Page is loading ...

CMF3 70-PG Convertible (60, 70, & 75 KBTU/H Inputs)

CMF3 70-PO Convertible (60, & 70 KBTU/H Inputs)

Counterflow Gas or Oil Heating Appliance

INSTALLATION INSTRUCTIONS

For installation in:

• ManufacturedHomes

• Recreational Vehicles, Park Models, & Manufactured

Buildings

• ModularHomes/Buildings

WARNING

FIRE OR EXPLOSION HAZARD

• Failuretofollowsafetywarningsexactlycould

resultinseriousinjuryorpropertydamage.

•Installationandservicemustbeperformed

byaqualiedinstaller,serviceagencyorthe

gassupplier.

•Do not store or use gasoline or other

ammablevaporsandliquidsinthevicinity

ofthisoranyotherappliance.

WHAT TO DO IF YOU SMELL GAS

•Donottrytolightanyappliance.

•Do not touch any electrical switch; do not

useanyphoneinyourbuilding.

•Leavethebuildingimmediately.

•Immediately call your gas supplier from a

neighborsphone.Followthegassuppliers

instructions.

•Ifyoucannotreachyourgassupplier,call

theredepartment.

DONOTDESTROY.PLEASEREADCAREFULLY&KEEPINASAFEPLACEFORFUTUREREFERENCE.

2

TABLE OF CONTENTS

IMPORTANT SAFETY INFORMATION..........................3

REQUIREMENTS & CODES..........................................3

GeneralInformation......................................................4

OperationofFurnaceDuringConstruction...................4

MinimumInstallationClearances..................................5

GeneralInformation......................................................6

CombustionAirQuality.................................................6

DirectVentFurnaces....................................................6

VentilaireIIIorIV(AccessoryItem)..............................7

CIRCULATING AIR REQUIREMENTS...........................7

Plenums&AirDucts.....................................................7

UnconditionedSpaces..................................................8

ClosetInstallations.......................................................8

FURNACE INSTALLATION............................................8

GeneralInformation......................................................8

BeforeYouInstallthisFurnace....................................8

LocatingtheUnit...........................................................9

MA-200BaseInstallation..............................................9

InstallingtheFurnaceonanMA-200Base..................10

MA-100UniversalBaseInstallation..............................10

InstallingtheFurnaceonanMA-100Base..................10

CombustionAirDuct/PipeInstallation..........................10

SRJRoofJackInstallation............................................11

DamperInstallation.......................................................11

Oilpiping-POSeriesOnly...........................................14

ELECTRICAL CONNECTIONS......................................15

Pre-ElectricalChecklist.................................................15

LineVoltage..................................................................16

WiringConnections......................................................16

Grounding.....................................................................16

ThermostatConnections..............................................16

BlowerSpeed...............................................................16

START-UP & ADJUSTMENTS.......................................17

Pre-StartCheckList.....................................................17

OperatingInstructionsforPGDirectIgnitionBurner....18

OperatingInstructionsforPOOILBurners...................19

FiringRateConversion.................................................19

OPERATING SEQUENCE..............................................20

PGGasFurnaces.........................................................20

POOilFurnaces...........................................................20

TROUBLESHOOTING....................................................21

PGDirectIgnition-GasGun(PowerBurner)................21

POOilFurnace.............................................................22

ControlModuleStatusIndicator...................................22

UNIT MAINTENANCE.....................................................23

FurnaceFilter...............................................................23

BlowerCompartment....................................................23

CombustionAirandVentingSystem............................23

COMPONENT FUNCTIONS...........................................23

FIGURES & TABLES......................................................24

WIRING DIAGRAM.........................................................25

FURNACE COMPONENTS............................................26

INSTALLATION CHECKLIST.........................................28

3

IMPORTANT SAFETY INFORMATION

INSTALLER:Pleaseread allinstructionsbefore servicing

this equipment. Pay attention to all safety warnings and

anyotherspecial noteshighlightedinthe manual.Safety

markings are used frequently throughout this manual to

designateadegreeorlevelofseriousnessandshouldnot

be ignored. WARNING indicates a potentially hazardous

situationthatifnotavoided,couldresultinpersonalinjuryor

death.CAUTIONindicatesapotentiallyhazardoussituation

thatifnotavoided,mayresultinminorormoderateinjuryor

propertydamage.

WARNING:

ELECTRICAL SHOCK, FIRE

OR EXPLOSION HAZARD

Failuretofollowsafetywarningsexactlycould

resultinseriousinjuryorpropertydamage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

•Before servicing, disconnect all electrical

powertoairhandler.

•Whenservicingcontrols,labelallwiresprior

todisconnecting.Reconnectwirescorrectly.

•Verifyproperoperationafterservicing.

WARNING:

Do not use this appliance if any part has been

submergedunderwater.Immediatelycallaqualied

service technician to inspect the appliance and

toreplaceanypartofthecontrolsystemandany

gascontrolthathasbeensubmergedunderwater.

REQUIREMENTS & CODES

WARNING:

This unit must be installed in accordance with

instructions outlined in this manual during the

installation, service, and operation of this unit.

Unqualied individuals should not attempt to

interprettheseinstructionsorinstallthisequipment.

Failure to follow safety recommendations could

resultinpossibledamagetotheequipment,serious

personalinjuryordeath.

• Furnace must be installed in accordance with these

instructions, all applicable local building codes and the

current revision of the National Fuel Gas Code (ANSI

Z223.1/NFPA54),InstallationofOilBurningEquipment

(ANSI/ NFPA31) or the National Electric Code (ANSI/

NFPA70),theManufacturedHomeConstruction&Safety

Standard,Title24CFR,Part3280,orwhenthisstandard

isnotapplicable, the Standard for Manufactured Home

InstallationManufacturedHomeSites,Communitiesand

Setups(ANSI225.1).

• Useonlywithtypeofgasoroilapprovedforthisfurnace.

Refertothefurnaceratingplate.

• Install this furnace only in a location and position as

speciedonpage5.

• Provide adequate combustion and ventilation air to the

furnacespaceasspeciedonpage5andpage6.

• Provideadequateclearancesaroundtheventairintake

terminalasspeciedinTable1(page8).

• Combustion products must be discharged outdoors.

Connectthisfurnacetoan approved vent system only,

asspeciedonpage5andpage6.

• Never test for gas leaks with an open ame. Use

a commercially available soap solution to check all

connections.Seepages13.

• This furnace is designed to operate with a maximum

external pressure rise of 0.3 inches of water column.

Consult Table 4 (page 17), and the rating plate for the

proper circulating air ow and temperature rise. It is

important that the duct system be designed to provide

the correct ow rates and external pressure rise. An

improperlydesignedductsystemcanresultinnuisance

shutdowns,andcomfortornoiseissues.

• Thisfurnacemaynotbeused for temporary heatingof

buildingsorstructuresunderconstruction.

• The Commonwealth of Massachusetts requires

compliancewithregulation248CMR 4.00 and 5.00 for

installationofthrough–the–wallventedgasappliances

asfollows:

1. For direct-vent appliances, mechanical-vent heating

appliancesordomestichotwaterequipment,wherethe

bottomoftheventterminalandtheairintakeisinstalled

belowfourfeetabovegradethefollowingrequirements

mustbesatised:

a.) Acarbonmonoxide(CO)detectorandalarmshallbe

placedoneachoorlevelwheretherearebedrooms.

The detector shall comply with NFPA 720 (2005

Edition) and be mounted in the living area outside

thebedroom(s).

b.) A (CO) detector shall be located in the room that

housestheapplianceorequipmentandshall:

•Be powered by the same electrical circuit as the

applianceorequipment.Onlyoneserviceswitchshall

powertheapplianceandthe(CO)detector;

4

•Havebatteryback-uppower;

•Meet ANSI/UL 2034 Standards and comply with

NFPA 720 (2005 Edition); and Approved and listed

by a Nationally Recognized Testing Laboratory as

recognizedunder527CMR.

c.) A Product-approved vent terminal must be used,

andifapplicable,aproduct-approvedairintakemust

be used. Installation shall be in strict compliance

with the manufacturer’s instructions. A copy of the

installationinstructionsshallremainwiththeappliance

orequipmentatthecompletionoftheinstallation.

d.) Ametalorplasticidenticationplateshallbemounted

attheexteriorofthebuilding,fourfeetdirectlyabove

the location of vent terminal. The plate shall be of

sufcientsize,easilyreadfrom a distance ofeight

feetaway,andread“GasVentDirectlyBelow”.

2. For direct-vent appliances, mechanical-vent heating

appliancesordomestichotwaterequipmentwherethe

bottomoftheventterminalandtheairintakeisinstalled

abovefourfeetabovegradethefollowingrequirements

mustbesatised:

a.) A(CO)detectorandalarmshallbeplacedoneach

oorlevelwheretherearebedrooms.Thedetector

shallcomplywithNFPA720(2005Edition)andbe

mountedinthelivingareaoutsidethebedroom(s).

b.) The(CO)detectorshall:

•Belocatedintheroomthathousestheapplianceor

equipment;

•Behard-wiredorbatterypoweredorboth.

•ShallcomplywithNFPA720(2005Edition).

c.) A product-approved vent terminal must be used,

andifapplicable,aproduct-approvedairintakemust

be used. Installation shall be in strict compliance

with the manufacturer’s instructions. A copy of the

installationinstructionsshallremainwiththeappliance

orequipmentatthecompletionoftheinstallation.

GeneralInformation

Theinformationlistedbelowisforreferencepurposesonly

anddoesnotnecessarilyhavejurisdictionoverlocalorstate

codes.Alwaysconsultwithlocalauthoritiesbeforeinstalling

anygasappliance.

DuctSystems

• USandCANADA:AirConditioningContractorsAssociation

(ACCA) Manual D, Sheet Metal and Air Conditioning

Contractors National Association (SMACNA), or American

Society of Heating, Refrigeration, and Air Conditioning

Engineers(ASHRAE)FundamentalsHandbook

Electrical Connections

• US:NationalElectricalCode(NEC)ANSI/NFPA70

• CANADA:CanadianElectricalCodeCSAC22.1

Gas Piping & Gas Pipe Pressure Testing

• US:NFGCandNationalPlumbingCodes

• CANADA:NSCNGPIC

General Installation

• US: Current edition of the NFGC and the NFPA 90B. For

copies,contacttheNationalFireProtectionAssociationInc.,

Batterymarch Park, Quincy, MA 02269; or American Gas

Association,400N.Capitol,N.W.,WashingtonDC20001or

www.NFPA.org

• CANADA:NSCNGPIC.Foracopy,contactStandardSales,

CSA International, 178 Rexdale Boulevard, Etobicoke

(Toronto),Ontario,M9W1R3Canada

Safety

• US:(NFGC)NFPA54–1999/ANSIZ223.1andtheInstallation

Standards,WarmAirHeatingandAirConditioningSystems

ANSI/NFPA90B.

• CANADA:CAN/CSA-B149.1and.2–M00NationalStandard

ofCanada.(NSCNGPIC)

OperationofFurnaceDuringConstruction

CAUTION:

Operatinggasfurnacesinconstructionenvironments

cancauseavarietyofproblemswithinthefurnace

and may significantly reduce the life or the

performanceofthefurnace.Thereforeoperating

thefurnaceduringconstructionisnotpermitted

andwillvoidthewarranty.

5

COMBUSTIONAIR&VENTING

REQUIREMENTS

WARNING:

CARBON MONOXIDE POISONING HAZARD

Failuretofollowthestepsoutlinedbelowfor

eachapplianceconnectedtotheventingsystem

being placed into operation could result in

carbonmonoxidepoisoningordeath.

Thefollowingstepsshallbefollowedwitheach

individualapplianceconnectedtotheventing

systembeingplacedinoperation,whileallother

appliancesconnectedtotheventingsystemare

not in operation:

1.Seal any unused openings in the venting

system.

2.Inspecttheventingsystemforpropersizeand

horizontalpitch,asrequiredintheNationalFuel

GasCode,ANSIZ223.1/NFPA54ortheCSA

B149.1,NaturalGasandPropaneInstallation

Codesandtheseinstructions.Determinethat

there is no blockage or restriction, leakage,

corrosionandotherdeciencieswhichcould

causeanunsafecondition.

3.Asfaraspractical,closeallbuildingdoors

andwindowsandalldoorsbetweenthespace

in which the appliance(s) connected to the

ventingsystemarelocatedandotherspaces

ofthebuilding.

4.Closereplacedampers.

5.Turn on clothes dryers and any appliance

notconnectedtotheventingsystem.Turnon

anyexhaust fans, suchas range hoodsand

bathroomexhausts,sotheyareoperatingat

maximum speed. Do not operate a summer

exhaustfan.

6.Follow the lighting instructions. Place the

appliance being inspected into operation.

Adjustthethermostatsoapplianceisoperating

continuously.

7.Test for spillage from draft hood equipped

appliances at the draft hood relief opening

after5minutesofmainburneroperation.Use

theameofamatchorcandle.

8.Ifimproperventingisobservedduringanyof

theabovetests,theventingsystemmustbe

correctedinaccordancewiththeNationalFuel

GasCode,ANSIZ223.1/NFPA54and/orCSA

B149.1,NaturalGasandPropaneInstallation

Codes.

9.After it has been determined that each

appliance connected to the venting system

properlyventswhentestedasoutlinedabove,

returndoors,windows,exhaustfans,replace

dampers and any other gas-red burning

appliancetotheirpreviousconditionsofuse.

Table1.MinimumClearanceRequirements

INSTALLATION CLEARANCES

CLOSET ALCOVE

Front* 6" 18"

Rear 0" 0"

Sides 0" 0"

Top 17" 17"

Ductw/in3ftoffurnace 1/4" 1/4"

Vent 6” 6”

Plenum 1" 1"

RoofJackBarrel 0” 0”

LEFT

SIDE

FRONT

RIGHT

SIDE

REAR

VENT

†

NOTES:

* ServiceClearance

AlcoveInstallations-Allow18in.minimumclearancefromfrontof

unittonearestwallorpartitionforservicing.

Closetinstallations-Requireareturnairgrillinstalledinthedooror

apartiallylouvereddooracrosstheopeningforproperaircirculation.

For clearances 6” or greater, the closet must have an open free

areaof235in

2

minimum.Forspecialclearancesbetween1”-5”,

requirementsarealouvereddoorwithaminimumof250in

2

(1613

cm

2

)freearea.Afullylouveredclosetdoorisstronglyrecommended

forbothinstallationtypes.

MinimumInstallationClearances

• Access for positioning and servicing the unit must be

considered when locating unit. The need to provide

clearance for access to panels or doors may require

clearancedistancesoverandabovetherequirements.

• This appliance must be installed in accordance with

clearances listed in Table 1. The furnace must be

installedwithampleclearanceforeasyaccesstotheair

lter, blower assembly, burner assembly, controls, and

ventconnections.

• Locate and install this unit in position as specied on

page 8 & page 9. This unit is designed only for Indoor

installationsandshouldbelocatedwithconsiderationof

minimizingthelengthofthesupplyandreturnducts.

• Sufcient clearance for unobstructed airow through a

louvered door must be maintained in order to achieve

ratedperformance.Airreturnto the furnace must have

the minimum required total free area of 200 in

2

(1290

cm

2

)Mayalsoincludereturnairgrilleandframeassembly

(P/N902989)orwallmountgrille(P/N902999).

6

GeneralInformation

WARNING:

This furnace must be installed by a qualied

installingagencyandinaccordancewithapplicable

localcodesandordinancesthatgovernthistypeof

equipment.Failuretoproperlyinstallthefurnace,

baseassembly,andventingsystemasdescribed

hereinmaydamagetheequipmentand/orthehome,

cancreateareorasphyxiationhazard,violates

U.S.listingrequirements,andwillvoidthewarranty.

ThisfurnaceisNOTapprovedforinstallationwith

split system air conditioning. Use a NORDYNE

packagedairconditioningsystem.

• Instructionsfordeterminingtheadequacyofcombustion

airforaninstallationcanbefoundinthecurrentrevisionof

theNFGC(ANSIZ223.1/NFPA54).Theserequirements

areforUSinstallationsasfoundintheNFGC.Consult

localcodesforspecialrequirements.

• The requirements in Canada (B149.1) are structured

differently. Consult with B149.1 and local code ofcials

forCanadianinstallations.

The CMF3 Series furnace can draw combustion air from

outside the home (direct vent) or from the space being

conditioned.Thishighquality,directventfurnaceisusedfor

manufacturedhousingapplications.ItiscertiedtotheUL307

standards(UL307-Aforoilmodels;UL307-Bforgasmodels).

TheCMF3furnaceisavailableinpowergas(PGmodels)

orpoweroil(POmodels)andcanbeconvertedfrompower

oil to power gas, and vice versa. The power gas models

aredesignedfor operation with either natural or propane

(LP) gas. The ring rate of the CMF3 Convertible Series

canbeeld-installed(usingacertiedconversionkit)bya

qualiedservicetechnician.Refertopage14forconversion

information.

CAUTION:

Exhaustfans,clothesdryers,replacesandother

appliances that force air from the house to the

outdoors can create a negative pressure inside

thehouse,resultinginimproperfurnaceoperation

orunsafeconditionssuchasamerollout.Itis

imperative that sufcient air exchange with the

outdoorsisprovidedtopreventdepressurization.

Additional information about how to test for

negativepressureproblemscanbefoundinthe

NFGC.

CombustionAirQuality

CAUTION:

Combustionairmustnotbedrawnfromacorrosive

atmosphere.

Provisionsforadequatecombustionairandventilationair

must be in accordance with the ANSI Z223.1/NFPA 54,

(NationalFuelGasCode),ANSI/NFPA31(InstallationofOil

BurningEquipment),andallapplicablelocalcodes.

The installation of the furnace must allow for adequate

supplyoffreshairforcombustion.Airopeningsontopofthe

furnaceandopeningsinclosetdoorsorwallsmustnever

be restricted. The combustion air opening of the furnace

mustbedesignedandlocatedtopreventblockagebysnow.

Ifthefurnaceisoperatedwithoutadequateairforcombustion,

theameroll-outswitchwillopenandshutoffthegassupply

totheburners.

IMPORTANT NOTE

Thissafetydeviceisamanuallyresetswitch.DONOT

install jumper wires across these switches to defeat

their function or reset a switch without identifying

andcorrectingthefaultcondition.Ifaswitchmustbe

replaced,useonlythecorrectsizedpartspeciedinthe

ReplacementPartsListprovidedonline.

Thecombustionairfromtheoutsideneedstobeclearof

chemicals that can cause corrosion. Excessive exposure

to contaminated combustion air will result in safety and

performancerelatedproblems.Thelistbelowareexamples

ofchemicalcontaminantsfoundinawidevarietyofsome

commoncommercialandhouseholdproducts:

Permanentwavesolutions

Chlorinatedwaxesandcleaners

Chlorinebasedswimmingpoolchemicals

Watersofteningchemicals

De-icingsaltsorchemicals

CarbonTetrachloride

Cleaningsolvents(perchloroethylene)

Printinginks,paintremovers,varnishes,etc.

HydrochloricAcid

Cementsandglues

Antistaticfabricsofteners

Masonryacidwashingmaterials

Whendrawingcombustionairfromunderneaththehome,a

ventorductofatleast18in

2

offreeareashouldbeinstalled

outside and completely unobstructed. When using the

combustionairduct,makesureitextendsthroughtheoor.

DirectVentFurnaces

Direct Vent furnaces draw combustion air directly from

theoutdoorsandthenventthecombustionproductsback

outside,isolatingtheentiresystemfromtheindoorspace.

Itisimportanttomakesurethatthewholesystemissealed

andclearancestocombustiblesaremaintainedregardless

oftheinstallationbeinginaconnedorunconnedspace.

Thecombustionairhoseisprovidedandmustbeusedfor

directventapplications.

OnlyforspecialCB-200Acottagebaseinstallationscanthe

CMF3furnacedrawscombustionairfromtheconditioned

space. The CB-200A cottage base is an accessory item

thatcanbepurchasedseparately.Refertothereplacement

partslistingprovidedwiththefurnacetoorderthecottage

basekit.Followthe instructionsprovidedwiththe kitsfor

properinstallation.

When unsure about combustion air supply availability, a

directventsystemshouldbeused.Forsmallrooms,conned

spaces,tightconstructionorsimilarsituationsinwhichthe

combustion air requirements of the furnace might not be

met,adirectventsystemmustbeused.

Forallmanufacturedhousingapplications,theCMF3furnace

mustbeventedusingtheSRJseriesroofjackasshownin

Figure1.Theinstructionsforselectingtheproperroofjack

foryourinstallationaredetailedlaterintheseinstructions.

7

VentilaireIIIorIV(AccessoryItem)

CAUTION:

MAINTAIN 2 1/2” MINIMUM CLEARANCE BETWEEN

FLUE PIPE AND FLEX DUCT. FAILURE TO

COMPLY WITH THIS RESTRICTION COULD

CAUSE EQUIPMENT DAMAGE. VENTILAIRE III

ILLUSTRATED OTHER LISTED VARIATIONS

AVAILABLE.CHECKWITHMANUFACTURER.

The Ventilaire air quality packages are available to meet

theventilationrequirementsasoutlinedinH.U.D.Standard

Part3280.103 (b)(2).Thesepackagesintroduceoutdoor

air into the living space during furnace blower operation.

TheVentilAireIValsoservestoexhaustmoistand/orhot

airfromtheatticspace.SeeFigure2fortypicalinstallation.

Completeinstallationinstructionsaresuppliedwitheachair

qualitypackage.

VENT PIPE

3 FEET

MIN.

ROOF JACK

ASSEMBLY

ROOF CAP

ASSEMBLY

FLEX

DUCT

CEILING TRIM

COLLAR

CONNECTOR

DRAW BAND

FURNACE

DRAW

BAND

57”

Figure1.TypicalInstallation

VentilAireIII

VentilAireIV

Figure2.VentilAireIII&IV

CIRCULATING AIR REQUIREMENTS

WARNING:

Allsupplyductsmustbesecuredtothefurnace

with sheet metal screws and adequately sealed.

Whensupplyairisprovidedthroughthebottom

oftheunit,thejointbetweenthefurnaceandthe

plenummustbeairtight.

Thesurfacethatthefurnaceismountedonmust

providesoundphysicalsupportofthefurnacewith

nogaps,cracksorsaggingbetweenthefurnace

andtheoororplatform.

Supply air ducts must not be connected to any

otherheat producingdevice such as a replace

insert,stove,etc.Thismayresultinre,explosion,

carbon monoxide poisoning, personal injury, or

propertydamage.

Plenums&AirDucts

Thisunitisdesignedonlyforusewithabottomsupplyduct

andmustbeinstalledinaccordancewiththestandardsofthe

NationalFireProtectionAssociationStandardforInstallation

of Air Conditioning Systems (NFPA 90A), Standard for

InstallationofResidenceTypeWarmAirHeating and Air

ConditioningSystems(NFPA90B),andallapplicablelocal

codes.NFPApublicationsareavailablebywritingto:National

FireProtectionAssociation,BatterymarchPark,Quincy,ME

02269orvisitwww.NFPA.orgontheinternet.

• Designtheairductsaccordingtomethodsdescribedby

theAirConditioningContractorsofAmerica(ACCA).

• Airductsmustbealuminum,tinplate,galvanizedsheet

steel, or other approved materials for outlet air ducts.

Snap-Lock or Pittsburgh-Lock seams are preferred. All

other types of seams must be made tight to prevent

leakage.

• It is good practice to seal all connections and joints

with industrial grade sealing tape or liquid sealant.

Requirements for sealing ducts vary from region to

region.Consultwithlocalcodesforrequirementsspecic

toyourarea.

• Gaspipingmustnotruninorthroughanyoftheairduct

system.

SupplyAirConnections

• The supply duct system must be designed so that the

static pressure measured external to the furnace does

not exceed the listed static pressure shown on the

furnace rating plate. The supply air must be delivered

to the heated space by duct(s) secured to the furnace

casing,runningfulllengthandwithoutinterruption.

• Ductsystemmustbedesignedsothatnosupplyregisters

arelocatedinductsystemdirectlybelowthefurnace.

Dampers

Anautomatedshutoffdamperisrequiredwhenthehomeis

airconditionedbyaself-containedunit.Adamperisrequired

to prevent chilled air from owing over the furnace heat

exchanger.Thisdamperisdesignedtotinthefeederduct

cavity,directlyunderthefurnace.Forproperinstallation,refer

totheinstructionsprovidedwiththedamper.SeeTechnical

SalesLiteratureonline.

8

UnconditionedSpaces

All duct work passing through unconditioned space must

beproperlyinsulatedtominimizeductlossesandprevent

condensation. Use insulation with an outer vapor barrier.

Refertolocalcodesforinsulationmaterialrequirements

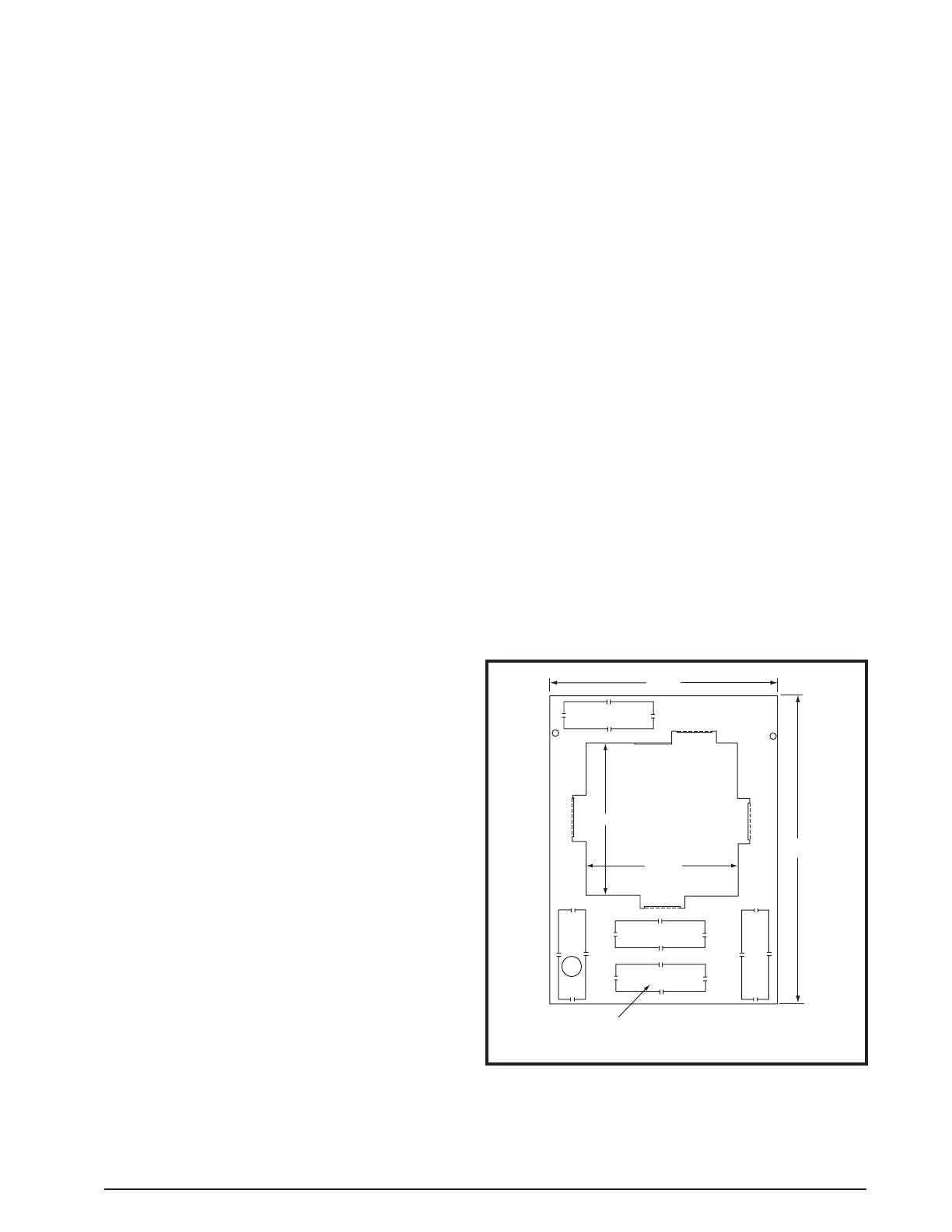

Closet Installations

WARNING:

Failuretocomplywiththethefollowinginstructions

mayresultinre,asphyxiationorcarbonmonoxide

poisoning.

Forproperaircirculation,closetinstallationsrequireareturn

airgrillinstalledinthedoororsidewallthatexchangeswith

thelivingareaofthehomeasshowninFigure3.Apartially

louvereddoormayalsobeusedacrosstheopening.Return

air openings should not be located to draw air directly

fromabathroom.Grillesplacedinasidewallrequirea6”

clearancefromthewalltothefurnacesothattheairmay

enterthefrontgrilleofthefurnace.Inaddition,allreturnair

systems,includingtheoorandceilingsystems,mustmeet

thefollowingconditions:

• The return air opening, regardless of its location in the

closet, must not be smaller than size specied on unit

data label. If located in the oor, the opening must be

provided with a means of preventing its inadvertent

closurebyatobject(s)placedovertheopening.

• The return-air opening into the closet, regardless of its

location,musthaveanopenfreeareaof200in

2

(1290

cm

2

)minimum.

• The cross-sectional area of the return duct system (in

oororceiling)leadingintotheclosetmustnotbeless

than200in

2

(1290cm

2

).

• The total free area of the openings in the oor or the

ceilingregistersservingthereturnairductsystemmust

notbenotlessthan300in

2

(1935cm

2

).

• Materialslocatedinthereturnductsystemshallhavea

amespreadclassicationof200orless.

• Noncombustiblepanshavingoneinchupturnedanges

are located beneath openings in a oor return duct

system.

• Hollowspacesusedasductsorplenumsforenvironmental

airmaycontainmineral-insulatedmetalsheathedcable,

aluminumsheathedcable,electricalmetallictubing,rigid

metalconduit,exiblemetalconduit(nottoexceed4ft),

ormetal-cladcables.Wiringmaterials,xtures,aretobe

suitablefortheexpectedambienttemperaturestowhich

theywillbesubjected.

• Thenegativepressureintheclosetmustnotbelessthan

minus 0.05 inches water column with the closet door

closed and the fan operating at high speed. A reading

below minus 0.05 inches indicates a dirty lter or a

restrictedreturnairsystem.

• For oor return systems, the manufactured housing

manufacturerorinstallershallafxaprominentmarking

onorneartheappliancewhereitiseasilyreadwhenthe

closetdoorisopen.Themarkingshallread:“CAUTION,

HAZARD OF ASPHYXIATION. DO NOT COVER

OR RESTRICT FLOOR RETURN AIR OPENING.”

or equivalent. NOTE: This label is supplied with the

instructionmanualineachfurnace.

• For closet installation with less than 6” front clearance,

butnotlessthan1”,alouvereddoormustbeusedhaving

aminimum200in

2

(1290cm

2

)freeareaopeningdirectly

inlinewithopeningsinthefurnacedoor.Afullylouvered

doorhavingtheminimumfreeareaisalsopermittedifthe

fronttoleranceisnotlessthan4”.Adjustductregistersto

obtain a temperature rise within the range specied on

thefurnacenameplate.

FURNACE INSTALLATION

NOTE: Sinceallinstallationsaredifferent,thesequenceof

thesestepsmaydifferfromthe actual installation. These

installation procedures are suggested for typical furnace

installations. Only qualied HVAC technicians should

installthisfurnace.

GeneralInformation

TheCMF3furnaceisdesignedonlyforindoorinstallations

andcanbereadilyconnectedtothehighstaticductsystem

ofahome.Unitsareapprovedforsinglemobile/modular/

manufactured structures in freestanding/closet/alcove

downowonlycongurations.

Thisappliancewillprovidemanyyearsofsafeanddependable

comfort, providing it is properly installed and maintained.

Abuse, improper use, and/or improper maintenance can

shortenthelifeoftheapplianceandcreateunsafehazards.

Pleasereadallinstructionsbeforeinstallingtheunit.

Approvedinstallation, operation, and maintenance of this

appliancemustbeinaccordancewiththelistedspecications

contained in these instructions and other documents

supplied with the furnace and/or optional air conditioning

equipment.Unlessitisnoteddifferentlyinthismanual,only

usefactoryauthorizedkitsandaccessorieswhenmodifying

thisappliance.Refertolocalauthoritieshavingjurisdiction

forfurtherinformation.

BeforeYouInstallthisFurnace

√This equipment is securely packaged at the time of

shipmentanduponarrivalshouldbecarefullyinspected

for damage prior to installing the equipment at the job

site.Claimsfordamage(apparentorconcealed)should

beledimmediatelywiththecarrier.

√Checktheelectricalsupplyandverifythepowersupply

isadequateforunitoperation.Thesystemmustbewired

and provided with circuit protection in accordance with

localbuildingcodes.Ifthereisanyquestionconcerning

thepowersupply,contactthelocalpowercompany.

√Verifytheairdeliveryofthefurnaceisadequatetohandle

thestaticpressuredropofthelterandductwork.

Figure3.Closet Installation

200 Sq. In. Minimum Free

Area in a Door or Wall

9

LocatingtheUnit

• Surveythehomeslayouttodeterminethebestlocation

for installing the unit. Consideration should be given to

availabilityofelectricpower,serviceaccess,andnoise.

• The dimensions of the room or alcove must be able

to accommodate the overall size of the unit and the

installation clearances in Table 1 (page 4). Physical

dimensionsforthisfurnaceareshowninFigure17(page

24).

• Theunitmustbeleveledatinstallationandattachedtoa

properlyinstalledductsystem.

• Thesurfacethatthefurnaceismountedonmustprovide

soundphysicalsupportoftheunit.

MA-200 Base Installation

TheMA-200baseisdesignedforO.E.M.andreplacement

installationoftheCMF3seriesfurnace.Thewarmairduct

systemshouldbedesignedsotheductstaticpressureexternal

tothefurnacedoesnotexceedthestaticpressurelistedon

thefurnacedatalabel.Itisrecommendedthatalterwitha

MERVratingnogreaterthan10beinstalled.

Floorcut-outsmustbecarefullylocatedtoavoidmisalignment

ofthefurnaceandairduct.

1. Usingthebasepan(Figure4)asaguide,locate and

markthe121/8”x121/8”openingfortheFeederDuct.

NOTE:Ifusingthecombustionairduct,knockoutthe

ductopeningtobeusedandmarkthe2-1/4”x7-1/4”

openingontheooralso.

2. Cutall4sidesoftheFeederDuctopening1”largerthan

thedrawncutout.NOTE:Cuttingtheopeningto14-1/8”

x14-1/8”willallowtheangesontheundersideofthe

basepantotintheopening.Cutallthewaythrough

theinsulationandbottomboardsothatthecombustion

airductisunobstructedtooutsideair.

3. If applicable, cut the 2 1/4” x 7 1/4” opening for the

combustionairduct.NOTE:Cuttheopeningfortheduct

about1/8”largerthantheactualcutoutdrawn.Thiswill

allowsomeclearancewheninstallingthefeederduct.

4. Drilla1”diameterholeforthefuellinethroughtheoor

andbottomboardtotheoutside.NOTE:Fuellinesare

notsuppliedwiththefurnace.Theyshouldbeinstalled

tocomplywithallapplicablecodes.

5. Droptransitionduct(Figure5)upsidedownthroughthe

ooropeningand centerthetopof thefeederductin

14-1/8”x14-1/8”ooropening.Usingthefeederductas

aguide,markandcuta12”x12”openinginthesupply

duct.

6. Insertthefeedertabsintothemainductandbendthem

over tightly so that the main duct edges are trapped

betweenangesandtabs.NOTE:Metaltapemaybe

beusedtoensureanairtightconnection.

7. Installthebasepanaroundthefeederduct.Securewith

2screwsintheholesneartherearofthebasepan.

8. Slitthecornersofthefeederductdowntothetopofthe

basepan(Figure6).Whilethetopofthedistributionduct

ispulledupwithonehand,benddowneachsideofthe

feederducttightlytothebasewiththeotherhand.Trim

themetaltoallowaoneinchangeoverthetopofthe

basepanandsealthatangewithmetaltape.

NOTE:Ifusinga“V”or“U”-boxcrossoversystem,use

manufacturersinstructionsforinstallationdetails.

Figure4.MA-200 Base Pan

FRONT

Combustion Air

Knock-outs

(7-1/4” X 2-1/4”)

Feeder Duct

Opening

Flue

Location

24 1/8

8 3/8

12 1/8

12 1/8

9 1/8

18 1/4

Figure5.Transition Duct

Heater Duct Below Joists

Flange

Bend

Over Tabs

Base

Floor

Joists

Slit 4 Corners

Bend Down 4 Sides

Figure6.FeederDuctInstallation

Heat Duct Below Joists

Base

Feeder Duct

Floor

Joists

Cut This Line

Bend Over

Along This Line

1"

10

InstallingtheFurnaceonanMA-100Base

1. Carefully lift the furnace over the universal base pan

andsetintoposition.Avoiddamagingthefeederduct

assembly and combustion air adapter, if present.

NOTE:Makesurethefurnaceispositionedagainstthe

backendofthebase.

2. Openthefurnacedoorandfastenthefurnacetothebase

using#8x1/2”sheetmetalscrews.

3. Using the provided hose clamp, secure the exible

combustionairtubingfromtheburnertothecombustion

airadapter.

CombustionAirDuct/PipeInstallation

The CMF3 furnace must draw the combustion air from

outside(exceptforspecialinstallations)andrequiresusing

the2”X7”rectangularcombustionairductprovidedintheMA

seriesbasekitorthedirectventkit.Ifusingtherectangular

combustionairduct,followthestepsbelow:

1. Install the combustion air duct through the selected

knockoutinthebase.Fordirectventapplications,the

rearknock-outinthefurnacebasecannotbeused.

2. Installthecombustionairadapter(afterthecombustion

air duct has been positioned) to transition the 2”X7”

openingofthecombustionairducttothe2”diameterof

theburnerexibletubing.NOTE:Adapterisincludedin

theMAseriesbasekits.Forretrotapplicationsinwhich

theMAseriesbaseisalreadyinstalled,thecombustionair

adaptercanbeorderedasakit.RefertotheReplacement

PartsListformoredetailsonorderingthiskit.

3. Securetheadapterwithwoodormetalfasteners(eld

supplied),dependinguponyourinstallation.NOTE:Make

sure the gasket for the adapter is positioned properly

beforeinstallingtheadapter.

4. Attachtheexiblehosefromtheburnertothecombustion

airadapterusingtheprovidedhoseclamp.

Figure7.MA-100UniversalBase,BottomPanel

12 1/8

Feeder Duct

Opening

18 1/4

24 1/2

12 1/8

FRONT

Combustion Air

Knock-outs

(7-1/4” X 2-1/4”)

InstallingtheFurnaceonanMA-200Base

1. Carefullyliftthefurnaceoverthebasepanandsetinto

position.Theangeonthebackofthefurnaceshould

restontheinsiderailsofthebase.

2. Raisethefrontofthefurnacetoclearthegasketonthe

bottomofthefurnaceandslidethebackuntiltherear

angedropsintothe channel at therearofthebase.

NOTE:Donotdamage the combustionairadapter,if

present,whilepositioningtheunit.Makesurethefurnace

engagesthetabsontherearangeofthebase.

3. Opentheaccessdoorandfastenthefrontofthefurnace

andthebasetotheoorwith#8x1/2”sheetmetalscrews.

4. Using the provided hose clamp, secure the exible

combustionairtubingfromtheburnertothecombustion

airadapter.

MA-100 Universal Base Installation

The MA-100 base is designed primarily for replacement

installation of the CMF3 series furnace where the

manufactured home duct system may be too small or

restrictivefor proper air ow. The MA-100 base provides

approximately4inchesofadditionalplenumspacebefore

thedischargeairenterstheductsystem.SeeFigure7.

1. Usingtheuniversalbaseasaguide,locateandmarkthe

12-1/8”x12-1/8”openingfortheFeederDuct.NOTE:If

usingthecombustionairduct,knockouttheductopening

tobeused.Thenmarkthe2-1/4”x7-1/4”openingonthe

oor.

2. Cutall4sidesoftheFeederDuctopening1”largerthan

thedrawncutout.NOTE:Cuttingtheopeningto14-1/8”

x14-1/8”willallowthefourangesontheundersideof

thepaneltotintotheopening.Cutallthewaythrough

theinsulationandbottomboardsothatthecombustion

airductisunobstructedtooutsideair.

3. If applicable, cut the 2 1/4” x 7 1/4” opening for the

combustionairduct.NOTE:Cuttheopeningfortheduct

about1/8”largerthantheactualcutoutdrawn.Thiswill

allowsomeclearancewheninstallingtheFeederDuct.

4. Drilla1”diameterholeforthefuellinethroughtheoor

andbottomboardtotheoutside.NOTE:Fuellinesare

notsuppliedwiththefurnace.Theyshouldbeinstalled

tocomplywithallapplicablecodes.

5. Set the universal base in place. Drop transition duct

(Figure5)upsidedownthroughtheooropeningand

centerthetopofthefeederductin14-1/8”x14-1/8”oor

opening.

6. Usingthefeederductasaguide,markandcuta12”x

12”openinginthesupplyduct.Removethebaseand

transitionfeederduct;thencuttheopeningintothesupply

duct.

7. Insertthefeedertabsintothemainductandbendthem

overuntilthemainductedgesaretrappedtightlybetween

anges and tabs. NOTE: Metal tape may be used to

ensureanairtightconnection.

8. Setthebottombasepaneloverthefeederduct.Slitthe

cornersofthefeederductdowntothetopofthebase.

Whilethetopofthedistributionductispulledupwithone

hand,benddowneachsideofthefeederducttightlyto

thebasewiththeotherhand.Trimthemetaltoallowone

inchangeoverthetopofthebaseandsealthatange

withmetaltape.

9. Securethetoppaneltotheoorwith2screwsthrough

thefrontange.NOTE:Ifusinga“V”or“U”-boxcrossover

system,use manufacturersinstructionsforinstallation

details.

11

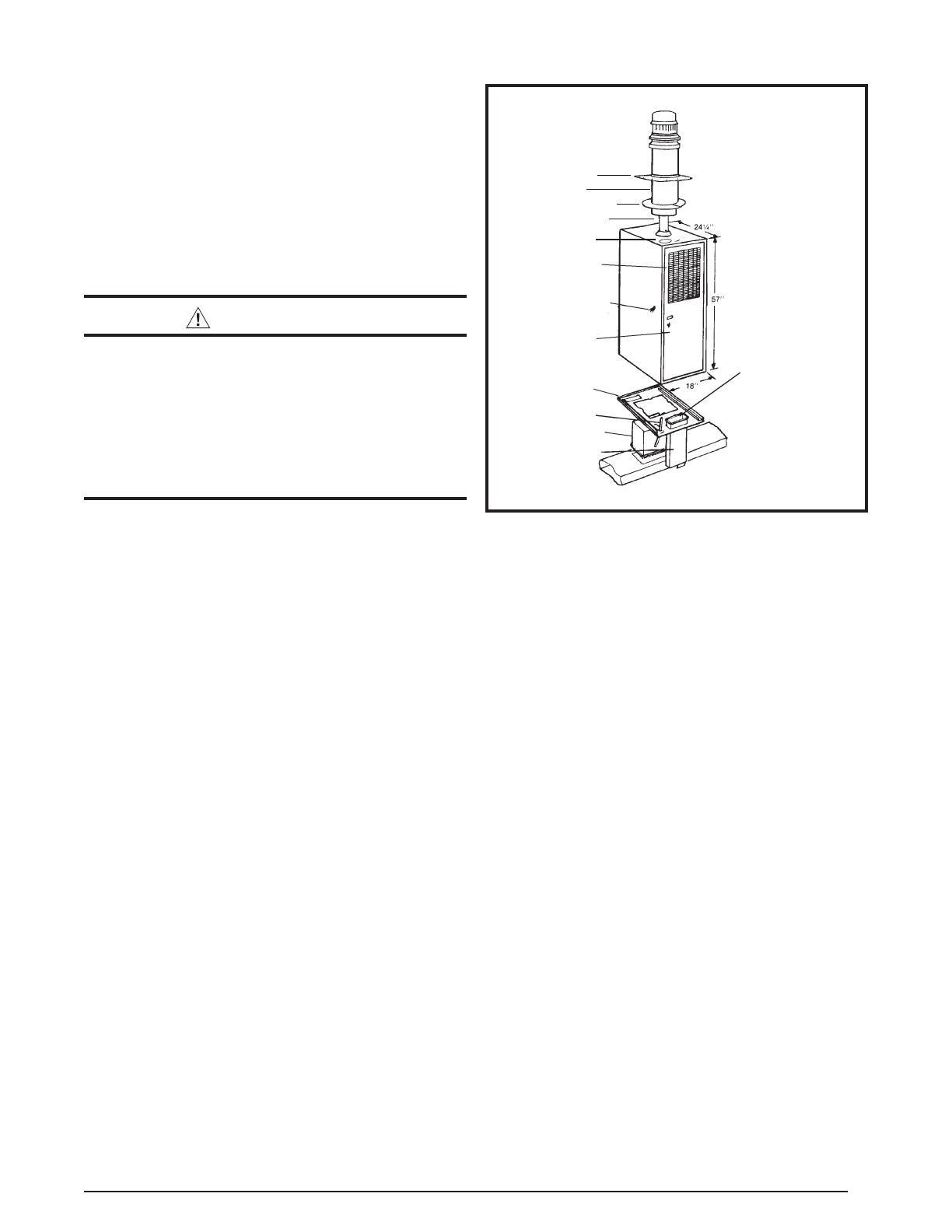

SRJRoofJackInstallation

Requiredceilingandroofcut-outopeningsmustbeaccurately

locatedtopreventhazardousmisalignmentofthefurnace

and roof jack. Figure 8 displays a typical installation for

maufacturedhousingapplications.RefertoFigure9(page

12)todetermineappropriateSRJroofjackandaccessories

requiredforyourinstallation.InstallonlySRJseriesroofjack

asspeciedonthefurnacelabel.

NOTE 1:Dependingon theslopeofthe roof,aroofjack

adaptormaybeneeded.

NOTE 2:Themaximumnumberofexternalextensionkits

allowedperinstallationis2.

WARNING:

• Theroofjackandventpipeasdeterminedfrom

thechartinFigure9mustbeapplied.

• Theindicatinglinenearthebottomoftheroof

jackmustextendbelowthenishedceiling.

• Theventpipemustbeattachedtothefurnace

uecollarwithprovidedsheetmetalscrews.

• DONOTinstallanyelbows(adjustableornon-

adjustable) or a stack damper in the venting

system.

1. Measureandcut an81/4”diameter holethroughthe

roofandceilingthatisalsoin direct line with theue

connectiononthetopofthefurnace.

2. Centertheadaptoropeningovertheroofopening.Use

sealantorcaulkingundertheadaptor.Useroongnails

orscrewsonwoodconstructionorsheetmetalscrews

onmetalroofs.

3. Inserttheventpipeintothebottomoftheroofjackwith

lockingslotpointedtowardsfurnace.Slidethepipeinto

theroofjacktoalengththatallowsconvenientreachto

theconnectionatthetopofthefurnace.

4. Ease the roof jack assembly through the openings.

NOTE: Thelowerportionoftheouterbarrelmustextend

throughthenishedceilingasindicatedonthebarrel.

Usesealantorcaulkingontherooforadaptortoseal

undertheashingoftheroofjackassembly.

5. Extendtheventpipeuntilthelockingslotengagesthe

screwinthetopofthefurnaceuepipe.

6. Twisttheventpipetolockthetwopipestogetherand

tightenthescrew.Alljointsandconnectionsshouldbe

inspectedbeforestartupofthefurnace.SeeFigure10

&Figure11(page12).

7. Fastentheceilingtrim/restopplatesaroundtheupper

barrelwithfournailsorwoodscrews(eldsupplied).

NOTE:ThetopsectionofroofjackmodelsSRJ-3,-4,

and-5canberemovedfordwellingtransit.Ifthetopis

removed,remainingopeningsmustbesealedfromrain,

debris,etc.,untilthetopisreinstalled.Aplasticaccessory

capmustbefastenedtothelowerroofjacksectionusing

thesamescrewssecuringtheroofjackcapassembly.

IMPORTANT NOTE:

Whenthetopsectionoftheroofjackisremovedfor

transit,aspecialwarninglabelmustbeattachedadjacent

tothefuellineconnectionofthegasoroilburner.The

special warning label is supplied with two piece roof

jackassemblies.

DamperInstallation

Anautomaticshut-offdamperisavailable(seereplacement

partslist).Anautomatedshutoffdamperisrequiredwhen

thehomeis airconditionedbyaself-containedunit.This

damperisdesignedtotinthefeederductcavity,directly

underthefurnace.Adamperisrequiredtopreventchilled

airfromowingoverthefurnaceheatexchanger.Forproper

installation,refertotheinstructionsprovidedwiththedamper.

Flashing

Barrel

Ceiling Plate

Vent

Ventilation

Knock-Out

DUCT

CONNECTOR

Return Air

Grille and

Filter

Power Supply

Connection

Access

Door

Base Pan

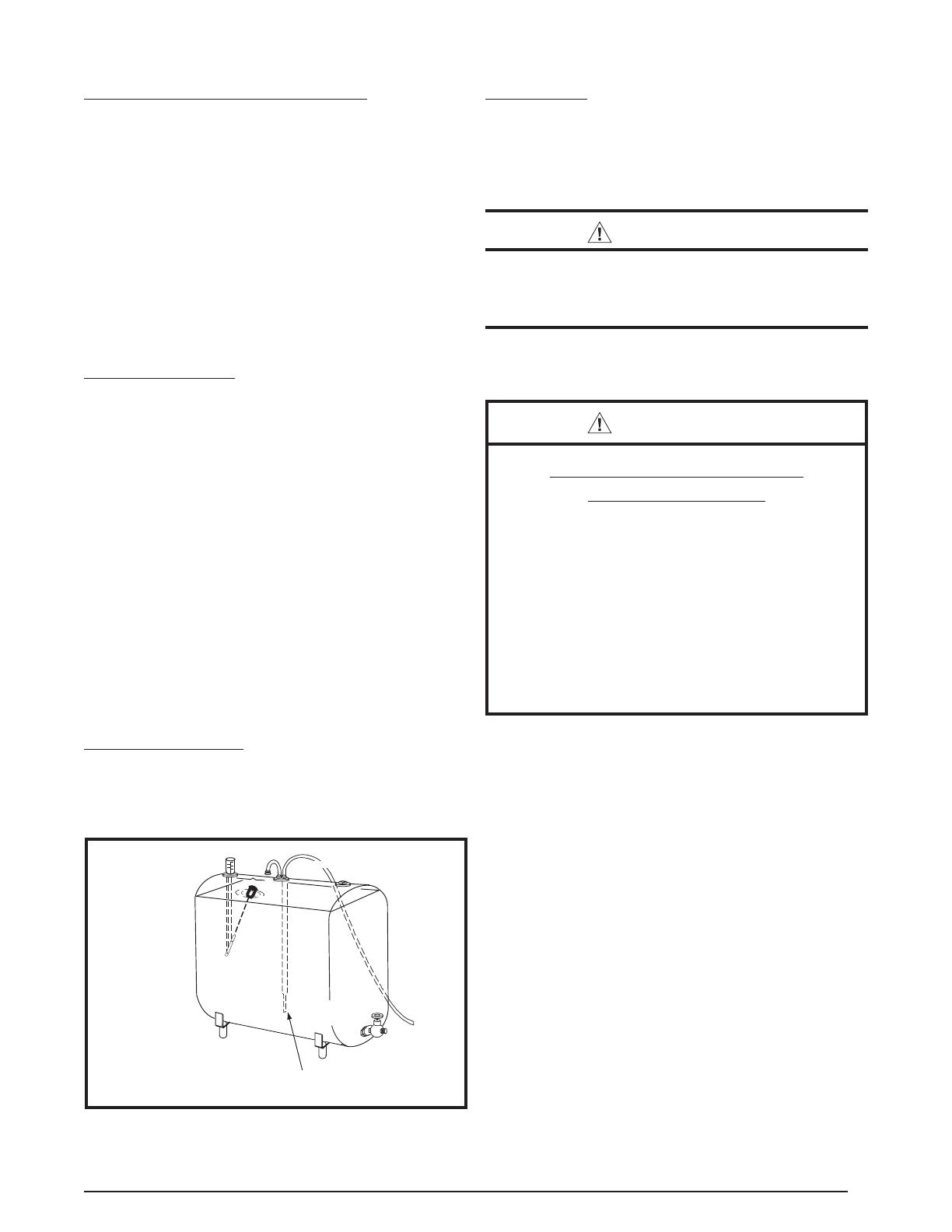

Fuel Line

Feeder Duct

Combustion

Air Duct

FURNACE

ASSEMBLY

ROOF JACK

ASSEMBLY

Combustion Air

Adapter (Not Shown)

is to be Installed

Over Combustion

Air Duct

Figure8.TypicalFurnaceInstallationfor

ManufacturedHousingApplications

12

RA-S4

RA-S3

RA-S2.5

4/12

3/12

2-1/2/12

None

Flat

NOTES:

SRJ1 & SRJ2 Models are one piece construction

SRJ3, SRJ4, & SRJ5 Models are two piece construction

-C Models are two piece construction

OPTIONAL:

Add -C for Raised Inlet Models (Example: SRJ3-34-C)

RoofJack Adaptor (for mounting roof jack on pitched roof)

Protective Cap (used when top of roofjack is removed)

Use Adaptor

Model No.

When roof pitch is:

1/2 Minimum

Furnace

CMF Series

57"

And Ceiling

Height is:

Add Suffix

For Vent Pipe

7'

-28

7'6"

-34

8'

-40

Ceiling Trim Plates

When Ceiling

Cavity is:

Use Roof Jack

Model No.

49" to 59"

37" to 48"

SRJ5

25" to 36"

13" to 24"

12" or Less

SRJ4

SRJ3

SRJ2

SRJ1

Adaptor

14" Removable SRJ3, SRJ4, & SRJ5

25" Removable All -C Models

Figure9.SelectionofRoofJack&AccessoriesChart

Figure11.VentPipeInstallation

Flue Pipe

of Furnace

Vent Pipe

Tu rn To Lock-

Tighten Screw

Insert Sliding Pipe

Fasten Ceiling

Trim Plates

Ceiling

Roof

Roof Jack Adaptor

Install With Line

Below Ceiling

Remove three screws

to separate two piece

models; replace with

protective cap for

transit only

Fasten roof flashing to adaptor

or flat roof; apply sealant or

caulking underneath

Fasten adaptor to

sloped roof; apply

sealant or caulking

underneath

Figure10.RoofJack

13

FUEL CONNECTIONS

Gaspiping-PGSeriesOnly

WARNING:

FIRE OR EXPLOSION HAZARD

• Failuretofollowsafetywarningsexactlycould

resultinseriousinjuryorpropertydamage.

• Installationandservicemustbeperformedby

aqualiedinstaller,serviceagencyorthegas

supplier.

• Donotstoreorusegasolineorotherammable

vaporsandliquidsinthevicinityofthisorany

otherappliance.

WHAT TO DO IF YOU SMELL GAS

• Donottrytolightanyappliance.

• Donottouchanyelectricalswitch;donotuse

anyphoneinyourbuilding.

• Leavethebuildingimmediately.

•Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• Ifyoucannotreachyourgassupplier,callthe

redepartment.

• Allgaspipingmustbeinstalledincompliancewith

localcodesandutilityregulations.Intheabsenceof

localcodesthegaslineinstallationmustcomplywith

thelatesteditionoftheNationalFuelGasCode(ANSI

Z223.1)or(CAN/CSAB149.1or.2)InstallationCodes

andHUDGasPipingSystems(3280.705).

• Some local regulations require the installation of a

manual main shut-off valve and ground joint union

externaltothefurnace.Theshut-offvalveshouldbe

readilyaccessibleforserviceand/oremergencyuse.

Consultthelocalutilityorgassupplierforadditional

requirementsregardingplacementofthemanualmain

gasshut-off.

• Gas piping must never run inorthroughairducts,

chimneys,gasvents,orelevatorshafts.

• Compounds used on threaded joints of gas piping

mustberesistanttotheactionsofLPpropanegas.

• Themaingasvalveandmainpowerdisconnecttothe

furnacemustbeproperlylabeledbytheinstallerin

caseemergencyshutdownisrequired.

• Flexiblegasconnectorsarenotrecommendedforthis

typeoffurnacebutmaybeusedifallowedbylocal

jurisdiction. Only new exible connectors may be

used.Donotuseaconnectorwhichhaspreviously

servicedanothergasappliance.

• Adriplegshouldbeinstalledintheverticalpiperun

totheunit.

TheCMF3furnacemaybeinstalledwithgasentrythrough

the bottom of the furnace. When installing the gas line,

connectaseparategaslinefromthegasmetertotheburner

withamanualshut-offvalveinstalledinthesupplylineat

thefurnace.Alwaysusenewcleanpipingandroutetheline

inaneasilyaccessiblemanner.Thepipingandthreading

mustbefreefromcuttingburrsanddefects.Thelinemust

bedurable,substantial,andgastight.Anadditionalmain

manualshut-offvalvemaybeinstalledinthegassupplyline

toshut-offthemainfuelsupply,ifdesiredbythehomeowner

orrequiredbylocalcodes.

Thepropergassupplylinesizecanbedeterminedbyreferring

tothelatesteditionoftheNationalFuelGasCode(NFGC)

andHUDGasPipingSystems(3280.705).Blackpipeisthe

mostpracticalfornaturalgas,becauseofthelargersizes

required. Copper tubing with an internal coating of tin is

recommendedforusewithpropane(LP)gasinstallations.

LeakCheck

WARNING:

ELECTRICAL SHOCK, FIRE OR

EXPLOSION HAZARD

Failuretofollowsafetywarningsexactlycould

resultinseriousinjuryorpropertydamage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

• Beforeservicing,disconnectallelectricalpower

tofurnace.

• Whenservicingcontrols,labelallwiresprior

todisconnecting.Reconnectwirescorrectly.

• Verifyproperoperationafterservicing.

Afterthegaspipingtothefurnaceiscomplete,allconnections

mustbetestedforgasleaks.Thisincludespipeconnections

atthemaingasvalve,emergencyshutoffvalveandexible

gasconnectors(ifapplicable).Thesoapandwatersolution

canbeappliedoneachjointorunionusingasmallpaintbrush.

Ifanybubblingisobserved,theconnectionisnotsealed

adequatelyandmustberetightened.Repeatthetightening

andsoapcheckprocessuntilbubblingceases.

IMPORTANT NOTE:

Whenpressuretestinggassupplylinesatpressures

greater than 1/2 psig (14 inch W.C.), the gas supply

pipingsystemmustbedisconnectedfromthefurnace

topreventdamagetothegascontrolvalve.Ifthetest

pressureislessthanorequalto1/2psig(14inchW.C.),

closethemanualshut-offvalve.

HighAltitudeApplication

Installation of this furnace at altitudes above 2,000 feet

shallbeinaccordancewithlocalcodes,orintheabsence

oflocalcodes,theNationalFuelGasCode,ANSIZ223.1/

NFPA54orNationalStandardofCanada,NaturalGas&

PropaneInstallationCodeCSAB149.1.Pleaseconsultyour

localcodeauthority.

WARNING:

Thereductionofinputratingnecessaryforhigh

altitudeinstallationmayonlybeaccomplishedwith

factorysuppliedorices.Donotattempttodrillout

oricesintheeld.Improperlydrilledoricesmay

causere,explosion,carbonmonoxidepoisoning,

personalinjuryordeath.

TheCMF3furnaceisshippedfromthefactorywithitsorices

andgasregulatorsettingfornaturalgasoperationatsea

levelaltitudes.At2,000feet,theNFGCrequiresthatthis

appliancebederated4%foreach1,000feetofaltitude.For

example,theinputneedstobereduced8%at2,000feet,

14

12%at3,000feet,etc.Thisderationisinreferencetothe

inputrateandgasheatingvalueatsealevel.

Highaltitudeconversionforthisfurnacerequiresreducing

theoricesizeordecreasingthemanifoldpressure.When

decreasingthemanifoldpressure,thepressuremustnotbe

setbelow3.2inWC.Ifthepressureneedstobesetbelow

3.2inWCtoachieveproperderation,thenchangetheorice

sizeandraisethemanifoldpressurebackto3.5inWC.

Afterchangingtheregulatorpressureortheorices,itis

requiredthatyoumeasurethegasinputrate.Thismaybe

accomplishedintheusualway,byclockingthegasmeter

andusingthelocalgasheatingvalue.Tochecktheinputof

thefurnaceseepage21.

IMPORTANT NOTE:

Observetheactionoftheburnerstomakesurethereis

noyellowing,liftingorashbackoftheame.

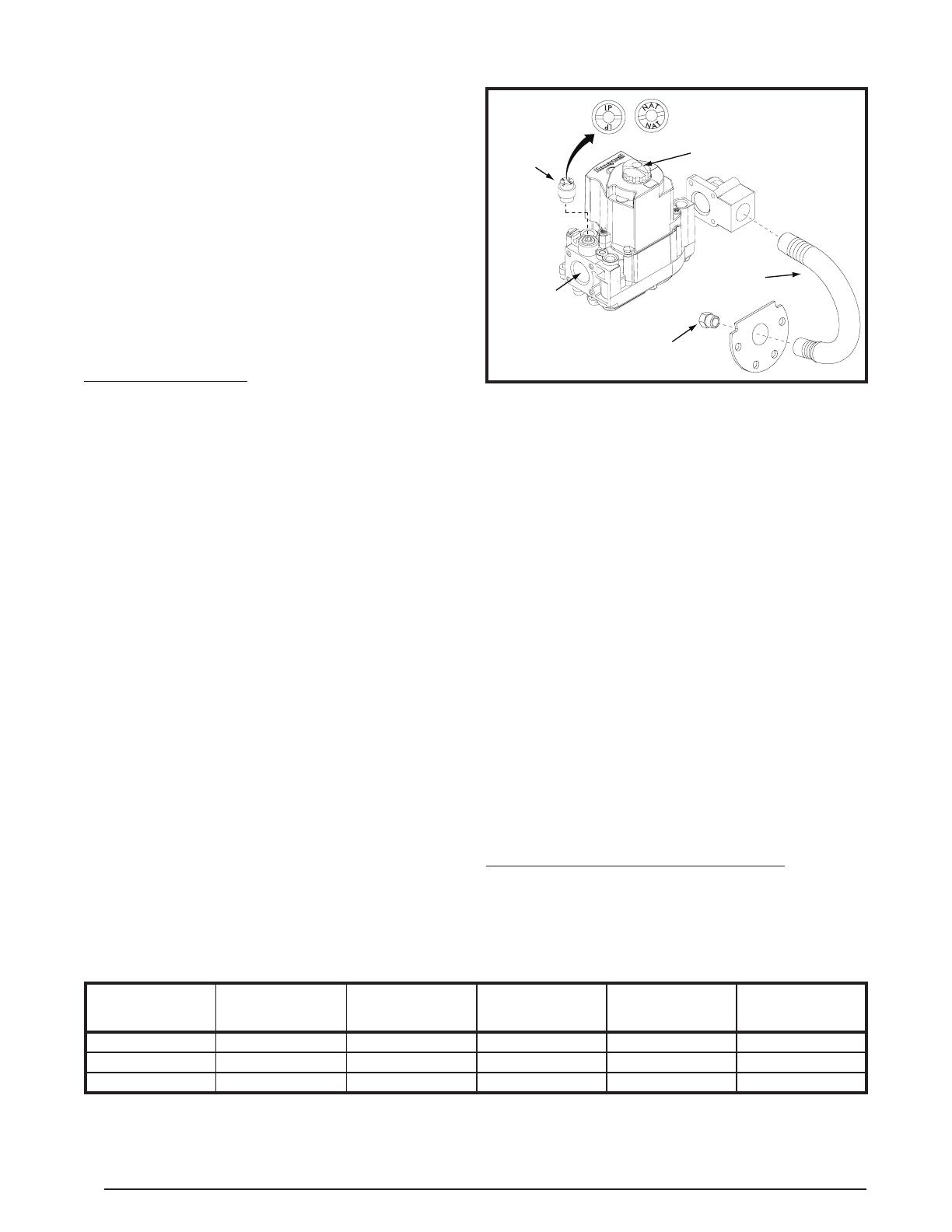

ConvertingtoLPGas

TheCMF3furnaceisshippedfromthefactoryforusewith

naturalgasbutcanbeconvertedtouseliquidpropanegas.

UsethefollowingprocedureandFigure18forconverting

thegasburner.

1. SetthermostattoOFF.

2. Turnoffallpowertothefurnace.

3. Openfurnacedoorandlocatethegasvalve.

4. PushinonthegasknobandturnittoOFF.

5. Shutoffgassupplyatmeter.

6. Disconnectgasburnerelectriccord,gaspipingtoburner,

andthermostatleads.

7. Removenutssecuringburnerinplace.

8. Disconnectinletpipeunionatburner.

9. Disconnectthetwowiresleadingtogascontrolvalve.

10.RemoveboltssecuringU-shapedmanifoldplatetoorice

assembly.

11.Removethemainoriceandreplaceitwiththecorrect

LPfueloriceasshowninTable2.Refertotherating

plateonthefurnacetodeterminetheringrateforyour

application.NOTE:Iftheringrateofyourfurnacehas

beenconverted,make suretheappropriateLPorice

forthenewringrateisinstalled.

12.Removetheregulatorconverterontopofthegasvalve.

Inverttheconvertersothattheredringwillbelocatedat

thebottomandtheLPstampingontheconverterappears

up.

13.Screwconverterbackintotheregulator,handtightplus

1/8turn.

14.Reinstalltheburnerassemblyintothefurnace.

15.Reconnectthegaspipingandelectricalwirestothegas

valve.

16.Openthemanualshut-offvalveandfollowtheOperating

Instructionsoutlinedonpage18.

Oilpiping-POSeriesOnly

Thefollowingproceduresarerecommendedasgoodpractice.

However,requirementsoflocalcodesandordinances,H.U.D.

ManufacturedHomeandSafetyStandardsorNationalFire

ProtectionAssociationmustbesatised,wheretheyapply,

foranapprovedinstallation.

• Use a tank capacity suitable for the application with a

weatherproof,cappedllopeningandshieldedventtolet

airinasfuelisused.NOTE:Theinsideofthetankmust

becleanbeforelling.Allwater,rust,sediment,andother

foreignmattermustbeushedout.

• If a two pipe system is used or if oil is taken from the

bottom of the tank, a lter is recommended. A manual

shut-offvalvemayalsobeusedonasinglepipeortwo

pipesystem.NOTE:Localcodesmaydictatethespecic

installationrequirements.

• Afuelortankgaugeisrecommendedforeasychecking

ofthefuellevel.Checkthegaugeusingadipstick.

• Locatethestoragetankconvenientlynearthehome.For

above ground fuel tank installations, the tank may rest

threetofourinchesofftheground.Fueltanksmayalso

beburiedifproperlycoatedtoresistcorrosion.Forbelow

groundfueltankinstallations,theverticaldimensionfrom

thebottomofthetanktothefuelpumpmustnotexceed

10feet.Keepthetanklledespeciallyinthesummerto

reducetheaccumulationofcondensation.

FuelLineHook-Up:SingleLineSystem

Thesinglelinesystemishighlyrecommendedwhenvertical

lift,frombottomoftanktopump,islessthan8feet.Asingle

linehookuphastheadvantageofcostinglessandgiving

quieteroperation.

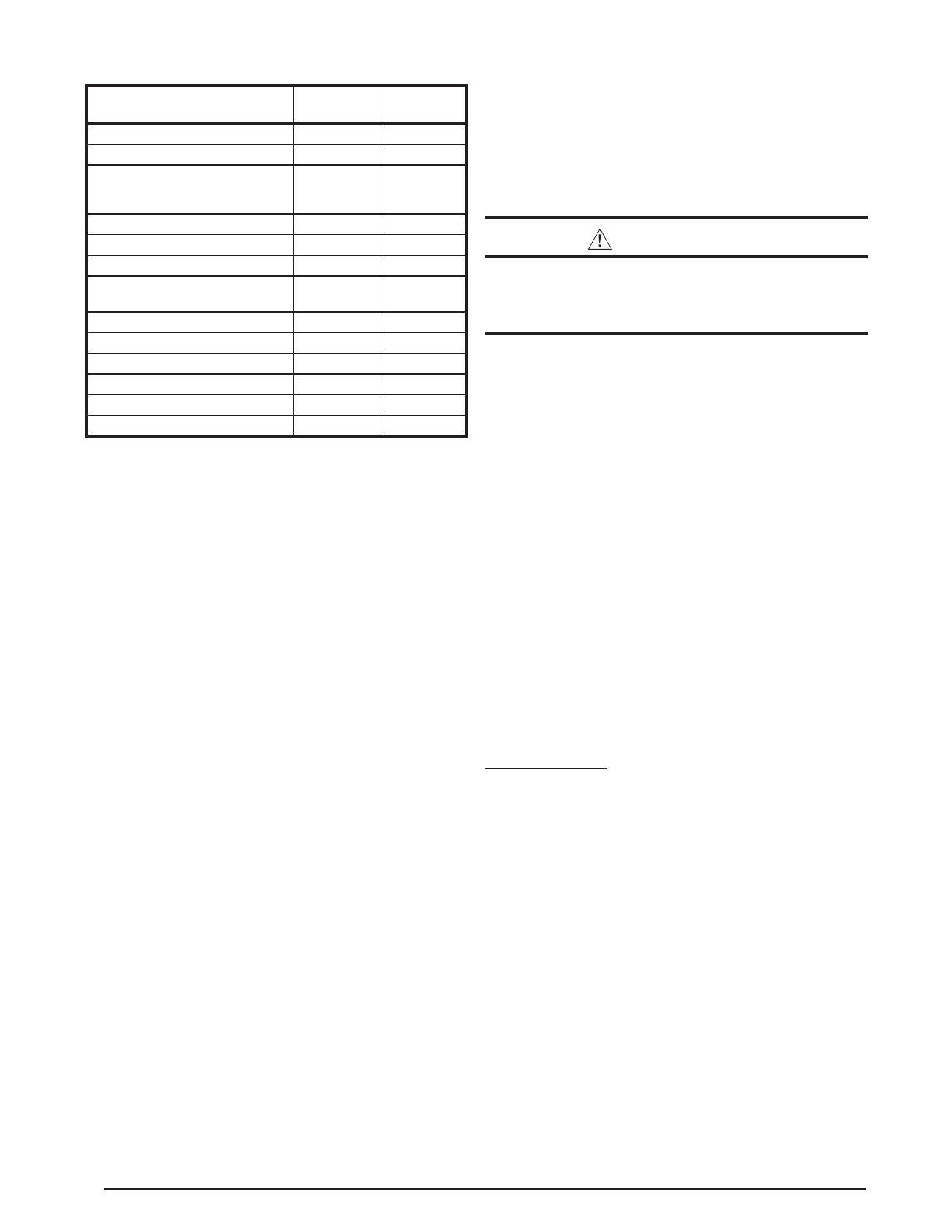

Table2.Natural&LPGasOrices

BURNER

DESIGNATION

FIRING RATE

INPUT (BTUH)

NATURAL GAS

ORIFICE NUMBER

NATURAL GAS

TIME TO CONSUME*

LP GAS

ORIFICE

NUMBER

LP GAS

TIME TO CONSUME**

GasGun-60-DI-S 60,000 27 60 43 148

GasGun-70-DI-S 70,000 22 52 41 126

GasGun-75-DI-S 75,000 20 48 40 120

*Timesarebasedonnaturalgasatanaverageof1,000BTUpercubicfoot,aburnermanifoldpressureof3.5inWC,and1CFM.

**TimesarebasedonLPgasatanaverageof2,500BTUpercubicfoot,aburnermanifoldpressureof10inWC,and1CFM.

Figure12.LP & Natural Gas Conversion

Orifice

Inlet

U-Shaped

Manifold

Regulator

Converter

Gas Control Knob

15

FuelLineHook-Up:TwoLineSystem

Twolinesystemsshouldonlybeusedwhentheverticallift

exceeds8feet.

1. Install the oil feed line as outlined in the Hook-up

Procedure.

2. Installtheoilpumpbypasspluginthebottomreturnport.

3. Runthereturnlineupthroughthefurnacebasetothe

returnportofthepump.Runtheotherendofthelineto

thetank,using3/8”O.D.coppertubingor1/4”pipewith

theendscapped,androutingthelinesoitstaysclean.

4. Insertthereturnlinethroughthesecondopeninginthe

duplexbushing.Ifthebottomofthetankislowerthanthe

pumpintake,thetubeshouldbeinserted3or4inches

fromthetankbottom.Ifthebottomofthetankishigher

thanthepumpintake,thereturnlineshouldextendnot

morethan8”insidethetank.

Hook-UpProcedure

1. Use3/8”O.D.coppertubingforthefuelline.Captheend

withtapetokeepoutdirtwhilethelineisbeingrouted.

SeeFigure13.

2. Installduplexbushingfortwo3/8”linesinthetoptting

ofthetank.

3. Insertoneendofthetubingthroughtheduplexbushing

until it is 3” to 5” from the bottom drain. Tighten the

bushing.

4. Routethefuellinewhereitwillnotbesubjecttodamage.

Makeallbendsgradualandavoidkinksthatmightrestrict

oilow.

5. Opentheburneraccessdoor.Connecttheoillinetothe

intakeportonthepump.Tightenotherportplugsonthe

pump.

6. Makesuretheoillineisairtight!NOTE:Airleakscancause

thepumptoloseprimeandwillcreateotherproblems

suchasnozzlefailure,odors,rumblingnoise,andfalse

safetyshutdown.

7. Inserttheshortlengthofthecoppertubelevelwiththe

bottomoftheduplexbushing.Tightenthebushing.Form

thetubeintoaninverted“U”toserveasavent.

EliminatingAirLeaks

To eliminate problems caused by air in the oil line, all

connectionsinthe oilsupplylineandallplugs,nuts, and

ttingsonthepumpmustbeairtight,includingthenutthat

coversthepressureadjustment.Itisimportantthatthehook-

upbedonewithagoodaringtool.

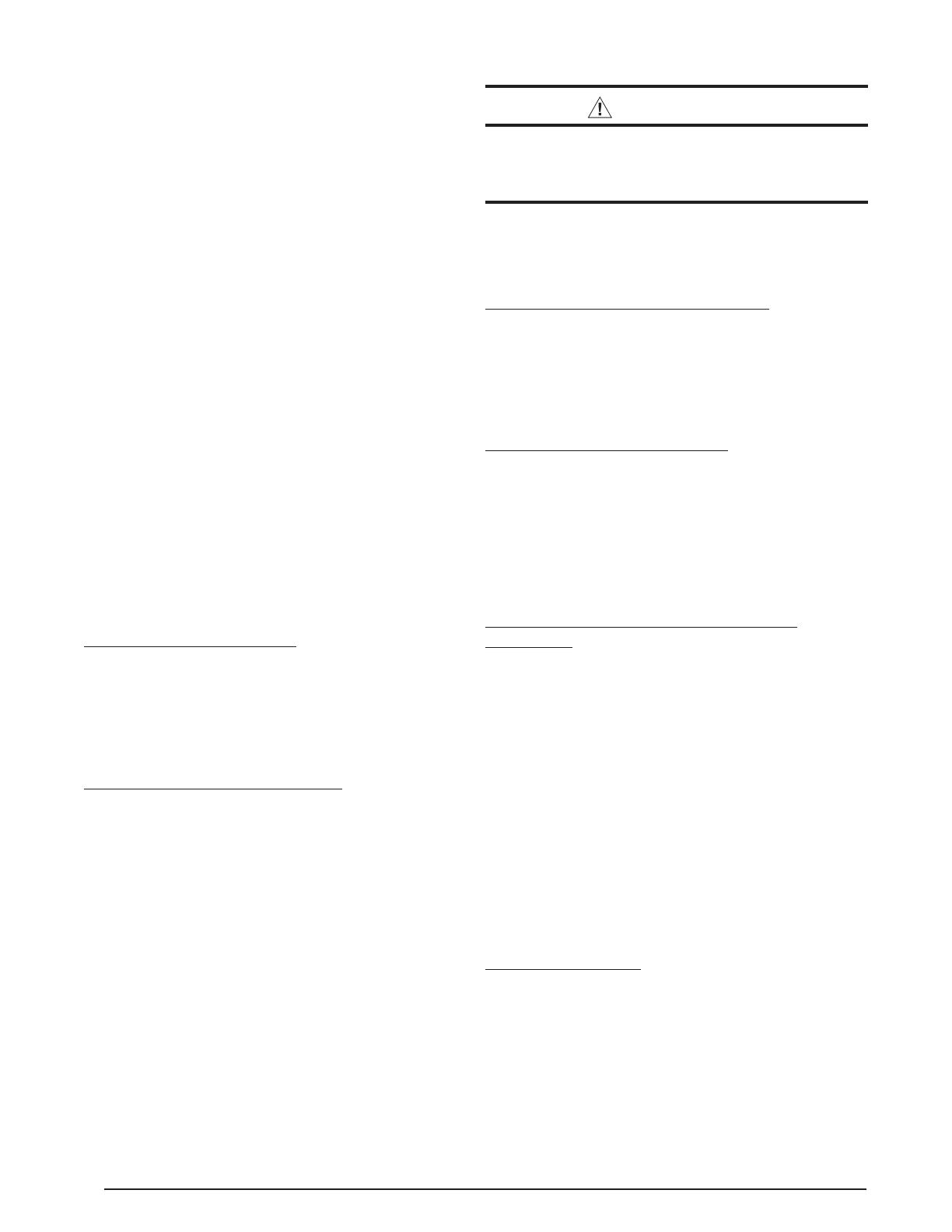

Figure13.RecommendedTankHook-Up

200-300GallonTank

Drain

End of Oil Supply Line

3" to 5" Above

Bottom Drain

Guide pipe

Gauge

Vent with

Cap

2" Duplex

Bushing

2" Fill

3/8" Oil Supply Line

Note: Additional venting may

be required if tank is filled rapidly.

FuelOilType

GradeNo.1maybeusedwheretheoilsupplyissubject

tolowtemperatures.DonotusefueloilheavierthanGrade

No.2.Biodieselblendsupto5%(B5)arealsoacceptable.

IMPORTANT NOTE:

DO NOT USE GASOLINE, CRANKCASE OIL, OR ANY

OILCONTAININGGASOLINE.

WARNING:

Failuretokeepsupplyoilcleanmaycausefailureof

certaincomponentssuchasthefuelpumpgears,

checkvalve,shaftseal,orburnernozzlewhichmay

resultinaburnerre.

ELECTRICAL CONNECTIONS

WARNING:

ELECTRICAL SHOCK, FIRE OR

EXPLOSION HAZARD

Failuretofollowsafetywarningsexactlycould

resultinseriousinjuryorpropertydamage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

• Beforeservicing,disconnectallelectricalpower

tofurnace.

• Whenservicingcontrols,labelallwiresprior

todisconnecting.Reconnectwirescorrectly.

• Verifyproperoperationafterservicing.

• Electrical connections must be in compliance with

all applicable local codes and ordinances, and with

the current revision of the National Electric Code

(ANSI/NFPA70).

• For Canadian installations, the electrical connections

and grounding shall comply with the current Canadian

ElectricalCode(CSAC22.1and/orlocalcodes).

Pre-ElectricalChecklist

√Verify the voltage, frequency, and phase of the supply

sourcematchthespecicationsontheunitratingplate.

√Verifythattheserviceprovidedbytheutilityissufcient

tohandletheadditionalloadimposedbythisequipment.

Refer to the unit wiring label or Table 3 (page 19) for

properhighandlowvoltagewiring.

√Verifyfactorywiringisinaccordancewiththeunitwiring

diagram(Figure18,page25).Makesurenoconnections

loosenedduringshippingorinstallation.

16

LineVoltage

• Anelectricaldisconnectmustbelocatedwithinsight

ofandeasilyaccessibletotheunit.Thisswitchshall

be capable of electrically de-energizing the unit. See

unitdatalabelforproperincomingeldwiring.Anyother

wiringmethodsmustbeacceptabletoauthorityhaving

jurisdiction.

• Itisrecommendedthat thelinevoltageto theunitbe

suppliedfromadedicatedbranchcircuitcontainingthe

correctfuseorcircuitbreakerfortheunit.SeeTable3

forunitspecications.

• Overcurrentprotectionmustbeprovidedatthebranch

circuitdistributionpanelandsizedasshownontheunit

ratinglabelandaccordingtoapplicablelocalcodes.

• Useonlycopperwireforthelinevoltagepowersupply

tothisunit.Use14-2TypeNMcableor codeagency

listed conduit and a conduit connector for connecting

thesupplywirestotheunit.

• Ifreplacinganyoftheoriginalwiressuppliedwiththeunit,

thereplacementwiremustbecopperwireconsistingof

thesamegaugeandtemperaturerating.

• Provide power supply for the unit in accordance with

theunitwiringdiagram, andtheunitrating plate.The

installershouldbecomefamiliarwiththewiringdiagram/

schematicbeforemakinganyelectricalconnectionsto

theunit.SeeFigure18(page25).

Wiring Connections

1. Opentheappliancedoorforaccesstothecontrolbox.

2. Removethecontrolboxcover.

3. Connecttheblackwireofthefurnacetotheblackwire

ofthepowersupplycable.

4. Connectthethewhitewireofthefurnacetothewhite

wireofthepowersupplycable.

5. Connectthegroundwireofthepowersupplycableto

thegreenscrewinthecontrolboxofthefurnace.

6. Verifyallelectricalconnectionsaresecurelyconnected.

7. Replacethecontrolboxcover.

Grounding

WARNING:

The unit cabinet must have an uninterrupted or

unbrokenelectricalgroundtominimizepersonal

injuryifanelectricalfaultshouldoccur.Donotuse

gaspipingasanelectricalground!

Thisunitmustbeelectricallygroundedinaccordancewith

localcodesor,intheabsenceoflocalcodes,withtheNational

ElectricalCode(ANSI/NFPA70)ortheCSAC22.1Electrical

Code.Usethegroundinglugprovidedinthecontrolboxfor

groundingtheunit.

ThermostatConnections

• Thermostatconnectionsshallbeinaccordancewiththe

instructionssuppliedwiththethermostatandtheindoor

equipment. The low voltage wires must be properly

connectedtotheunitslowvoltageterminalblock.Route

R&Wfromthethermostattotheburnercompartment.

Connect R to one of the low voltage terminals of the

burner. Connect W to the burner’s other low voltage

terminal.

• A single stage thermostat is used with this equipment

and must operate in conjunction with any installed

accessories.

• The thermostat should be mounted about 5 feet above

theooronaninsidewall.DONOTinstallthethermostat

on an outside wall or any other location where its

operationmaybeadverselyaffectedbyradiantheatfrom

replaces, sunlight, or lighting xtures, and convective

heat from warm air registers or electrical appliances.

Refertothethermostatmanufacturer’sinstructionsheet

fordetailedmountingandinstallationinformation.

HeatAnticipator

Settheheatanticipatoraccordingtotheinstructionssupplied

by the thermostat manufacturer. To determine the heat

anticipatorsetting:

1. Addthecurrentdrawofthesystemcomponents;or

2. MeasurethecurrentowonthethermostatR-Wcircuit

afterthecirculatingblowermotorhasstarted.

BlowerSpeed

TheCMF3furnaceisequippedwitha3speedPSCmotor

thatispre-setatthefactoryforMEDIUMspeedoperation.

Foroptimumsystemperformanceandcomfort,itmaybe

necessary to change the factory speed setting. This is

accomplishedbychangingawireconnectionattheblower

motor.Refertothewiringdiagramlabelontheinsideofthe

paneldoororseeFigure18(page29)forwiringconguration.

Table4liststhepropercirculatingairowandtemperature

risefortheCMF3furnace.

CMF 70 PG

CONVERTIBLE

CMF 70 PO

CONVERTIBLE

FactorySetFiringRate(btu/hr)* 70,000 70,000

HeatingCapactiy(btu/hr) 56,000 56,000

KitConvertedFiringRate(btu/hr)**

60,000

or

75,000

60,000

AFUERating(%) 80+ 80+

OriceNumber(NaturalGas) 22 N/A

OriceNumber(PropaneGas) 41 N/A

BurnerNozzleforOil N/A

0.50gph;

A;80

o

BlowerDxW 10x7 10x7

MotorH.P.-Speed-Type 1/4-3-PSC 1/4-3-PSC

MotorFLA 3.3Amps 3.3Amps

FuseorBreaker 15Amps 15Amps

Nom.AnticipatorSetting 0.6 0.6

TemperatureRiseRange(

o

F) 55

o

-85

o

55

o

-85

o

NOTES:

Electrical:Allmodelsare115volt,60Hz,1phase.

Thermostatcircuitis24VAC,60Hz.

Gasconnection:1/2”NPT.

* Ratingsto2,000feet.Over2,000ft,reduceratingsby4%foreach

additional1,000ftabovesealevel.

** TheringrateoftheCMF70seriesfurnacecanbechangedusing

anapprovedconversionkit.

AFUE=AnnualFuelUtilizationEfciency

Table3.CMF3Specications

17

CAUTION:

Toavoidpersonalinjuryorpropertydamage,make

surethemotorleadsdonotcomeintocontactwith

anyuninsulatedmetalcomponentsoftheunit.

• High Speed Operation:Connecttheblackwirefromthe

fanswitchtotheblackwireoftheblowermotor.

• Medium Speed Operation: Connect the black wire

fromthefanswitchtothebluewireoftheblowermotor.

NOTE: Thisisthefactorydefaultsettingandshouldnot

bechangedifhighspeedoperationisdesired.

• Low Speed Operation:Connecttheblackwirefromthe

fanswitchtotheredwireoftheblowermotor.

ConstantBlowerOperation

TheFANON&OFFswitchislocatedontopofthecontrol

box.Thisswitchprovideseitherautomaticoperationofthe

blowerthroughthethermostatorconstantbloweropeation.

Table4.CMF3 Airflow Data

EXTERNAL

STATIC

PRESSURE

(IN WC)

AIRFLOW (CFM)

LOW SPEED

FOR

60 KBTU/H INPUT

MEDIUM SPEED

FOR

70 KBTU/H INPUT

HIGH SPEED

FOR

75 KBTU/H INPUT

0.1 710 740 820

0.2 670 700 780

0.3 640 660 730

0.4 600 620 680

0.5 550 570 630

0.6 500 520 570

START-UP & ADJUSTMENTS

WARNING:

Allsafetyinformationmustbefollowedduringthe

start-upandoperationofthefurnace.Unqualied

individualsshouldnotattempttointerpretthese

instructions. Improper servicing could result in

dangerousoperation,propertydamage,personal

injuryordeath.

WARNING:

FIRE OR EXPLOSION HAZARD

• Failuretofollowsafetywarningsexactlycould

resultinseriousinjuryorpropertydamage.

• Installationandservicemustbeperformedby

aqualiedinstaller,serviceagencyorthegas

supplier.

• Donotstoreorusegasolineorotherammable

vaporsandliquidsinthevicinityofthisorany

otherappliance.

WHAT TO DO IF YOU SMELL GAS

• Donottrytolightanyappliance.

• Donottouchanyelectricalswitch;donotuse

anyphoneinyourbuilding.

• Leavethebuildingimmediately.

•Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• Ifyoucannotreachyourgassupplier,callthe

redepartment.

• Thisappliancedoesnothaveapilot.Itisequippedwith

anignitiondevicewhichautomaticallylightstheburner.

Donottrytolighttheburnerbyhand.

• BEFORELIGHTINGOROPERATINGsmellallaround

theapplianceareaforgas.Besuretosmellnexttothe

oorbecausesomegasisheavierthanairandwillsettle

ontheoor.

• Useonlyyourhandtopushinandmovethegascontrol

lever.Neverusetools.Iftheleverwillnotpushinbyhand,

don’t try to repair it, call a qualied service technician.

Forceorattemptedrepairmayresultinareorexplosion.

• Shouldoverheatingoccur,orthegassupplyfailtoshut

off,turnthemanualgasvalvetotheapplianceOFF.

Pre-StartCheckList

√Verifythepolarityoftheconnectionsarecorrect,theline

voltage power leads are securely connected and the

furnaceisproperlygrounded.

√Verify the thermostat wires (R & W) are securely

connectedintheburnercompartment.

√Verifythegaslineservicepressurebeforethefurnaceis

running:

For natural gas, the pressure should not exceed 10.0

inchesofW.C.,andisnotlessthan3.5inchesW.C.

ForLPgas,thelineservicepressuremustnotexceed14

in.W.C.,andmustnotbelessthan11.0in.W.C.

18

√Verify the roll-out and manual reset switchis closed. If

necessary, press the red button to reset a switch. DO

NOTinstallajumperwireacrossaswitchtodefeat

its function. If a switch reopens on startup, DO NOT

reset the switch without identifying and correcting the

faultcondition.

√Verifytheblowerdoorisinplace,closingthedoorswitch

inthelinevoltagecircuit.

√Verifythegaslineandallconnectionsareleakfree.

Operating Instructions for PG Direct Ignition

Burner

Do not perform these steps until all of the safety checks

havebeencompleted:

1. STOP!Readallsafetyinformationonthispage.

2. SetthethermostattoOFFortoitslowestsetting.

3. Turnoffallelectricpowertotheappliance.NOTE:This

appliance is equipped with an ignition device which

automaticallylightstheburner.DONOTtrytolightthe

burnerbyhand.

4. Turnthelatchandopenthefurnacedoor.

5. Push in the gas control knob and turn to OFF.

IMPORTANT:DONOTFORCE.Wait10minutesto

clearoutanygas.Ifyoustillsmellgas,STOP!and

readWHATTODOIFYOUSMELLGAS.Ifyoudon’t

smellgas,gotothenextstep.

6. TurnthegascontrolknobtoON.

7. Closethefurnacedoorandturnthelatch.

8. Turnonallelectricpowertotheappliance.

9. TurnthethermostattoONandsettothedesiredsetting.

10.Iftheappliancewillnotoperateafteronere-try,follow

theinstructionsShuttingOfftheGasSupplybelowand

callyourservicetechnicianorgassupplier.

ShuttingOfftheGasSupply

1. SetthethermostattoOFFortoitslowestsetting.

2. Turnoffallelectricpowertotheapplianceifserviceis

tobeperformed.

3. Turnthelatchandopenthefurnacedoor.

4. PushinthegascontrolknobandmovetoOFF.DONOT

FORCE.

5. Closethefurnacedoorandturnthelatch.

CheckingtheInputoftheFurnace

Refertothefurnaceratingplatetodeterminetheringrate

of the furnace. Using Table 2 (page 14), determine the

appropriateoricesizefortheringrateandgasbeingused

inyourapplication.Checktheburneroricetoensurethatit

isthecorrectsize.Theinputofthisfurnacecanbechecked

usingthefollowingsteps:

1. Shutoffallothergasredappliances.

2. Startthefurnacerunitforatleast3minutes.

3. Measurethetime(inseconds)requiredforthegasmeter

tocompleteonerevolution.NOTE:Onerevolutionequals

1cubicfootofgas.

4. Comparethetimemeasuredwiththeappropriatetime

listedinTable2(page14).Ifthetimevariesbymorethat

5%fromthetimesshowninthetable,thenmeasurethe

inletandgasvalvemanifoldpressures.SeeCheckingthe

InletGasPressureandCheckingtheManifoldPressures

sectionsbelow.

WARNING:

Donotattempttodrillthegasorices.Useonly

factorysuppliedorices.Improperlydrilledorices

may cause fire, explosion, carbon monoxide

poisoning,personalinjuryordeath.

5. Iftheinletgaspressureandthemanifoldpressureare

bothproperlyset,thenchecktheburneroricetoensure

thatitisproperlysized.Furthergasproblemsshouldbe

referredtothelocalgassupplier.

CheckingtheInletGasLinePressure

Theinletgaslinepressurecanbecheckedattheportlocated

ontheinletendofthegasvalve.SeeInstallingthePressure

GaugeorU-TubeManometersection.

• Natural gas installations:Theinletgaslinepressureat

thegasvalvemustbebetween5in.W.C.&7in.W.C.

• LP gas installations:Theinletgaslinepressureatthe

gasvalvemustbebetween11in.W.C.&13in.W.C.

CheckingtheManifoldPressure

Themanifoldpressurecanbecheckedattheportlocatedon

thegasoutletendofthegasvalveusingapressuregauge

orU-tubemanometer.Ifthemanifoldpressureisnotequal

tothevaluesbelow,thenitmustbeadjusted.SeeInstalling

thePressureGaugeorU-TubeManometer.

• Natural gas installations:Themanifoldpressuremust

besetat3.5in.W.C.

• LP gas installations:Themanifoldpressuremustbeset

at10.0in.W.C.

InstallingthePressureGaugeorU-Tube

Manometer

1. Determinewhichtypeofpressure(inletgasormanifold

pressure)needstobemeasured.

2. Usinga3/16”Allenwrench,removetheappropriatetap

pluglocatedonthegasvalve.SeeFigure14(page19).

NOTE:Tomeasuretheinletgaspressure,removethe

tapplugontheinletsideofthegasvalve.Tomeasure

themanifoldpressure,removethetapplugontheoutlet

sideofthegasvalve.

3. Installattingthathasa1/8”NPTpipethreadandis

compatiblewiththepressuregaugeorU-tubemanometer

onthevalve.

4. ConnectthepressuregaugeorU-tubemanometertothe

gasvalve.Refertothegaugemanufacturer’ssupplied

instructionsforproperhookupandusage.

5. Aftermeasuringthepressure,removethepressuregauge

orU-tubemanometerfromthegasvalveandreplacethe

tapplug.NOTE:Makesurethetapplugistightandisn’t

cross-threaded.

AdjustingtheBurner

Theairshutterofthegasgunburnerispre-setatthefactory

andshouldnotbeadjustedunlesstheringrateofthefurnace

needstobeconverted.Theburnershouldrunquietly.Verify

theairshuttersettingiscorrectasshowninTable5(page

19).NOTE:Itisveryimportantthatthereisanamplesupply

ofcombustionairwithoutdecreasingburnerefciency.An

inadequateamountoffreshaircancausecarbonmonoxide

(CO)production.Thecarbondioxide(CO

2)contentoftheue

productsshouldbeintherangeof8.5%to9.5%fornatural

gasor9.0%to10.0%forLPgas.

19

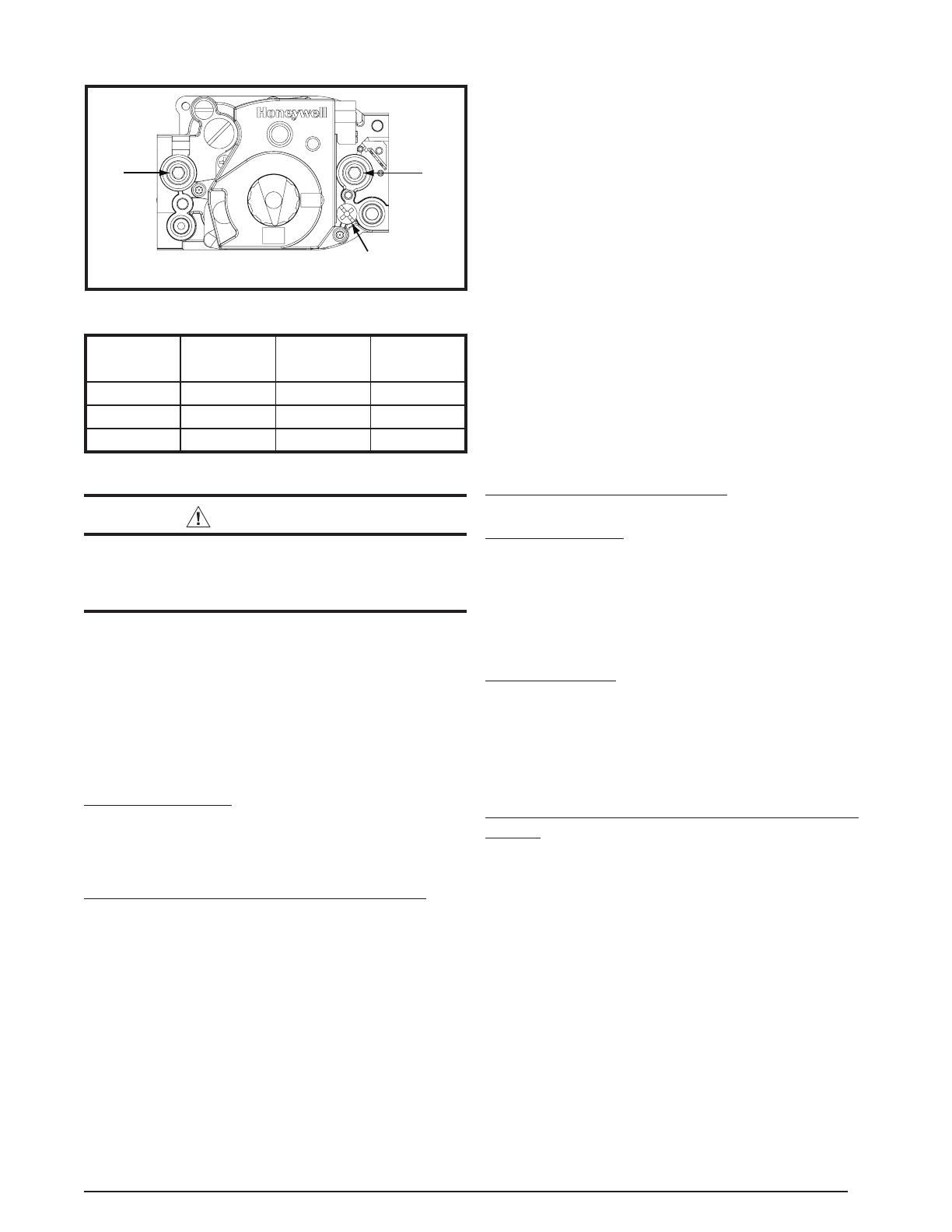

INLET

TA P

OUTLET

TA P

Regulator

Converter

Figure14.DirectIgnitionGasValve

WARNING:

Donotattempttodrillthegasorices.Useonly

factorysuppliedorices.Improperlydrilledorices

may cause fire, explosion, carbon monoxide

poisoning,personalinjuryordeath.

At 2,000 feet, the NFGC requires that this appliance be

derated4%foreach1,000feetofaltitude.Forexample,the

inputneedstobereduced8%at2,000feet,12%at3,000

feet,etc.Thisfurnacecanbederatedbyreducingtheorice

sizeordecreasingthemanifoldpressure.

OperatingInstructionsforPOOILBurners

OilburnersinPOseriesfurnacesarefactoryequippedwith

aprimarycontrolcapableofeitherintermittentorinterrupted

ignition.

Start-UpProcedure

1. Openallmanualshut-offvalvesintheoilsupplylinefrom

thetanktotheburner.

2. TurnONtheelectricalsupplytothefurnace.

3. Settheroomthermostattothedesiredtemperature.

Air-BleedProcedure-SinglePipeInstallation

1. Openthedoortothefurnace.

2. Attach1/4”I.D.plastictubeovertheendoftheairbleed

valveontheoilpumpasshowninFigure15.Placethe

otherendofthetubeinalargecontainer.

3. Pressthedoorswitchintostarttheburner.

4. Turntheairbleedvalveopennotmorethan1/2turnto

getafastowofoilintothecontainer.

5. To assure continuous operation, use a wire to jump

terminals T-T on the primary control while burner is

running.IffurnaceisequippedwiththeHoneywellR7184

orBeckett7505primarycontrol,performthenext3steps

toprimetheoilpump:

a. While the ignition is on, press the reset button for

1/2secondorlessandreleasetheresetbutton.The

lockouttimewillbeextendedto4minutes.

Table5.AirShutterSettingforDifferentFuels

INPUT

(BTU/H)

NATURAL

GAS SETTING

LP GAS

SETTING

OIL SETTING

60,000 4.0 4.5 2.0

70,000 4.5 4.5 2.25

75,000 5.0 5.0 N/A

b. Ifprimeisnotestablishedwithinthe4minutes,the

controlwilllockout.Presstheresetbuttontoreset

thecontrolandgobacktostep“a”.

c. Repeatsteps“a”&“b”,ifneeded,untilthepumpis

fullyprimed.

6. Whenoilowisclearofairbubbles,closeair-bleedvalve

andtighten.NOTE:Airbleedouttimewillvarydepending

onlengthofoilline,numberofbends,etc.

7. Removethejumperwireontheprimarycontrol.

NOTE:IffurnaceisequippedwiththeBeckett7505primary

control,primetheoilpumpusingthefollowingsteps:

1. Aftertheburnerstarts,pressandholdtheresetbuttonfor

15secondsuntiltheyellowlightturnson.Thisindicates

thatthebuttonhasbeenheldlongenough.

2. Releasethe resetbutton.Theyellow lightwillturnoff

andtheburnerwillstartupagain.

3. Atburnerstartup,clicktheresetbuttonwhiletheigniteris

stillon.NOTE:Thiswilltransitionthecontroltoadedicated

pumpprimemode,duringwhichthemotor,igniterand

valvearepoweredfor4minutes.Theyellowlightwillbe

on.NOTE:Iftheprimeisnotestablishedduringthe4

minutepumpprimemode,repeatstep3untilthepump

isfullyprimed.

OilBurnerShutdownProcedure

Settheroomthermostatto“OFF”oritslowestsetting.

FlameAdjustment

1. Setthethermostatbelowroomtemperaturetostartthe

furnace.

2. Allowthefurnacetooperateforabout10minutes.

3. Adjustthe air shutter setting until 10% CO

2 with zero

smokeorlessisachieved.NOTE:Thedraftoverthere

mustbeatleastnegative0.02in.W.C.Thefactoryset

airshuttersettingsareshowninTable5.

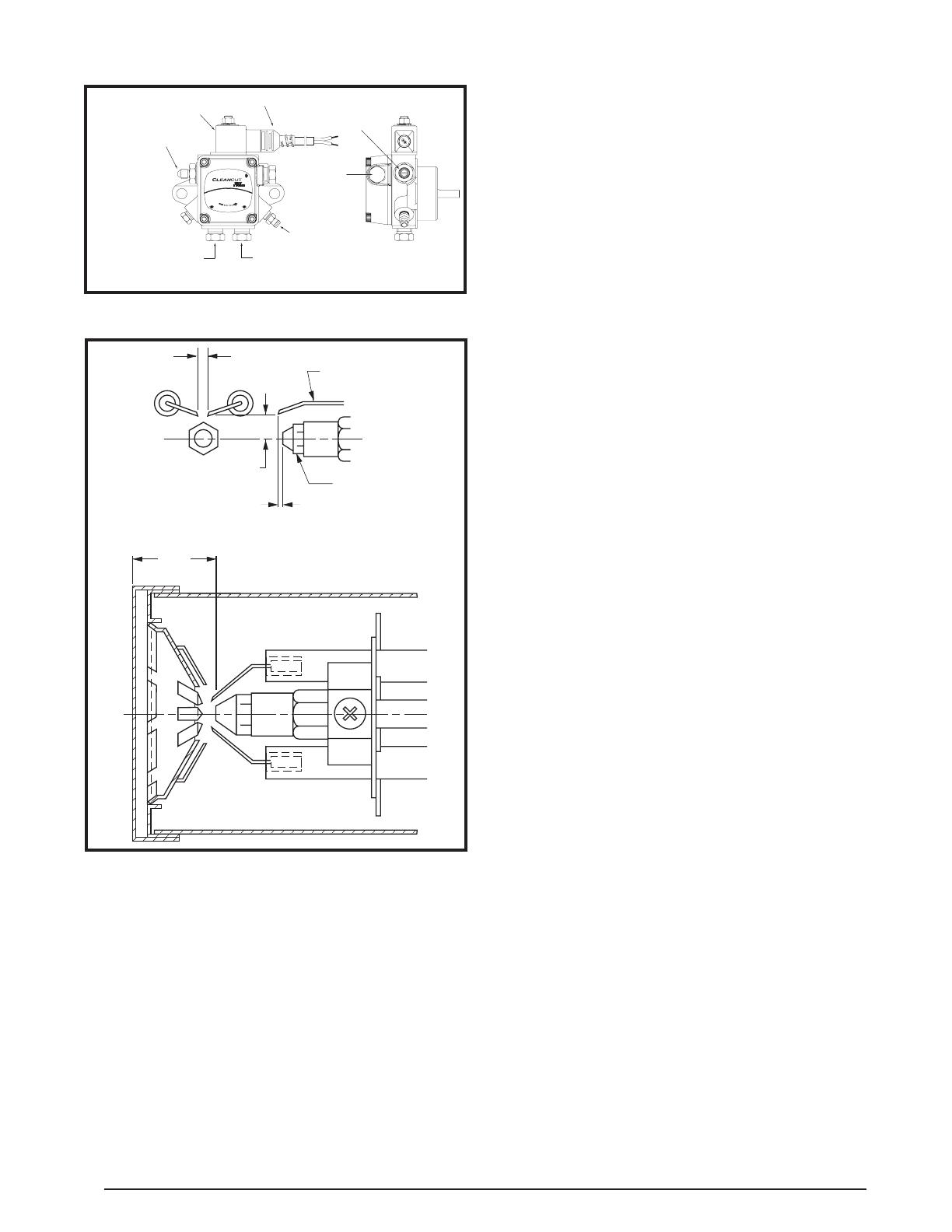

ElectrodeSetting

Theelectrodesettingiscarefullysetatthefactory.However,

during transit, the setting of the electrodes may become

improper.Beforeattemptingtostarttheoilburner,checkthe

positioningoftheelectrodestoensurethattheyareproperly

positioned, as shown in Figure 16 (page 20). Improperly

adjustedelectrodescanresultinpoorignition.Donotpermit

theelectrodestobecloserthan¼”toanygroundedsurface.

SwitchingfromInterruptedtointermittentIgnition

Control

HoneywellandBeckettoilprimarycontrolscanbeswitched

between interrupted and intermittent ignition control. To

switchfrominterruptedduty(Factoryset)tointermittentduty,

removetheblueignitorwirefromthequick-connectterminal.