– 3 –

TABLE OF CONTENTS

GENERAL ............................................................................................................................................ 5

SPECIFICATIONS......................................................................................................................... 5

OPTIONS AND FEATURES......................................................................................................... 6

BATTERY CONFIGURATIONS ................................................................................................... 6

FIELD-INSTALLED ACCESSORIES ........................................................................................... 8

FACTORY-INSTALLED ACCESSORIES.................................................................................... 8

HGF SERIES FRYMATE (Dump Station) .................................................................................... 8

INSTALLATION ................................................................................................................................... 9

UNPACKING ................................................................................................................................. 9

LOCATION ................................................................................................................................... 10

INSTALLATION CODES AND STANDARDS ........................................................................... 10

ASSEMBLY .................................................................................................................................. 11

GAS CONNECTIONS ................................................................................................................. 12

GAS PRESSURES AND ORIFICES ......................................................................................... 12

TESTING THE GAS SUPPLY PIPING SYSTEM...................................................................... 12

LEVELING FRYER ...................................................................................................................... 13

FLUE CONNECTIONS ............................................................................................................... 13

ELECTRICAL CONNECTIONS.................................................................................................. 13

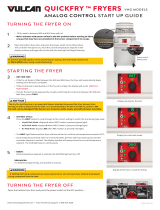

OPERATION...................................................................................................................................... 14

BEFORE FIRST USE.................................................................................................................. 14

FILLING FRY TANK WITH SHORTENING ............................................................................... 14

LIGHTING INSTRUCTIONS FOR HGF FRYER WITH MANUAL PILOT IGNITION............. 15

LIGHTING INSTRUCTIONS FOR MANUAL PILOT IGNITION (HGFD/HGFC SERIES) ..... 16

STARTUP WITH ELECTRONIC IGNITION .............................................................................. 16

HGFD SERIES .................................................................................................................................. 17

CONTROLS ................................................................................................................................. 17

PROGRAMMING ......................................................................................................................... 18

MELT OPERATION ..................................................................................................................... 19

USING THE FRYER (AFTER STARTUP) ................................................................................. 20

SHUTDOWN ................................................................................................................................20

EXTENDED SHUTDOWN .......................................................................................................... 20