Product manual

Articulated robot

IRB 7600 - 500/2.55

IRB 7600 - 500/2.3

IRB 7600 - 400/2.55

IRB 7600 - 340/2.8

IRB 7600 - 325/3.1

IRB 7600 - 150/3.5

M2000, M2000A, M2004

© Copyright 2004 - 2008 ABB. All rights reserved.

Product manual

IRB 7600 - 500/2.55

IRB 7600 - 500/2.3

IRB 7600 - 400/2.55

IRB 7600 - 340/2.8

IRB 7600 - 325/3.1

IRB 7600 - 150/3.5

M2000

M2000A

M2004

Document ID: 3HAC022033-001

Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

The information in this manual is subject to change without notice and should not be

construed as a commitment by ABB. ABB assumes no responsibility for any errors that

may appear in this manual.

Except as may be expressly stated anywhere in this manual, nothing herein shall be

construed as any kind of guarantee or warranty by ABB for losses, damages to persons

or property, fitness for a specific purpose or the like.

In no event shall ABB be liable for incidental or consequential damages arising from

use of this manual and products described herein.

This manual and parts thereof must not be reproduced or copied without ABB's written

permission, and contents thereof must not be imparted to a third party nor be used for

any unauthorized purpose. Contravention will be prosecuted.

Additional copies of this manual may be obtained from ABB at its then current charge.

© Copyright 2004 - 2008 ABB All rights reserved.

ABB AB

Robotics Products

SE-721 68 Västerås

Sweden

Table of Contents

33HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product documentation, M2000/M2000A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Product documentation, M2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

How to read the product manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1 Safety 15

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2 General safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2.1 Safety in the robot system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2.2 Safety risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.2.1 Safety risks during installation and service work on robot. . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.2.2 Safety risks related to tools/workpieces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.2.2.3 Safety risks related to pneumatic/hydraulic systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2.2.4 Safety risks during operational disturbances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.2.2.5 Risks associated with live electric parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.2.3 Safety actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.2.3.1 Safety fence dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.2.3.2 Fire extinguishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.2.3.3 Emergency release of the robot’s arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.2.3.4 Brake testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.2.3.5 Risk of disabling function "Reduced speed 250 mm/s" . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.2.3.6 Safe use of the FlexPendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

1.2.3.7 Work inside the robot's working range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.2.3.8 Signal lamp (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1.2.3.9 Translate the information on safety and information labels . . . . . . . . . . . . . . . . . . . . . . . 32

1.3 Safety related instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1.3.1 Safety signals, general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1.3.2 DANGER - Moving robots are potentially lethal! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1.3.3 DANGER - First test run may cause injury or damage! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1.3.4 WARNING - The brake release buttons may be jammed after service work . . . . . . . . . . . . . . . . 37

1.3.5 WARNING - The unit is sensitive to ESD! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

1.3.6 WARNING - Safety risks during work with gearbox oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2 Installation and commissioning 41

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.2 Robot transportation precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.3 Securing the robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.4 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.4.1 Pre-installation procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.4.2 Working range, IRB 7600 - 150/3.5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2.4.3 Working range, IRB 7600 - 325/3.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.4.4 Working range, IRB 7600 - 340/2.8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2.4.5 Working range, IRB 7600 - 400/2.55, IRB 7600 - 500/2.55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.4.6 Working range, IRB 7600 - 500/2.3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.4.7 Risk of tipping / stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.5 On-site Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.5.1 Lifting robot with fork lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.5.2 Lifting robot with lifting slings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2.5.3 Lifting robot with roundslings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2.5.4 Manually releasing the brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2.5.5 Manually releasing the brakes, external brake release unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2.5.6 Lifting the base plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2.5.7 Securing the base plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.5.8 Orienting and securing the robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table of Contents

4 3HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

2.5.9 Fitting equipment on robot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2.5.10 Installation of base spacers (option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2.5.11 Installation of cooling fan for motors, axes 1-3 (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

2.5.12 Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

2.6 Restricting the working range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

2.6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

2.6.2 Mechanically restricting the working range of axis 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

2.6.3 Mechanically restricting the working range of axis 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

2.6.4 Mechanically restricting the working range of axis 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

2.6.5 Installation of position switches (option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

2.7 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

2.7.1 Robot cabling and connection points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

2.8 Making robot ready for operation (Foundry Prime) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

2.8.1 Additional installation procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

2.8.2 Commissioning (Foundry Prime). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

3 Maintenance 127

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.2 Maintenance schedule and expected life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

3.2.1 Specification of maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

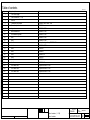

3.2.2 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3.2.3 Expected component life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

3.3 Inspection activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

3.3.1 Inspection, oil level gearbox axis 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

3.3.2 Inspection, oil level gearbox axis 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

3.3.3 Inspection, oil level gearbox axis 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

3.3.4 Inspection, oil level gearbox axis 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

3.3.5 Inspection, oil level, gearbox axis 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

3.3.6 Inspection, oil level gearbox axis 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

3.3.7 Inspection, balancing device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

3.3.8 Inspection, cable harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

3.3.9 Inspection, mechanical stop, axis 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

3.3.10 Inspection, mechanical stop, axes 1, 2 and 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

3.3.11 Inspection, damper axes 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

3.3.12 Inspection, position switch axes 1, 2 and 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

3.3.13 Inspection, information labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

3.3.14 Inspection, UL-lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

3.3.15 Inspection of air hoses (Foundry Prime) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

3.4 Changing/replacement activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

3.4.1 Type of oil in gearboxes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

3.4.2 Oil change, gearbox axis 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

3.4.3 Oil change, gearbox axis 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

3.4.4 Oil change, gearbox, axis 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

3.4.5 Oil change, gearbox, axis 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

3.4.6 Oil change, gearbox, axis 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

3.4.7 Oil change, gearbox axis 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

3.4.8 Replacement of SMB battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

3.5 Lubrication activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

3.5.1 Lubrication of spherical roller bearing, balancing device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

3.5.2 Rust preventive measures, bearing axis 1 (Foundry Prime) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

3.5.3 Rust preventive measures, bearing axis 4 (Foundry Prime) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

3.5.4 Rust preventive measures, support bearing in wrist (Foundry Prime). . . . . . . . . . . . . . . . . . . . . 209

Table of Contents

53HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

3.6 Cleaning activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

3.6.1 Flushing a contaminated gearbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

3.6.2 Cleaning, robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

4 Repair 215

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

4.2 General procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

4.2.1 Performing a leak-down test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

4.2.2 Mounting instructions for bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

4.2.3 Mounting instructions for seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

4.3 Complete robot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

4.3.1 Replacement of cable harness, axes 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

4.3.2 Replacement of cable harness, axes 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

4.3.3 Replacement of complete arm system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

4.3.4 Replacement of air nipple and hose (Foundry Prime) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

4.4 Upper and lower arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

4.4.1 Replacement of turning disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

4.4.2 Replacement of complete wrist unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

4.4.3 Replacement of complete upper arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

4.4.4 Replacement of complete lower arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

4.5 Frame and base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

4.5.1 Replacement of SMB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

4.5.2 Replacement of brake release unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

4.5.3 Replacement of balancing device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

4.5.4 Replacement of spherical roller bearing, balancing device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

4.5.5 Unloading the balancing device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

4.5.6 Restoring the balancing device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

4.6 Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

4.6.1 Replacement of motor, axis 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

4.6.2 Replacement of motor axis 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

4.6.3 Replacement of motor, axis 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

4.6.4 Replacement of motor, axis 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

4.6.5 Replacement of motor, axis 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

4.6.6 Replacement of motor, axis 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

4.7 Gearboxes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

4.7.1 Replacement of gearbox, axis 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

4.7.2 Replacement of gearbox, axis 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

4.7.3 Replacement of gearbox, axis 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

4.7.4 Replacement of gearbox, axis 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

4.7.5 Replacement of gearbox, axis 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

4.7.6 Replacement of gearbox, axis 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

5 Calibration information 371

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

5.2 Calibration methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

5.3 Calibration scales and correct axis position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

5.4 Calibration movement directions for all axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

5.5 Updating revolution counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

5.6 Checking the calibration position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

6 Decommissioning 383

6.1 Environmental information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

6.2 Decommissioning of balancing device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

Table of Contents

6 3HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

7 Reference information 387

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

7.2 Applicable Safety Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 388

7.3 Unit conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

7.4 Screw joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

7.5 Weight specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

7.6 Standard toolkit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

7.7 Special tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

7.8 Lifting equipment and lifting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

8 Spare part / part list 399

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

8.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

8.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

8.2.2 Spare part list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

8.3 Part list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

8.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

8.3.2 Rebuilding parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

8.3.3 Part list, overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

8.3.4 Mechanical stop axis 1, 3HAC12812-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

8.3.5 Base incl frame axis 1, 3HAC12304-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

8.3.6 Axis 3-4, 3HAC13063-1 (IRB 7600 - 150/3.5, - 325/3.1, -340/2.8, -400/2.55, -500/2.55). . . . . 409

8.3.7 Axis 3-4, 3HAC13063-2 (IRB 7600 - 500/2.3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

8.3.8 Axis 3-4, Foundry, 3HAC13063-4 (IRB 7600 -150/3.5, - 325/3.1, - 340/2.8, - 400/2.55, - 500/2.55)

413

8.3.9 Axis 3-4 Foundry, 3HAC13063-5 (IRB 7600 - 500/2.3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

8.3.10 Wrist, 3HAC16628-4 / 3HAC16628-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 415

8.3.11 Material set robot, 3HAC13079-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 420

8.3.12 Material set axis 1-2, 3HAC13077-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

8.3.13 Material set balancing device, 3HAC13082-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

8.3.14 Arm extension set, 956 mm, 3HAC12311-1 (IRB 7600 - 150/3.5). . . . . . . . . . . . . . . . . . . . . . 425

8.3.15 Arm extension set, 250 mm, 3HAC12311-2 (IRB 7600 - 340/2,8). . . . . . . . . . . . . . . . . . . . . . 426

8.3.16 Arm extension set, 500 mm, 3HAC12311-3 (IRB 7600 - 325/3,1). . . . . . . . . . . . . . . . . . . . . . 427

9 Exploded views 429

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

9.2 Base incl. Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

9.3 Frame-Lower arm 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

9.4 Frame-Lower arm 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 432

9.5 Upper arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

9.6 Wrist complete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

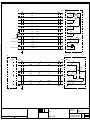

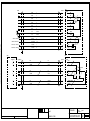

10 Circuit Diagram 435

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435

10.2 Circuit diagram 3HAC025744-001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

10.2.1 Validity of circuit diagram 3HAC025744-001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

10.3 Circuit diagram 3HAC13347-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

10.3.1 Validity of circuit diagram 3HAC13347-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

Index 439

Overview

73HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

Overview

About this manual

This manual contains instructions for

• installing the robot, mechanically as well as electrically

• maintenance of the robot

• mechanical and electrical repair of the robot.

Usage

This manual should be used during

• installation, from lifting the robot to its work site and securing it to the foundation to

making it ready for operation

• maintenance work

• repair work.

Who should read this manual?

This manual is intended for:

• installation personnel

• maintenance personnel

• repair personnel.

Prerequisites

A maintenance/repair/ installation craftsman working with an ABB Robot must:

• be trained by ABB and have the required knowledge of mechanical and electrical

installation/repair/maintenance work.

Organization of chapters

The manual is organized in the following chapters:

Chapter Contents

Safety Safety information that must be read through before performing any

installation or service work on the robot. Contains general safety

aspects as well as more specific information on how to avoid

personal injuries and damage to the product.

Installation and com-

missioning

Required information about installation of the robot, including

working ranges, lifting instructions, on-site installation, fitting of

extra equipment, etc.

Maintenance Step-by-step procedures that describe how to perform

maintenance of the robot. Based on a maintenance schedule that

may be used to plan periodical maintenance.

Repair Step-by-step procedures that describe how to perform repair

activities of the robot. Based on available spare parts, tools, etc.

Calibration information Procedures that do not require specific calibration equipment.

General information about calibration.

Decommissioning Environmental information about the robot and its components.

Continues on next page

Overview

3HAC022033-001 Revision: E8

© Copyright 2004 - 2008 ABB. All rights reserved.

References

Procedures in this product manual contain references to the following manuals:

Additional document references

Reference information Useful information when performing installation, maintenance or

repair work. Includes lists of necessary tools, additional documents,

safety standards etc.

Spare part list Complete spare part list shown in exploded views.

Exploded views Detailed illustrations of the robot with reference numbers to the part

list.

Circuit diagram Circuit diagram for the robot.

Chapter Contents

Document name Document ID Note

Product specification - IRB 7600 3HAC023934-001

Product specification - IRB 7600 M2000/M2000A 3HAC13491-1

Product manual - IRC5 3HAC021313-001

Product manual - S4Cplus M2000 3HAC021333-001

Product manual - S4Cplus M2000A 3HAC022419-001

Operating manual - IRC5 with FlexPendant 3HAC16590-1

User’s guide - S4Cplus 3HAC7793-1

Operating manual - Calibration Pendulum 3HAC16578-1

Operating manual - Service Information System 3HAC025709-001 M2004

Operating manual - Levelmeter Calibration 3HAC022907-001 M2000/M2000A

Technical reference manual - System parameters 3HAC17076-1

Application manual - Additional axes and stand

alone controller

3HAC021395-001 M2004

Application manual - External axes 3HAC9299-1 M2000

Document name Document ID

CalibWare 2.0 Users Guide (M2000) 3HAC16090-1

Continued

Continues on next page

Overview

93HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

Revisions

Revision Description

- First edition.

Replaces previous manuals:

• Installation and Commissioning Manual

• Maintenance Manual

• Repair Manual, part 1

• Repair Manual, part 2.

Changes made in the material from the previous manuals:

• Model M2004 implemented.

• Various corrections due to technical revisions, changes in the toolkits

etc.

A Chapter Calibration replaced with chapter Calibration information.

Following corrections are made:

• In chapter 3: Maintenance in section Exporting the SIS data, the unit

seconds for different SIS parameters is replaced by the unit hours. The

change is only valid for RobotWare release 5.0.

Following updates are made:

• In chapter 4: Repair, the sections Removal of complete lower arm and

Refitting of complete lower arm are completed with more detailed

information about how to use the glycerin pump.

• Section Document references is completed with article numbers for

calibration manuals.

• Section Part list is completed with the spare part number for a variant of

the cable harness/brake release unit.

B New lubricating oil in the gearboxes. Changes made in the chapter

Maintenance and Part list.

C • New variant of the robot (IRB 7600 - 500/2.55) implemented throughout

the manual.

• Wrist unit updated, new spare part number is specified in Replacement

of complete wrist unit on page 248 and Spare part list on page 401.

• Insulated wrist unit implemented, new spare part number is specified in

Replacement of complete wrist unit on page 248 and Spare part list on

page 401. Amount of oil differs from non-insulated wrist unit, changes

made in sections Type of oil on page 179 and Oil change, gearbox axis

6 on page 197.

• New section that describes how to replace the bearing at the front eye

of the balancing device, Replacement of spherical roller bearing,

balancing device on page 285.

• Incorrect article numbers for position switches are corrected, section

Installation of position switches (option) on page 108.

• New section: Installation of cooling fan for motors, axes 1-3 (option) on

page 93.

• New section: Installation of base spacers (option) on page 91

• New section that specifies all the recommended spare parts: Spare part

list on page 401.

• Repair sections for removal/refitting are restructured into replacement

sections.

• Various corrections made, due to technical revisions etc.

D Foundry Prime option included.

Continued

Continues on next page

Overview

3HAC022033-001 Revision: E10

© Copyright 2004 - 2008 ABB. All rights reserved.

E • New variant of the robot (IRB 7600 - 325/3.1) implemented throughout

the manual.

• In chapter 3 Maintenance section Oil in gearboxes type of oil and art.

no. in gearbox axes 1 has been added.

• New product name has been implemented throughout the manual:

"Mobilgear 600 XP 320". Replaces "Mobil Gearlube X320". Art. no. has

not been changed.

• Interval for change of Shell Tivela S 150 has been changed in section

Maintenance schedule.

• Section Service Information System has been removed from the

manual. There is a specific manual for SIS. See References.

• Section Chip and dust protection has been removed from the manual.

This option is no longer available.

• Tightening torque for M24 Allen head screws has been added in section

Screw joints.

• Prerequisites in section Overview has been changed.

• New section that describes Robot transportation precautions .

• New section that describes Securing the robot .

• Product name Sikaflex 252FC changed to Sikaflex 521FC. New article

number is 3HAC026759-001.

Revision Description

Continued

Product documentation, M2000/M2000A

113HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

Product documentation, M2000/M2000A

General

The complete product documentation kit for the M2000 robot system, including controller,

robot and any hardware option, consists of the manuals listed below:

Product manuals

All hardware, robots and controllers, will be delivered with a Product manual that contains:

• Safety information

• Installation and commissioning (descriptions of mechanical installation, electrical

connections)

• Maintenance (descriptions of all required preventive maintenance procedures

including intervals)

• Repair (descriptions of all recommended repair procedures including spare parts)

• Additional procedures, if any (calibration, decommissioning)

• Reference information (article numbers for documentation referred to in Product

manual, procedures, lists of tools, safety standards)

• Part list

• Foldouts or exploded views

• Circuit diagrams

Software manuals

The software documentation consists of a wide range of manuals, ranging from manuals for

basic understanding of the operating system to manuals for entering parameters during

operation.

A complete listing of all available software manuals is available from ABB.

Controller hardware option manual

Each hardware option for the controller is supplied with its own documentation. Each

document set contains the types of information specified below:

• Installation information

• Repair information

• Maintenance information

In addition, spare part information is supplied for the entire option.

Product documentation, M2004

3HAC022033-001 Revision: E12

© Copyright 2004 - 2008 ABB. All rights reserved.

Product documentation, M2004

General

The robot documentation is divided into a number of categories. This listing is based on the

type of information contained within the documents, regardless of whether the products are

standard or optional. This means that any given delivery of robot products will not contain all

documents listed, only the ones pertaining to the equipment delivered.

However, all documents listed may be ordered from ABB. The documents listed are valid for

M2004 robot systems.

Product manuals

All hardware, robots and controllers, will be delivered with a Product manual that contains:

• Safety information

• Installation and commissioning (descriptions of mechanical installation, electrical

connections)

• Maintenance (descriptions of all required preventive maintenance procedures

including intervals)

• Repair (descriptions of all recommended repair procedures including spare parts)

• Additional procedures, if any (calibration, decommissioning)

• Reference information (article numbers for documentation referred to in Product

manual, procedures, lists of tools, safety standards)

• Part list

• Foldouts or exploded views

• Circuit diagrams

Technical reference manuals

The following manuals describe the robot software in general and contain relevant reference

information:

• RAPID Overview: An overview of the RAPID programming language.

• RAPID Instructions, Functions and Data types: Description and syntax for all

RAPID instructions, functions and data types.

• System parameters: Description of system parameters and configuration workflows.

Application manuals

Specific applications (for example software or hardware options) are described in

Application manuals. An application manual can describe one or several applications.

An application manual generally contains information about:

• The purpose of the application (what it does and when it is useful)

• What is included (for example cables, I/O boards, RAPID instructions, system

parameters, CD with PC software)

• How to use the application

• Examples of how to use the application

Continues on next page

Product documentation, M2004

133HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

Operating manuals

This group of manuals is aimed at those having first hand operational contact with the robot,

that is production cell operators, programmers and trouble shooters. The group of manuals

includes:

• Emergency safety information

• General safety information

• Getting started - IRC5 and RobotStudio

• IRC5 with FlexPendant

• RobotStudio

• Introduction to RAPID

• Trouble shooting - IRC5 for the controller and robot

Continued

How to read the product manual

3HAC022033-001 Revision: E14

© Copyright 2004 - 2008 ABB. All rights reserved.

How to read the product manual

Reading the procedures

The procedures contain references to figures, tools, material etc. The references are read as

described below.

References to figures

The procedures often include references to components or attachment points located on the

robot/controller. The components or attachment points are marked with italic text in the

procedures and completed with a reference to the figure where the current component or

attachment point is shown.

The denomination in the procedure for the component or attachment point corresponds to the

denomination in the referenced figure.

The table below shows an example of a reference to a figure from a step in a procedure.

References to required equipment

The procedures often include references to equipment (spare parts, tools etc.) required for the

different actions in the procedure. The equipment is marked with italic text in the procedures

and completed with a reference to the section where the equipment is listed with further

information, that is article number, dimensions.

The denomination in the procedure for the component or attachment point corresponds to the

denomination in the referenced list.

The table below shows an example of a reference to a list of required equipment, from a step

in a procedure.

Safety information

The manual includes a separate safety chapter that must be read through before proceeding

with any service or installation procedures. All procedures also include specific safety

information when dangerous steps are to be performed.

Read more in chapter Safety on page 15.

Action Note/Illustration

8. Remove the rear attachment screws, gearbox. Shown in the figure Location of

gearbox on page xx.

Action Note/Illustration

3. Fit a new sealing, axis 2 to the gearbox. Art. no. is specified in Required

equipment on page xx.

1 Safety

1.1. Introduction

153HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

1 Safety

1.1. Introduction

Overview

The safety information in this manual is divided in two categories:

• general safety aspects, important to attend to before performing any service work on

the robot. These are applicable for all service work and are found in section General

safety information on page 16.

• specific safety information, pointed out in the procedure at the moment of the danger.

How to avoid and eliminate the danger is either detailed directly in the procedure, or

further detailed in separate instructions, found in section Safety related instructions on

page 33.

1 Safety

1.2.1. Safety in the robot system

3HAC022033-001 Revision: E16

© Copyright 2004 - 2008 ABB. All rights reserved.

1.2 General safety information

1.2.1. Safety in the robot system

Validity and responsibility

The information does not cover how to design, install and operate a complete system, nor

does it cover all peripheral equipment, which can influence the safety of the total system. To

protect personnel, the complete system must be designed and installed in accordance with the

safety requirements set forth in the standards and regulations of the country where the robot

is installed.

The users of ABB industrial robots are responsible for ensuring that the applicable safety laws

and regulations in the country concerned are observed and that the safety devices necessary

to protect people working with the robot system are designed and installed correctly.

Personnel working with robots must be familiar with the operation and handling of the

industrial robot, described in the applicable documents, for example:

• User’s Guide - S4Cplus (M2000)

• Operating Manual - IRC5 with FlexPendant (M2004)

• Product Manual

Connection of external safety devices

Apart from the built-in safety functions, the robot is also supplied with an interface for the

connection of external safety devices. Via this interface, an external safety function can

interact with other machines and peripheral equipment. This means that control signals can

act on safety signals received from the peripheral equipment as well as from the robot.

Limitation of liability

Any information given in this manual regarding safety, must not be construed as a warranty

by ABB that the industrial robot will not cause injury or damage even if all safety instructions

are complied with.

Related information

Type of information Detailed in document Section

Installation of safety

devices

Product manual for the robot Installation and commissioning

Changing operating

modes

User´s Guide - S4Cplus

(RobotWare 4.0)

Operating manual - IRC5 with

FlexPendant

(RobotWare 5.0)

Start-up

Operating modes

Restricting the working

space

Product manual for the robot Installation and commissioning

1 Safety

1.2.2.1. Safety risks during installation and service work on robot

173HAC022033-001 Revision: E

© Copyright 2004 - 2008 ABB. All rights reserved.

1.2.2. Safety risks

1.2.2.1. Safety risks during installation and service work on robot

Overview

This section includes information of general safety risks to be considered when performing

installation and service work on the robot.

General risks during installation and service

• The instructions in the Product Manual, chapter Installation and Commissioning must

always be followed.

• Emergency stop buttons must be positioned in easily accessible places so that the robot

can be stopped quickly.

• Those in charge of operations must make sure that safety instructions are available for

the installation in question.

• Those who install the robot must have the appropriate training for the robot system in

question and in any safety matters associated with it.

Nation/region specific regulations

To prevent injuries and damage during the installation of the robot system, the regulations

applicable in the country concerned and the instructions of ABB Robotics must be complied

with.

Non-voltage related risks

• Safety zones, which must be crossed before admittance, must be set up in front of the

robot's working space. Light beams or sensitive mats are suitable devices.

• Turntables or the like should be used to keep the operator out of the robot's working

space.

• The axes are affected by the force of gravity when the brakes are released. In addition

to the risk of being hit by moving robot parts, you run the risk of being crushed by the

parallel arm.

• Energy, stored in the robot for the purpose of counterbalancing certain axes, may be

released if the robot, or parts thereof, are dismantled.

• When dismantling/assembling mechanical units, watch out for falling objects.

• Be aware of stored heat energy in the controller.

• Never use the robot as a ladder, that is, do not climb on the robot motors or other part

during service work. There is a serious risk of slipping because of the high temperature

of the motors or oil spills that can occur on the robot.

To be observed by the supplier of the complete system

• The supplier of the complete system must ensure that all circuits used in the safety

function are interlocked in accordance with the applicable standards for that function.

• The supplier of the complete system must ensure that all circuits used in the

emergency stop function are interlocked in a safe manner, in accordance with the

applicable standards for the emergency stop function.

Continues on next page

1 Safety

1.2.2.1. Safety risks during installation and service work on robot

3HAC022033-001 Revision: E18

© Copyright 2004 - 2008 ABB. All rights reserved.

Complete robot

Cabling

Gearboxes and motors

Balancing device

Safety risk Description

Hot components!

CAUTION!

Motors and gears are HOT after running the robot!

Touching motors and gears may result in burns!

With higher environment temperature more surfaces on

the robot are getting HOT and may result in burns too!

Removed parts may result in

collapse of robot!

WARNING!

Take any necessary measures to ensure that the robot

does not collapse as parts are removed, e.g. secure the

lower arm with fixtures if removing motor, axis 2.

Safety risk Description

Cable packs are sensitive to

mechanical damage!

CAUTION!

The cable packs are sensitive to mechanical damage!

They must be handled with care, especially the

connectors, in order to avoid damaging them!

Safety risk Description

Gears may be damaged if

excessive force is used!

CAUTION!

Whenever parting/mating motor and gearbox, the gears

may be damaged if excessive force is used!

Safety risk Description

Dangerous balancing device!

WARNING!

Do not under any circumstances, deal with the balancing

device in any other way than that detailed in the product

documentation! For example, attempting to open the

balancing device is potentially lethal!

Continued

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

-

205

205

-

206

206

-

207

207

-

208

208

-

209

209

-

210

210

-

211

211

-

212

212

-

213

213

-

214

214

-

215

215

-

216

216

-

217

217

-

218

218

-

219

219

-

220

220

-

221

221

-

222

222

-

223

223

-

224

224

-

225

225

-

226

226

-

227

227

-

228

228

-

229

229

-

230

230

-

231

231

-

232

232

-

233

233

-

234

234

-

235

235

-

236

236

-

237

237

-

238

238

-

239

239

-

240

240

-

241

241

-

242

242

-

243

243

-

244

244

-

245

245

-

246

246

-

247

247

-

248

248

-

249

249

-

250

250

-

251

251

-

252

252

-

253

253

-

254

254

-

255

255

-

256

256

-

257

257

-

258

258

-

259

259

-

260

260

-

261

261

-

262

262

-

263

263

-

264

264

-

265

265

-

266

266

-

267

267

-

268

268

-

269

269

-

270

270

-

271

271

-

272

272

-

273

273

-

274

274

-

275

275

-

276

276

-

277

277

-

278

278

-

279

279

-

280

280

-

281

281

-

282

282

-

283

283

-

284

284

-

285

285

-

286

286

-

287

287

-

288

288

-

289

289

-

290

290

-

291

291

-

292

292

-

293

293

-

294

294

-

295

295

-

296

296

-

297

297

-

298

298

-

299

299

-

300

300

-

301

301

-

302

302

-

303

303

-

304

304

-

305

305

-

306

306

-

307

307

-

308

308

-

309

309

-

310

310

-

311

311

-

312

312

-

313

313

-

314

314

-

315

315

-

316

316

-

317

317

-

318

318

-

319

319

-

320

320

-

321

321

-

322

322

-

323

323

-

324

324

-

325

325

-

326

326

-

327

327

-

328

328

-

329

329

-

330

330

-

331

331

-

332

332

-

333

333

-

334

334

-

335

335

-

336

336

-

337

337

-

338

338

-

339

339

-

340

340

-

341

341

-

342

342

-

343

343

-

344

344

-

345

345

-

346

346

-

347

347

-

348

348

-

349

349

-

350

350

-

351

351

-

352

352

-

353

353

-

354

354

-

355

355

-

356

356

-

357

357

-

358

358

-

359

359

-

360

360

-

361

361

-

362

362

-

363

363

-

364

364

-

365

365

-

366

366

-

367

367

-

368

368

-

369

369

-

370

370

-

371

371

-

372

372

-

373

373

-

374

374

-

375

375

-

376

376

-

377

377

-

378

378

-

379

379

-

380

380

-

381

381

-

382

382

-

383

383

-

384

384

-

385

385

-

386

386

-

387

387

-

388

388

-

389

389

-

390

390

-

391

391

-

392

392

-

393

393

-

394

394

-

395

395

-

396

396

-

397

397

-

398

398

-

399

399

-

400

400

-

401

401

-

402

402

-

403

403

-

404

404

-

405

405

-

406

406

-

407

407

-

408

408

-

409

409

-

410

410

-

411

411

-

412

412

-

413

413

-

414

414

-

415

415

-

416

416

-

417

417

-

418

418

-

419

419

-

420

420

-

421

421

-

422

422

-

423

423

-

424

424

-

425

425

-

426

426

-

427

427

-

428

428

-

429

429

-

430

430

-

431

431

-

432

432

-

433

433

-

434

434

-

435

435

-

436

436

-

437

437

-

438

438

-

439

439

-

440

440

-

441

441

-

442

442

-

443

443

-

444

444

-

445

445

-

446

446

-

447

447

-

448

448

-

449

449

-

450

450

-

451

451

-

452

452

-

453

453

-

454

454

-

455

455

-

456

456

-

457

457

-

458

458

-

459

459

-

460

460

-

461

461

-

462

462

-

463

463

-

464

464

-

465

465

-

466

466

-

467

467

-

468

468

-

469

469

-

470

470

-

471

471

-

472

472

-

473

473

-

474

474

-

475

475

-

476

476

-

477

477

-

478

478

-

479

479

-

480

480

-

481

481

-

482

482

ABB IRB 7600 - 340/2.8 User manual

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

ABB M2000 User manual

-

ABB M2000 User manual

-

ABB IRB 6640 Foundry Prime User manual

-

ABB IRB 140T-6/0.8 type C User manual