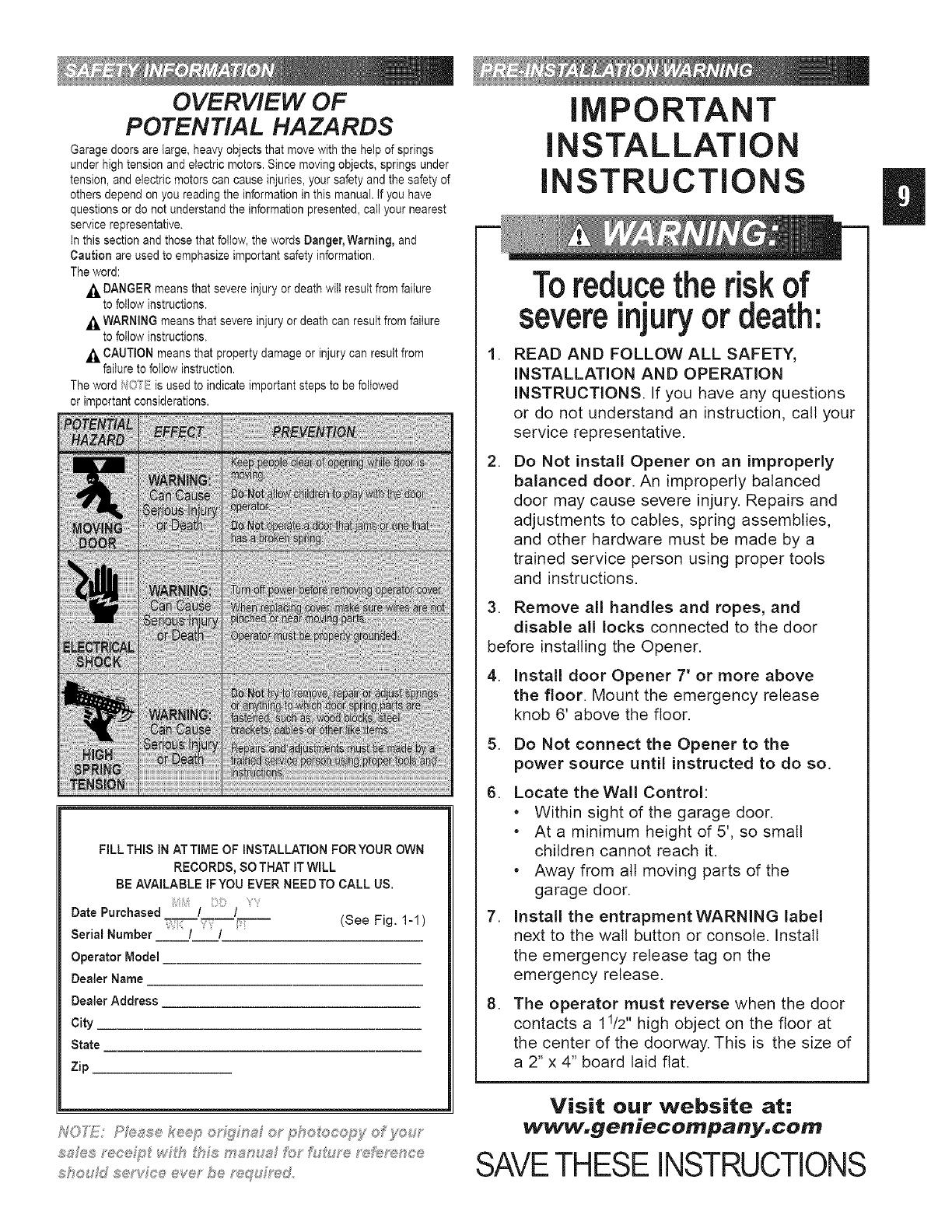

OVERVIEW OF

POTENTIAL HAZARDS

Garage doors are large, heavy objects that move with the help of springs

under high tension and electric motors. Since moving objects, springs under

tension, and electric motors can cause injuries, your safety and the safety of

others depend on you reading the information in this manual, if you have

questions or do not understand the information presented, call your nearest

service representative.

in this section and those that foilow, the words Danger, Warning, and

Caution are used to emphasize important safety information.

The word:

,_ DANGER means that severe injury or death wilt result from failure

to follow instructions.

,_ WARNING means that severe injury or death can result from failure

to follow instructions.

,_ CAUTION means that property damage or injury can result from

failure to foliow instruction.

The word f40*__:is used to indicate important steps to be followed

or important considerations.

FILL THISIN ATTIMEOF INSTALLATIONFORYOUROWN

RECORDS,SOTHATITWILL

BE AVAILABLE IFYOU EVERNEEDTOCALL US.

Date Purchased / /

Serial Number / / (See Fig. 1-1)

Operator Model

DealerName

DealerAddress

City

State

Zip

S'_ou d se vFo@eve" be ,u,_dr_,d

IMPORTANT

INSTALLATION

INSTRUCTIONS

,

,

Toreducethe risk of

severeinjuryordeath:

READ AND FOLLOW ALL SAFETY,

INSTALLATION AND OPERATION

INSTRUCTIONS. If you have any questions

or do not understand an instruction, call your

service representative.

Do Not install Opener on an improperly

balanced door. An improperly balanced

door may cause severe injury. Repairs and

adjustments to cables, spring assemblies,

and other hardware must be made by a

trained service person using proper tools

and instructions.

3. Remove all handles and ropes, and

disable all locks connected to the door

before installing the Opener.

4. Install door Opener 7' or more above

the floor. Mount the emergency release

knob 6' above the floor.

5. Do Not connect the Opener to the

power source until instructed to do so.

6. Locate theWall Control:

* Within sight of the garage door.

* At a minimum height of 5', so small

children cannot reach it.

* Away from all moving parts of the

garage door.

7. Install the entrapment WARNING label

next to the wall button or console. Install

the emergency release tag on the

emergency release.

8. The operator must reverse when the door

contacts a 11/2" high object on the floor at

the center of the doorway. This is the size of

a 2" x 4" board laid flat.

Visit our website at:

www.geniecompany.com

SAVETHESEINSTRUCTIONS