Page is loading ...

71ba75750e01 07/2008

Oxi 4000

Operating instructions

Oxygen Monitor

Oxi 4000

mg/l

1

1

85

°

C

REL1

5 6

O

Oxi 4000

72

ba75750e01 07/2008

Accuracy when

going to press

The use of advanced technology and the high quality standard of our

instruments are the result of continuous development. This may result

in differences between this operating manual and your instrument.

Also, we cannot guarantee that there are absolutely no errors in this

manual. Therefore, we are sure you will understand that we cannot

accept any legal claims resulting from the data, figures or descriptions.

Copyright

© Weilheim 2008, WTW GmbH

Reprinting - even as excerpts - is only allowed with the explicit written

authorization of WTW GmbH, Weilheim.

Printed in Germany.

Oxi 4000 Contents

73

ba75750e01 07/2008

Oxi 4000 - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

1.1 General features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

1.2 Outputs and interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1.2.2 Freely configurable relay (RT and RT RS option) . . . . . . . . . . . . . . . . . . . . . . . . 76

1.2.3 RS 485 digital interface (RT RS option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

1.3 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.2 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.3 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.1 Onsite installation: General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.2 Electrical terminal strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.3.1 General installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.3.2 Line power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.3.3 Relay contacts and current outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.3.4 RS 485 digital interface (RS option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.3.5 Connecting the oxygen sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.2 Operating keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.3 Operating levels and general operating principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4.4.1 Call up configuration level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4.4.2 Configuration setting table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.5 Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.5.1 Calling up the parameterization level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.5.2 Setting table of parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.6 PID controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

4.7 Freely configurable relays (RT and RT RS option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

4.7.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

4.7.2 Limit indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4.7.3 Proportional control with relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

4.7.4 Timer for external sensor cleaning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Contents Oxi 4000

74

ba75750e01 07/2008

4.7.5 Display of the relay states in the operating level . . . . . . . . . . . . . . . . . . . . . . . . . 118

4.8 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

4.9 Display of instrument information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4.10 Test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

5 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

5.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

5.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

6 What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

7.1 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

7.2 Oxygen measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

7.3 Temperature measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8 Indexes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

8.1 Display abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

8.2 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

8.3 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Oxi 4000 Overview

75

ba75750e01 07/2008

1Overview

1.1 General features

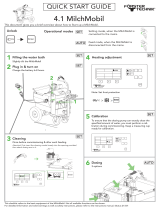

Fig. 1-1 Oxi 4000

1 Waterproof housing (IP 66)

2 Display

3 Operating keys

4 Cable glands

Oxi 4000

mg/l

1

1

85

°

C

REL1

5 6

1

2

3

4

O

Overview Oxi 4000

76

ba75750e01 07/2008

1.2 Outputs and interfaces

1.2.1 Overview

The monitor has the following outputs and interfaces depending on the

instrument version:

1.2.2 Freely configurable relay (RT and RT RS option)

Both potential-free K1 and K2 relays of the RT and RT RS instrument

versions can be used as follows:

z As a fault indicator if the power fails

z As an indicator relay for a frozen measured value (e.g. when

calibrating)

z As a threshold indicator if a specified threshold is undercut or

exceeded (main measured value)

z As a proportional controller with pulse width or frequency modulation

for controlling the measured oxygen value

z As a control relay with timer function, e.g. for time-controlled sensor

cleaning operated by compressed air.

Instrument version Relays Current outputs Digital

interfaces

Oxi 4000 (standard) - 1 x,

can be used as an analog

output for the main or

auxiliary measured value

(oxygen or temperature)

or as a PID controller.

-

Oxi 4000 RT 2 x,

freely configurable

A further current output in

addition.

For usability, see

Oxi 4000 Standard

-

Oxi 4000 RT RS as RT option as RT option 1 x RS 485

Oxi 4000 Overview

77

ba75750e01 07/2008

1.2.3 RS 485 digital interface (RT RS option)

The monitor can communicate with other instruments via the RS 485

digital interface of the RS instrument versions.

The following operating modes are possible:

z Master mode (

Prn mode): Unidirectional mode for the output of

measured values. Main and auxiliary measured value are sent. The

interface is constantly active in master mode. The data are sent to a

data terminal (e.g. PC with terminal software or printer).

z Slave mode (

SL mode): Bidirectional mode in the bus network. In this

operating mode the monitor ("slave") works together with a control

computer ("master") on the master/slave principle. A total of 31

slave devices can be connected to one master in the bus network.

All slave devices are addressed by the control computer under their

bus address and execute the transferred commands, e.g. sending

measured values, calibration data, relay states.

Note

The RS 485 interface that accompanies the RT RS instrument versions

is described in detail in a separate manual.

PROFIBUS connection The monitor can be connected to a PROFIBUS DP network via the

RS 485 interface with the PROFIBUS converter PKV 30-DPS that is

available as an accessory.

1.3 Nameplate

Fig. 1-2 Nameplate (example)

The nameplate also includes the serial number as well as details of the

supply voltage and the installed instrument options. The nameplate is

located on the right side of the housing.

Ser.-Nr: xxxxxxxxx

230 VAC 50/60Hz 18VA

WTW

Oxi 4000-RT-RS

Instrument options

Overview Oxi 4000

78

ba75750e01 07/2008

Oxi 4000 Safety instructions

79

ba75750e01 07/2008

2 Safety instructions

This operating manual contains essential instructions that must be

followed during the commissioning, operation and maintenance of the

Oxi 4000 monitor. Thus, it is essential for the operator to read this

component operating manual before carrying out any work with the

system. Always keep this operating manual available close to the

Oxi 4000 monitor.

General safety

instructions

Safety instructions in this operating manual are indicated by the

warning symbol (triangle) in the left column. The signal word (e.g.

"'CAUTION") indicates the severity of the danger:

WARNING

indicates instructions that must be followed precisely in order to

prevent serious danger to personnel.

CAUTION

indicates instructions that must be followed precisely in order to

avoid slight injury to personnel or damage to the instrument or the

environment.

Other labels

Note

This symbol indicates instructions that describe special features.

Note

This symbol indicates cross-references to other documents, e.g.

component operating manuals.

2.1 User qualification

Target group The Oxi 4000 monitor has been developed for online analysis. Some

maintenance activities, e.g. changing the electrolytes of the oxygen

sensor, require the safe handling of chemicals. Thus, we assume that

the maintenance personnel is familiar with the necessary precautions

to take when dealing with chemicals as a result of their professional

training and experience.

Safety instructions Oxi 4000

80

ba75750e01 07/2008

Special user

qualifications

The following installation activities may only be performed by a

qualified electrician:

z Connection of the Oxi 4000 monitor to the mains supply.

z Connection of external, mains voltage conducting power circuits to

the Oxi 4000 monitor.

2.2 Authorized use

The authorized use of the Oxi 4000 monitor consists solely in the use

as part of a measuring system for measuring the oxygen content in

drinking water and similar media.

Read the technical specifications in accordance with chapter

7T

ECHNICAL DATA. Only the operation and use according to the

instructions in this operating manual is authorized.

Any other use is considered as unauthorized. Unauthorized use

invalidates any claims with regard to the guarantee.

2.3 General safety instructions

The Oxi 4000 monitor is manufactured and tested in accordance with

the relevant guidelines and standards for electronic instruments (see

chapter 7 T

ECHNICAL DATA). It left the factory in perfect condition.

Function and

operational safety

The flawless functioning of theOxi 4000 monitor is only guaranteed if

attention is paid to the generally accepted safety measures and the

special safety instructions in this operating manual during use.

The flawless functioning and operating safety of the Oxi 4000 monitor

is only guaranteed under the ambient conditions specified in chapter

7T

ECHNICAL DATA.

Oxi 4000 Safety instructions

81

ba75750e01 07/2008

Safe operation Assuming that risk-free operation is no longer possible, take the

Oxi 4000 monitor out of operation and secure it against unintentional

operation.

Risk-free operation is no longer possible if the Oxi 4000 monitor:

z has been damaged in transport

z has been stored under adverse conditions for a lengthy period of

time

z is visibly damaged

z no longer operates as described in this manual.

If in doubt, contact the supplier of the Oxi 4000 monitor.

Safety instructions Oxi 4000

82

ba75750e01 07/2008

Oxi 4000 Installation

83

ba75750e01 07/2008

3 Installation

3.1 Onsite installation: General instructions

z The measurement location must meet the environmental conditions

specified in chapter 7 T

ECHNICAL DATA.

z Pay attention to the following points for outdoor installations:

– Always protect instruments installed outdoors against rough

weather conditions with a protective cover.

– Close the housing cover after installation to ensure tightness

(IP 66).

– Also seal all non-required cable glands with the associated

dummy plugs.

Installation Oxi 4000

84

ba75750e01 07/2008

3.2 Electrical terminal strip

Fig. 3-1 Oxi 4000 terminal strip inside the housing

Terminal connections

-+-

ih

g

f

e

d

cba

Rec2

L1N

K2

K1

RS

Option

Sensor/Probe

Rec1

Netz

Mains

c

Option

ba

+

X2

X1

13 12 11 1110 109

9

8

8

7

7

6

6

5

5

4

4

332211

43

X3

21

Sensor/Probe

No. X1 X2

1 RS 485 A (RS option) Current output REC1+

2 RS 485 B (RS option) Current output REC1-

3 RS 485 GND (RS option) Current output REC2+

(RT option)

4 - Current output REC2-

(RT option)

5 --

6 Relay K1 (RT option) -

7 Relay K1 (RT option) -

8 Relay K2 (RT option) -

9 Relay K2 (RT option) -

10 N (mains) -

11 L1 (mains) -

12 --

13 --

No. X3

1 Temperature sensor

2 Temperature sensor

3 Cathode sensor

4 Anode sensor

Oxi 4000 Installation

85

ba75750e01 07/2008

3.3 Electrical connection

3.3.1 General installation instructions

Pay attention to the following points when connecting cable wires to the

terminal strip:

z Shorten all the wires to be used to the length required for the

installation

z Fit all wires with wire sleeves before connecting to the terminal strip

z Cut off any wires that are not used and project into the housing as

close as possible to the cable gland

z Seal all open cable glands with matching blind plugs.

WARNING

Free wires must not protrude into the housing of the Oxi 4000 .

Danger of short-circuit and fire! Touch-proof circuits can also

come into contact with dangerous voltages if touched and lead to

life threatening situations when working with the Oxi 4000 .

Always cut off any wires that are not in use as closely as possible

to the cable gland.

Installation Oxi 4000

86

ba75750e01 07/2008

3.3.2 Line power connection

WARNING

If the power supply is connected incorrectly, it may represent a

danger to life from electric shock. Pay attention to the following

points during installation:

z The monitor must only be connected by an electrician.

z The monitor must only be connected in a voltage-free

condition.

z The power supply must fulfill the specifications given on the

nameplate and in chapter 7 T

ECHNICAL DATA.

z A switch or circuit breaker must be provided in the building

installation as an interrupt facility for the monitor. The interrupt

facility must be

– installed close to the monitor and easy to reach by the user

and

– marked as an interrupt facility for the monitor.

z The monitor must only be opened after the installation if the

mains voltage has been switched off beforehand.

The instruments are designed for 230 or 115 VAC depending on the

version. The correct voltage can be found on the nameplate (see

section 1.3 N

AMEPLATE). In all cases check that the correct mains

voltage is present prior to installing the instrument.

Oxi 4000 Installation

87

ba75750e01 07/2008

3.3.3 Relay contacts and current outputs

WARNING

If external electrical circuits that are subject to the danger of

physical contact are incorrectly connected to the relay contacts,

there may be a danger of life threatening electric shock. Electrical

circuits are regarded to be subject to the danger of physical

contact when there are voltages higher than the Safety Extra Low

Voltage (SELV).

Pay attention to the following points during installation:

z Electrical circuits subject to the danger of physical contact

must only be connected by a qualified electrician.

z Electrical circuits subject to the danger of physical contact

must only be connected when they are voltage-free.

z Switching voltages and switching currents on the relay

contacts must not exceed the values specified in chapter

7T

ECHNICAL DATA. Protect electrical circuits against currents

that are too high with an electrical fuse.

z After the monitor has been installed, it may only be opened if

the mains voltage and all external voltages have been switched

off beforehand.

An overview of the relay and current outputs of the individual

instrument versions can be found in section 1.2 O

UTPUTS AND

INTERFACES. The configuration and parameterization is described in

sections 4.4 to 4.5.

3.3.4 RS 485 digital interface (RS option)

Note

The connection of the monitor to other instruments via the RS 485

interface is described in detail in a separate manual that accompanies

the RT RS instrument versions.

Installation Oxi 4000

88

ba75750e01 07/2008

3.3.5 Connecting the oxygen sensor

The open wire ends of the sensor connection cable must be connected

to the terminal strip inside the monitor for connection of the oxygen

sensor:

Fig. 3-2 Sensor connection of Oxi 4000

-+-

ih

g

f

e

d

cba

Rec2

L1N

K2

K1

RS

Option

Sensor/Probe

Rec1

Netz

Mains

c

Option

ba

+

X2

X1

13 12 11 1110 109

9

8

8

7

7

6

6

5

5

4

4

332211

43

X3

21

Sensor/Probe

* Insulate yellow and gray wires and fix to

the other wires with a cable tie, for example

Oxygen sensor

wire color

X3 terminal strip

connection

Brown 1

Green 2

White 3

Shield 4

Yellow - *

Gray - *

Oxi ML 41

Oxi 4000 Operation

89

ba75750e01 07/2008

4 Operation

4.1 Display

Display elements

1 Upper display line:

Measured oxygen value, operator guidance

2 Lower display line:

Measured temperature value, operator guidance

3 Status displays, depending on instrument status

and operating situation

Sal

%

mg/l

Sal

O

8

8

88

1

°

C

Oxi

Cal

AR

Ident

Auto

REL2

Baud

REL1

S

8 8 8

1

2

3

Oxi 4000

Operation Oxi 4000

90

ba75750e01 07/2008

4.2 Operating keys

The monitor is operated via the following six keys below the display:

Key functions

Key Function

Call up measuring mode

<M>

Start the calibration (only active in measuring mode)

<C>

In measuring mode: Show sensor slope

Confirm current selection

<ENTER>

Leave the menu

<ESC>

Increase the value,

scroll upwards in the selection,

or navigate one menu level upwards

<UP>

Decrease the value,

scroll downwards in the selection,

or navigate one menu level downwards

<DOWN>

/