Page is loading ...

August

1985

FORM:

OM-1542A

OWN

ERS

MANUAL

Effective

With

Style

No.

JE-12

MODEL

GA-6OCF

Gun

AFT-100

Flux

Tank

Fr-i

Cart

ALE

COPY

RETURN

TO

FOLDER

MILLER

ELECTRIC

MFG.

CO.

718

S.

BOUNDS

ST,

P.O.

Box

1079

APPLETON,

WI

54912

USA

ADDITIONAL

COPY

PRICE

40

CENTS

IMPORTANT:

Read

and

understand

the

entire

contents

of

both

this

manual

and

the

power

source

manual

used

with

this

unit,

with

special

emphasis

on

the

safety

material

throughout

both

manuals,

before

installing,

operating,

or

maintaining

this

equipment.

This

unit

and

these

instructions

are

for

use

only

by

persons

trained

and

experienced

in

the

safe

operation

of

welding

equipment.

Do

not

allow

untrained

persons

to

install,

operate,

or

maintain

this

unit.

Contact

your

distributor

if

you

do

not

fully

understand

these

instructions.

111111E11

NWSA

CODE

NO.

4579

PRINTED

IN

U.S.A.

LIMITED

WARRANTY

EFFECTIVE:

FEBRUARY

25,

1985

This

warranty

supersedes

all

previous

MILLER

warranties

and

is

ex

clusive

with

no

other

guarantees

or

warranties

expressed

or

implied.

LIMITED

WARRANTY

-

Subject

to

the

terms

and

condi-

In

the

case

of

Millers

breach

of

warranty

or

any

other

duty

tions

hereof,

Miller

Electric

Mfg.

Co..

Appleton,

Wisconsin

with

respect

to

the

quality

of

any

goods,

the

exclusive

remedies

warrants

to

its

Distributor/Dealer

that

all

new

and

unused

therefore

shall

be,

at

Millers

option

Ii)

repair

or

(21

replacement

Equipment

furnished

by

Miller

is

free

from

defect

in

workman-

or,

where

authorized

in

writing

by

Miller

in

appropriate

cases,

(3)

ship

and

material

as

of

the

time

and

place

of

delivery

by

Miller.

the

reasonable

cost

of

repair

or

replacement

at

an

authorized

No

warranty

is

made

by

Miller

with

respect

to

engines,

trade

Miller

service

station

or

(4)

payment

of

or

credit for

the

purchase

~

accessories

or

other

items

manufactured

by

others.

Such

pnce

(less

reasonable

depreciation

based

upon

actual

use)

upon

~

engines,

trade

accessories

and

other

items

are

sold

subject

to

retum

of

the

goods

at

Customers

risk

and

expense.

MILLERs

the

warranties

of

their

respective

manufacturers,

if

any

.

All

option

of

repair

or

replacement

will

be

F.O.B.,

Factory,

at

engines

are

warranted

by

their

manufacturer

for

one

year

from

Appleton,

Wisconsin,

or

FOB.,

at

a

MILLER

authorized

service

~4

~

date

of

original

purchase,

except

Tecumseh

engines

which

facility,

therefore,

no

compensation

for

transportation

costs

of

have

a

two

year

warranty.

any

kind

will

be

allowed.

Upon

receipt

of

notice

of

apparent

defect

or

failure,

Miller

shall

instruct

the

claimant

on

the

warranty

Except

as

specified

below,

Millers

warranty

does

not

apply

claim

procedures

to

be

followed.

r,

to

components

having

normal

useful

life

of

less

than

one

(1)

year,

such

as

spot

welder

tips,

relay

and

contactor

points,

MILLERMATIC

parts

that

come

in

contact

with

the

welding

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

AND

j,~)

wire

including

nozzles

and

nozzle

insulators

where

failure

does

ANY

IMPLIED

WARRANTY,

GUARANTY

OR

REPRESENTA-

t~

r,

not

result

from

defect

in

workmanship

or

material.

TION

AS

TO

PERFORMANCE,

AND

ANY

REMEDY

FOR

BREACH

OF

CONTRACT

WHICH,

BUT

FOR

THIS

PROVISION,

Miller

shall

be

required

to

honor

warranty

claims

on

war-

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW,

.~

ranted

Equipment

in

the

event

of

failure

resulting

from

a

defect

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING,

INCLUDING

~

within

the

following

periods

from

the

date

of

delivery

of

Equip-

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

OF

~

ment

to

the

original

user:

FITNESS

FOR

PARTICULAR

PURPOSE.

WITH

RESPECT

TO

ANY

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

EX

~

~:

A

de~powes

CLUDED

AND

DISCLAIMED

BY

MILLER.

3.

Allweldingguris,feeder/gunsandplasmatorches...

90daye

EXCEPT

AS

EXPRESSLY

PROVIDED

BY

MILLER

IN

4.

All

other

Millermatic

Feeders

1

year

WRITING,

MILLER

PRODUCTS

ARE

INTENDED

FOR

5.

Replacement

or

repair

parts,

exclusive

of

labor..

60

days

ULTIMATE

PURCHASE

BY

COMMERCIAL/INDUSTRIAL

6.

Batteries

6

months

USERS

AND

FOR

OPERATION

BY

PERSONS

TRAINED

AND

EXPERIENCED

IN

THE

USE

AND

MAINTENANCE

OF

?

provided

that

Miller

is

notified

in

writing

within

thirty

(30)

days

WELDING

EQUIPMENT

AND

NOT

FOR

CONSUMERS

OR

of

the

date

of

such

failure.

CONSUMER

USE.

MILLERS

WARRANTIES

DO

NOT

EXTEND

submthed

by

the

or~nal

user

withi

the

foregoing

~

MILLERS

WAR

RANTI

ES

TO,

ANY

CONSUMER.

EXTEND

~

~

j~.

~

,,!~

~

j1

~

~

~

~

.~,.,

~

j1~

~,

,r

.

ERRATA

SHEET

After

this

manual

was

printed,

refinements

in

equipment

design

occurred.

This

sheet

lists

exceptions

to

data

appearing

later

in

this

manual.

Effective

With

Style

No.

JF-38

Item

Part

Replaced

No.

No.

With

Description

Quantity

49

094

701

082

750

ADAPTER,

hose-flux

1

51

094669

082754

TUBING,5/l6IDxl/l6walIx6

1

106449

TUBING,1/2x5/8

1

106450

TUBING,1/2x2

1

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

F

~

~QPY

~vc~

Sept.

9,

1985

FORM:

OM-1542A

SECTION

1

-

INTRODUCTION

GUN

Rating

100%

Duty

Cycle

Wire

Diameter

Capacity

Cable

And

Hose

Length

Cooling

Method

Weight

Net

Ship

600

Amperes

1/16

in.

(1.6mm)

through

3/32

in.

(2.4

mm)

10

ft.

(3.05

m)

15

ft.

(4.57

m)

Air

12

lbs.

(5.44

kg)

13

lbs.

(5.89

kg)

17

lbs.

(7.71

kg)

18

lbs.

(8.16

kg)

TAN

K

Air

Requirements

Capacity

Dimensions

Weight

Net

Ship

Pressure:

60

to

120

pounds

per

square

inch

(414

to

827

kilopascals)

100

lbs.

(45.4

kg)

Height

-

37-1/2

in.

(953

mm)

Diameter

-

16

in.

(407

mm)

107

lbs.

(48.5

kg)

124

lbs.

(56.2

kg)

Includes

3-1/4

lbs.

(1

.47

kg)

for

supplied

funnel.

CART

(Optional)

Dimensions

Weight

Net

Ship

Height

34-1 /2

in.

(876

mm)

Width

-

24-1/4

in.

(616

mm)

Length

-65

in.

(1651

mm)

91

lbs.

(41.3

kg)

98

lbs.

(44.5

kg)

Figure

1-1.

Specifications

1-1.

GENERAL

INFORMATION

AND

SAFETY

A.

General

ment.

B.

Safety

WARNING

CAUTION

WARNING

Information

presented

in

this

manual

and

on

various

labels,

tags,

and

plates

on

the

units

pertains

to

equip

ment

design,

installation,

operation,

maintenance,

and

troubleshooting

which

should

be

read,

understood,

and

followed

for

the

safe

and

effective

use

of

the

this

equip-

The

installation,

operation,

maintenance,

and

troubleshooting

of

arc

welding

equipment

requires

practices

and

procedures

which

ensure

personal

safety

and

the

safety

of

others.

Therefore,

this

equipment

is

to

be

installed,

operated,

and

maintained

only

by

qualified

persons

in

accordance

with

this

manual

and

all

ap

plicable

codes

such

as,

but

not

limited

to,

those

listed

at

CAUTION

the

end

of

Section

1

-

Safety

Rules

For

Operation

Of

Arc

Welding

Power

Source

in

the

welding

power

source

Owners

Manual.

Safety

instructions

specifically

pertaining

to

this

unit

ap

pear

throughout

this

manual

highlighted

by

the

signal

words

____________

and

___________

which

identify

different

levels

of

hazard.

____________statements

include

installation,

operating,

and

maintenance

procedures

or

practices

which

if

not

carefully

followed

could

result

in

serious

personal

injury

or

loss

of

life.

___________

statements

include

installation,

operating,

and

maintenance

procedures

or

practices

which

if

not

carefully

followed

could

result

in

minor

personal

injury

or

damage

to

this

equipment.

OM.1

542

Page

1

A

third

signal

word,

II~I~s]:If~1~Il

highlights

instruc

tions

which

need

special

emphasis

to

obtain

the

most

efficient

operation

of

this

equipment.

1-2.

RECEIVING-HANDLING

-

Prior

to

installing

this

equipment,

clean

all

packing

material

from

around

the

unit

and

carefully

inspect

for

any

damage

that

may

have

occurred

during

shipment.

Any

claims

for

loss

or

damage

that

may

have

occurred

in

transit

must

be

filed

by

the

purchaser

with

the

carrier.

A

copy

of

the

bill

of

lading

will

be

furnished

by

the

manufacturer

on

re

quest

if

occasion

to

file

claim

arises.

When

requesting

information

concerning

this

equip

ment,

it

is

essential

that

Model

Description

and

Style

Number

of

the

equipment

be

supplied.

1-3.

DESCRIPTION

-

The

pressurized

flux

delivery

system

is

designed

for

use

with

the

semiautomatic

Submerged

Arc

Welding

(SAW)

process

and

includes

two

pieces

of

equipment:

A

GA-6OCF

gun

and

an

AFT-i

00

flux

tank.

An

optional

FT-i

cart

is

available

to

make

the

system

portable.

A

wire

feeder

and

constant

potential

welding

power

source

are

required

to

com

plete

the

package.

The

alpha-numeric

designations

of

the

components

are

explained

as

follows:

Gun

Air-Cooled

Ampere

Rating:

600

Amperes

Curved

Head

Tube

Flux

(For

Flux

Use)

The

gun

is

equipped

with

a

trigger

lock

for

operator

comfort

during

long

welds.

The

gun

trigger

is

dual

pur

pose

-

it

controls

flux

flow

and

energizes

the

wire

feeder.

Tank

AFT-100

=

Air-Operated

Flux

Tank

With

100

lbs.

(45.4

kg)

Flux

Capacity

Cart

(Optional)

FT-i

=

Flux

Tank

Model

1

Cart

SECTION

2

-

INSTALLATION

2-1.

CART

ASSEMBLY

AND

COMPONENT

IN

STALLATION

(Figure

2-1)

-

Assemble

cart,

if

ap

plicable,

as

shown

in

Figure

2-1.

Be

sure

all

bolts,

nuts,

etc.,

are

tightened

securely.

Install

flux

tank

onto

cart,

if

applicable,

as

shown

in

Figure

2-i.

Tighten

all

mounting

hardware

securely.

If

applicable,

install

wire

feeder

onto

cart

as

shown

in

Figure

2-i.

Tighten

bolts

securely.

the

unit

can

be

lifted

with

a

hoist

or

overhead

crane

us

ing

the

provided

lifting

bail

on

cart

(see

Figure

2-1).

CAUTION

_________

IMPROPER

LIFTING

OF

EQUIPMENT

can

result

in

personal

injury

and

equipment

damage.

Use

equipment

of

adequate

capacity

to

lift

the

unit.

Lifting

eyes

are

provided

on

the

sides

of

the

tank

for

handling

purposes

when

the

tank

is

not

installed

on

a

TC-084

388-A

Gun

G=

A=

60

=

C=

F=

Once

the

cart

is

assembled

and

components

installed,

cart.

Figure

2-1.

Assembly

And

Installation

OM-1542

Page

2

2-2.

FLUX

TANK

CONNECTIONS

AND

INFORMA

To

Add

Flux

TION

(Figure

2-2)

~

Cover;

Remove

Air

Hose

Fitting

Air

Valve

Air

Pres8ure

Regulator

Air

Dryer

With

Bleeder

Line

Gun

Flux

Hoae

Air

Pressure

Fitting

Safety

Valve

Ret:

TC~84

388-A

With

Bleeder

Handle

Flux

Drain

Cover

Figure

2-2.

Flux

Tank

Component

Identifications

Connect

gun

flux

hose

to

tank

fitting,

and

secure

with

To

bleed

air

pressure

from

tank,

pull

out

and

hold

safety

supplied

hose

clamp

(see

Figures

2-2

and

2-3).

valve

bleeder

handle

(see

Figure

2-2).

Connect

air

supply

to

air

hose

fitting

(see

Figure

2-2).

To

add

flux,

proceed

as

follows:

This

fitting

will

accept

standard

air

hose

connectors.

1.

Close

air

valve,

bleed

pressure

from

tank,

and

For

normal

welding

conditions,

open

air

valve

and

ad-

disconnect

air

supply.

just

the

regulator

for

30

pounds

per

square

inch

(207

kilopascals)

of

air

pressure.

If

necessary,

readjust

air

2.

Remove

cover

from

tank

slowly.

(A

screen

is

pressure

for

different

welding

conditions.

If

the

flux

is

provided

inside

the

tank

and

must

remain

in

pushed

up

and

over

a

boom,

or

the

hoses

are

extended,

place.)

the

pressure

will

also

have

to

be

increased.

~NARNlNG

and

skin.

Do

not

allow

flux

flow

to

stop

while

welding.

Do

not

use

wet

or

damp

flux.

Do

not

restrict

flux

feed

hose.

Ensure

continuous

air

supply

to

flux

system.

Keep

foreign

material

out

of

flux

system.

Use

reclaimed

flux

only

which

has

been

sifted

through

.062

inch

(1.57

mm)

mesh.

Do

not

allow

flux

flow

to

stop

while

welding

to

avoid

be

ing

exposed

to

a

bare

arc.

The

arc

must

be

covered

at

all

times

to

prevent

arc

flashing.

EXPOSED

ARC

RAYS

can

burn

eyes

3.

Place

supplied

funnel

into

tank

opening,

and

pour

in

flux.

Prescreen

reclaimed

flux

through

.062

inch

(1

.57

mm)

mesh

before

adding

to

tank.

4.

Remove

funnel

and

reinstall

cover

tightly

onto

tank.

5.

Reconnect

air

supply

and

open

air

valve.

To

change

to

a

different

flux,

proceed

as

follows:

1.

Close

air

valve,

bleed

pressure

from

tank,

and

FLYING

FLUX

PARTICLES

can

punc-

disconnect

air

supply.

2.

Remove

bottom

tank

cover

(see

Figure

2-2),

and

drain

existing

flux

into

an

appropriate

container.

3.

Reinstall

bottom

tank

cover

tightely.

4.

Add

desired

flux

to

tank

according

to

the

preceeding

instructions.

OM-1542Page3

ture

eyes

and

skin.

Wear

proper

eye,

hand.

and

body

protection.

Close

air

line

valve

and

bleed

pressure

from

tank

before

disconnecting

air

supply

or

opening

top

or

bottom

cover(s).

After

connecting

air

supply,

open

air

line

valve

to

energize

tank.

Consult

the

flux

manufacturer

for

the

proper

ratio

of

new

to

recycled

flux.

WARNING

IMPORTANT:

2-3.

GUN/WIRE

FEEDER

CONNECTIONS

(Figure

2-1)

IMPORTANT

______________

If

an

optional

gun/feeder

adapter

kit

is

to

be

used,

make

gun/feeder

connections

according

to

the

instructions

furnished

with

the

kit.

A.

Gun/Feeder

Connector

Installation

Loosen

the

gun/feeder

connector

securing

knob

on

wire

feeder

drive

housing

(see

wire

feeder

Owners

Manual

for

location).

Insert

the

gun/feeder

connector

into

opening

in

housing

(see

Figure

2-1).

IMPORTANT

Whenever

the

electrode

wire

size

is

changed,

blow

out

both

the

monocoil

finer

and

monocoil

casing

with

compressed

air.

1.

Remove

the

nozzle

and

extension

if

applicable.

2.

Cut

off

any

portion

of

the

electrode

wire

which

extends

beyond

the

end

of

the

contact

tube.

3.

Remove

the

contact

tube.

4.

Retract

remaining

electrode

wire

onto

wire

spool.

Install

connector

so

that

outlet

wire

guide

is

as

close

to

drive

rolls

as

possible

without

touching.

5.

Install

the

appropriate

contact

tube.

6.

Reinstall

the

nozzle

and

extension

if

applicable.

WARNING

Tighten

the

gun/feeder

connector

securing

knob.

B.

Gun

Trigger

Connections

Locate

TRIGGER

receptacle

on

wire

feeder

control.

Connect

gun

trigger

plug

to

this

receptacle

and

secure.

2-4.

GUN

TRIGGER

OPERATION

-

The

gun

trigger

has

two

standard

features:

a

locking

device,

and

control

of

both

flux

flow

and

wire

feeder.

The

locking

device

allows

the

trigger

to

be

held

fully

depressed

providing

operator

comfort

on

long

or

sus

tained

welds.

The

control

of

flux

flow

and

wire

feeder

is

obtained

by

depressing

the

trigger.

Up

to

approximately

2/3

depres

sion

will

allow

partial

flux

flow

only

without

energizing

the

wire

feeder.

Full

depression

gives

full

flux

flow

and

energizes

wire

feeder.

__________

FLYING

FLUX

PARTICLES

can

punc

ture

eyes

and

skin;

WELDING

WIRE

can

cause

puncture

wounds.

Do

not

point

gun

toward

any

part

of

the

body

or

other

personnel.

Do

not

depress

gun

trigger

until

ready

to

begin

welding.

2-5.

CHANGING

WIRE

SIZE

(Figure

2-3)

-

To

change

the

size

of

the

electrode

wire,

the

only

gun

part

necessary

to

change

is

the

contact

tube.

It

may

be

necessary

to

change

the

wire

feeder

inlet

wire

guide

-see

wire

feeder

Owners

Manual

for

information.

I~:~II~Ic~

ELECTRIC

SHOCK

can

kill;

FLYING

FLUX

PARTICLES

can

puncture

eyes

and

skin;

WELDING

WIRE

can

cause

puncture

wounds.

Do

not

touch

five

electrical

parts.

Shut

down

we/ding

power

source

and

wire

feeder

and

be

sure

they

cannot

be

accidentally

energized

before

working

on

gun

components.

Close

air

valve,

bleed

pressure

from

tank,

and

disconnect

air

supply.

Do

not

point

gun

toward

any

part

of

the

body

or

other

personnel.

7.

Make

necessary

changes

to

wire

feeder

to

ac

comodate

new

wire

size.

8.

Thread

new

size

electrode

wire

(see

wire

feeder

Owners

Manual).

9.

Reconnect

air

supply

to

flux

tank.

10.

Resume

operation.

TC-084

443

Moriocoil

Liner

Extension

(Optional)

Contact

Tuba

Outlet

Wire

Guide

Monocoll

Liner

Monocoil

Liner

Setscrew

Gun

Trigger

Flux

Hose

Figure

2-3.

Gun

Components

OM-1542

Page

4

2-6.

CHANGING

CONTACT

TUBE

(Figure

2-3)

1.

Remove

the

nozzle

and

extension

if

applicable.

WARNING

__________

ELECTRIC

SHOCK

can

kill;

FLYING

FLUX

PARTICLES

can

puncture

eyes

and

skin;

WELDING

WIRE

can

cause

puncture

wounds.

Do

not

touch

live

electrical

parts.

Shut

down

welding

power

source

and

wire

feeder

and

be

sure

they

cannot

be

accidentally

energized

before

working

on

gun

components.

Close

air

valve,

bleed

pressure

from

tank,

and

disconnect

air

supply.

Do

not

point

gun

toward

any

part

of

the

body

or

other

personnel.

2.

Cut

off

any

portion

of

the

electrode

wire

which

extends

beyond

the

end

of

the

contact

tube.

3.

Remove

the

contact

tube.

4.

Install

new

contact

tube.

5.

Reinstall

the

nozzle

and

extension

if

applicable.

6.

Resume

operation.

SECTION

3

-

SEQUENCE

OF

OPERATION

WARNING

EXPOSED

ARC

RAYS

can

burn

eyes

and

skin.

Do

not

allow

flux

flow

to

stop

while

welding.

Do

not

use

wet

or

damp

flux.

Do

not

restrict

flux

feed

hose.

Ensure

continuous

air

supply

to

flux

system.

Keep

foreign

material

out

of

flux

system.

Use

reclaimed

flux

only

which

has

been

sifted

through

.062

inch

(1.57

mm)

mesh.

Do

not

allow

flux

flow

to

stop

while

welding

to

avoid

be

ing

exposed

to

a

bare

arc.

The

arc

must

be

covered

at

all

times

to

prevent

arc

flashing.

ITAY1~t1~lIk~IC~

ELECTRIC

SHOCK

can

kill;

FLYING

FLUX

PARTICLES

can

puncture

eyes

and

skin.

Do

not

touch

live

electrical

parts.

Do

not

energize

welding

power

source

or

wire

feeder

until

instructed

to

do

so.

Do

not

touch

welding

wire

or

any

metal

part

in

contact

with

it

while

welding.

Wear

proper

eye,

hand;

and

body

protection

when

welding.

Welding

wire

and

all

metal

parts

in

contact

with

it

carry

weld

current

when

the

gun

trigger

is

depressed

and

the

welding

power

source

contactor

is

energized.

See

Sec

tion

1

-

Safety

Rules

For

Operation

Of

Arc

Welding

Power

Source

in

welding

power

source

Owners

Manual

for

basic

welding

safety

information.

1.

Assemble,

install,

and

connect

components

as

applicable

as

instructed

in

Section

2.

2.

Fill

tank with

flux

as

instructed

in

Section

2-2.

WARNING

FLYING

FLUX

PARTICLES

can

punc

ture

eyes

and

skin.

Wear

proper

eye,

hand;

and

body

protection.

Close

air

line

valve

and

bleed

pressure

from

tank

before

disconnecting

air

supply

or

opening

top

or

bottom

cover(s).

After

connecting

air

supply,

open

air

line

valve

to

energize

tank.

3.

Connect

air

supply

to

tank,

open

air

valve,

and

adjust

pressure

as

instructed

in

Section

2-2.

4.

Make

connections

to

welding

power

source

as

instructed

in

power

source

and

wire

feeder

Owners

Manuals.

5.

Begin

welding.

3-2.

SHUTFING

DOWN

1.

Turn

off

all

equipment.

2.

Close

air

valve,

bleed

pressure

from

tank,

and

disconnect

air

supply

as

instructed

in

Section

2-2.

SECTION

4

-

MAINTENANCE

Periodically

inspect

the

labels

on

this

unit

for

legibility.

All

labels

must

be

maintained

in

a

clearly

readable

state

and

replaced

when

necessary.

See

the

Parts

List

for

part

number

of

labels.

4-1.

GUN

INSPECTION

AND

UPKEEP

WARNING

_________

ELECTRIC

SHOCK

can

kill;

FLYING

FLUX

PARTICLES

can

puncture

eyes

and

skin;

WELDING

WIRE

can

cause

puncture

wounds.

Do

not

touch

live

electrical

parts.

Shut

down

welding

power

source

and

wire

feeder

and

be

sure

they

cannot

be

accidentally

energized

before

inspecting

or

servicing

gun.

Close

air

valve,

bleed

pressure

from

tan/c

and

disconnect

air

supply.

Usage

and

shop

conditions

will

determine

frequency

and

type

of

maintenance

required.

1.

Inspect

gun

for

broken

areas,

cracks

and

loose

parts;

tighten,

repair

and

replace

as

required.

2.

Carefully

remove

any

weld

spatter

or

foreign

matter

which

may

accumulate

around

the

nozzle

orifice

and

inside

nozzle.

3.

Repair

or

replace

as

required

all

hose

and

cables;

give

particular

attention

to

frayed

and

cracked

in

sulation

and

areas

where

it

enters

equipment.

4.

Remove

grease

and

grime

from

components;

moisture

from

electrical

parts

and

cables.

3-1.

SUBMERGED

ARC

WELDING

IMPORTANT

OM-1

542

Page

5

5.

Blow

out

the

casing

with

compressed

air

when

1.

Cut

off

any

portion

of

the

electrode

wire

which

changing

wire.

This

removes

any

loose

metal

extends

beyond

the

end

of

the

nozzle.

chips

and

dirt

that

may

have

accumulated.

2.

Retract

remaining

electrode

wire

onto

wire

4-2.

FLUX

SYSTEM

spool.

Flux

is

very

abrasive

and

has

a

wear

ing

and

clogging

effect

on

all

parts

and

pieces

exposed

to

it.

Good

maintenance

is

essential

for

proper

opera

tion.

Periodically,

depending

on

usage

and

conditions,

check

flux

hose

and

tank

for

secure

connections.

Be

sure

hose

is

securely

installed

onto

tank

and

gun

fittings

and

that

clamps

are

tight.

Be

sure

all

component

mounting

bolts

are

tight.

Using

a

soft

brush

or

cloth,

clean

dirt

and

flux

particles

off

all

components.

Check

hose

and

air

lines

for

damage

or

leaks.

Repair

or

replace

defective

com

ponents

as

necessary.

Periodically

examine

flux

screen

inside

tank

and

clean

out

large

particles

if

necessary.

4-3.

CHANGING

MONOCOIL

LINER

(Figure

2-3)

ITi!i~:hIl~Ie~

ELECTRIC

SHOCK

can

kill;

FLYING

FLUX

PARTICLES

can

puncture

eyes

and

skin;

WELDING

WIRE

can

cause

puncture

wounds.

Do

not

touch

live

electrical

parts.

Shut

down

we/ding

power

source

and

wire

feeder

and

be

sure

they

cannot

be

accidentally

energized

before

working

on

gun

components.

Close

air

valve,

bleed

pressure

from

tank,

and

disconnect

air

supply.

Do

not

point

gun

toward

any

part

of

the

body

or

other

personnel.

3.

Disconnect

gun

from

wire

feeder

and

lay

gun

out

flat

(no

coils

in

cable/conduit).

4.

Remove

outlet

wire

guide

from

gun/feeder

con

nector.

5.

Loosen

setscrew

in

gun

handle

and

large

setscrew

in

gun/feeder

connector

(see

Figure

2-3).

6.

Pull

out

monocoil

liner

from

gun/feeder

connec

tor

end

of

casing.

7.

Insert

new

liner

fully

into

casing

and

tighten

both

setscrews

to

hold

liner

in

place.

~

OVERTIGHTENING

MONOCOIL

LINER

SETSCREWS

will

damage

liner.

Do

not

overtighten

setscrews.

8.

Reinstall

outlet

wire

guide

into

gun/feeder

con

nector.

9.

Cut

off

new

liner

so

that

it

sticks

out

approx

imately

1/8

in.

(3.2

mm)

from

wire

guide.

10.

Reconnect

gun

to

wire

feeder.

11.

Thread

electrode

wire

through

gun

(see

wire

feeder

Owners

Manual).

12.

Reconnect

air

supply

to

flux

tank.

13.

Resume

operation.

IMPORTANT

IMPORTANT

Whenever

the

monocoil

liner,

is

changed,

blow

out

both

the

monocoil

finer

and

monocoil

casing

with

compressed

air.

OM-1

542

Page

6

August

1985

FORM:

OM-1542A

PARTS

LIST

Effective

With

Style

No.

JE-12

CD

U)

N

CD

0

I-.

I.

N

t

U

K

4

0

N

a,

I1~

/

/

U

OM-1

542

Page

1

Item

No.

Figure

A

Gun,

Flux

Tank

&

Cart

1

601

956

2

032

524

3

602 250

4

605

755

5

082

643

6

601

965

7

602213

8

601

872

9

Figure

B

10

601

948

11

602211

12

082646

13

082637

14

604631

15

082636

16

602207

17

601

865

18 601

957

19

027

376

20

602216

21

601

879

22

082

644

23

604

423

24

Figure

C

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

4

2

2

4

4

7

7

2

2

4

4

2

2

2

2

Part

No.

Description

Quantity

SCREW,cap-hexhdl/4-20x1-1/4

PIN,

cotter3/16x1-1/2

WASHER,

flat

SAE

-

3/4

WHEEL,

rubber

10

OD

x

2-3/4

x

3/4

bore

BRACKET,

lifting

-

cart

SCREW,

cap

-

hex

hd

3/8-16

x

1

WASHER,

lock-split

3/8

NUT,

hex-full

3/8-16

FLUX

TANK,

AFT-i 00

(Pg

4)

SCREW,

cap-hex

hd5/16-18x1

WASHER,

lock-split

5/16

BASE

AXLE

SCREW,

cap-hex

hdi/4-20x1

BRACE,

handle

WASHER,

lock

-

split

1/4

NUT,

hex

full

1/4-20

SCREW,

cap

-

hex

hd

1/4-20

x

1-1/2

CASTER,

swivel

5

inch

WASHER,

lock

-

split

1/2

NUT,

hex-fulIl/2-13

HANDLE

GRIP,

handle

GA-6OCF

Gun

(Pg

6)

OM-1542

Page

2

0

01

II

(0

C

-

0

I

-I

C)

8

t0

-J

C)

3

0

(0

-4

C~)

F..)

Item

Part

No.

No.

Description

Quantity

Figure

B

AFT-100

Flux

Tank

1

083757

1

2

082544

1

602

178

1

3

082540

1

4

082622

1

5

083485

1

6

082546

1

7605106

1

8

082613

1

9071270

1

10

082621

4ft

11

082589

1

12

010678

1

13

082 579

1

14

082536

1

15

082587

1

16

082

537

1

17

082586

1

18

602934

3

19

602920

3

20

601

117

3

21

082

593

1

084

640

1

22

082

578

1

23

082

588

1

24

082

541

1

25

082

538

1

26

082

577

1

27

082

594

1

28

073 524

1

29

602

902

1

30

082614

1

31

084

939

1

602

085

2

601

925

2

602

200

2

602

207

2

601

860

2

FUNNEL

CAP,

tank

-

flux

(consisting

of)

SCREW,

set

socket

hd

1/4-20

x

3/8

SEAL,

cap-tank

STRAINER,

tank

-

flux

TANK

FITTING,

Y-45

deg

tank

bottom

FITTING,

pipe

-

cap

2

NPT

FITTING,

w/screen

FITTING,

pipe

-

tee

st

L

1/4

NPT

TUBING,

copper

1/4

00

x

0.030

waIl

(order

by

ft)

FITTING,

brass

-

cOmpression

connector

M

1/4

TBG

x

1/4

NPT

FITTING,

pipe

-

brass

elbow

St

1/4

NPT

L

VALVE,

relief

-

pressure

75

PSi

G

1/4

NPTF

VENT,

air

-

filter

FITTING,

brass

-

compression

union

1/2

TBG

TUBE,

filter

-

final

FITTING,

brass

-

compression

elbow

F

1/2

TBG

x

1/4

FITTING,

pipe

-

coupling

1/4

NPT

FITTING,

pipe

-

nipple

L

1/4

NPT

x

2

CLIP,

jiffy

-

tubing

1/2

inch

REGULATOR,

pressure

-

air

KIT,

repair

-

regulator

GAUGE,

pressure-air

0.60

+

0-4

PS1G

FITTING,

brass

-

compression

elbow

F

1/4

TBG

x

1/4

BRACKET,

mtg

-

components

CANNISTER,

filter

0-RING,

2-1/8

ID

x

2-5/16

OD

x

3/32

FILTER,

air

-5

oz

1/4

NPT

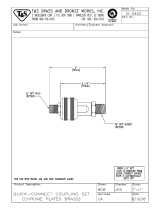

FITTING,

pipe

-

brass

quick

disconnect

M

1/4

NPT

FITTING,

pipe

-

valve

2

way

1/4

FPT

x

1/4

NP

VALVE,

check

1

PSIG

1/4

MNPT

both

ends

LABEL,

warning

-

flux

particles,

etc

Attaching

Hardware

SCREW,

round

-

hd

8-32

x

3/4

SCREW,

cap

-

hex

hd

1/4-20

x

1/2

WASHER,

lock

-

split

No.

8

WASHER,

lock

-

split

1/4

NUT,

hex

8-32

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

OM-1542

Page

4

5,

39,

37

36

44

1

2.

3

21

Figure

C

-

GA-6OCF

Gun

41

TC-084

444-0

OM-1

542

PageS

Item

Part

No.

No.

Description

Quantity

Figure

C

GA-6OCF

Gun

1

082741

1

2

052098

1

3

009709

1

3

052055

1

4

082298

1

5

t082

297

1

6

t083

697

1

7

000425

2

8

083610

1

9

094703

1

10

094705

1

11

094698

1

12

t082

322

1

13

094698

1

14

094704

1

15

094702

1

16

082312

1

17

000425

2

18

082782

1

19

059290

1

20

082 870

1

21

082

745

1

22 084 463

2

23

602

196

2

24

082

858

1

25

082

856

1

26

084

465

1

27

084

464

2

28

023 562

2

29

049 872

1

30

079

878

1

31

079

535

4

32

048

834

1

33

604

525

2

ft

34

081

909

2

35

082

796

1

35

082

797

1

36

004

732

2

37

004 733

2

38

082

757

1

39

004

731

1

40

078 892

1

41

091

602

1

42

049312

3

43

095015

1

44

094

554

1

44

094

555

1

45 082

749

1

46

602

173

2

47

605

422

15

ft

47

605

422

20

ft

48

073

476

12

49

094701

1

50

082861

1

51

094699

1

52

082

747

1

ADAPTER,

nozzle

SCREW,

set

-

hollow

lock

3/8-16

x

3/16

(included

with

head

tube)

TUBE,

contact

1/16

wire

TUBE,

contact

5/64

wire

NOZZLE,

screw

type

3/4

orifice

x

1-3/8

NOZZLE,

screw

type

5/8

orifice

x

1-3/8

EXTENSION,

nozzle

(consisting

of)

SCREW,

4-40

x

3/8

flat

head

EXTENSION,

nozzle

GUIDE,

wire

INSERT,

nozzle-extension

RING,

retaining

~/8

shaft

EXTENSION,

nozzle

(consisting

of)

RING,

retaining

3/8

shaft

INSERT,

nozzle-extension

GUIDE,

wire

EXTENSION,

nozzle

SCREW,

flat-hd

4-40

x

3/8

RIVET,

round

hd

5/32

dia

x

7/8

NUT,

speed

-

push

on

0.320

ID

x7/16

OD

SPRING,

compression

0.22

OD

x

3/4

inches

TRIGGER,

gun

SCREW,

pan

-

hd

4-40

x

9/16

WASHER,

lock

-

internal

tooth

No.

4

LOCK,

trigger

HANDLE,

gun

-

bottom

SWITCH

TUBING,

No.

7

x

2

inches

long

CLAMP,

hose

5/16-7/8

dia

CORD,

power

(consisting

of)

HOUSING

PLUG

&

PINS

(consisting

of)

TERMINAL,

male

CLAMP,

cable

CORD,

No.

18

2/c

(order

by

ft)

SPLICE,

20-16

wire

-

insulated

CABLE/CONDUIT,

lOft.

(consisting

of)

CABLE/CONDUIT,

15

ft.

(consisting

of)

CLAMP,

cable

conduit

CLAMP,

cable

conduit

ADAPTER,

gun/feeder

ADAPTER,

head

tube/power

cable

SCREW,

set

-

socket

hd

3/8-16

x

3/8

STRAIN

RELIEF

RING,

locking

-

handle

GUIDE,

wire

-

outlet

1/16-5/64

wire

MONOCOIL

MONOCOIL

SLEEVE,

centering

-

monocoil

SCREW,

set

-

socket

hd

10-32

x

1/4

HOSE,

No.

1

x

3/8

ID

(order

by

ft)

HOSE,

No.

1

x

3/8

ID

(order

by

ft)

CLAMP,

strap

3/8

x

4-5/8

ADAPTER,

hose

-

flux

INSULATOR,

terminal

-

switch

TUBING,5/l6IDxl/l6wallx4

GUARD,

switch

OM-1542

Page

6

Item

Part

No. No.

Description

Quantity

Figure

C

GA-6OCF

Gun

(Contd)

53

082 746

CLIP,

wire

-

trigger

1

54

082

748

HANDLE,

gun

-

top

1

55

052

884

SCREW,

set

-

socket

hd

10-32

x

1/4

2

56

082781

SCREW,set-sockethd5/16-18x3/8

1

57

082

743

TUBE,

head

(includes

item

2)

1

t085

277

ADAPTER,

gun/feeder

(LN-7,

8

&

9)

(consisting

of)

1

085

697

.

ADAPTER,

gun/feeder

1

048

713

.CLAMP,

power

1

t084

172

ADAPTER,

gun/feeder

(Hobart

27)

(consisting

of)

1

O84

358

.

ADAPTER,

gun/feeder

1

084

355

.

ADAPTER,

cord-power

1

602

177

.

SCREW,

set-socket

hd

1/4-20

x

1/4

1

tOptional

Parts.

BE

SURE

TO

PROVIDE

MODEL

AND

STYLE

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

OM-1542Page7

/