Page is loading ...

INSTALLATIONGUIDELINESFORVINYLPLANKANDTILE

TABLEOFCONTENTSSECTION:

1. TESTBEFORESTARTINGINSTALLATIONS

2. MATERIALSTORAGEANDHANDLING

3. SUBSTRATES

4. SHAWADHESIVES

5. INSTALLINGRESILIENTTILE&PLANKPRODUCTS

6. ARRAYGROUT

7. WARRANTY

1.TESTBEFORESTARTINGINSTALLATION

Note:Allsubstratestoreceivemoisturesensitivefloorcoveringmustbetestedformoisture.

CONCRETESUBSTRATES:

AllconcretesubstratesshouldbetestedforIRH(InternalRelativeHumidity)accordingtoASTMF2170.

CalciumChloridetestsmaybeconductedinadditiontoIRHandmustbeperformedperthelatesteditionofASTMF1869.

NEWANDEXISTINGCONCRETESUBFLOORSSHOULDMEETTHEGUIDELINESOFTHELATESTEDITIONOFACI302ANDASTMF710,“STANDARD

PRACTICEFORPREPARINGCONCRETEFLOORSTORECEIVERESILIENTFLOORING”AVAILABLEFROMTHEAMERICANSOCIETYFORTESTINGAND

MATERIALS,100BARRHARBORDRIVE,WESTCONSHOHOCKEN,PA19428;610‐832‐9585;HTTP://WWW.ASTM.ORG.

a. Substratesshallbesmooth,structurallysound,permanentlydry,cleanandfreeofallforeignmaterialsuchasdust,wax,solvents,paint,

grease,oils,oldadhesiveresidue,curingandhardening/curingcompounds,sealersandotherforeignmaterialthatmightprevent

adhesivebond.

b. Concretefloorsshallbeflatandsmoothwithin

1/8"in6feetor3/16”in10feet.

c. F‐NumberSystem:OverallvaluesofFF36/FL20maybeappropriateforresilientfloorcoverings.

d. ASTMF2170IRH(InternalRelativeHumidity)arerequiredfortheShawwarranty.Threetestsmustbeconductedforareasupto

1000SF,

andoneadditionaltest,foreachadditional1000SF.

e. MoistureVaporEmission Rate(MVER)

• 200&KwikflashAdhesive‐maynotexceed85%RH.

• S150&4100Adhesive‐maynotexceed90%RH.

f. UseonlyPortlandbasedpatchingandlevelingcompounds.DonotinstallShawresilient

flooringovergypsumbasedpatchingand/or

levelingcompounds.

g. PerformBondtestingtodeterminecompatibilityofadhesivetothesubstrate.Shaw9050primercanbeutilizedtopromoteadhesion.

h. Workingandopentimesofadhesivesmayvarybasedonjobconditions,substrate,temperature,andhumidity.

i. Areastoreceive

flooringshouldbeadequatelylightedduringallphasesoftheinstallationprocess.

j. Itisrecommendedthatresilientfloorcoveringinstallationshallnotbeginuntilallothertradeshavecompleted.

TEMPERATURE‐AMBIENT:

a. Controlledenvironmentsarecritical.FullyfunctionalHVACsystemsarethebestwaytoensuretemperatureandhumidity

control.

• DONOTinstallresilientflooringproductsuntiltheworkareacanbetemperaturecontrolled.

• ThepermanentHVACsystemturnedonandsettoaminimumof65°F(20°C)oramaximumof85°F,foraminimumof7days

priorto,during,andafterinstallation.Oncetheinstallation

iscompletethe temperatureshouldnotexceed85°F.

PH:

a. ConcretefloorsmustbetestedperthelatesteditionofASTMF710.

PHreadingmustnotexceed9.0.

Readingsbelow5.0andinexcessof9.0affectresilientflooringandadhesivesnegatively.

Rinsingthesurfacewith

clearwatermayloweralkalinity.“DAMPMOP”

Shaw9050anacrylicsolutioncanbeutilizedtocorrecthighPHreadings.

NOTE:ITMAYNOTBETHEFLOORCOVERINGINSTALLER’SRESPONSIBILITYTOCONDUCTTHESETESTS.ITIS,HOWEVER,THEFLOORCOVERING

INSTALLER’SRESPONSIBILITYTOMAKESURETHESETESTSHAVEBEENCONDUCTED,ANDTHATTHERESULTSAREACCEPTABLEPRIORTO

INSTALLINGTHEFLOORCOVERING.WHENMOISTURETESTSARECONDUCTED,ITINDICATESTHECONDITIONS

ONLYATTHETIMEOFTHETEST.

2.MATERIALSTORAGEANDHANDLING:

a. Flooringmaterialandadhesivemustbeacclimatedtotheinstallationareaforaminimumof48hours priortoinstallation.

b. Storecartonsoftileorplankproductsflatandsquarelyontopofoneanother.Tile

orplankproductsshouldbestackednomorethan6

highandallowforairflowaroundstackswhenun‐palletized.Preferably,locatematerialinthe“center”oftheinstallationarea(i.e.away

fromvents,directsunlight,etc.)Storingcartonsindirectsunlightmayaffectproperacclimationbyinducingthermal

expansion/contraction.

c. Whenpalletizingonajobsitevinylplankortilesneedtobestacked2rowshighsidebysidewithnoairspacebetween.Thenquarter

turnedfor2rowssidebyside,nottoexceed12boxeshigh.A5/8”orthickerplywoodmustalsobeplacedonthe

palletfirst.

d. Donotstackpallet’s2highunlessutilizinga1”thickplywoodinbetweenpallets.

3.SUBSTRATES:

Note:Allsubstratestoreceiveresilientflooringshallbedry,clean,smoothandstructurallysound.Theyshallbefreeofdust,solvent,paint,

wax,oil,grease,residualadhesive,adhesiveremovers,curing,sealing,hardening/partingcompounds,alkalinesalts,excessive

carbonation/laitance,mold,mildew,andotherforeignmaterialsthatmightpreventtheadhesive

frombonding.

WOODSUBSTRATES:

Woodsubfloorsmustbestructurallysoundandincompliancewithlocalbuildingcodes.

a. Double‐LayeredAPAratedplywoodsubfloorsshouldbeaminimum1"totalthickness,withatleast18"wellventilatedairspacebeneath.

b. Insulateandprotectcrawlspaceswithavaporbarriercoveringtheground.

c. DONOTinstalloversleeperconstructionsubfloorsorwoodsubfloorsapplieddirectlyoverconcrete.

d. Underlaymentpanelscanonlycorrectminordeficienciesinthesub‐floorwhileprovidingasmooth,soundsurfaceonwhichtoadherethe

resilientflooring.

e. Anyfailuresintheperformanceoftheunderlaymentpanel

restwiththepanelmanufacturerandnotwithShawIndustries,Inc.

f. ItisrecommendedthatyourchosenAPAunderlaymentgradepanelsbedesignedforinstallationunderresilientflooring,andcarrya

writtenwarrantycoveringreplacementoftheentireflooringsystem.

g. SHAWresilientflooringisnotrecommendeddirectlyoverfire

‐retardanttreatedplywoodorpreservativetreatedplywood.

h. Thematerialsusedtotreattheplywoodmaycauseproblemswithadhesivebonding.AnadditionallayerofAPArated1/4"thick

underlaymentshouldbeinstalled.

i. Alwaysfollowtheunderlaymentmanufacturer’sinstallationinstructions.

STRIP–PLANKWOODFLOORING:

Duetoexpansion/contractionofindividualboardsduringseasonalchanges,SHAWrecommends1/4"orthickerAPAratedunderlaymentpanelsbe

installedoverthesetypesofsubfloors.

CONCRETE:

NeworexistingconcretesubfloorsmustmeettheguidelinesofthelatesteditionofACI302andASTMF710,“StandardPracticeforPreparing

ConcreteFloorstoReceiveResilientFlooring”.

a. Onorbelow‐gradeslabsmusthaveaneffectivevaporretarderdirectlyundertheslab.

b. Wetcuring7

daysisthepreferredmethodforcuringnewconcrete.

c. Curingcompounds(DONOTUSE).Ifpresenttheycaninterferewiththebondoftheadhesivetotheconcrete.Seekassistancefroma

substratemanufacturerifcuringagentsaredetected.

d. Removecuringcompounds28daysafterplacement,soconcrete

canbegindrying.

e. Concretefloorsshallbeflatandsmoothwithin1/8"in6feetor3/16”in10feet.

f. F‐NumberSystem:OverallvaluesofFF36/FL20maybeappropriateforresilientfloorcoverings.

g. AdhesiveMoisturevaporemissionmaynotexceed87%RH(Shaw4100)

or90%(ShawS150).

Note:PerformBondtestingtodeterminecompatibilityofadhesivetothesubstrate.Shaw9050primercanbeutilizedtopromoteadhesion.

Expansionjointsinconcretearedesignedtoallowfortheexpansionandcontractionoftheconcrete.Resilientflooringproductsshouldneverbe

installedoverexpansion

joints.Expansionjointcoversdesignedforusewithresilientflooringsshouldbeused.Controljoints(sawcuts)maybe

patchedandcoveredwithresilientoncetheconcreteisthoroughlycured,dryandacclimated.

LIGHTWEIGHTCONCRETE

Allrecommendationsandguaranteesastothesuitabilityandperformanceoflightweightconcreteunderresilientflooringaretheresponsibilityof

thelightweightconcretemanufacturer.Theinstallerofthelightweightproductmayberequiredtobeauthorizedorcertifiedbythemanufacturer.

Correcton‐sitemixingratiosandproperlyfunctioning

pumpingequipmentarecritical.Toensurepropermixture,slumptestingisrecommended.

a. Lightweightaggregateconcreteshavingdensitiesgreaterthan90lbs.percubicfootmaybeacceptableunderresilientflooring.

b. Concreteslabswithheavystaticand/ordynamicloadsshouldbedesignedwithhigherstrengthsanddensitiestosupport

suchloads.

c. Surfacemustbepermanentlydry,clean,andsmooth,freeofalldust,andstructurallysound.

d. PerformBondtestingtodeterminecompatibilityofadhesivetothesubstrate.Shaw9050primercanbeutilizedtopromoteadhesion.

RadiantHeat:HydronicOnly

Radiantheatedsubstratesmustnotexceed85°F(29°C)surfacetemperature.

a. Sevendayspriortoinstallingresilientproductsovernewlyconstructedradiantheatedsystems,makesuretheradiantsystemhasbeen

onandoperatingatmaximumtemperaturetoreduceresidualmoisturewithintheconcrete.

b. Threedays

priortoinstallationlowerthetemperatureto65°F.24hoursafterinstallation,graduallyincreasethetemperaturein

incrementsof5°Ftoavoidoverheating.

c. Aftercontinuousoperationoftheradiantsystem,ensurethesurfaceofthefloordoesnotexceed85°F(29°C)

d. Useofanin‐floortemperaturesensor

isrecommendedtoavoidoverheating.

WARNING!DONOTSAND,DRYSWEEP,DRYSCRAPE,DRILL,SAW,BEADBLASTORMECHANICALLYCHIPORPULVERIZEEXISTINGRESILIENT

FLOORING,BACKING,LININGFELT,ASPHALTIC“CUTBACK”ADHESIVESOROTHERADHESIVES.Theseproductsmaycontaineitherasbestosfibers

and/orcrystallinesilica.Avoidcreatingdust.Inhalationofsuchdustisacancerandrespiratorytracthazard.Smokingbyindividualsexposedto

asbestosfibersgreatlyincreasestheriskofserious bodilyharm.Unlesspositivelycertainthattheproductisanon‐asbestos‐containingmaterial,

youmustpresumeitcontainsasbestos.Regulationsmayrequirethatthematerialbetestedtodetermineasbestoscontentandmaygovernthe

removalanddisposalofmaterial.SeecurrenteditionoftheResilientFloorCovering Institute(RFCI)publicationRecommendedWorkPracticesfor

RemovalofResilientFloorCoveringsfordetailedinformationandinstructionsonremovingallresilientcoveringstructures.Forcurrent

informationgotowww.rfci.com

RESILIENTFLOORCOVERING:

a. Mustbesinglelayered,non‐cushionbacked,fullyadhered,andsmooth.

b. Shownosignsofmoistureoralkalinity.

c. Waxes,polishes,grease,grime,andoilmustberemoved.

d. Cuts,cracks,gouges,dentsandotherirregularitiesintheexistingfloorcoveringmustberepairedorreplaced.

e. Embossinglevelerrecommendedtoaidinproperbondingandtopreventtelegraphing.

f. Donotinstalloverrubberbasedsubstrates.

NOTE:THERESPONSIBILITYOFDETERMININGIFTHEEXISTINGFLOORINGISSUITABLETOBEINSTALLEDOVERTOPOFWITHRESILIENT,RESTS

SOLELYWITHINSTALLER/FLOORINGCONTRACTORONSITE.IFTHEREISANYDOUBTASTOSUITABILITY,THEEXISTINGFLOORINGSHOULDBE

REMOVED,ORANACCEPTABLEUNDERLAYMENTINSTALLEDOVERIT.INSTALLATIONSOVEREXISTINGRESILIENT

FLOORINGMAYBEMORE

SUSCEPTIBLETOINDENTATION.

QuarryTile,Terrazzo,CeramicTile,PouredFloors(Epoxy,Polymeric,Seamless):

a. Mustbetotallycuredandwellbondedtotheconcrete.

b. Mustbefreeofanyresidualsolventsandpetroleumderivatives.

c. Waxes,polishes,grease,grime,andoilmustberemoved.

d. Shownosignsofmoistureoralkalinity.

e.

Cuts,cracks,gouges,dents,andotherirregularitiesintheexistingfloorcoveringmustberepairedorreplaced.

f. Fillanylowspots,holes,chipsandseamsthatmaytelegraphthroughthenewflooring.

g. Grindanyhighlypolishedorirregular/smoothsurfaces.

QuarrytileorCeramictilegroutjointsandtextured

surfacesmustbefilledwithanembossinglevelerorsubstratemanufacturer

approvedmaterial.

OldAdhesiveResidue:

a. Iftheadhesiveresidueisasphalt‐based(cut‐back),oranyothertypeofadhesiveispresent,itmustbedealtwithinoneoftwoways:

1. Itmaybemechanicallyremovedsuchas:beadblastingorscarifying

2. Aself‐levelingPortlandbasedunderlaymentmay

beappliedoverit.Checkwithasubstratemanufacturerforsuitability,

applicationinstructions,andwarranties.

b. Neverusesolventsorcitrusadhesiveremoverstoremoveoldadhesiveresidue.Solventresidueleftin/onthesub‐floormayaffectthe

newadhesiveandfloorcovering.

WARNING:SKIMCOATINGOVEROLDADHESIVEISNOTRECOMMENDED.THEADHESIVEMAYBREAKDOWNANDCOULDLEADTOFAILURE.THE

OLDADHESIVEMAYNOTALLOWTHERESILIENTFLOORINGTORETAINITSDIMENSIONALSTABILITY,POSSIBLYLEADINGTOUNNECESSARY

INDENTATIONS.SOMESOLVENTBASED‘CUT‐BACK’ASPHALT‐BASEDADHESIVESMAYCONTAINASBESTOSFIBERSTHAT

ARENOTREADILY

IDENTIFIABLE.DONOTUSEPOWERDEVICES,WHICHCANCREATEASBESTOSDUSTINREMOVINGTHESEADHESIVES.THEINHALATIONOF

ASBESTOSDUSTMAYCAUSEASBESTOSISOROTHERSERIOUSBODILYHARM.

4.SHAWADHESIVES&PRIMER

Refertoadhesivelabelforpropertrowelrequirements,spreadratesandapplication.

Priortoapplicationofadhesivedetermineifthesubstrateisaporousornon‐poroussubstrate.Followinstructionsontheadhesivelabelforporous

ornon‐poroussubfloor.

IMPORTANT:Recommendedtoperformabondtestinordertodetermineadhesiveworkingtimeperjobsiteconditions.Thestrengthofthe

bondtest

willindicatewhetherShaw9050floorprimerisnecessary.

5.INSTALLINGRESILIENTTILE&PLANKPRODUCTS

General:

a. Ensurethatmoisturetestshavebeenconductedandthattheresultsdonotexceedtheacceptablemoisturelimitfortheadhesiveused.

b. PHofconcretesub‐floorneedstobebetween5&9.

c. ThepermanentHVACsystemisturnedonandsettoaminimumof65°F(20°C))oramaximumof85°F,foraminimumof72hoursprior

to,duringandafterinstallation.Aftertheinstallations,themaximumtemperatureshouldnotexceed85°F.

d. Donotstackmorethan

5cartonshigh.

e. Flooringmaterialandadhesivemustbeacclimatedtotheinstallationareaforaminimumof48hourspriortoinstallation.

f. UseappropriatetrowelsizeregardingsubstrateporosityunlessusingS150SprayAdhesivewherenotrowelisrequired.

g. Materialshouldalwaysbevisuallyinspectedpriorto

installation.Anymaterialinstalledwithvisualdefectswillnotbeconsidereda

legitimateclaimasitpertainstolaborcost.

h. Installtilesrunninginsamedirection.

i. Ensurethatallrecommendationsforsub‐floorandjobsiteconditionsaremetpriortobeginning theinstallation.Directionaldesignsare

optional,however,

oncetheinstallationisstarted,youhaveacceptedthoseconditions.

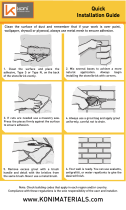

LAYOUTANDINSTALLATIONGENERALRULES:

a. Shawtileandplank‐Installusingconventionaltileandplankinstallationtechniques.Plankproductsshouldhaveaminimumof6–8"

seamstagger.

b. Carefullydeterminewheretobegintileorplankinstallation.

c. Itiscustomarytocenterroomsandhallwayssobordersarenotlessthanhalfatileorplank.

d. Workingoutofmultipleboxes atatimeisrecommended.

e. Inhallwaysand smallspaces,itmaybesimplertoworklengthwisefromoneendusingacenterreference

lineasaguide.

f. Makesurecutedgesarealwaysagainstthewall.

g. ToproperlycutLVT/LVPproductsscorethetopsideofthematerialwithautilityknife.Bendtheproductandfinishthecutthroughthe

backside.Thiswillensurethecleanestcut.Itmaybe

necessarytouseaheatguntocutaroundverticalobstructions.Allowtheheated

LVT/LVPtoreturntoroomtemperaturebeforeinstallation.

h. Cuttingtheproductintoafinepointmayleadtodelamination. UseanethylcyanoacrylatebasedsupergluetohelpfusetheLVT/LVP

pointtogether.Besureto

cleanallgluefromthetopsurfaceimmediately.Alcoholbasedsupergluesmaycausevinyltoswell.

NOTE:Recommendedtousefloorprotectionafterinstallation.DONOTuseaplasticadhesivebasedprotectionsystem.

INSTALLATIONFORTILE:

LayoutoftheRoomforSquarelyLaidFields

Tosquaretheareato

becovered,firstfindthecenterofoneendofthemainrectangle.Locatethesamepointatthe

otherendwall.Snapachalklinebetweenthesepointstomarkthecenterlineonthefloor.Thenmeasurealongthis

centerlinetofindthemiddle oftheroom.

Atthecenterpoint,markoffalineacrossthe roomatexactlyrightangles

tothefirstline.Thismaybeaccomplishedbythe3‐4‐5‐trianglemethodasshowninFigure 1 .Thenmeasure4feet

towardeachsidewallfromthecenterpoint.Thenmeasure3

feetfromthecenterpointalong thelongerline,

measureexactly5feetfromthe3footmarkonthecenterlinetothe4footmarkonthecrossline.Ifthe5foot

Fi

g

ure1

measurementsdonotcomeoutexactly5feet,thecentercrossinglinesarenotatatruerightangle.Forlargerooms,

multiplesoftheabovedimensionsmaybeusedtoobtaingreateraccuracy.(6‐8‐10or9‐12‐15,etc.)

Dry‐layarowoftilesfromthecenter

linetothesidewalltodeterminethespaceleftfortheborders.Iftheresulting

borderistoosmall,movethestartingpointoverahalftilewidthsothatitstraddlesthecenterline.

Repeatthesameprocedurelengthwiseofthe room.(Thiscanreadilybefiguredout

fromtheroomdimensions

withoutputtingdownthetilesifdesired.)

Figure2

Ifitisdecidedtohavethecenterrowoftilesstraddleeitherorbothofthecenterlines,additionalguidelinesshouldbesnappedonthefloor½tiles

widthononesideofeitherorbothcenterlinesasrequired.(SeeFigure2)Aftertheborderwidthshavebeendeterminedandthecenterstarting

lineshavebeensnappedspreadtherecommendedadhesiveonthecenterlinesleavingportionsofthelinesatcenterandneareachwall

uncoveredasshowninFigure3.

Spreadtheadhesiveoverone‐halftheareaandafteritisready,startlayingtilefromtherightangleformedinthe

centeroftheroombycenterlines.

Laytowardthetwocornersoftheroomas shown.Alwaysrefertoyourguidelinesasyouprogresswithlayingtile

sothat

anymistakecanbecorrectedbeforeitistoolate .

Sometimesit’snecessarytocompromiseontherightnessofjointstomakeallowancesforunevennessorwavesof

thesubfloor.

Takecaretoplacetileasaccuratelyaspossiblewithoutslidingthemintoplace.Ifgroutingtilepleaseleave

appropriatespacer

betweentilesandfollowinstructionforuseofArray‐Grout.

IMPORTANT:Allflooringmustbyrolledwithaminimum100‐lbrollerafterinstallation.Useahandrollerinareasnotreachedwitha100‐lb.

roller.

VERSAILLESPATTERNTILES:

TheVersaillesPattern(Frenchpattern).Properinstallationandlayoutisimportant.Thematerialmusthaveagroutlineof3mmforproper

placement.Useof3mmspacersisrequiredtoachievepropergroutlinesizeandtoensurethetilesarespacedevenly.

a. Thepatterniscomposedof

‐44%16"x16"tiles

‐33%16"x24"

tiles

‐11%8"x16"tiles

‐11%8"x8"tiles

b. Instructions–Usea3mmspacertoseparatethetilesasthepatternisconstructed.

c. Placeone8‐inchby8‐inchtileinthecenter.

d. Positiontwo16‐inchby16‐inchtileswithone

abovewheretherightedgeofthelargertileisflushwiththe

rightedgeofthesmallertile,andonetotheleftsothatthetopedgeofthesecondlargertileisflushwiththe

topedgeofthesmallertile.

e. Placeone 8‐inchby

16‐inchtileonthebottomofthesectionsothatthe8‐inchedgepressesagainstthe16‐inchsquaretileandhalfof

the16‐inchedgeispressedagainstthebaseedgeofthesquaretile.

f. Placea16‐inchby24‐inchtileinthecorner

createdbytherectangulartilefromStep3and thesquaretilefromStep1sothatthe16‐inch

edgerunshorizontally,extendingouttotherightofthestructure.

g. Positiona16‐inchby16‐inchtileimmediatelybelowthe16‐inchby24‐inchtileso

thattheleftedgeof thesquaretileispressedagainst

theshortedgeoftherectangulartile.

h. Laya16‐inchby24‐inchtilewiththe24‐inchsiderunninghorizontallyimmediatelytotheleftofthetilefromandpressedagainstthe

baseoftherectangulartile

andhalfofthebaseofthefirst16‐inchsquaretile.

i. Placean8‐inchsquaretileagainstthelasthalfofthebaseofthefirst16‐inchtileandagainsttheleftedgeofthe16‐inchby24‐inchtile.

j. Placean8‐inch

squaretileimmediatelyabovethefirst16‐inchsquaretilewitha16‐inchsquaretilerightabovethe8‐inchtile.

k. Positionan8‐inchby16‐inchtilewiththe16‐inchedgepressedagainstthe8‐inchsquaretileandtheoriginal16‐inchsquaretile.

l. Positionthelasttile,an8‐inchsquaretile,sothattherightedgeisflushwiththerightedgeofthetop‐right16‐inchby24‐inchtile.The8‐

inchtilemustbeontopofthe largerectanglewiththerightedgesflushtocompletethe

overalldesign.

6.ARRAYGROUT:

Array‐Grout,withauniqueformula,offersstainresistancecolorconsistencyandasmoothtextureforeasyspreadingandclean‐up.

a. ForGroutingShawgroutabletiles.Canalsobeusedonvitreous,semi‐vitreousorabsorptivetileincludingceramic,mosaic,quarry,

cement,porcelain,brick,

mini‐brick,precastterrazzoandnaturalstone.

b. Stainresistant,premixed,noshadevariance,resistsmoldandmildew.

c. Useonfloors,countertops,walls,andceilings.

Figure3

d. Forinteriorinstallationsonly.

COVERAGE:

a. 1/16“Groutjointapproximately500sqft/gallon.

b. 1/8“Groutjointapproximately300sqft/gallon.

c. 1/4“Groutjointapproximately140sqft/gallon.

LIMITATIONS:

a. ShawArray‐Groutshouldnotbeinstalled,whenambienttemperatureisbelow60°Fandabove90°F.ShawArray‐Groutshould

bekept

atroomtemperaturefor24hoursbeforeinstallation.

b. Sometypesofglazedceramictile,marbleandstonecanbescratched,stainedordamagedwhengroutedwithpigmentedorsanded

grouts.Generallywhitegroutisbestsuitedforgroutingwhiteorlightcoloredmarbleorgranite.Followtile

manufacturer’s

recommendations.Testasmallareapriortouse.Certaintilewithhighabsorption,surfaceporosityorroughtexturedsurfacesand

certaintypesofporcelainmayrequiresealingpriortogroutingtopreventstaining.

SURFACEPREPARATION:

a. Tilemustbefirmlyattachedtoasoundsubstrateandsettingmaterialmustbe

curedforaminimumof24‐48hoursbeforegrouting.

b. Removeallspacers.Groutjointsshouldbeuniformindepthandwidthandfreeofallloosedebris,contaminantsandexcessmortaror

adhesive.

APPLICATION:

Newinstallation:

a. Beforegrouting,soakthegroutspongeinapailofcleancoolwaterandthoroughly wringout.

b. Usethedampenedspongeandlightlywipethetilesurfaceinanareanolargerthan5‐10sq.ft.Aslightlywettilesurfaceallowsthe

grouttoglideeasilyoverthetileandintothegroutjointwhileprovidingforeasier

cleanup.

c. Whiletileisstilldamp,dispensealiberalamountofgroutontothetilesurface.

d. Usingthegroutfloat,pressthegroutintothegroutjointsoverthedampenedareaapplygroutonnomorethan5‐10sq.ft.atatimeto

allowforpromptcleaning;

delayedcleaningmaycausesomecracking.

e. Placethe groutfloatonedgeata45°angleandrakethefloatdiagonallyacrossthetilesurfacewhileexertingadownwardpressure.This

willforcethegroutevenlyintothegroutjoints.

f. Immediatelyremoveallexcessgroutfromthe

tilesurfacebyholdingthegroutflatata90°angletothetileanddrawingitdiagonally

acrossthetile.

g. Cleanbysoakinggroutspongeincleancoolwater .Wringoutexcesswatercompletely.

h. Usedampenedspongeinacircularmotiontosmoothgroutjointsandclean

offanyremainingexcessgrout.

i. Continue rinsingofspongeinclean,coolwaterwillaidincleanup.

j. Avoidexcesswateringroutjoints.Forfinalcleaning/hazeremoval,allowgrouttocurefor24hours.Useadampenedsponge,thensoft

clothtopolishoffresidue.

Repairexistinggrout:

a. Removeexistingoldgroutwithagroutsaw1/8”belowthesurfaceofexistingtile,Sweeporvacuumdustanddebrisfromsurfaceoftile

andgroutjoints.

b. ShawArray‐Groutcanbeapplieddirectlyoveroldgrout.Applyenoughtototallycovertheoldgrout.Followdirectionsfor

new

installationasshownabove.

CLEANUP:

Cleantoolsandhandswithcoldwaterbeforematerialdries.

CARE&MAINTENANCE:

MoldandMildewcangrowondirt,food,andsoapscumthatcanaccumulateonthegroutsurface.Routinecleaningwilllimitmoldandmildew

growth.

SAFETY:

Avoideyecontactor

prolongedcontactwithskin.Washthoroughlyafterhandling.Ifeyecontactoccurs,flushwithwaterfor15minutesand

consultaphysician.

INSTALLATIONFORVINYLPLANKS:

LayoutoftheRoom:

a. Findthecenterpointoftheroom.Strikealine.

b. Obtainatrue90’anglebyusing

acarpenter’ssquare.

c. Strikeasecondlinewhichwilldividetheroomintofourequalparts.

d. Measurethedistancefromthecentertothewall,paralleltothedirectionoftheplank.

e. Dividethemeasurementbythewidthoftheplank.Iflessthanhalfremainsas

theborderplank,adjustthe

pointtocompensate.Thiswillgivealargerborderalongthewallandreducethechanceofhavingtocutasmall

sliverofflooringtoplacealongthewall.

LayoutofthePlank:

a. Carefullyplacethefirstpieceofplankatthejunctionofthechalklines.

b. Continuetolaytheplank,makingsureeachplankflushagainstthechalklineandtightagainsttheadjoiningplank.

c. Makesuretheplankiswellseatedintotheadhesivepayingspecialattention,to the edges.Layrow by row, or in a pyramidfashionas

shownbelow.

FittingtheBorder:

a. Measurethedistancefromthelastplankintherowtothewall.

b. Marktheplankandcutitagainstthemark.

c. Laythe

plankinplace,makingsurethatthecutedgeisagainstthewall.

FittingAroundIrregularObjects:

a. Makeapatternoutofheavypapertofitaroundpipesandotherirregularities.

b. Placethepatternontheplank,tracecuttingalongthetracelines.

IMPORTANT:Allflooringmustbyrolledwithaminimum100‐lbrollerafterinstallation.Useahandrollerinareasnotreachedwitha100‐lb.

roller.

7.LIMITEDWARRANTY

Forcompletewarrantyinformation,pleasecall–ShawInformationCenter:1800.441.7429

Shaw Industries Group, Inc., a Berkshire Hathaway Company. Revised05/07/15

/