IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Version Version française Versión en español

See page 2 Voir page 25 Ver la página 48

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1-877-SKIL999 (1-877-754-5999) www.skil.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

5995

5996

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 1

-2-

*<?8.?2.@.32AF

22=D<?8.?2.092.;.;1D29996ACluttered

or dark areas invite accidents.

< ;<A<=2?.A2 =<D2? A<<9@ 6; 2E=9<@6C2

.A:<@=52?2@ @B05 .@ 6; A52 =?2@2;02 <3

39.::./92 96>B61@ 4.@2@ <? 1B@A Power

tools create sparks which may ignite the dust

or fumes.

22= 05691?2;.;1/F@A.;12?@.D.FD5692

<=2?.A6;4 . =<D2? A<<9 Distractions can

cause you to lose control.

920A?60.9@.32AF

#<D2? A<<9 =9B4@:B@A :.A05 A52 <BA92A

!2C2?:<163FA52=9B46;.;FD.F<;<A

B@2 .;F .1.=A2? =9B4@ D6A5 2.?A521

4?<B;121 =<D2? A<<9@ Unmodified plugs

and matching outlets will reduce risk of electric

shock.

C<61/<1F0<;A.0AD6A52.?A521<?4?<B;121

@B?3.02@@B05.@ =6=2@?.16.A<?@ ?.;42@

.;1?23?642?.A<?@There is an increased risk

of electric shock if your body is earthed or

grounded.

<;<A 2E=<@2 =<D2?A<<9@A< ?.6;<?D2A

0<;16A6<;@ Water entering a power tool will

increase the risk of electric shock.

<;<A./B@2A520<?1!2C2?B@2A520<?1

3<?0.??F6;4=B996;4<?B;=9B446;4A52=<D2?

A<<922=0<?1.D.F3?<:52.A<69@5.?=

2142@<?:<C6;4=.?A@Damaged or entangled

cords increase the risk of electric shock.

*52; <=2?.A6;4 .=<D2? A<<9 <BA1<<?@

B@2.;2EA2;@6<;0<?1@B6A./923<?<BA1<<?

B@2 Use of a cord suitable for outdoor use

reduces the risk of electric shock.

3<=2?.A6;4.=<D2?A<<96;.1.:=9<0.A6<;

6@B;.C<61./92B@2.?<B;1.B9A6?0B6A

;A2??B=A2?=?<A20A21@B==9FUse of

an GFCI reduces the risk of electric shock.

#2?@<;.9@.32AF

&A.F.92?A D.A05 D5.AF<B.?21<6;4.;1

B@2 0<::<; @2;@2 D52; <=2?.A6;4 .

=<D2?A<<9<;<AB@2.=<D2?A<<9D5692

F<B.?2A6?21<?B;12?A526;39B2;02<31?B4@

.90<5<9<?:2160.A6<;A moment of inattention

while operating power tools may result in

serious personal injury.

(@2=2?@<;.9=?<A20A6C22>B6=:2;A9D.F@

D2.? 2F2 =?<A20A6<; Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

#?2C2;AB;6;A2;A6<;.9@A.?A6;4;@B?2A52

@D6A05 6@ 6; A52 <33=<@6A6<; /23<?2

0<;;20A6;4A<=<D2?@<B?02.;1<?/.AA2?F

=.08=6086;4 B= <? 0.??F6;4 A52 A<<9

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

%2:<C2.;F.17B@A6;482F<?D?2;05/23<?2

AB?;6;4 A52 =<D2? A<<9 <; A wrench or a

key left attached to a rotating part of the power

tool may result in personal injury.

<;<A<C2??2.0522==?<=2?3<<A6;4.;1

/.9.;02 .A .99 A6:2@ This enables better

control of the power tool in unexpected

situations.

?2@@=?<=2?9F<;<AD2.?9<<@209<A56;4

<?72D29?F 22= F<B? 5.6? 09<A56;4 .;1

49<C2@ .D.F 3?<::<C6;4 =.?A@Loose

clothes, jewelry or long hair can be caught in

moving parts.

312C602@.?2=?<C61213<?A520<;;20A6<;

<31B@A2EA?.0A6<; .;10<9920A6<;3.0696A62@

2;@B?2A52@2 .?2 0<;;20A21 .;1 =?<=2?9F

B@21Use of dust collection can reduce dust-

related hazards.

#<D2?A<<9B@2.;10.?2

<;<A3<?02A52=<D2?A<<9(@2A520<??20A

=<D2? A<<93<?F<B?.==960.A6<;The correct

power tool will do the job better and safer at

the rate for which it was designed.

<;<AB@2A52=<D2?A<<963A52@D6A051<2@

;<A AB?; 6A <; .;1 <33 Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

%2.1.99@.32AFD.?;6;4@.;1.996;@A?B0A6<;@Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

&)*%!!&!!&'%('"!&"%('(%%%!

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

!

WARNING

2;2?.9#<D2?'<<9&.32AF*.?;6;4@

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 2

-3-

6@0<;;20AA52=9B43?<:A52=<D2?@<B?02

.;1<?A52/.AA2?F=.083?<:A52=<D2?A<<9

/23<?2:.86;4.;F.17B@A:2;A@05.;46;4

.002@@<?62@<? @A<?6;4 =<D2? A<<9@ Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

&A<?26192=<D2?A<<9@ <BA<3A52?2.05 <3

05691?2; .;1 1< ;<A .99<D =2?@<;@

B;3.:696.? D6A5 A52 =<D2?A<<9 <? A52@2

6;@A?B0A6<;@A< <=2?.A2 A52 =<D2?A<<9

Power tools are dangerous in the hands of

untrained users.

.6;A.6;=<D2?A<<9@52083<?:6@.964;:2;A

<? /6;16;4 <3:<C6;4 =.?A@/?2.8.42 <3

=.?A@.;1 .;F<A52?0<;16A6<; A5.A :.F

.3320A A52 =<D2? A<<9L@ <=2?.A6<; 3

1.:.421 5.C2A52 =<D2?A<<9 ?2=.6?21

/23<?2 B@2 Many accidents are caused by

poorly maintained power tools.

22=0BAA6;4A<<9@@5.?=.;1092.;Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

(@2A52 =<D2?A<<9.002@@<?62@ .;1 A<<9

/6A@2A06;.00<?1.;02D6A5A52@26;@A?B0A6<;@

A.86;46;A<.00<B;AA52D<?86;40<;16A6<;@

.;1A52 D<?8 A< /2 =2?3<?:21Use of the

power tool for operations different from those

intended could result in a hazardous situation.

.AA2?FA<<9B@2.;10.?2

%205.?42<;9F D6A5A5205.?42? @=2063621

/F A52 :.;B3.0AB?2? A charger that is

suitable for one type of battery pack may

create a risk of fire when used with another

battery pack.

(@2 =<D2? A<<9@ <;9F D6A5 @=206360.99F

12@64;.A21/.AA2?F=.08@ Use of any other

battery packs may create a risk of injury and

fire.

*52; /.AA2?F =.08 6@ ;<A 6; B@2 822= 6A

.D.F3?<:<A52?:2A.9</720A@9682=.=2?

096=@0<6;@82F@;.69@ @0?2D@ <? <A52?

@:.99 :2A.9 </720A@ A5.A 0.; :.82 .

0<;;20A6<;3?<: <;2A2?:6;.9A< .;<A52?

Shorting the battery terminals together may

cause burns or a fire.

(;12? ./B@6C2 0<;16A6<;@ 96>B61 :.F /2

2720A213?<:A52/.AA2?F.C<610<;A.0A3

0<;A.0A .00612;A.99F <00B?@ 39B@5 D6A5

D.A2?396>B610<;A.0A@2F2@.116A6<;.99F

@228 :2160.9 529= Liquid ejected from the

battery may cause irritation or burns.

&2?C602

.C2F<B?=<D2?A<<9@2?C6021/F.>B.963621

?2=.6? =2?@<; B@6;4 <;9F 612;A60.9

?2=9.02:2;A=.?A@ This will ensure that the

safety of the power tool is maintained.

BAA6;4=?<021B?2@

22= 5.;1@ .D.F 3?<:

0BAA6;4.?2..;1A52/9.12

22=F<B?@20<;15.;1<;.BE696.?F5.;192

<?:<A<?5<B@6;4 If both hands are holding

the saw, they cannot be cut by the blade.

< ;<A?2.05 B;12?;2.A5 A52 D<?8=6202

The guard cannot protect you from the blade

below the workpiece.

17B@AA520BAA6;412=A5A<A52A5608;2@@<3

A52D<?8=6202Less than a full tooth of the

blade teeth should be visible below the

workpiece.

!2C2?5<91=6202/26;40BA6;F<B?5.;1@

<?.0?<@@F<B?924 &20B?2A52D<?8=6202A<

@A./92=9.A3<?: It is important to support the

work properly to minimize body exposure,

blade binding, or loss of control.

<91 =<D2?A<<9/F 6;@B9.A21 4?6==6;4

@B?3.02@D52;=2?3<?:6;4.;<=2?.A6<;

D52?2A520BAA6;4A<<9:.F0<;A.0A56112;

D6?6;4 Contact with a "live" wire will also make

exposed metal parts of the tool “live” and shock

the operator.

*52; ?6==6;4 .9D.F@ B@2 . ?6= 32;02 <?

@A?.645A 2142 4B612 This improves the

accuracy of cut and reduces the chance for

blade binding.

9D.F@ B@2 /9.12@ D6A5 0<??20A@6G2.;1

@5.=216.:<;1 C2?@B@ ?<B;1 <3 .?/<?

5<92@Blades that do not match the mounting

hardware of the saw will run eccentrically,

causing loss of control.

!2C2?B@2 1.:.421 <? 6;0<??20A/9.12

D.@52?@<?/<9A The blade washers and bolt

were specially designed for your saw, for

&.32AF%B92@3<?6?0B9.?&.D@

%2.1.99@.32AFD.?;6;4@.;1.996;@A?B0A6<;@

!

WARNING

!

DANGER

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 3

-4-

optimum performance and safety of operation.

'56@=?<1B0A6@6;A2;121A<0BAD<<1.;1

D<<19682 =?<1B0A@ <;9F. Dust build up

around the lower guard and hub from other

materials (plastic, masonry or metal) may

disable the lower guard operation.

;@=20A A520<;16A6<; .;1 >B.96AF <3 A52

D<<1 .;1 ?2:<C2 .99;.69@ 3?<:9B:/2?

/23<?20BAA6;4Wet lumber, green lumber or

pressure treated lumber require special

attention during cutting operation to prevent

kickback.

<91 A52 @.D 36?:9F A< =?2C2;A 9<@@ <3

0<;A?<9 Figures in this manual illustrate

typical hand support of the saw.

2=2;16;4B=<; B@2 A52 @D6A05 :.F ;<A

9.@AA529632<3A52@.D3A52@D6A05@5<B91

3.696;A52I"J=<@6A6<;A52@.D:.F;<A

@A.?A 3 6A @5<B91 3.69 D5692 A52 @.D 6@

?B;;6;4A52@.D:.F;<A@5BA<33 If either

occurs, unplug the saw immediately and do not

use until repaired.

'56@06?0B9.?@.D@5<B91;<A/2:<B;A21A<

. A./92.;1 0<;C2?A21 A< . A./92 @.D

Circular saws are not designed or intended to

be used as table saws.

608/.08.;1?29.A21D.?;6;4@

.B@2@.;1<=2?.A<?=?2C2;A6<;<3

8608/.08

Kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the

workpiece toward the operator.

When the blade is pinched or bound tightly by

the kerf closing down, the blade stalls and the

motor reaction drives the unit rapidly back

toward the operator.

If the blade becomes twisted or misaligned in

the cut, the teeth at the back edge of the blade

can dig into the top surface of the wood

causing the blade to climb out of the kerf and

jump back toward the operator.

Kickback is the result of tool misuse and/or

incorrect operating procedures or conditions

and can be avoided by taking proper

precautions as given below:

.6;A.6;.36?:4?6=D6A5/<A55.;1@<;A52

@.D .;1 =<@6A6<; F<B? .?:@ A< ?2@6@A

8608/.08 3<?02@ #<@6A6<;F<B? /<1F A<

26A52?@612<3A52/9.12/BA;<A6;96;2D6A5

A52/9.12 Kickback could cause the saw to

jump backwards, but kickback forces can be

controlled by the operator, if proper

precautions are taken.

*52;/9.126@/6;16;4<?D52;6;A2??B=A6;4

.0BA3<?.;F?2.@<;?292.@2A52A?6442?.;1

5<91A52 @.D:<A6<;92@@ 6;A52 :.A2?6.9

B;A69A52/9.12 0<:2@A< . 0<:=92A2@A<=

!2C2?.AA2:=AA<?2:<C2A52@.D3?<:A52

D<?8 <? =B99A52@.D /.08D.?1 D5692 A52

/9.126@6;:<A6<;<?8608/.08:.F<00B?

Investigate and take corrective action to

eliminate the cause of blade binding.

*52;?2@A.?A6;4. @.D 6; . D<?8=6202

02;A2?A52@.D/9.126;A5282?3.;105208

A5.A@.D A22A5 .?2 ;<A 2;4.4216;A<A52

:.A2?6.9 If saw blade is binding, it may walk

up or kickback from the workpiece as the saw

is restarted.

&B==<?A9.?42=.;29@A<:6;6:6G2A52?6@8<3

/9.12 =6;056;4.;18608/.08 Large panels

tend to sag under their own weight. Supports

must be placed under the panel on both sides,

near the line of cut and near the edge of the

panel.

< ;<A B@2 1B99 <? 1.:.421 /9.12@

Unsharpened or improperly set blades

produce narrow kerf causing excessive friction,

blade binding and kickback.

9.12 12=A5.;1 /2C29 .17B@A6;4 9<086;4

92C2?@ :B@A /2A645A .;1 @20B?2/23<?2

:.86;40BA If blade adjustment shifts while

cutting, it may cause binding and kickback.

(@22EA?.0.BA6<;D52;:.86;4 .I#9B;42

BAJ 6;A< 2E6@A6;4 D.99@<? <A52? /96;1

.?2.@ The protruding blade may cut objects

that can cause kickback.

'52/9.12 D.@52?@.;1 A52 /<9A<; F<B?

@.D 5.C2 /22; 12@64;21 A<D<?8.@ .

09BA05A<?21B02A526;A2;@6AF<3.8608/.08

(;12?@A.;1A52 <=2?.A6<; .;1 @2AA6;4@ <3

A52 )%'"%$( (' The proper

setting of the clutch, combined with firm

handling of the saw will allow you to control

kickback.

!2C2? =9.02 F<B? 5.;1/256;1 A52 @.D

/9.12Kickback could cause the saw to jump

backwards over your hand.

< ;<A B@2 A52 @.DD6A5 .; 2E02@@6C2

12=A5 <3 0BA @2AA6;4 Too much blade

exposure increases the likelihood of the blade

twisting in the kerf and increases the surface

area of the blade available for pinching that

leads to kickback.

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 4

-5-

<D2?4B.?13B;0A6<;

5208 9<D2? 4B.?1 3<? =?<=2? 09<@6;4

/23<?2 2.05B@2<;<A <=2?.A2@.D 63

9<D2?4B.?1 1<2@ ;<A :<C2 3?229F .;1

09<@26;@A.;A9F!2C2? 09.:=<? A62 A52

9<D2?4B.?16;A<A52<=2;=<@6A6<; If saw is

accidentally dropped, lower guard may be

bent. Raise the lower guard only with the lower

guard lift lever and make sure it moves freely

and does not touch the blade or any other part,

in all angles and depths of cut.

5208A52 <=2?.A6<; <3 A52 9<D2? 4B.?1

@=?6;43A524B.?1.;1A52@=?6;4.?2;<A

<=2?.A6;4=?<=2?9F A52F:B@A/2 @2?C6021

/23<?2 B@2 Lower guard may operate

sluggishly due to damaged parts, gummy

deposits, or a buildup of debris.

<D2?4B.?1@5<B91/2?2A?.0A21:.;B.99F

<;9F3<?@=206.90BA@@B05.@I#9B;42BA@J

.;1I<:=<B;1BA@J %.6@29<D2?4B.?1

/F 9<D2? 4B.?1963A92C2?.;1 .@ @<<; .@

/9.122;A2?@A52:.A2?6.99<D2?4B.?1:B@A

/2?292.@21 For all other sawing, the lower

guard should operate automatically.

9D.F@ </@2?C2 A5.A A52 9<D2? 4B.?1 6@

0<C2?6;4 A52 /9.12 /23<?2=9.06;4@.D

1<D;<; /2;05 <?39<<? An unprotected,

coasting blade will cause the saw to walk

backwards, cutting whatever is in its path. Be

aware of the time it takes for the blade to stop

after switch is released.

<;<A?B;A52A<<9D56920.??F6;46A.AF<B?

@612 <D2? 4B.?1:.F /2<=2;21 /F.

0<;A.0A D6A5 F<B? 09<A56;4 Accidental

contact with the spinning saw blade could

result in serious personal injury.

#2?6<160.99F ?2:<C2A52 /9.12 092.;A52

B==2?9<D2?4B.?1@.;1A525B/.?2.D6A5

82?<@2;2.;1D6=26A1?F<?/9<D6A092.;

D6A50<:=?2@@21.6?Preventive maintenance

and properly operating guard will reduce the

probability of an accident.

KICKBACK

116A6<;.9&.32AF*.?;6;4@

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

<;<A B@2 <;9F?.A21 A<<9@D6A5.

=<D2? @B==9FWhile the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

22= 5.;192@1?F092.;.;13?223?<:<69

.;14?2.@2 Slippery hands cannot safely

control the power tool.

2C29<=. =2?6<160:.6;A2;.;02@0521B92

3<?F<B?A<<9 *52; 092.;6;4 . A<<9 /2

0.?23B9;<AA< 16@.@@2:/92.;F=<?A6<;<3

A52 A<<9 @6;02 6;A2?;.9 D6?2@ :.F /2

:6@=9.021<?=6;0521<?@.32AF4B.?1?2AB?;

@=?6;4@ :.F /2 6:=?<=2?9F :<B;A21

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

;@B?2 A52 @D6A05 6@ 6; A52 <33 =<@6A6<;

/23<?26;@2?A6;4/.AA2?F=.08 Inserting the

battery pack into power tools that have the

switch on invites accidents.

&<:21B@A0?2.A21/F=<D2?

@.;16;4 @.D6;4 4?6;16;4

1?6996;4 .;1 <A52? 0<;@A?B0A6<; .0A6C6A62@

0<;A.6;@052:60.9@8;<D;A<0.B@20.;02?

/6?A5 12320A@<? <A52? ?2=?<1B0A6C2 5.?:

&<:22E.:=92@<3A52@2052:60.9@.?2

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

!

WARNING

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 5

.AA2?F5.?42?

23<?2 B@6;4 /.AA2?F

05.?42? ?2.1 .99

6;@A?B0A6<;@.;1 0.BA6<;.?F :.?86;4@ <;

/.AA2?F05.?42?/.AA2?F=.08.;1

=?<1B0AB@6;4/.AA2?F

(@2<;9F A5205.?42?D5605 .00<:=.;621

F<B? =?<1B0A <? 16?20A ?2=9.02:2;A .@

96@A216;A520.A.9<4<?A56@:.;B.9 Do not

substitute any other charger. Use only Skil

approved chargers with your product. See

Functional Description and Specifications.

<;<A16@.@@2:/9205.?42?<?<=2?.A2A52

05.?42? 636A 5.@?2026C21. @5.?= /9<D

/22; 1?<==21 <? <A52?D6@2 1.:.421 6;

.;F D.F%2=9.021.:.421 0<?1 <? =9B4@

6::216.A29F Incorrect reassembly or

damage may result in electric shock or fire.

<;<A ?205.?42/.AA2?F 6;1.:= <? D2A

2;C6?<;:2;A< ;<A 2E=<@205.?42? A<

?.6;<?@;<D3/.AA2?F0.@26@0?.0821<?

<A52?D6@2 1.:.421 1<;<A6;@2?A6;A<

05.?42? Battery short or fire may result.

5.?42<;9F &869 .==?<C21 ?205.?42./92

/.AA2?62@ See Functional Description and

Specifications. Other types of batteries may

burst causing personal injury and damage.

5.?42 /.AA2?F =.08 6; A2:=2?.AB?2@

./<C2 124?22@ 124?22@ .;1

/29<D 124?22@ 124?22@

&A<?2 A<<9.;1/.AA2?F =.08 6;9<0.A6<;@

D52?2 A2:=2?.AB?2@ D699 ;<A 2E0221

124?22@124?22@ This is important

to prevent serious damage to the battery cells.

.AA2?F92.8.42:.F <00B?B;12? 2EA?2:2

B@.42 <? A2:=2?.AB?2 0<;16A6<;@ C<61

0<;A.0AD6A5@86; .;1 2F2@ The battery

liquid is caustic and could cause chemical

burns to tissues. If liquid comes in contact with

skin, wash quickly with soap and water. If the

liquid contacts your eyes, flush them with

water for a minimum of 10 minutes and seek

medical attention.

#9.02 05.?42? <; 39.A ;<;39.::./92

@B?3.02@ .;1 .D.F 3?<: 39.::./92

:.A2?6.9@ D52; ?205.?46;4 /.AA2?F =.08

The charger and battery pack heat during

charging. Carpeting and other heat insulating

surfaces block proper air circulation which

may cause overheating of the charger and

battery pack. If smoke or melting of the case

are observed unplug the charger immediately

and do not use the battery pack or charger.

(@2 <3 .; .AA.05:2;A ;<A ?20<:

:2;121<?@<91/F&869:.F?2@B9A6;.?6@8

<336?22920A?60@5<08<?6;7B?FA<=2?@<;@

-6-

*52; /.AA2?62@ .?2;<A 6;

A<<9<?05.?42?822=A52:

.D.F 3?<: :2A.9 </720A@ For example, to

protect terminals from shorting, "K!"'

place batteries in a tool box or pocket with

nails, screws, keys, etc. Fire or injury may

result.

" !"' #(' ''%& !'" % "%

+#"& '" ' They may

explode.

.AA2?F.?2

!

WARNING

!

WARNING

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 6

< ;<A.AA2:=AA< 16@.@@2:/92 A52 /.AA2?F <? ?2:<C2 .;F0<:=<;2;A

=?<720A6;4 3?<: A52/.AA2?F A2?:6;.9@ Fire or injury may result. Prior to

disposal, protect exposed terminals with heavy insulating tape to prevent shorting.

-7-

! ( ''%&

If equipped with a nickel-cadmium battery, the

battery must be collected, recycled or

disposed of in an environ mentally sound

manner.

“The EPA certified RBRC

Battery Recycling Seal on the

nickel-cadmium (Ni-Cd)

battery indicates Robert

Bosch Tool Corporation is

voluntarily participating in an

industry program to collect and recycle these

batteries at the end of their useful life, when

taken out of service in the United States or

Canada. The RBRC program provides a

convenient alterative to placing used Ni-Cd

batteries into the trash or the munici pal waste

stream, which may be illegal in your area.

Please call 1-800-8-BATTERY for information

on Ni-Cd battery recycling and disposal

bans/restrictions in your area, or return your

batteries to a Skil/Bosch/Dremel Service

Center for recycling. Robert Bosch Tool

Corporation’s involvement in this program is

part of our commitment to preserving our

environment and conserving our natural

resources.”

'( "!''%&

If equipped with a lithium-ion battery, the

battery must be collected, recycled or disposed

of in an environ mentally sound manner.

“The EPA certified RBRC

Battery Recycling Seal on the

lithium-ion (Li-ion) battery

indicates Robert Bosch Tool

Corporation is voluntarily

participating in an industry

program to collect and recycle these batteries

at the end of their useful life, when taken out

of service in the United States or Canada.

The RBRC program provides a convenient

alterative to placing used Li-ion batteries into

the trash or the munici pal waste stream, which

may be illegal in your area.

Please call 1-800-8-BATTERY for information

on Li-ion battery recycling and disposal

bans/restrictions in your area, or return your

batteries to a Skil/Bosch/Dremel Service

Center for recycling. Robert Bosch Tool

Corporation’s involvement in this program is

part of our commitment to preserving our

environment and conserving our natural

resources.”

!

WARNING

.AA2?F6@=<@.9

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 7

-8-

#"%'!' Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

&F:/<9 !.:2 2@64;.A6<;E=9.;.A6<;

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

n Rated speed Maximum attainable speed

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

per minute orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling

program

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

&F:/<9@

0

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 8

-9-

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

&F:/<9@0<;A6;B21

#"%'!' Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

This symbol designates that this tool is recognized by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 9

Model number 5995 & 5996

Voltage rating 18 V

No load speed n

0

4,200/min

Charge time 1 hr

5.?42?!6.1 SC118, SC118B & SC118C

.AA2?F=.08 SB18A, SB18B & SB18C

5.?42?66<; SC118B-LI or SC118C-LI

.AA2?F=.08 SB18B-LI or SB18C-LI

Voltage rating 120 V 60 Hz

.E6:B:.=.06A62@

Blade 5-3/8"

Depth of cut at 90° 1-5/8"

Depth of cut at 45° 1-1/4"

Depth of cut at 50° 1-13/64"

''!'"! Use only thin kerf

blades designed for Cordless

Circular Saws.

6@0<;;20A /.AA2?F =.08 3?<: A<<9 /23<?2 :.86;4 .;F .@@2:/9F

.17B@A:2;A@ <? 05.;46;4 .002@@<?62@. Such preventive safety measures

reduce the risk of starting the tool accidentally.

-10-

B;0A6<;.92@0?6=A6<;.;1&=206360.A6<;@

!

WARNING

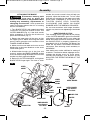

LOWER GUARD

LIFT LEVER

AUXILIARY

HANDLE

SAFETY SWITCH

RELEASE BUTTON

TRIGGER

DEPTH ADJUSTMENT

KNOB

BLADE WRENCH &

STORAGE AREA

BATTERY RELEASE

BUTTON

BUTTON

BATTERY CHARGE

CONDITION INDICATOR

LIGHTS

BATTERY PACK

FOOT

BEVEL

ADJUSTMENT

KNOB

CALIBRATED

BEVEL QUADRANT

VENTILATION

OPENINGS

CALIBRATED

DEPTH BRACKET

LASER BUTTON

(Model 5996 only)

LOWER GUARD

RUBBERIZED

GRIP

UPPER GUARD

FIG. 1

<?192@@

6?0B9.?&.D

For replacement blades we recommend Skil Cordless Circular saw blades. Their thin kerf and

tooth design deliver the best speed, quality of cut, and reduce battery drain. Use of standard

blades will substantially affect the performance and reduce run-time.

LOCK

BUTTON

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 10

-11-

@@2:/9F

''!'

6@0<;;20A /.AA2?F =.08

3?<: A<<9 <? =9.02 A52

@D6A056;A529<0821<?<33=<@6A6<;/23<?2

:.86;4 .;F .@@2:/9F .17B@A:2;A@ <?

05.;46;4 .002@@<?62@. Such preventive

safety measures reduce the risk of starting

the tool accidentally.

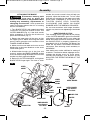

1. Turn BLADE STUD with wrench provided

clockwise and remove BLADE STUD and

OUTER WASHER (Fig. 2). If the shaft moves

while attempting to loosen the blade stud

press the lock button (Fig. 1).

2. Retract the lower guard all the way up into

the upper guard. While retracting the lower

guard, check operation and condition of the

LOWER GUARD SPRING.

3. Make sure the saw teeth and arrow on the

blade point in the same direction as the arrow

on the lower guard.

4. Slide blade through slot in the foot and

mount it against the INNER WASHER on the

shaft. Be sure the large diameter of the OUTER

washer lays flush against the blade.

5. Reinstall OUTER WASHER and tighten

BLADE STUD finger tight. The face of outer

washer has marks around it that will help you

properly adjust the blade stud. To lock shaft

hold the saw securely by the upper guard with

blade teeth imbedded in scrap wood and

TIGHTEN BLADE STUD COUNTER-

CLOCKWISE ONE MARK ON BLADE

WASHER WITH THE WRENCH PROVIDED.

Do not use wrenches with longer handles,

since it may lead to over tightening of the blade

stud.

)%'"%$(('

This clutching action is provided by the friction

of the OUTER WASHER against the BLADE

and permits the blade shaft to turn when the

blade encounters excessive resistance. When

the BLADE STUD is properly tightened (as

described in No. 5 of Attaching The Blade), the

blade will slip when it encounters ex cessive

resistance, thus reducing saw’s tendency to

KICKBACK.

One setting may not be sufficient for cutting all

materials. If ex cessive blade slippage occurs,

tighten the blade stud 1/2 mark more.

OVERTIGHTENING THE BLADE STUD

NULLIFIES THE EFFECTIVE-NESS OF THE

CLUTCH.

!

WARNING

LOWER

GUARD

BLADE SHAFT

INNER WASHER

Large Diameter

Faces Blade

OUTER WASHER

Large Diameter

Faces Blade

BLADE STUD

BLADE

WRENCH

OUTER WASHER

MARK

TIGHTEN

LOOSEN

LOWER

GUARD

SPRING

UPPER

GUARD

FIG. 2

LOCK BUTTON

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 11

-12-

Disconnect battery pack from tool. Loosen the

depth adjustment knob located on the right

side of the tool. Hold the foot down with one

hand and raise or lower saw by the handle.

Tighten knob at the depth setting desired.

Check desired depth (Fig. 3).

Not more than one tooth length of the blade

should extend below the material to be cut, for

minimum splintering (Fig. 4).

&',&*'

The safety switch is designed to prevent

accidental starts. To operate safety switch,

press the release button with your thumb on

either side of handle to disengage the lock,

then pull the trigger (Fig. 5). When the trigger

is released the button will engage the safety

switch automatically, and the trigger will no

longer operate. (See Switch & General Cuts

on page 13.)

H(''!!

Disconnect battery pack from tool. Set foot to

maximum depth of cut setting. Loosen bevel

adjustment knob, set to 0° on quadrant,

retighten knob and check for 90° angle

between the blade and bottom plane of foot

with a square (Fig. 6). If adjustment is

necessary, tilt foot to 50°, tighten bevel

adjustment knob and bend "TAB" with an

adjustable wrench or pliers (Fig. 7).

#'(&' !'

"=2?.A6;4;@A?B0A6<;@

FIG. 3

FIG. 4

FIG. 5

FIG. 7

FIG. 6

ONE TOOTH LENGTH SHOULD

PENETRATE WOOD FOR

MINIMUM SPLINTERING

DEPTH

ADJUSTMENT

KNOB

CALIBRATED

DEPTH BRACKET

BLADE

WRENCH &

STORAGE AREA

SAFETY SWITCH

RELEASE BUTTON

TAB

BEVEL

ADJUSTMENT

KNOB

BLADE

TRIGGER

FOOT

90°

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 12

-13-

)(&' !'

Disconnect battery pack from tool. The foot

can be adjusted up to 50° by loosening the

bevel adjustment knob at the front of the saw.

Align to desired angle on calibrated quadrant.

Then tighten bevel adjustment knob (Fig. 8).

Because of the increased amount of blade

engagement in the work and decreased

stability of the foot, blade binding may occur.

Keep the saw steady and the foot firmly on the

workpiece.

(&'&%!(

<129<;9F

*52;.17B@A6;4A52 9.@2?

96;24B612F<B D699 ;221 A<

5.C2 A52 /.AA2?F 0<;;20A21A< A52 A<<9

#.F.AA2;A6<;A<A52=9.02:2;A<3A52@.D

/9.12D6A5?2@=20AA<F<B?5.;1@.;1/<1F

.;1 .C<61 .00612;A.9 .0AB.A6<; <3 A52

=<D2? @D6A05 Accidental start-up of the

saw may cause injury.

Your tool is equipped with a laser line guide

that will turn on whenever the battery is

connected to the tool and the laser button is

pushed in. The two laser lines are set to the

kerf of the blade supplied and indicate the

outer edges of the blade. If you use a blade

with a different kerf the laser lines will need to

be adjusted to match the kerf of the new

blade. You should adjust the laser lines to

whichever side of the blade the user would

prefer the cut line to be on. The laser guide

does not need to be adjusted for bevel cuts

after it is aligned for straight 90° cuts.

If using the laser line guide for cutting you do

not need the line guide incorporated in the

foot as it may be in a different setting than the

laser line guide.

The laser light guide is a class IIIA laser with a

maximum output power of 5.0 mWatts and

conforms to 21 CFR 1040.10 and 1040.11.

TO ADJUST:

Use a flat head screwdriver to turn the

adjustment screw located on the side of the

laser module (Fig. 10). Turn on the laser line

guide by pressing the safety switch and rotate

the adjustment screw until the laser line is

aligned. There is no need to power the saw

“on” while adjusting the light beam.

FIG. 8

BEVEL

ADJUSTMENT

KNOB

QUADRANT

LASER LIGHT

ADJUSTMENT

SCREW

!

WARNING

LASER BUTTON

(Model 5996 only)

(&'!(

<129<;9F

For a straight 90° cut you can use the left or

right side of notch in the foot. For 45° & 50°

bevel cuts, use the right side (Fig 9). The

guide can be adjusted to allow for variation in

blade thicknesses for which ever side of the

blade the user would prefer to cut the line on.

TO ATTACH: Disconnect battery pack from

tool. Align hole in adjustable line guide with

hole in foot and secure with screw provide.

TO ADJUST: Loosen but don’t remove, the

adjustment screw enough so the guide can

move freely. Set a straightedge flat on the

preferred side of the blade, lining up both the

edge of the straightedge and the edge of the

guide where the 0° mark is located.

FIG. 9

45° & 50°

BEVEL CUTS

GUIDE

ADJUSTMENT

SCREW

ADJUSTABLE

LINE GUIDE

90°

VERTICAL CUTS

FIG. 10

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 13

-14-

The Laser line guide has a limited amount of

travel. Do not continue to turn the adjustment

screw after the line stops moving or if it

becomes significantly harder to turn the screw.

Overturning the adjustment screw may cause

the adjustment system to break or cause the

adjustment screw to fall out of the tool.

&%%'"!)"

%' , +#"&(%

" !"' @A.?2 6;A< A52 9.@2? 9645A @<B?02

!2C2?.6:9645A.A.;<A52?=2?@<;<?</720A

<A52? A5.; A52 D<?8=6202 Laser light can

damage your eyes.

"!"'B@2A6;A2149.@@2@

A< 2;5.;02 A52 9.@2? 9645A

Tinted glasses will reduce overall vision for the

application and interfere with the normal

operation of the tool.

!2C2? .6: A52 /2.: .A .

D<?8=6202D6A5 . ?23920A6C2

@B?3.02Bright shiny reflective sheet steel or

similar reflective surfaces are not

recommended for laser use. Reflective

surfaces could direct the beam back toward

the operator.

Use of controls or adjustments

or performance of procedures

other than those specified herein may result in

hazardous radiation exposure.

The use of optical instruments

with this product will increase

eye hazards.

!

CAUTION

!

WARNING

!

CAUTION

!

WARNING

DANGER

!

&*'

To turn tool “ON”, press the release button with

your thumb on either side of handle to

disengage the lock, then squeeze the trigger

switch. To turn the tool “OFF”, release the

trigger switch, which is spring loaded and will

return to the off position automatically.

Your saw should be running at full speed

BEFORE starting the cut, and turned off only

AFTER completing the cut. To increase switch

life, do not turn switch on and off while cutting.

!%('&

Always hold the saw handle with one hand and

the auxiliary handle or housing with the other.

Always make sure saw foot rests on portion of

work surface that does not drop off.

9D.F@/2@B?226A52?5.;1

1<2@;<A 6;A2?32?2D6A5A52

3?22:<C2:2;A<3A529<D2?4B.?1

Maintain a firm grip and operate the switch

with a decisive action. Never force the saw.

Use light and continuous pressure.

3A2?0<:=92A6;4. 0BA.;1

A52 A?6442? 5.@ /22;

?292.@21/2.D.?2<3A52;202@@.?FA6:26A

A.82@3<?A52/9.12A<0<:2A<.0<:=92A2

@A<=1B?6;40<.@A 1<D;< ;<A.99<DA52

@.DA</?B@5.4.6;@AF<B?924<?@612@6;02

A52 9<D2?4B.?16@ ?2A?.0A./92 6A 0<B91

0.A05<; F<B? 09<A56;4 .;12E=<@2 A52

/9.122.D.?2<3A52;202@@.?F/9.122E

=<@B?2@A5.A 2E6@A 6;/<A5 A52 B==2?.;1

9<D2?4B.?1.?2.@

When cutting is interrupted, to resume cutting:

squeeze the trigger and allow the blade to

reach full speed, re-enter the cut slowly and

resume cutting.

When cutting across the grain, the fibers of the

wood have a ten den cy to tear and lift.

Advancing the saw slowly minimizes this

effect. For a finished cut, a cross cut blade or

miter blade is rec om mended.

(''! &"!%, '

This tool is not designed for use with metal or

masonry cut-off wheels.

<;<AB@2./?.@6C2D5229@

D6A506?0B9.?@.D@/?.@6C2

1B@A:.F0.B@29<D2?4B.?1A<3.69

!

WARNING

!

WARNING

!

WARNING

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 14

-15-

#(!('&

Disconnect battery pack from tool before

making ad justments. Set depth adjustment

according to material to be cut. Tilt saw

forward with cutting guide notch lined up with

the line you’ve drawn. Raise the lower guard,

using lift lever and hold the saw by the front

and rear handles (Fig. 11).

With the blade just clearing the material to be

cut, start the motor. Gradually lower the back

end of saw using the front end of the foot as

the hinge point.

@/9.12 @A.?A@0BAA6;4A52

:.A2?6.9 ?292.@2 A52 9<D2?

4B.?16::216.A29F When the foot rests flat

on the surface being cut, proceed cutting in

forward direction to end of cut.

99<D /9.12A< 0<:2 A< .

0<:=92A2@A<=/23<?2963A6;4

A52@.D3?<:0BA 9@<;2C2?=B99A52@.D

/.08D.?1@6;02/9.12D699096:/<BA<3A52

:.A2?6.9.;1D699<00B?

Turn saw around and finish the cut in the

normal manner, sawing forward. If corners of

your pocket cut are not completely cut through,

use a jigsaw or hand saw to finish the corners.

!

WARNING

!

WARNING

FIG. 11

FOOT

LOWER

GUARD LIFT

LEVER

FIG. 12

FIG. 13

WRONG

RIGHT

(''!%&'&

Large sheets and long boards sag or bend,

depending on support. If you attempt to cut

without leveling and properly supporting the

piece, the blade will tend to bind, causing

KICK-BACK and extra load on the motor

(Fig. 12).

Support the panel or board close to the cut, as

shown in (Fig. 13). Be sure to set the depth of

the cut so that you cut through the sheet or

board only and not the table or work bench.

The two-by-fours used to raise and support the

work should be positioned so that the broadest

sides support the work and rest on the table or

bench. Do not support the work with the

narrow sides as this is an unsteady

arrangement. If the sheet or board to be cut is

too large for a table or work bench, use the

supporting two-by-fours on the floor and

secure.

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 15

-16-

%#('&

The combination blade provided with your saw

is for both cross cuts and rip cuts. Ripping is

cutting lengthwise with the grain of the wood.

Rip cuts are easy to do with a rip fence (Fig. 14).

Rip Fence is available as an accessory (not

included). To attach fence, insert fence

through slots in foot to desired width as shown

and secure with the wing nut (not included).

FIG. 14

RIP FENCE

WING NUT

DESIRED

WIDTH

OF CUT

%#"%(

When rip cutting large sheets, the rip fence

may not allow the desired width of cut. Clamp

or nail a straight piece of 1" (25 mm) lumber to

the sheet as a guide (Fig. 15). Use the right

side of the foot against the board guide.

FIG. 15

DESIRED

LINE

OF CUT

RIP BOARD

GUIDE

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 16

-17-

Release battery pack from tool by pressing

the battery release button and sliding pack

out of handle base (Fig. 1). To insert battery,

align battery and slide battery pack into tool

until it locks into position. Do not force.

1. The battery pack accepts only about 80% of

its maximum capacity with its first few charge

cycles. However, after the first few charge

cycles, the battery will charge to full capacity.

2. The charger was designed to fast charge

the battery only when the battery temperature

is between 32˚F (0˚C) and 113˚F (45˚C).

3. A substantial drop in operating time per

charge may mean that the battery pack is

nearing the end of its life and should be

replaced.

4. If you anticipate long periods (i.e. a month

or more) of non-use of your tool, it is best to

run your tool down until it is fully discharged

before storing your battery pack. After a long

period of storage, the capacity at first recharge

will be lower. Normal capacity will be restored

in two or three charge/discharge cycles.

Remember to unplug charger during storage

period.

5. If battery does not charge properly:

a. Check for voltage at outlet by plugging

in some other electrical device.

b. Check to see if outlet is connected to a

light switch which turns power “off” when lights

are turned off.

c. Check battery pack terminals for dirt.

Clean with cotton swab if necessary.

d. If you still do not get proper charging,

take or send tool, battery pack and charger to

your local Skil Service Center.

!<A2 Use of charger’s or battery packs not

sold by Skil will void the warranty.

#"%'!'%!!"'&! ( ''%&

Your battery pack is equipped with charge

condition indicator lights (Fig. 16). The

indicator lights shows the charge condition of

the battery during operation.

To check battery charge condition, depress

and hold the button on the backside of the

battery pack.

• • • • • When all five lights are illuminated,

this indicates the batter pack is fully charged.

• • • When only three lights illuminate, this

indicates the battery pack is partially charged.

• When only one light illuminates, this

indicates the battery pack is slightly charged.

When no lights illuminate, this indicates the

battery pack is completely discharged.

''%,%"!'"!!'"%'&&''%,

%!''%,#&"%&%%

Plug charger cord into your standard power

outlet, then slide the battery pack into charger

(Fig. 16).

The charger’s green indicator will begin to

“BLINK”. This indicates that the battery is

receiving a fast charge. Fast-charging will

automatically stop when the battery pack is

fully charged.

When the indicator light stops “BLINKING”

(and becomes a steady green light) fast

charging is complete.

%&!!!&%'!''%,#

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 17

-18-

When you begin the charging process of the

battery pack, a steady green light could also

mean the battery pack is too hot or too cold.

The purpose of the light is to indicate that the

battery pack is fast-charging. It does not

indicate the exact point of full charge. The light

will stop blinking in less time if the battery pack

was not completely discharged.

When the battery pack is fully charged, unplug

the charger (unless you're charging another

battery pack) and slip the battery pack back

into the tool handle.

INDICATOR LIGHT

CHARGER

BATTERY

PACK

FIG. 16

* BUTTON

* BATTERY

CHARGE

CONDITION

INDICATOR

LIGHTS

!"')"! "&

%!''%,#&%%

#9.02/.AA2?F=.08.;105.?42?<;39.A;<;39.::./92@B?3.02@.;1.D.F

3?<:39.::./92:.A2?6.9@D52;?205.?46;4/.AA2?F=.08

!

WARNING

Plug charger cord into your standard power

outlet, then slide battery pack into charger

(Fig. 17). The charger’s green light will turn

“ON”. The green light remains ‘‘ON’’ as long as

charger is plugged in, and does not shut off.

After normal usage, the battery pack requires

approximately 4-6 hours or less charging

time to become fully charged. If the battery

pack is run-down completely, it may require

up to 6 hours charging time to become fully

charged.

When the battery pack is fully charged,

unplug the charger (unless you're charging

another battery pack) and slide the battery

pack back into the tool handle.

INDICATOR LIGHT

BATTERY PACK

CHARGER

FIG. 17

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 18

-19-

<B;A6;45.?42?

"(!'!%%'"

)%'&(%

<129@&& <;9F

For convenience, your charger was designed

so it may be used on a flat horizontal surface,

or it may be mounted onto a vertical surface.

The mounting clip also features a bit storage on

top of the clip.

1. Select mounting location near a electrical

outlet so that the plug will reach the outlet.

Check for studs or other support.

2. Using a pencil, mark two places on the

surface in a vertical line about 3/4" apart.

3. Secure mounting clip to the vertical surface

using two #8 round head screws (Fig. 18).

4. Remove battery pack from charger before

mounting.

5. Insert handle of charger into the mounting

clip in the horizontal position (Fig 19).

6. Gently lower the charger into the vertical

position until it lays flat against the vertical

surface and locks the charger into the mounting

the clip (Fig. 20).

7. To remove charger when desired, raise the

charger back into the horizontal position to

unlock the charger, then remove charger from

the mounting clip (Fig. 20).

8. To charge the battery pack, simply slide

battery pack into charger (Fig. 21).

VERTICAL

SURFACE

MOUNTING

CLIP

#8 ROUND HEAD

WOOD SCREWS

CHARGER

TO LOCK

MOUNTING

CLIP

TO

UNLOCK

BATTERY

PACK

CHARGER

BIT STORAGE

COMPARTMENT

FIG. 18 FIG. 19

FIG. 20

FIG. 21

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 19

-20-

Your battery pack is equipped with charge

condition indicator lights (Fig. 22). The

indicator lights shows the charge condition of

the battery during operation.

To check battery charge condition, depress

and hold the button on the backside of the

battery pack.

1. The charger was designed to fast charge

the battery only when the battery temperature

is between 32˚F (0˚C) and 113˚F (45˚C). If the

battery pack is too hot or too cold, the charger

will not fast charge the battery. (This may

happen if the battery pack is hot from heavy

use). When the battery temperature returns to

between 32˚F (0˚C) and 113˚F (45˚C), the

charger will automatically begin charging.

2. A substantial drop in operating time per

charge may mean that the battery pack is

nearing the end of its life and should be replaced.

3. Remember to unplug charger during storage

period.

4. If battery does not charge properly:

a. Check for voltage at outlet by plugging in

some other electrical device.

b. Check to see if outlet is connected to a

light switch which turns power “off” when lights

are turned off.

c. Check battery pack terminals for dirt.

Clean with cotton swab and alcohol if

necessary.

d. If you still do not get proper charging,

take or send tool, battery pack and charger to

your local Skil Service Center. See “Tools,

Electric” in the Yellow Pages for names and

addresses.

!<A2 Use of chargers or battery packs not

sold by Skil will void the warranty.

"#'"!&&"%,

Skil models SB18B-LI & SB18C-LI lithium ion battery packs are compatible with all existing Skil

18V tools that use the SB18A, SB18B and SB18C Ni-Cd batteries.

Only use the specified charger to charge your Li-Ion batteries. Do not charge

Li-ion batteries with a Ni-Cd charger.

!

WARNING

#"%'!'%!!"'&'( "!''%&

''%,%"!'"!!'"%'&&''%,

.=.06AF

Continuous lighting 3 x blue 66% - 100%

Continuous lighting 2 x blue 34 - 65%

Continuous lighting 1 x blue 11 - 33%

Slow flashing 1x blue 0% - 10%

* BATTERY

CHARGE

CONDITION

INDICATOR

LIGHTS

* BUTTON

FIG. 22

??<? 2@@.42

Alternating Battery temperature is not

left middle within normal operating

right 1 temperature range of

x blue 0°C (32°F) to 45°C (113°F),

<? battery current is over

the normal operating range.

%!''%,#& %%

Plug charger cord into your standard power

outlet, then insert battery pack into charger

(Fig. 23).

If the green indicator light is “ON”,

the charger is plugged in but the

battery pack is not inserted, or the

battery pack is fully charged.

If the green indicator light is

“BLINKING”, the battery pack is

being fast-charged. Fast-

charging will automatically stop when the

battery pack is fully charged.

SM 1619X07795 06-12_SM 1619X07795 06-12.qxp 6/26/12 7:58 AM Page 20

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

Skil 5995-RT User guide

- Category

- Power tools

- Type

- User guide

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

in other languages

- français: Skil 5995-RT Mode d'emploi

- español: Skil 5995-RT Guía del usuario

Related papers

Other documents

-

Bosch 1671K Owner's manual

-

Bosch Power Tools 1662 User manual

-

Bosch CCS180B Owner's manual

-

Bosch Power Tools 1658 User manual

-

SKILSAW SPTH77M User manual

-

Bosch Power Tools Saw 1678 User manual

-

Bosch Power Tools BSH180BN User manual

-

Bosch Power Tools Saw 1657 User manual

-

Bosch Power Tools Saw 1655 User manual

-

Bosch Power Tools 1656 User manual