MANUAL MOTOR STARTER GUIDE

APRIL 19 3/80

Table of Contents

Foreword .................................................................................................................................................................................. 2

1. Standards and approvals for manual motor starters ...................................................................................................... 8

1.1 European directives applicable for manual motor starters ................................................................................................ 8

1.2 CE Marking ..................................................................................................................................................................................... 8

1.3 Standards for North America ..................................................................................................................................................... 8

1.4 CCC (China Compulsory Certification) .................................................................................................................................... 9

1.5 Other local approvals based on IEC-standard ........................................................................................................................ 9

1.6 Marine approvals .......................................................................................................................................................................... 9

1.7 Potentially explosive atmospheres (ATEX) .............................................................................................................................. 9

1.8 Applied standards ...................................................................................................................................................................... 12

2. General product overview ................................................................................................................................................ 13

2.1 Basic function .............................................................................................................................................................................. 13

2.1.1 Release (tripping element) ............................................................................................................................................... 14

2.1.2 Time-current characteristics (tripping characteristics) ........................................................................................... 14

2.1.3 Overload protection .......................................................................................................................................................... 15

2.1.4 Overload trip classes ........................................................................................................................................................ 15

2.1.5 Short-circuit protection ................................................................................................................................................... 15

2.1.6 Phase loss sensitivity ........................................................................................................................................................ 16

2.1.7 Single-phase and direct current (DC) loads ................................................................................................................. 16

2.2 Terms and ratings ........................................................................................................................................................................ 17

2.2.1 Rated operational voltage (U

e

) ........................................................................................................................................ 17

2.2.2 Rated short-circuit making capacity (I

cm

) ..................................................................................................................... 17

2.2.3 Rated short-circuit breaking capacity ........................................................................................................................... 17

2.2.4 Rated short-time withstand current (I

cw

) ...................................................................................................................... 17

2.2.5 Selectivity categories ....................................................................................................................................................... 18

2.2.6 Ambient air temperature compensation ..................................................................................................................... 18

2.2.7 Temperature rise of the manual motor starter ........................................................................................................... 19

2.2.8 Trip-free mechanism ........................................................................................................................................................ 20

2.2.9 Phase loss sensitivity........................................................................................................................................................ 20

2.2.10 Mechanical and electrical durability ............................................................................................................................ 20

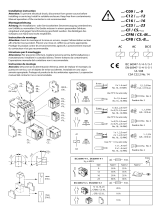

2.3 Switch and breaker types ......................................................................................................................................................... 21

2.3.1 Motor protection circuit-breaker ................................................................................................................................... 21

2.3.2 Circuit-breaker ................................................................................................................................................................... 21

2.3.3 Load switch ......................................................................................................................................................................... 21

2.3.4 Disconnect switch ............................................................................................................................................................. 21

2.4 Product offering ......................................................................................................................................................................... 22

2.4.1 MS116 .................................................................................................................................................................................... 23

2.4.2 MS132 ................................................................................................................................................................................... 23

2.4.2.1 MS132-K ............................................................................................................................................................................ 23

2.4.3 MS165 ................................................................................................................................................................................... 23

2.4.4 MS132-T and MS132-KT .................................................................................................................................................... 23

2.4.5 MO132 and MO165 ............................................................................................................................................................. 23

2.4.6 Accessories and enclosures ............................................................................................................................................ 24

3. Load types .......................................................................................................................................................................... 29

3.1 General use and heaters ............................................................................................................................................................ 29

3.2 Motors ........................................................................................................................................................................................... 30

3.2.1 About motors...................................................................................................................................................................... 31

3.2.2 Squirrel cage motors ........................................................................................................................................................ 31

3.2.3 International motor efficiency standards and regulations ...................................................................................... 32

3.2.4 Rating plate of a motor .................................................................................................................................................... 37

3.2.5 Voltage ................................................................................................................................................................................. 38

3.2.6 Current ................................................................................................................................................................................. 38

3.2.7 Power factor ........................................................................................................................................................................ 39