total distance meter displays the total distance covered since first use of the instrument. This

value is kept even if the on-board power supply is switched off. It can be reset to 0 via the special

subitem "RESET/ALL" in the setup. The start-up value can also be preset in setup (ODO2set).

11.3.5 The Trip Time Meter (hh:mm:ss)

The trip time meter determines the actual driving time, since counting stops when the vehicle

comes to a stop. Road time is established to the second up to a time span of max. 99 hours and

59 minutes (delete by push-button level 2).

11.3.6 On-Board Voltage

This value represents the actual on-board voltage in the 9-18V range.

12

11.3.7 Temperature Gauge T1, Optional Air (AIR) or Water Temperature (H2O)

This value represents the actual air or water temperature as soon as it reaches the measuring

range of the sensors. Out of range is indicated by "---" .

In setup, upper and lower limits (minT, maxT) can be set. These values have to be inside the

measuring range.

Once values are set, blinking of the red warning LED and a message indicate the underrun of the

lower limit. The alarm starts at the lower measuring range. The equivalent goes for exceeding the

upper limit.

If the alarm is confirmed by a button, blinking and message disappear. When the measuring value

T1 is selected and displayed on the display, message and blinking persist as long as any preset

limits have been exceeded or under-run resp..

Temperature values can be displayed on the °C or °F scale (refer to setup).

11.3.8 Temperature Display T2, Oil Temperature (oil)

This value shows the current oil temperature as soon as it is inside the measuring range of the

sensor. The definition of limits is equivalent to the one described for T1.

11.3.9 Oil Pressure Indicator (bar or psi)

This value shows the current oil pressure as soon as it is inside the measuring range of the sensor.

For minimum and maximum limits (minP, maxP) please refer to T1 above. Pressure values can be

displayed on the bar or psi scale (refer to setup).

11.3.10 Actual Acceleration (m/s

2

)

This value represents the current acceleration from -20.0 m/s

2

to +20.0 m/s

2

. Negative values are

generated while breaking. All reached limits are recorded (see below).

11.3.11 RPM Display on the LCD (RPM)

This value shows the current engine RPM as numeric value in the range of 0-20.000 rpm. For this,

some vehicle specific presets have to be made in setup (see analog rpm display).

11.3.12 Average Speed (km/h or mph)

This value shows the average ground speed from all trips since the last reset to 0. The display

range is 0-350 km/h (or mph).

11.3.13 Timekeeping from 0-100 km/h (in s)

This value represents the time in seconds needed to accelerate from 0-100 km/h.

The measurement is taken by a level 2 push-button action. The vehicle has to stand still while

activating the push-button. A small square is displayed in front of the value. Now you can

accelerate, the measurement is started and stopped automatically when reaching 100 km/h.

11.3.14 Maximum Speed Reached (km/h or mph)

Under this value, the maximum speed reached is recorded (delete by push-button level 2).

11.3.15 Maximum RPM Reached (RPM)

Under this value, the maximum speed reached is recorded (delete by push-button level 2).

11.03.16 Maximum Positive Acceleration Reached (m/s

2

)

Under this value, the maximum positive acceleration is recorded (delete by push-button level 2).

13

11.03.17 Maximum Negative Acceleration Reached (m/s

2

)

Under this value, the maximum negative acceleration is recorded (delete by push-button level 2).

11.3.18 Gear Indicator

The gear indicator displays the current gear as numeral from 1 to 6 on the display, on the left hand

side next to the ground speed. Condition for displaying this value is the implementation of the

learning function (see setup‚ menu PARAM, subitem GearTCH). The gear shift indicator is a

mathematical function and is calculated from rpm and ground speed values. No additional sensors

or connectors are required.

12 The Setup

Operation and setup of the motoscope classic is conducted via one push-button. For this reason,

the setup is organised in "levels". Push-button activation for different durations is used for toggling

and selecting these levels. The activation time of the push-button is indicated by 1, 2 or 3

horizontal lines on the display.

The setup is accessed by a level 3 push-button action.

The topmost line displays the selected setup menu (SCREEN, LCD, MOTOR, PARAM, SENSOR,

RESET) while the lower line shows the selected option.

The next menu or the next option is selected with a level 1 push-button action.

Switching from menu (upper line) to option (lower line) is achieved by a level 2 push-button action

and is indicated by a small rectangle.

Exiting the active option or the setup is always achieved by a level 2 push-button action. Please

refer to the overview in the appendix for a guide to toggling and selecting levels and subitems.

12.1 The Subitem SCREEN (Display Setup)

Definition of display values. A level 2 push-button action switches to the lower line (option). You

can chose any display value by a level 2 push-button action. A level 2 push-button action selects

the value. An arrow is displayed. Now the displayed value can be toggled "on" or "off" by a level 1

push-button action. The factory default for all displayed values is "on". The following features can

be activated or deactivated:

• ODO1 (day trip meter)

• ODO2 (total trip meter)

• TIME (trip time)

• VOLT (on-board voltage)

• TMP1 (temperature 1)

• TMP2 (temperature 2)

• PRES (pressure)

• ACCE (acceleration)

• RPM (engine rpm)

• AVG (average speed)

• 0100 (timekeeping 0-100 km/h)

• MAXS (maximum speed)

• MAXR (maximum engine rpm)

• MAXA (maximum positive acceleration)

• MINA (maximum negative acceleration)

A level 3 push-button action exits the option and the menu.

12.2 The Subitem LCD (Display Setup)

The option CNTR sets the display contrast in steps from 0 to 6.

14

12.3 The Subitem MOTOR (Stepping Motor Setting)

DAMP

Setting the electronic indicator damping in steps from 1 to 9 by level 1 push-button actions. Step 1

represents the weakest and step 9 the strongest damping. Exit the option by a level 3 push-button

action.

SCL

Setting the rpm scale of the analog rpm meter. Available scales: 8K, 10K or 14k, select by level 1

push-button action, exit by level 3 push-button action.

12.4 The Subitem PARAM (Parameter: Vehicle Specific Settings)

This subitem allows to enter vehicle specific values and to display the software version.

WHLSIZE

This option allows entering the wheel diameter im millimeters. A level 1 push-button action

increments the active digit, level 2 switches to the next digit and level 3 exits the menu to the

PARAM main menu.

Please refer to the table in the appendix for the right outer tire diameter (alternative download at

www.motogadget.de). The ABE is only valid with a correct value from this table.

If your tires can not be found in the table, please measure the outer diameter of the tire (of the

wheel the speedometer sensor is attached to) with a piece of cord. Add 5% speedometer lead by

multiplying the measured value by 1.05.

When using the TTEACH feature, nothing has to be set in this menu.

ImpWHL

Setting the amount of speedometer sensor impulses per wheel rotation from 1 to 99. A level 1

push-button action increments the active digit, level 2 switches to the next digit and level 3 exits the

menu to the PARAM main menu.

When using a megnet, no changes are required (factory preset is 1). When using more than one

magnet, set the number of used magnets. When using the original speedometer sensor, set the

number of output signals per wheel rotation.

When teaching the speedometer sensor via the TTEACH function, the ImpWHL parameter must

not be altered.

The instrument calculates the ground speed and many other values from the values WHLSIZE und

IMPWHL. Please use the utmost caution. Please check the plausibility of the displayed

speedometer values and only afterwards drive on public roads. If false data has been entered, the

instrument will supply false display values and the process of entering data has to be repeated.

Another possibility to set the ground speed calculation factors is the TTeach ("tachometer teach")

feature in the sensor subitem.

15

ImpENG

This feature determines the number of ignition impulses per crankshift revolution. A level 1 push-

button action toggles the next value, level 3 exits the menu and switches back to the PARAM main

menu.

If your vehicle is equipped with multiple ignition coils, only the impulses from the coil with the signal

cable attached (i. e. the one actually measured) are counted.

Examples:

Single cylinder, 4-stroke, one ignition coil ImpE = 0,5 (SR 500, XT 500)

Single cylinder, 4-stroke, two ignition coils ImpE = 1 (GSXR 1000)

Two cylinders, 4-stroke, one ignition coil ImpE = 1 (Harley Davidson, dual fire)

Two cylinders, 4-stroke, two ignition coils ImpE = 0,5 (Harley Davidson, single fire)

How can I determine the proper setting for my vehicle?

99% of all motorcycles use either 0.5 or 1.

Please choose setting 1. Exit the setup menu and start the engine. If only half the idle rpm value is

displayed, enter the value 0.5.

SEL

Setting option for the distance or ground speed unit resp. Can be set to km or mi by a level 1 push-

button action. Exit the option by a level 3 push-button action.

InpF

Setting the input filter for rpm measurement. A level 1 push-button action toggles between values

A, B, C and D. A level 3 push-button action exits the menu and switches back to the PARAM main

menu. If the rpm meter does not work satisfying with filter B activated, please try another filter

setting.

GearTch

This option is selected by a level 2 push-button action (-> READY is displayed).

Activate by a level 1 push-button action (G1 <-<- is displayed).

Start measuring the displayed gear by a level 1 push-button action or select another gear to be

learned by a level 2 push-button action.

Important:

The selected gear has to be engaged in advance of the measurement and must not be shifted

while measuring. The clutch must not be engaged as well.

While driving, alternate rpm and load (more throttle, less throttle) and amploy the front brake

(without clutch) lightly until reaching the lowest querter of the rpm band. This measures the

tolerances (reaction to load change, slip) within the gear transmission ratios.

If back wheel spin or front wheel blocking occurs, the measurement will be biased must be

repeated for the respective gear. Exit the option with a level 3 push-button action and restart the

teaching process for this gear. Brake and accelerate repeatedly during the countdown and drive

normally during its last seconds. Then, shift gears to the next higher gear and afterwards press

the menu push-button to activate the countdown. Repeat this procedure until all gears have been

processed. If your vehicle has less than 6 gears, finish the measurement when the next gear is

displayed with a level 3 push-button action. The teaching procedures for the respective gears may

also be conducted seperately. To do this, navigate from gear to gear and always keep two lines on

the display. You can start the countdown for each gear when the driving situation allows for a

sound processing of the gear. After finishing the teaching process and exiting the setup with a level

3 push-button action, the instrument has to be power cycled. Only then will the right gear number

be displayed.

16

Test the display for accuracy. In threshold ranges, the instrument might temporarily display the

wrong gear. If the result is overall inconsistent, the teaching process has to be repeated. Please do

not teach the gears to your device on public roads but on a suitable, blocked area. The measuring

is made at your own risk.

FLASH

Setting the threshold range ("red range") and/or the red gear shift flash. Please enter the desired

rpm value digit by digit (e. g. 8500). Level 1 push-button actions will increment the digits. Level 2

push-button actions change digits and a level 3 push-button action exits the option.

FlM

Choosing between flashing ALT and continuous lighting LEV of warning light and gear shift flash.

VER

Displays the software version number; no adjustment possible.

12.5 The Subitem SENSOR (Sensor Setup)

T1

Selects temperature measurement value T1 as air or water temperature. A matching sensor is

crucial for obtaining a precise measurement.

Temp

Sets the temperature unit to °C (Celsius) or °F (Fahrenheit).

PRS

Sets the pressure unit to bar or psi.

AIRmaxT / H2OmaxT

Sets the upper warning threshold for air and/or water temperature.

AIRminT / H2OminT

Sets the lower warning threshold for air and/or water temperature.

OILmaxT

Sets the oil temperature upper limit.

OILminT

Sets the oil temperature lower limit.

OILmaxP

Sets the oil pressure upper limit.

OILminP

Sets the oil pressure lower limit.

TTeach (Tacho Teach)

Automatic calibration of the speedometer sensor when using OEM speedo sensors. For this

calibration, the vehicle has to be driven at a constant 50 km/h for 10 seconds. Using the OEM

speedometer, a GPS device or a second vehicle is usefull. Please take the appropriate care when

conducting such measuring/calibration drives. When the countdown expires after 10 seconds, the

speedometer records the measurement values and switches back to its normal display screen.

Please recheck the speed measurement for precision and repeat the process, if necessary. We

recommend this method only as implement when using on-board sensors, e. g. at the gear box

output. Entering the values directly under PARAM is preferable (if possible). After a calibration by

TTeach is finished, it will be indicated by an asterisk under the WHLSIZE menu item.

17

12.6 The Subitem RESET (Reset Features)

RESET

Reset of all saved values to 0 or to factory default resp..

ALL

Selection of "yes" deletes all values accumulated during operatioon as well as the total trip value.

Internally, the instrument is set to a "new condition".

DEF

Selection of "yes" resets all setup settings to factory default but keeps the total trip meter value.

ODO2Set

Setting a total trip meter value. Increment the selected digit by a level 1 push-button action, select

the next digit by a level 2 push-button action and exit with a level 3 push-button action.

13 Safety Instructions for Operation in Traffic

Please do not get distracted from traffic by the instrument. You as the operator are responsible for

the proper setting of all device parameters as well as properly mounting all hardware. Greatest

care has to be taken while mounting sensors or setting parameters – the precision of the displayed

values depends on it.

PLEASE DO NOT OPERATE THE INSTRUMENT WHILE DRIVING, IT MAY LEAD TO A LOSS

OF CONTROL AND SEVERE ACCIDENTS.

14 Troubleshooting

14.1 After Mounting and at First Use

• Make sure to provide an adequate power supply of at least 10V. Ascertain yourself of the

faultless operation of the vehicle's battery.

• Do not use a battery charger to test the functioning of the device.

• Check all cables for proper connections and contact.

• Check all cables for proper pin contact inside the connector bodies.

• Make sure that your vehicle is equipped with an interference suppressing ignition system.

Operating it in vehicles without interference suppression may damage the instrument.

• How to check all inputs of your instrument:

- Reset the device.

- Disconnect all wires to the instrument.

- Only connect +12V to the red cable and ground to the black cable.

- The display should light up. If not, check your power supply and the priority of the red and

blue cables.

- Repeatedly tap the orange wire briefly to ground. If the speedometer display shows any

digit, this input is flawless.

- Tap the green wire to ground in short succession until the tacho display (RPM) is shown.

- Repeatedly tap the yellow wire briefly to ground. If the tacho display shows any digit, this

input is flawless.

- If this test finishes successfully, the device is operational. Please check your wiring. If this

test does not finish successfully, the instrument has to be returned.

18

14.2 Returns and Complaints

If you like to return a defective instrument for repair or change please observes following issues:

- Make sure again there is no connection failure. In doubt use a different voltage source to

recheck.

- print and fill the repair return form (refer link below) and attach it

http://motogadget.com/media/downloads/support/form_return_repair.pdf

- Not prepaid shipments will be rejected.

- The Shipment to motogadget is carried out by your own risk - you are responsible for a

sufficient insurance.

- Make sure the package is adequate.

- If you are located outside the EU, you have to declare “repair item” and value 1 Euro in

shipment custom declaration.

- Service provided for all not instrument related malfunctions (i.e. defective connection joints,

wrong parameter settings and other vehicle related problems) will be charged with 20 EUR.

- Software updates for extending functionality will be charged with 25 EUR.

The motogadget team wishes you a safe and pleasant ride and much

fun with your new motoscope.

19

15 Appendix

15.1 Connection Diagram (System Connector, 6-Pin and 9-Pin)

20

15.2 Overview: Operation with the Menu Push-Button

/