EN INSTALLATION AND USER GUIDE

ES MANUAL DE INSTALACIÓN Y UTILIZACIÓN

NL INSTALLATIE- EN GEBRUIKSGIDS

Cooking hob

Placa de cocción

Kookplaat

2

As part of our commitment to constantly improve our products, we reserve the right to alter

their technical, functional and/or aesthetic characteristics as part of their continuous

development.

IImmppoorrttaanntt nnoottee

: Please read this Installation and User Guide carefully before installing

and using the appliance, as this will help you to quickly familiarise yourself with its

operation.

TABLE OF CONTENTS

• Safety guidelines

___________________________________________

70

• Caring for the environment

__________________________________

71

• Description of your appliance

________________________________

72

1 / INSTALLING YOUR APPLIANCE

• Choice of location

__________________________________________

73

• Fitting

___________________________________________________

73

• Flush Fitting recommendations

_______________________________

74

• Electrical connection

_______________________________________

75

• Gas connection

____________________________________________

76

• Changing the gas supply

____________________________________

78

2 / USING YOUR APPLIANCE

• Description of the surface control panel

_______________________

83

• Switching on the gas burners

________________________________

84

• Suitable cookware for gas burners

____________________________

85

3 / REGULAR CARE OF YOUR APPLIANCE

• Caring for your appliance

____________________________________

86

4 / SPECIAL INSTRUCTIONS, TROUBLESHOOTING

• During use

________________________________________________

87

5 / COOKING CHART

• Gas cooking guide

_________________________________________

88

6 / SOME RECOMMENDATIONS

___________________________________

88

7 / AFTER-SALES SERVICE DEPARTMENT AND CUSTOMER RELATIONS

• Service calls

______________________________________________

89

3

EN

4

SAFETY GUIDELINES

SAFETY GUIDELINES

— This cooking hob has been designed for

private domestic use.

— This appliance must be installed in

compliance with currently applicable

regulations and used only in a well-ventilated

location. Consult this guide before installing

and using your appliance.

— Never leave the appliance unattended when

in use.

— These cooking hobs are intended solely for

cooking food and drinks and do not contain

any asbestos-based materials.

— This appliance is not connected to a

combustion by-product disposal system. It

must be installed and connected in

compliance with all applicable laws. Special

attention should be given to applicable

ventilation regulations.

— Do not store cleaning

PRODUCTS or

FLAMMABLE PRODUCTS (aerosol cans or

pressurised containers, as well as papers,

cookbooks, etc.) in the cabinet beneath your

cooking hob.

— If you use a drawer under the hob, avoid

using it to store heat sensitive items (plastic,

papers, aerosol cans, etc.).

— Your hob must be disconnected from the

power supply (electricity and gas) before

undertaking repair work.

— If you plug electrical appliances into a plug

socket which is within close proximity of the

hob ensure that any wires do not contact the

cooking zones.

— As a safety measure, remember to shut-off

the mains gas supply tap or the

butane/propane gas cylinder tap (whichever

is applicable).

— The CE compliance mark is affixed to these

hobs.

— Installation should only be undertaken by

qualified fitters and technicians.

— Before installation, make sure that the local

distribution conditions (gas type and

pressure) and the settings on the appliance

are compatible.

— This appliance is not intended to be used

by persons (including children) with reduced

physical, sensory or mental abilities, or those

lacking experience or awareness, unless they

are supervised by someone responsible for

their safety or they have received suitable

training in its operation from the said person.

Children must be supervised to prevent them

from playing with the appliance.

— This unit is not intended to be operated

using an external timer or a separate remote

control system.

— This hob is compliant with standard

EN 60335-2-6 relating to the heating of

cabinets and the Class 3 standard with regard

to installation (as per standard EN 30-1-1).

•

Warning

The required hob settings are written

on a sticker inside the instruction guide

pouch and on the packaging.

In order to easily locate any reference

information relating to your appliance, we

recommend that it is noted on the “After-

Sales Service Department and Customer

Relations” page (this page also explains

where this information can be found on your

appliance).

CAUTION: if a crack appears in the surface,

disconnect the appliance from the power

supply to prevent any risk of electric shock.

For the following references : CFI-4GLSTANAT* - CFI-3GLSTANAT*

your hob is delivered set-up for natural gas.

For the following references : CFI-4GLSTABUT* - CFI-3GLSTABUT* - 2MCF-

2GSAXBUT* your hob is delivered set-up for butane gas.

CARING FOR THE ENVIRONMENT

•

— This appliance’s packing materials can be

recycled. Please recycle the packaging and

share in the protection of the environment by

depositing them in municipal containers

provided for this purpose.

— Your appliance also contains

many recyclable materials. It is

therefore marked with this logo to

indicate that used appliances must

not be mixed with other waste. The

manufacturer will organise

recycling of the appliances in

optimum conditions, in accordance with

European directive EC/2002/96 governing

electrical and electronic equipment waste.

Consult your local authority or your retailer to

find the drop-off points for used appliances

which are nearest to your home.

— Thank you for your help in protecting the

environment.

CARING FOR THE ENVIRONMENT

5

EN

6

DESCRIPTION OF YOUR APPLIANCE

•

DESCRIPTION OF THE HOB

Hob model: 4 gas burners

with super fast burner

Hob model: 3 gas burners

with triple ring burner

Hob model: 2 gas burners

with super fast burner

A

B

Burner cover

Burner head

Injector

C

D

E

Spark plug

Thermocouple

Control Knob

F

G

H

Tap

Gasket

Note

This Installation and User guide covers several models. There may be minor differences

in details and fittings between your appliance and the descriptions provided.

D

E

A

B

F

H

G

C

1/ INSTALLING YOUR APPLIANCE

•

CHOICE OF LOCATION

Your appliance must be flush fitted into a

support cabinet surface which is at least 3 cm

thick and is manufactured from heat resistant

material or covered in a heat resistant

coating.

A minimum distance of 30 cm either side of

the hob should be free from any obstructions

(cabinet or panel) which could hinder safe

handling of cooking utensils.

If a horizontal divider wall is positioned under

the hob, it must be located between 10 cm and

15 cm from the top of the work surface. In any

event, do not store aerosol cans or

pressurised containers in any compartments

located under the hob (refer to the

“

Safety

Recommendations

”

) chapter.

FITTING

In order to guarantee the seal between the

hob and the work top, the supplied seal must

be glued into the insert prior to hob

installation:

Refer to the diagram

(Fig. 01)

.

— Remove the pan supports, burner covers

and burner heads; noting their positions.

— Turn the hob over and carefully place it on

top of the opening in the cabinet to prevent

damage to the knobs and spark plugs.

— In order to guarantee the seal between the

housing and the worktop, stick the foam seal

around the edge of the frame

(Fig. 02

).

•

49 cm mini

3 cm mini

30 cm mini

56 cm / 26,5 cm

30 cm mini

5,8 cm mini

70 cm mini

Fig. 01

Fig. 02

Housing

Seal

APPLIANCE (60 cm model)

Standard

cabinet

cut-out

Total

dimensions

above

the work

surface

Total

dimensions

below

the work

surface

Width

56 cm

71 cm

55.4 cm

Depth

49 cm

52.2 cm

47 cm

Thickness

depending

on

cabinet

5 cm

5.1 cm

APPLIANCE (30 cm model)

Standard

cabinet

cut-out

Total

dimensions

above

the work

surface

Total

dimensions

below

the work

surface

Width

26.5 cm

29,3 cm

26,3 cm

Depth

49 cm

52,5cm

47,9 cm

Thickness

depending

on

cabinet

5,4 cm

5.1 cm

7

EN

8

A

A

— Place your hob in the support cabinet

opening and carefully draw the hob towards

you.

— Re-position the burner heads, burner

covers and pan supports on the hob.

Connect the hob to the gas supply (See “Gas

Connection” chapter) and to the power

supply (See “Electrical Connection” chapter).

— If you wish, you can immobilise the hob

using the four mounting brackets (supplied

with screws)

(Fig. 02)

to attach them to the

four corners of the housing. You must use the

holes provided for this purpose, according

to the diagram above

(Fig. 02)

.

— Stop screwing when the mounting bracket

becomes deformed.

Do not use an electric screwdriver.

Fig. 01

Fig. 03

Screw

•

FLUSH FITTING RECOMMENDATIONS

Mounting brackets

A

A

Cabinet

1/ INSTALLING YOUR APPLIANCE

Fig. 02

Mounting holes

located using

arrows

A

Fig. 01

Mounting holes

A

Mounting holes

A

A

• 4 Burner Model

(underside view of the housing)

• 3 Burner Model (underside view

of the housing)

• 2 Burner Model

(underside view of the housing)

A

A

A A

Fig. 01

Mounting bracket

1/ INSTALLING YOUR APPLIANCE

9

EN

•

ELECTRICAL CONNECTION

Your hob (which is supplied with an H05V2V2-

F type wire) must be connected to the 220-

240 V

~

single phase grid via a standardised

CEI 60083 2-pole + ground electrical outlet

plug or an all-pole cut-off device, in

compliance with the current regulations.

The electrical plug socket must remain

accessible after installation.

TYPE OF CABLE SECTION TO BE USED

H05V2V2F -T90 cable

Ref. After-sales

service: 77x9060

Conductor section

in mm

2

Fuse

220-240 V

~

- 50 Hz

3 conductors

including

1 ground

1

10 A

Warning

The safety wire (green/yellow) is

connected to the appliance’s ground terminal

and must be connected to the installation’s

ground terminal . A 10 amperes fuse must

be used in the installation. If the power cable is

damaged, it must be replaced by a cable or a

special kit which is available from the

manufacturer or their After-Sales Service

Department.

Tip

Using a gas cooking appliance generates

heat and humidity in its local vicinity. Make sure

that your kitchen is well-ventilated: ensure

natural ventilation openings in your home are

unobstructed or install a mechanical ventilation

device (mechanical ventilation hood). Intensive,

prolonged use of the appliance may require

additional ventilation; you can, for example,

open a window or provide more effective

ventilation by increasing the setting on a

mechanical ventilation system, where installed.

(a minimum air flow of 2 m

3

/hr per kW of gas

power is required).

For example : 30 cm - 2 gas burners

Total power : 1.5 + 3.1 = 4.6 kW

4.6 kW x 2 = 9.2 m

3

/h

minimum flow.

10

The gas connection must be installed in

compliance with applicable regulations in the

country of installation.

• Gas distributed via natural gas

pipework

For your safety, you can only choose from the

following 3 connection options:

— Connection with a rigid copper pipe

with

screw-on mechanical connectors (G1/2 gas

standard mark). Connect directly to the end of

the elbow fitted on the appliance.

— Connection with a flexible metal hose

(stainless steel)

with screw-on mechanical

connectors

(compliant with standard NF D 36-

121) with lifetime service guarantee

(Fig. A).

— Connection with a reinforced rubber

hose

with screw-on mechanical

connectors

(compliant with the NF D 36-103 standard)

with 10 year service life guarantee

(Fig. B).

Warning

If you have to change the direction

of the elbow fitted on the appliance

when connecting your hob’s gas supply:

①①

Change the sealing washer.

②②

Tighten the elbow nut but do not

exceed 17 N.m. torque.

GAS CONNECTION

• Preliminary comments

If your hob is installed above an oven or if the proximity of other heating elements risks

overheating the connection, you must insulate the cable in a rigid pipe.

If a flexible hose or pipe (in the case of butane gas) is used, it must contact a moving part of the

cabinet or traverse a location likely to become blocked.

•

Fig. A

Fig. B

1/ INSTALLING YOUR APPLIANCE

1/ INSTALLING YOUR APPLIANCE

11

EN

• Gas supplied by tank or

cylinder (butane/propane)

For your safety, you can only choose from the

following 3 connection options:

— Connection with a rigid copper pipe

with

screw-on mechanical connectors (G1/2 gas

standard mark). Connect directly to the end of

the elbow fitted on the appliance.

— Connection with a flexible metal hose

(stainless steel)

with screw-on mechanical

connectors (compliant with standard

NF D 36 121) with lifetime service guarantee

(Fig. 01).

— Connection with a reinforced rubber

hose

with screw-on mechanical

connectors

(compliant with the NF D 36-112 standard)

with 10 year service life guarantee (Fig. 02).

A

B

Sealing washer (not provided)

Adaptor (not provided)

Hose clip (not provided)

C

Warning

All flexible pipes and hoses with a

limited service life must have a maximum

length of 2 meters and must be accessible

along their entire length. They must be

replaced before the end of their service life

(indicated on the pipe). Regardless of the

chosen connection type, use soapy water to

ensure that the connection is leaktight once

installation is complete.

In France, you must use a hose or a pipe

bearing the “NF Gaz” stamp .

In an existing system, a flexible pipe fitted

with hose clips (compliant with the XP D 36-

110 standard) with a five year service life

guarantee can be used. In this case an

adaptor must be used and a sealing washer

must be inserted between the adaptor and

the hob’s elbow

(Fig. 03).

Tip

You can obtain the adaptor and the sealing

washer from your After-Sales Service

Department.

Warning

Do not exceed 25 N.m. torque when

tightening the adaptor.

Fig. 01

Fig. 02

Fig. 03

A

B

C

12

1/ INSTALLING YOUR APPLIANCE

CHANGING THE GAS SUPPLY

Proceed as follows every time you change the

gas supply:

— Modify the gas connection

— Change the injectors

— Adjust the hob connections.

•

Modify the gas connection : refer to the

“Gas Connection” section.

•

Change the injectors, proceed as follows:

—

Remove the pan supports, heads and

covers from all burners.

For a 3-ring burner :

—

Use a 7mm type pipe spanner (not

supplied).

For other burners:

—

Use the spanner provided.

—

Unscrew and remove the injectors located

in the base of each crucible

(Fig. 01).

—

Replace with the corresponding gas

injectors, in compliance with the injector

positioning markers and the gas

characteristics table at the end of this chapter;

proceed as follows:

—

First, manually tighten until the injector

locks into place.

—

Fully connect the spanner onto the injector.

—

Draw a line on the burner plate using a

pencil where shown

(Fig. 02).

—

Turn the spanner clockwise until the line

appears on the opposite side

(Fig. 03).

Warning

Exceeding this limit may damage the

product.

•

Fig. 02

Fig. 03

Line

Line

Fig. 01

Spanner

Injector

Crucible

Warning

- For the following references : CFI-

4GLSTANAT* - CFI-3GLSTANAT*, your hob

is delivered set-up for

nnaattuurraall ggaass

.

- For the following references : CFI-

4GLSTABUT* - CFI-3GLSTABUT* - 2MCF-

2GSAXBUT*, your hob is delivered set-up for

bbuuttaannee ggaass

.

The injectors which are needed to change

the gas can be found in the installation

guide pouch.

Warning

Exceeding this limit may damage the

product.

-

Reposition the burner heads, burner covers

and pan supports on the hob.

Tip

Each time you change the gas supply,

tick the box corresponding to the new gas

level on the label found in the instruction

guide pouch.

Refer to the corresponding “Gas

Connection” section.

Spanner

Spanner

1/ INSTALLING YOUR APPLIANCE

13

EN

•

Adjust the hob connections: these are

located underneath the control knobs

(Fig. 04)

.

—

Proceed one tap at a time.

—

Remove the control knobs and the gaskets

by pulling upwards.

- Switching from natural gas to

butane/propane

-

Using a small flat-head screwdriver, fully

tighten the brass burner power screws

(yellow)

(Fig. 05),

in a clockwise direction.

-

Replace the gaskets and the control knobs,

noting their direction and ensuring that the

control knobs are fully inserted.

- Switching from butane/propane to natural

gas

-

Unscrew the brass (yellow) burner power

screws

(Fig. 05)

, using a small flat-head

screwdriver, turn twice anti-clockwise.

-

Replace the control knob.

-

Ignite the burner in maximum heat mode,

then turn down to reduced heat mode.

-

Remove the control knob again, then turn

the burner power screw clockwise until it

reaches the lowest possible setting without

extinguishing the flame.

-

Replace the gasket and control knob.

-

Repeatedly change from the maximum to

the minimum flow rate: the flame must not go

out ; if it does, unscrew the burner adjustment

screw to achieve good flame retention during

these changes.

-

Replace the burner heads, burner covers

and pan supports on the hob.

Sealing ring

Tap

Fig. 04

Fig. 05

Tap axis

Burner power

adjustment screw

Control Knob

14

1/ INSTALLING YOUR APPLIANCE

• Injector markings

The diagram opposite shows where the

injectors are positioned on your appliance

according to the type of gas used.

Each number is marked on the injector.

INJECTOR MARKINGS

4 gas burner hob with triple ring

3 gas burner hob with triple ring

62

For example:

injector marking 62

Natural Gas

Butane/Propane

Gas

2 gas burner hob

Natural Gas

Butane/Propane Gas

137

63

Natural Gas

Butane/Propane

Gas

94

1R

63

62

7R

45

88A

45

092/55B/092

092/55B/092

60/37/60

60/37/60

137

94

88A

62

1/ INSTALLING YOUR APPLIANCE

15

EN

• Injector markings

TRIPLE RING BURNER INJECTOR MARKINGS

Natural Gas

Butane/Propane Gas

092

60

55B

37

092

60

16

1/ INSTALLING YOUR APPLIANCE

•Gas Properties

Appliance intended to be installed for use with:

Butane Butane Propane Natural Natural

FR.......................cat : II2E+3+ gas gas

ES - PT ..............cat : II2H3+ G30 G30 G31 G20 G25

CZ - SK ..............cat : 2H3B/P 28-30 mbar 30 mbar 37 mbar 20 mbar 25 mbar

Following hourly rate at 15°C under 1013 mbar:

H

IGH-SPEED BURNER

Marking engraved on injector 7R 7R 7R 1R 1R

Nominal heat release rate (kW) 2.15 2.15 2.15 2.25 2.25

Reduced heat release rate (kW) 0.830 0.830 0.870 0.870

Hourly rate (g/hr) 156 156 154

Hourly rate (l/hr) 214 249

S

UPER-FAST BURNER

Marking engraved on injector 88A 88A 88A 137 137

Nominal heat release rate (kW) 3.15 3.15 3.15 3.10 3.10

Reduced heat release rate (with safety) (kW) 0.830 0.830 0.870 0.870

Hourly rate (g/hr) 229 229

Hourly rate (l/hr) 225 295 343

S

EMI-FAST BURNER

Marking engraved on injector 62 62 62 94 94

Nominal heat release rate (kW) 1.50 1.50 1.50 1.50 1.50

Reduced heat release rate (with safety) (kW) 0.620 0.620 0.615 0.615

Hourly rate (g/hr) 109 109

Hourly rate (l/hr) 107 143 166

A

UXILIARY BURNER

Marking engraved on injector 45 45 45 63 63

Nominal heat release rate (kW) 0.75 0.75 0.75 0.85 0.85

Reduced heat flow (kW) 0.300 0.300 0.350 0.350

Hourly rate (g/hr) 55 55

Hourly rate (l/hr) 54 81 94

T

RIPLE RING BURNER

Marking engraved on injector 60/37/60 60/37/60 60/37/60 092/055B/092 092/055B/092

Nominal heat release rate (kW) 3.25 3.25 3.25 3.60 3.60

Reduced heat flow (kW) 1.650 1.650 1.450 1.450

Hourly rate (g/hr) 236 236 232

Hourly rate (l/hr) 343 399

4

GAS BURNER HOB WITH TRIPLE RING

Total heat release rate (kW) 7.65 7.65 7.65 8.20 8.20

Maximum flow rate (g/hr) 556 556 547

(l/hr) 781 908

3

GAS BURNER HOB WITH TRIPLE RING

Total heat release rate (kW) 7.15 7.15 7.15 7.55 7.55

Maximum flow rate (g/hr) 520 520 511

(l/hr) 719 836

2

GAS BURNER HOB

WITH SUPER FAST

Total heat release rate (kW) 4.65 4.65 4.65 4.60 4.60

Maximum flow rate (g/hr) 338 338 332

(l/hr) 438 509

ES - PT -

FR

CZ - SK ES - PT -

FR

FR - ES -

PT - CZ -

SK

FR

2 / USING YOUR APPLIANCE

17

EN

DESCRIPTION OF THE SURFACE CONTROL PANEL

•

CFI-4GLSTA*

2MCF-2GSAX*

A

B

C

D

E

C

A

E

B

D

Semi-fast burner 1.50 kW*

High-speed burner 2.25 kW

*

Super fast burner 3.10 kW*

Auxiliary burner 0.85 kW *

Triple-ring burner 3.6 kW*

* Power obtained with natural gas G20

C

A

CFI-3GLSTA*

C

E

D

18

2 / USING YOUR APPLIANCE

Gas is supplied to each burner via a tap which

is opened by pressing and turning the gas

control knob anti-clockwise.

The black

“

●

”

indicates the closed position.

— Choose the desired burner by using the

symbols located near the control knobs (e.g. :

right hand side burner ).

The control knobs on your hob are fitted with

an integrated burner-ignition system.

— To light a burner, press in and turn the

control knob anti-clockwise to the

maximum setting .

— Hold down the control knob to produce a

series of sparks until the burner lights.

The setting for more moderate flame

intensities is between the symbol and

the symbol.

Tip

If a control knob becomes difficult to

turn, do not force it. Call the installer for

emergency repairs.

If the flame is extinguished accidentally, re-

ignite as normal following the burner

ignition instructions.

•

Fig. 01

SWITCHING ON THE GAS BURNERS

2 / USING YOUR APPLIANCE

19

EN

•

CORRECT

INCORRECT

CONVEX

CONCAVE

Fig. 01

Fig. 02

Fig. 03

SUITABLE COOKWARE FOR GAS BURNERS

• Which burner should you use for your particular cookware?

Warning

— Adjust the burner flame so that it

does not extend beyond the edge of the

cookware (Fig. 01).

— Do not use cookware with a concave or

convex base without the appropriate supports

(Fig. 02).

— Do not use cookware that partially covers

the control knobs (Fig. 03).

— Do not leave empty cookware over an

ignited gas burner.

— Do not use heat regulators, toasters, steel

meat grills or stewpots with feet which sit on

or contact the glass worktop.

Cookware diameter

20 to 30 cm

18 to 28 cm

16 to 22 cm

12 to 20 cm

8 to 14 cm

Cookware diameter

Triple ring

Super fast

High-speed

Semi-fast

Auxiliary

Usage

Frying - Boiling

Searing

Sauces - Reheating

Gentle simmer

20

PRODUCTS/ACCESSORIES

TO BE USED

. Small, hard-bristled brush.

. Safety pin.

. Gentle scouring cream.

. Cleaning sponge.

- Cleaning sponge.

- Special vitroceramic glass

products (e.g.: Cera-Clean).

Warning

- Never clean your appliance while it is in operation. Set all the electric and gas

controls to zero.

- WARNING: if a crack appears in the surface, disconnect the appliance from the power

supply to prevent any risk of electric shock.

Tip

—

We recommend cleaning hob fittings by hand rather than in a dishwasher.

—

Do not use an abrasive sponge to clean your hob.

—

Do not use a steam cleaner.

CARING FOR YOUR APPLIANCE

•

MAINTENANCE......

Of the spark plugs

and injectors

Of the pan supports

and gas burners

Of the glass

worktop

3 / REGULAR CARE OF YOUR APPLIANCE

ACTION

If spark plugs become soiled, clean them

using a small, hard-bristled brush (non-

metallic).

The gas injector is located in the centre of

the burner in the form of a crucible. Avoid

obstructing the injector during cleaning, as

this will adversely affect hob performance.

Use a safety pin to unclog the injector if it

becomes obstructed.

For tough stains, use a non-abrasive

cream, then rinse with clean water.

Carefully wipe each part of the burner

before re-using your hob.

- Clean with warm water and then wipe.

For tough stains, use products designed

for vitroceramic glass.

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

Groupe Brandt CFI-4GLSTANAT Owner's manual

- Type

- Owner's manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

De Dietrich DPE7649XF Owner's manual

De Dietrich DPE7649XF Owner's manual

-

Groupe Brandt BPE6410XE Owner's manual

-

De Dietrich MC-2LSAXNAT Owner's manual

De Dietrich MC-2LSAXNAT Owner's manual

-

De Dietrich DTG915X Owner's manual

De Dietrich DTG915X Owner's manual

-

Groupe Brandt BPI6413BM Owner's manual

-

De Dietrich DTG701B Owner's manual

De Dietrich DTG701B Owner's manual

-

Groupe Brandt TE560WF1 Owner's manual

-

Groupe Brandt STE147X Owner's manual

-

De Dietrich DTG703X Owner's manual

De Dietrich DTG703X Owner's manual

Other documents

-

Fagor CFI-4GLSTANAT User guide

-

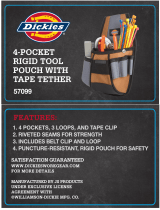

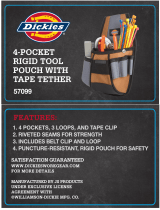

Dickies 57099 Operating instructions

Dickies 57099 Operating instructions

-

Brandt TE560WF1 Owner's manual

-

Brandt TE1416W Owner's manual

-

Brandt TE541WF1 Owner's manual

-

Brandt TG1013B User manual

-

Brandt TG1012B Important information

-

De Dietrich DPE7649XF Operating instructions

De Dietrich DPE7649XF Operating instructions

-

Samsung GN752CFX User manual

-

Samsung GN642BFX User manual