Page is loading ...

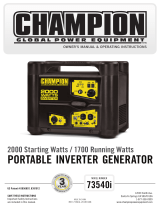

2000/3000 WATT ELECTRIC START DIGITAL PORTABLE

INVERTER GENERATOR

SAVE THIS MANUAL: KEEP THIS MANUAL FOR SAFETY WARNINGS, PRECAUTIONS, ASSEMBLY,

OPERATING, INSPECTION, MAINTENANCE AND CLEANING PROCEDURES. WRITE THE

PRODUCT’S SERIAL NUMBER ON THE BACK OF THE MANUAL NEAR THE ASSEMBLY DIAGRAM

(OR MONTH AND YEAR OF PURCHASE IF PRODUCT HAS NO NUMBER).

OWNER’S MANUAL AND SAFETY INSTRUCTIONS

ITEM #65064 & #65065

FOR QUESTIONS PLEASE CALL OUR CUSTOMER SUPPORT: (909) 628 4900 MON-FRI 9AM TO 3PM PST

IMPORTANT SAFETY INFORMATION

GENERAL SAFETY WARNINGS

Read and thoroughly understand all instructions and safety information before assembling

or operating this log splitter. Failure to do so may cause serious injury or death. Do not

allow anyone to operate this inverter generator who has not read and understood this

manual. Do not operate this device if you have doubts or questions concerning safe

operation.

SAFETY

The warnings, precautions, and instructions discussed in this instruction manual cannot cover

all possible conditions and situations that may occur. It must be understood by the operator

that common sense and caution are factors which cannot be built into this product, but must be

supplied by the operator.

IMPORTANT: Read all safety warnings and instructions. Failure to follow the warnings

and instructions may result in electric shock, re and/or serious injury. Save all warnings

and instructions for future reference.

1

Gasoline fuel and fumes are ammable, and potentially explosive. Use proper fuel storage

and handling procedures. Do not store fuel or other ammable materials nearby.

Have multiple ABC class re extinguishers nearby.

Operation of this equipment may create sparks that can start res around dry vegetation.

A spark arrestor may be required. The operator should contact local re agencies for laws or

regulations relating to re prevention requirements.

Set up and use only on a at, level, well-ventilated surface.

All connections and conduits from the Generator to the load must only be installed by trained

and licensed electricians, and in compliance with all relevant local, state, and federal electrical

codes and standards, and other regulations where applicable.

Connections for standby power to a building electrical system must be made by a qualied

electrician. The connection must isolate the Generator power from utility power, and must

comply with all applicable laws and electrical codes.

Wear ANSI-approved safety goggles, heavy-duty work gloves, and dust mask/respirator during

set up.

Use only lubricants and fuel recommended in the Specications chart of this manual.

Improper connections to a building electrical system can allow electrical current from the

Generator to backfeed into the utility lines. Such backfeed may electrocute utility company

workers or others who contact the lines during a power outage, and the Generator may

explode, burn, or cause res when utility power is restored. Consult the utility company and a

qualied electrician if intending to use the Generator for back up power.

Do not operate the Generator before grounding. The Generator must be earth-grounded

in accordance with all relevant electrical codes and standards before operation.

IMPORTANT SAFETY INFORMATION

2

Never use a generator indoors, including in garages,

basements, crawl spaces and sheds. Opening doors and

windows or using fans will NOT prevent carbon monoxide

build up in the home.

When using generators, keep them outdoors and far away

from open doors, windows, and vents to avoid toxic levels of

carbon monoxide from building up indoors.

If you start to feel sick, dizzy, or weak while using a generator,

get to fresh air right away. The carbon monoxide from

generators can quickly lead to full incapacitation and death.

Keep children away from the equipment, especially while it is

operating.

Keep all spectators at least six feet from the engine during

operation.

Fire Hazard! Do not ll gas tank while engine is running. Do not operate if gasoline has been spilled.

Clean spilled gasoline before starting engine. Do not operate near pilot light or open ame.

Do not touch engine during use. Let engine cool down after use.

Never store fuel or other ammable materials near the engine.

If the plugged in product operates abnormally or unusually slow, immediately stop using the

generator as a power source. Read and adhere to the instruction manual of the product to be

powered to make sure that it can be safely and efciently powered by a portable generator.

Before connecting an appliance or power cord to the generator: Make sure that it is in good

working order. Faulty appliances or power cords can create a potential for electrical shock.

Do not exceed the running wattage of the generator. Make sure that the total electrical rating of the

all of the tools or appliances plugged into the generator at the same time does not exceed that

of the generator. Check that the startup surge will not be beyond the limit of the generator.

Avoid substantially overloading which will trip the circuit breaker. Slightly overloading the generator

may not trip the circuit breaker, but will lead to premature generator failure.

Do not attempt to connect or disconnect load connections while standing in water, or on wet or

soggy ground.

Do not touch electrically energized parts of the generator and interconnecting cables or conductors

with any part of the body, or with any non-insulated conductive object.

Connect the generator only to a load that is compatible with the electrical characteristics and

running wattage of the generator.

Guard against electric shock. Prevent body contact with grounded surfaces such as pipes,

radiators, ranges, and refrigerators.

Insulate all connections and disconnected wires.

3

IMPORTANT SAFETY INFORMATION

Only use a suitable means of transport and lifting devices with sufcient weight bearing capacity

when transporting the generator.

Secure the generator on transport vehicles to prevent it from rolling, slipping, and tilting.

Industrial applications must follow OSHA requirements.

Do not leave the generator unattended when it is running. Turn off the generator (and remove safety

keys, if available) before leaving the work area.

The generator can produce high noise levels. Prolonged exposure to noise levels above 85 dBA is

hazardous to hearing. Wear ear protection when operating the generator or when working nearby

while it is operating.

Wear ANSI-approved safety glasses and hearing protection during use.

People with pacemakers should consult their physician(s) before use. Electromagnetic elds in

close proximity to a heart pacemaker could cause pacemaker interference or pacemaker failure.

Caution is necessary when near the engine’s or recoil starter.

Do not operate in explosive atmospheres, such as in the presence of ammable liquids, gases, or

dust. Gasoline-powered engines may ignite the dust or fumes.

Stay alert, watch what you are doing and use common sense when operating this generator. Do not

use while tired or under the inuence of drugs, alcohol or medication.

Dress properly. Do not wear loose clothing or jewelry. Keep hair, clothing and gloves away from

moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

Parts, especially exhaust system components, get very hot during use. Stay clear of hot parts.

Do not cover the generator during operation.

Keep the generator and surrounding area clean at all times.

Do not smoke, or allow sparks, ames, or other sources of ignition around the equipment, especially

when refuelling.

Use the equipment, accessories, etc., in accordance with these instructions and in the manner

intended for the particular type of equipment, taking into account the working conditions and the

work to be performed. Use of the equipment for operations different from those intended could result

in a hazardous situation

Do not operate the equipment with known leaks in the engine’s fuel system.

When spills of fuel or oil occur, they must be cleaned up immediately. Dispose of uids and cleaning

materials as per any local, state, or federal codes and regulations. Store oil rags in a bottom

ventilated, covered, metal container.

Keep hands and feet away from moving parts. Do not reach over or across equipment while

operating.

Before use, check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the equipment’s operation. if damaged, have the equipment serviced

before using.

Use the correct equipment for the application. Do not modify the equipment and do not use the

equipment for a purpose for which it is not intended.

4

IMPORTANT SAFETY INFORMATION

SERVICE PRECAUTIONS

Before service, maintenance, or cleaning: A. Unplug all devices from the generator. B. Turn the

Combination Switch C. to its “OFF” position. C. Allow the engine to completely cool. D. Then,

remove the spark plug cap

Keep all safety guards in place and in proper working order.

Keep all electrical equipment clean and dry. Replace any wiring where the insulation is

cracked, cut, abraded, or otherwise degraded. Replace terminals that are worn, discolored, or

corroded. Keep terminals clean and tight.

Do not alter or adjust any part of the equipment or its engine that is sealed by the manufacturer

or distributor. Only a qualied service technician may adjust parts that may increase or decrease

governed engine speed.

Have the equipment serviced by a qualied repair person using only identical replacement parts.

This will ensure that the safety of the equipment is maintained. Do not attempt any service or

maintenance procedures not explained in this manual or any procedures that you are uncertain

about your ability to perform safely or correctly.

Store equipment out of the reach of children.

Follow scheduled engine and equipment maintenance.

If you intend for this generator to be connected to a home power supply as a standby, the

connection should be performed by a professional electrician, When the loads are connected to the

generator, carefully check whether the electrical connections are safe and reliable. Any improper

connection may cause damage to the generator and can cause a re.

In order to prevent electric shock due to inferior electrical appliances or wrong use of electricity, the

generator must be grounded with good quality insulated conducted.

NOTICE

Make sure the control panel and the inverter bottom side cooling well and without chips, mud and

water come in. It may damage the engine, inverter or alternator if the cooling vent is blocked. Do

not mix the generator if moving, storing or running the unit. Doing so may cause damage to the

generator.

COMPONENTS AND CONTROLS

5

CONTROL FUNCTIONS

6

OIL WARNING LIGHT: When the oil level falls below recommended levels, the oil warning light

lights up and the engine will automatically stop. Rell with oil to get the engine to start again. If

the engine stalls or doesn’t start, turn the engine switch to “ON” and pull the recoil starter. If the oil

indicator light ickers, the engine oil is insufcient, add oil and restart.

OVERLOAD INDICATOR LIGHT: The overload indicator light comes on when an overload of

a connected device is detected, the inverter control unit overheats or the AC output voltage rises.

Then the AC protector will trip, stopping the power generation in order to protect the generator and

any connected electrical devices. The AC pilot light will go off and the overload indicator light will

stay on, but the engine will stop running. When the overload indicator light comes on and power

generation stops, proceed as follows:

1. Turn off any connected electric devices and stop the engine.

2. Reduce the total wattage of connected appliances into the rated output.

3. Check for blockages in the cooling air inlet and around the control unit. If any blockages are

found, remove them.

4. After checking, restart the engine.

TIP: The overload indicator light may come on for a few seconds at rst

when using electric devices that require a large starting current, such a

compressor or submergible pump. However, this is not a malfunction.

AC PILOT LIGHT (GREEN): The AC pilot light comes on when the

engine starts and produces power.

DC PROTECTOR: The DC protector turns to OFF automatically when

the electric device being connected to the generator is operating and the

current is above the rated ows. To turn on DC proctor by pressing the

ON button. ON is direct current output, OFF signies direct current is not

output.

CAUTION

Reduce the load of the connected electric device below the specic rated output of the generator if

the DC Protector turns off. If the DC Protector turns off again, stop using the device immediately and

consult a qualied technician.

ECONOMY CONTROL SWITCH (ECS): When the ECS switch is

turned on, the economy control unit controls the engine speed according

to the connected load. The results are better fuel consumption and less

noise. When the ECS is turned OFF, the engine runs at the rated speed

(4500r/min) regardless of whether is a load connected or not.

TIP: The ECS must be turned to OFF when using electric devices that

require a large starting current, such as a compressor of a submergible

pump.

7

CONTROL FUNCTIONS

FUEL TANK CAP: Remove the fuel tank cap by turning it counter-clockwise.

FUEL TANK CAP AIR VENT KNOB: The fuel tank cap features an air

vent knob to stop fuel ow. The air vent knob must be turned to ON. This will

allow fuel to ow to the carburettor and the engine to run. When the engine is

not in use, turn the air vent knob to OFF to stop fuel ow.

GROUND EARTH TERMINAL: Ground Earth Terminal connects the

earth line for protection and prevention of electric shock.

PREPARATION

CAUTION

Fuel is highly ammable and dangerous. Check the SAFETY INFORMATION in this manual before

lling. DO NOT overll the fuel tank as it may overow when the fuel warms up and expands. After

lling the fuel tank, make sure the fuel tank cap is securely tightened.

NOTICE

Immediately wipe off spilled fuel with a dry, clean cloth. Fuel can deteriorate painted surfaces or

plastic parts. Use only unleaded gasoline. The use of leaded gasoline will cause sever damage

to internal engine parts. Remove the fuel tank cap and ll the fuel into the tank up to the red level

indicator.

RECOMMENDED FUEL: Unleaded gasoline

FUEL TANK CAPACITY: Total 4.0L (1.06 US gal, 0.88 lmp gal)

NOTICE

The generator is shipped without engine oil. Do not start the engine until it has been lled with

engine oil.

1. Place the generator on a level surface.

2. Remove the screws (1) and remove the cover (2).

3. remove the oil ller cap.

4. Fill the specic amount of the recommended engine oil

and install and tighten the oil ller cap.

5. Install the cover and tighten the screws.

RECOMMENDED ENGINE OIL : SAE SJ 15W-40

RECOMMENDED ENGINE OIL GRADE: API Service SE type or higher

ENGINE OIL CAPACITY: 0.35 L

PRE-START CHECKS

8

Inspect the engine and generator looking for damaged, loose and missing parts before set up and

starting. If any problems are found, do not use the equipment until it is properly xed. The condition

of the generator is the owner’s responsibility. Vital components can start to deteriorate quickly and

unexpectedly, even if the generator is unused.

TIP: Pre-operation checks should be made each time the generator is used.

PRE-START CHECK:

Check fuel level in fuel tank, refuel if necessary

Check oil level in engine

If necessary, add recommended oil to specic level.

Check generator for leakage

Check operation

If necessary, add recommended oil to specic level.

If necessary, consult a qualied technician

Never operate the engine in a closed area or it may cause unconsciousness and death within a

short time. Operate the engine in a well ventilated area. Before starting the engine, do not connect

any electric devices.

TIP: The generator can be used with the rated output load at standard atmospheric conditions.

Ambient temperature 25 °C

Barometric pressure 100kPa

Relative humidity 30%

The output of the generator varies due to change of temperature, altitude and humidity. The output

of the generator is reduced when the temperature, the humidity and the altitude are higher than the

standard atmospheric conditions. Additionally, the load must be reduced when using in a conned

area as generator cooling will be affected.

BREAK-IN PERIOD

Breaking-in the Engine will help to ensure proper equipment and Engine operation.

The break-in period will last about 30 hours of use. DO NOT exceed 75% of the Generator’s

running wattage during this period.

Change the engine oil after this period.

Under normal operating conditions subsequent maintenance follows the schedule explained in the

maintenance section of this manual.

OPERATION

9

1. Turn the ECS black switch to OFF

2. Turn the air vent knob to ON

3. Turn the fuel knob to ON

4. Turn the red engine switch to ON

5. Pull the choke know out fully

TIP: The choke knob is not required to start a warm engine, push the choke knob

back in into the original position.

6. Grasp the generator handle to steady the unit. Pull slowly on the recoil

starter until it is engaged, then pull it briskly.

7. After the engine starts, warm up the engine until the engine does not stop

when the choke knob is returned to the original position.

10

OPERATION

TIP: When starting the engine, with the ECS ON, and there is no load on the generator:

In ambient temperature below 0 °C (32 °F), the engine will run at the rated r/min (4500r/min) for ve

minutes to warm up the engine.

In ambient temperature below 5 °C (41 °F), the engine will run at the rated r/min (4500r/min) for

three minutes to warm up the engine.

The ECS unit operates normally after the above time period, while the ECS is ON.

STOPPING THE ENGINE : Turn off the electric devices.

1. Turn the ECS black switch to OFF

2. Disconnect any electric devices

3. Turn the red engine switch to STOP

4. Turn the fuel cock knob to OFF

5. Turn the fuel tank cap air vent knob to OFF after the engine has

completely cooled down.

ALTERNATING CURRENT (AC) CONNECTION

BE SURE ANY ELECTRIC DEVICES ARE TURNED OFF BEFORE PLUGGING THEM IN

NOTICE

Be sure all electric devices including the lines and plug connections are in good condition before

connecting to the generator.

Be sure the total load is within generator rated output.

Be sure the receptacle load current is within receptacle rated current.

TIP: Make sure to ground (Earth) the generator. When the electric device is earthed, the generator

must always be earthed.

1. Start the engine

2. Turn the ECS to ON

3. Plug in to the AC receptacle

4. Make sure the AC pilot light is on

5. Turn on any electric devices

TIP: The ECS must be turned to OFF to increase engine speed to rated rpm. If the generator is

connected to multiple loads or electricity consumers, remember to rst connect the one with the

highest starting current, then lastly connect the one with the lowest starting current.

BATTERY CHARGING

The generator DC rated voltage is 12V

Start the engine rst and then connect the generator to the battery for charging.

Before starting to charge the battery, make sure that the DC protector is turned on.

1. Start the engine.

2. Connect the red battery charger lead to the positive (+) battery terminal.

3. Connect the black battery charger lead to the negative (-) battery.

4. Turn the ECS to OFF to start battery charge.

11

BATTERY CHARGING

NOTICE

Be sure the ECS is turned off while changing the battery.

Be sure the connect the red battery charger lead to the positive (+) battery terminal and connect the

black lead to the negative (-) battery terminal. DO NOT reverse these positions.

Connect the battery charger leads to the battery terminals securely so that they are not

disconnected due to engine vibration or other disturbances.

Charge the battery in the correct procedure by the following instructions in the owner’s manual for

the battery.

The DC protector turns off automatically if the current above the rated ows during battery charg-

ing. To restart charging the battery, turn the DC protector on by pressing its button to ON. If the DC

protector turns off again, top charging the battery immediately and consult our company authorized

dealer.

Follow instructions in the owner’s manual for the battery to determine the end of battery charging.

Measure the specic gravity of electrolyte to determine if the battery is fully charged. At full charge,

the electrolyte specic gravity is between 1.26 and 1.28

It is advisable to check the specic gravity of the electrolyte at least once every hour to prevent

overcharging the battery.

NEVER SMOKE OR MAKE AND BREAK CONNECTIONS AT THE BATTERY WHILE

CHARGING. SPARKS MAY IGNITE THE BATTERY GAS. BATTERY ELECTROLYTE IS

POISONOUS AND DANGEROUS, CAUSING SEVERE BURNS AND CONTAINS SULPHURIC

ACID. AVOID CONTACT WITH SKIN, EYES OR CLOTHING.

ANTIDOTE:

EXTERNAL: Flush with water

INTERNAL: Drink large quantities of water or milk. Follow with milk of magnesia, beaten egg or

vegetable oil. Call your doctor immediately.

EYES: Flush with water for 15 minutes and get medical attention right away.

TIP: Batteries produce explosive gases. Keep sparks, ame, cigarettes, etc. away from the

generator. Ventilate when charging or using in a enclosed space. Always cover your eyes when

working near batteries.

12

ALTERNATING CURRENT (AC) CONNECTION

When using the generator, make sure the total load is within rated output of a generator. Otherwise,

generator damage may occur.

TIP: Application wattage indicates when each device is used by itself. The simultaneous usage of

AC and DC power is possible but total wattage should not exceed the rated output.

The overload indicator light comes on when total wattage exceeds the application range.

NOTICE

Do not overload. The total load of all electrical appliances must not exceed the supply range of the

generator. Overloading will damage the generator.

When supplying precision equipment, electronic controllers, computers, microcomputers or battery

charges. Keep the generator a sufcient distance away to prevent electrical interference from the

engine. Also ensure that electrical noise from the engine does not interfere with any other electrical

devices located near the generator.

Some electrical appliances or general purpose electric motors have high starting currents and

cannot be used, even if they lie within the supply ranges given in the above table.

MAINTENANCE

13

The engine must be properly maintained to ensure safety, trouble-free and eco-friendly. In order to

keep your gasoline engine in good working condition, it must be periodically serviced. The following

maintenance schedule and routine inspection procedures must be carefully followed.

MAINTENANCE

14

NOTICE

If the gasoline engine frequently works under high temperatures or heavy loads, change the oil

every 25 hours.

If the engine frequently works under dusty circumstances, clean the air lter element every 10

hours. If necessary, change the air lter element every 25 hours.

Some electrical appliances or general purpose electric motors have high starting currents and

cannot be used, even if they lie within the supply ranges given in the above table.

STOP THE ENGINE BEFORE SERVICING, PUT THE ENGINE ON A LEVEL SURFACE AND

REMOVE THE SPARK PLUG CAP TO PREVENT THE ENGINE FROM STARTING. DO NOT

OPERATE THE ENGINE IN A POORLY VENTILATED ROOM OR ENCLOSED AREA. BE SURE

TO KEEP THE WORKING ROOM WELL VENTILATED. EXHAUST FROM THE ENGINE MAY

CONTAIN POISONOUS CO, INHALATION CAN CAUSE SERIOUS INJURY OR DEATH.

15

SPARK PLUG INSPECTION

The spark plug are important components that should be checked periodically.

1. Remove the cap and spark plug cap and insert the tool through the hole from the outside cover.

2. Insert the handlebar into the tool and turn it counter-clockwise to remove the spark plug.

3. Check for discolouration and remove the carbon. The porcelain insulator around the center

electrode of the spark plug should be a medium to light tan color

4. Check the spark plug gap. STANDARD SPARK PLUG: E6TC/E6RTC

SPARK PLUG GAP: 036 - 0.7MM (0.024-0.028IN)

5. Install the spark plug. SPARK PLUG TORQUE: 20.0N*m, 14.8 lb*ft)

TIP: If a torque wrench is not available when installing a spark plug, a good estimate of the correct

torque is 1/4 - 1/2 turn past nger tight. However, the spark plug should be tightened to the specied

torque as soon as possible.

6. Install the spark plug and spark plug cover

ENGINE OIL REPLACEMENT

Avoid draining the engine oil immediately after stopping the engine. The oil is hot and should be

handled with care to avoid burns.

1. Place the generator on a level surface and warm up the engine for several

minutes. Stop the engine and turn the 3 in 1 switch knob, fuel tank cap air vent

knob to OFF.

2. Remove screws and the cover.

3. Remove the oil ller cap.

4. Place an oil pan under the engine, tilt the generator to drain the oil completely.

5. Replace the generator on a surface level.

6. Add engine oil to the upper level.

TIP: Do not tilt the generator when adding oil, this could result in over-lling and damage to the

engine.

7. Be sure no foreign material enters the crankcase.

8. Install the ller cap.

9. Install the cover and tighten the screws

16

AIR FILTER

1. Remove the screws (1) and then remove the cover (2).

2. Remove the screw (3) and then remove the air lter case cover (4)

3. Remove the foam element, wash it in solvent and dry it.

4. Oil the foam element and squeeze out excess oil. The element should

not be dripping. Do not wring out the foam element when squeezing as

6. Insert the foam element into the lter case. Be sure the element sealing surface matches the air

lter. Never run the engine without the foam element in the correct position.

5. Install the air lter case cover and tighten the screws.

6. Install the over and tighten screws.

MUFFLER SCREEN AND SPARK ARRESTER

THE ENGINE AND MUFFLER WILL BE VERY HOT AFTER THE ENGINE HAS BEEN RUN.

AVOID TOUCHING THE ENGINE AND/OR MUFFLER WHILE STILL HOT. SERIOUS INJURY

CAN OCCUR.

1. Remove the screws (1) and pull outward on the areas of the cover (2)

2. Loosen the bolt (3) then remove the mufer cap (4the mufer screen (5) and

spark arrester (6)

3. Clean the carbon deposits on the mufer screen and spark arrested using a

wire brush.

4. Check the mufer screen and spark arrester, replace if damaged.

5. Install the spark arrester, mufer screen, mufer cap and cover, to be sure to

tighten the screws.

FUEL TANK FILTER

Never use gasoline while smoking or in the vicinity of an open ame.

1. Remove the fuel tank cap lter.

2. Clean the lter with gasoline.

3. Wipe the lter and install it.

4. Install the fuel tank cap Be sure it is tightened securely.

FUEL TANK FILTER

1. Remove the screws (1) then remover the cover (2) and drain the fuel.

2. Hold and move the clamp up (4) take off the hose from the tank (5)

3.Clean the lter with gasoline.

4.Dry the lter and put it back into the tank.

5.Install the hose clamp, then open the fuel valve to check for a leak.

6.Install the cover and tighten the screws.

DRAINING THE FUEL

1. Turn the engine switch to OFF (1)

2. Remove the fuel tank cap and remove the lter. Extract the fuel from fuel

tank, then install the fuel cap.

3. Start the engine and let it run until it stops. The engine should stop in

approximately 20 minutes by running out of fuel.

4.Remove the screws, then the cover.

5. Drain the fuel from the carburettor by loosening the drain screw on the carburettor oat chamber.

6. Turn the engine switch to STOP and tighten the drain screw.

7. Install the cover and tighten the screws.

8. Turn the fuel tank cap air vent knob to OFF after the engine has completely cooled.

17

ENGINE

18

Perform these steps to protect the cylinder, piston ring etc., from corrosion

1. Remove the spark plug and pour about one tablespoon of SAE 10W-30 into the spark plug hole,

then reinstall the spark plug. Recoil start the engine by turning over several times to coal the cylinder

walls with oil.

2. Pull the recoil starter until you feel compression, then stop pulling.

3. Clean the exterior of the generator and store in a dry, well ventilated area with the cover placed

over it

TROUBLESHOOTING

TROUBLESHOOTING

19

/