Page is loading ...

Advance Optima

Module Uras 14

Service Manual 43/24-1005-1 EN

SHB_U14 Contents

Table of contents

Page

Chapter 1: Description of functions 1-1

Chapter 2: Module versions 2-1

Chapter 3: Module components 3-1

Chapter 4: Troubleshooting 4-1

Chapter 5: Testing 5-1

Chapter 6: Component replacement 6-1

Chapter 7: Configuration 7-1

Chapter 8: Calibration 8-1

Attachment Parts catalog

Contents SHB_U14

Contents

Chapter 1:

Description of functions

Page

Physical principle 1-2

Determination of influence values 1-6

Ex Concept 1-7

Chapter 2:

Module versions

Summary 2-2

Module versions (principles) 2-5

Module versions ( plastic tubing connections) 2-7

Module versions (stainless steel tubing) 2-12

Ex analyzer module 2-14

Chapter 3:

Module components

Emitter 3-2

Modulator 3-3

Apertures 3-6

Sample Cell 3-7

Filter Cell 3-11

Optical Filter 3-12

Calibration Unit 3-13

Calibration Cell 3-15

Infrared detector 3-16

IR module circuit board 3-19

Sensor-CPU circuit board 3-23

Pressure sensor circuit board 3-28

Thermostat circuit board 3-29

Hood with supplement heater 3-30

Connecting cable 3-31

Fortsetzung auf der folgenden Seite

SHB_U14 Contents

Contents, Fortsetzung

Chapter 4:

Troubleshooting

Status messages 4-2

No measurement signal 4-4

Unstable measurement value reading 4-5

Zero drift / Measured value drift 4-6

Negative measured signal 4-7

Measurement signal not enough sensitive 4-8

Excessive measurement signal preparation time 4-9

Temperature error 4-10

Continued on next page

Contents SHB_U14

Contents, continued

Chapter 5:

Testing

Page

Electrical connections 5-2

IR Detector measurement signal 5-4

IR detector preamplifier 5-5

Emitter insert 5-6

Modulator with emitter circuit board 5-7

Sample cell 5-8

Thermostat temperature 5-9

Heater 5-10

Temperature sensor 5-11

Thermal link 5-12

Calibration cell 5-13

Calibration unit 5-14

Pressure sensor 5-15

IR module circuit board 5-16

Sensor –CPU circuit board 5-18

Chapter 6:

Component replacement

Summary 6-2

Remove / install Uras14 analyzer module 6-3

Change emitter insert 6-5

Change modulator 6-6

Change sample cell 6-7

Change calibration cell and calibration unit 6-9

Change infrared detector 6-10

Change IR module and Sensor –CPU circuit boards 6-11

Change thermal link 6-12

Fortsetzung auf der folgenden Seite

SHB_U14 Contents

Contents, Fortsetzung

Chapter 7:

Configuration

Hardware configuration 7-2

Software configuration with TCT 7-4

General data 7-6

IR detectors 7-8

Temperature detectors 7-31

Pressure detector 7-36

Flow detector 7-40

Calibration cell 7-45

Solenoids 7-46

Pump 7-48

Chapter 8:

Calibration

Overview 8-2

Optical Alignment 8-3

Phese Alignment 8-6

Initial Calibration of Uras 14 IR detectors 8-9

Initial Zero Calibration 8-12

Postlinearisation 8-14

Cross-sensitivity alignment 8-17

Delta Phase 8-19

Calibration Cell measurement 8-22

Pressure Detector initial calibration 8-24

Flow detector initial calibration 8-26

Temperature detector initial calibration 8-31

Attachment

Parts catalog

SDE_U14 Chapter 1: Description of functions 1-1

Chapter 1: Description of functions

Overview

This chapter ... describes the underlying physical principles and provides information on the

determination of influence values.

˝

Chapter Contents In this chapter you will find the following information:

˝

Subject See Page

Physical principle 1-2

Determination of influence values 1-6

Ex Concept 1-7

˝

1-2 Chapter 1: Description of functions

SDE_U14

Physical principles

Measurement

principle

• NDIR technique

(Nondispersive infrared analysis)

• The measurement effect is based on resonance absorption of gas-specific

vibration-rotation bands of differing atom gas molecules in the median infrared

spectrum at wavelengths between 2.5 and 8 µm.

• The individual gases to be measured are identified by their specific absorption

bands. Each gas has such an absorption spectrum (fingerprint).

Exceptions:

- Monoatomic gases, such as inert gases

- Symmetrical gases, such as N

2

, O

2

and H

2

- These types of gases cannot be measured with this method.

• The relationship between measured infrared radiation absorption and the

measurement component is based on the LAMBERT-BEER law:

A = (I0 - I1) / I0 = 1 - e

-ε(λ)⋅ρ⋅l

where

A= Absorption

I0 = Radiation entering the cell

I1 = Radiation leaving the cell

ε(λ) = Sample component extinction factor

ρ = Sample component density

l = Sample cell length

The relationship between sample component density

ρ and its volumetric

concentration c is

ρ = ρ

0

⋅ c ⋅ p/p

0

⋅ T

0

/T

where

ρ

0

= Pure gas density

p

0

= Pressure

T

0

= Temperature

under standard conditions (1013 hPa, 0°C).

The second equation shows that the sample component's volumetric

concentration depends on the sample cell pressure and temperature.

The first equation finds a non-linear relationship between absorption and

volumetric concentration.

Fortsetzung auf der folgenden Seite

SDE_U14 Chapter 1: Description of functions 1-3

Physical principles, Fortsetzung

˝

Basic design

• The Uras 14 analyzer module is a twin-beam NDIR process photometer with no

dispersive elements.

The module consists of a completely self-contained optical unit with the

following elements:

• Infrared source (emitter)

• Aperture wheel (chopper)

• Emitter aperture

• Sample cell with measurement and reference chambers

• Infrared detector with diaphragm capacitor (receiver)

Figure 1-1

Measurement

principle

CO

N

2

A

D

µP

RS232 Int.Bus

A

D

CO

Sensor-CPU

IR-Elektronic

Uras14_1

1 Emitter

2 Emitter aperture

3 Aperture wheel

4 Sample cell

5 Measurement chamber

6 Reference chamber

7 Infrared detector

8 Diaphragm capacitor

Fortsetzung auf der folgenden Seite

1-4 Chapter 1: Description of functions

SDE_U14

Physical principles, Fortsetzung

IR radiation

• Generated by broad-band emitter

• Emitted as a beam package alternately in the form of a sample and reference

beam through the sample and reference chambers of the sample cell and is

partially absorbed by the sample component molecules

• Counterphase modulation by means of a motorized aperture wheel

• Both modulated beam packages appear alternately at the infrared detector

Apertures • Created by applicable regulation of the sample and reference beam balance

Sample cell • Depending on the application, the sample chamber receives a sample, zero-point

or end-point gas flow so that a part of the infrared radiation is absorbed in a

concentration-dependent manner

˝

• The radiation passes unhindered if the reference chamber is filled with a gas that

does not absorb infrared (N

2

).

Infrared detector • A two-part transmission detector with front and rear chambers filled with the gas

components to be measured, with selectivity being determined by the infrared

detector. The two chambers are separated by an infrared-transparent window.

Additionally, the two chambers are separated by a stressed metal membrane with

counterelectrodes. This unit is known as the diaphragm capacitor.

•It reacts in the following manner in the presence of the sample component:

• IR radiation is weakened in the sample cell's sample chamber and enters the

receiver's front chamber.

• The equilibrium between the sample and reference beams initially established

by calibration and the aperture is now disturbed.

• There is an energy difference (temperature change) in the form of reduced

pressure in the front chamber.

• This pressure reduction is transformed into a capacitance change in the

membrane capacitor by deflecting the metal diaphragm.

• Since the diaphragm capacitor is connected to a high-impedance DC voltage, a

corresponding periodic AC signal is generated.

Fortsetzung auf der folgenden Seite

SDE_U14 Chapter 1: Description of functions 1-5

Physical principles, Fortsetzung

˝

Figure 1-2

Signal flow schematic

A

D

µP

RS232 Int.Bus

A

D

CO

N

2

N

2

N

2

N

2

CO

M

M

IR-Modul Sensor-CPU

p

t

R

t

t

Uras14_2

Figure 1-3

Block diagram as

fully equipped

N

2

CO

SO

2

NO

N

2

N

2

N

2

N

2

CO

SO

2

N

2

N

2

N

2

NO

CO

2

CO

2

M

M

Uras14_3

1-6 Chapter 1: Description of functions

SDE_U14

Determination of influence values

Associated gas

effects

The sample gas is a mixture of the sample component(s) and associated gas

components. If the infrared absorption bands of one or more associated gas

components overlap the sample component’s bands, the sample results will be

affected.

The influence of interfering gas components is termed cross sensitivity or carrier

gas dependence.

Cross sensitivity is determined by connecting an inert gas (e.g. N

2

) which is mixed

with the interfering gas components (corresponding to the sample gas).

The influence acts on the zero-point measurement value indication.

Carrier gas dependence, which is rarely observed. Occurs when the physical

properties of the sample gas differ markedly from those of the sample gas. This

interference changes the slope of the device’s characteristic curve. This curve is

corrected at the end-point.

The Uras 14 has the following methods available for interference correction:

• Interference filter

• Filter cells

• Internal electronic cross-sensitivity correction

• Internal electronic carrier gas correction

Pressure In accordance with the gas laws, the sample cell’s volumetric concentration

depends on the pressure in the sample cell and is thus dependent on the process

gas and air pressure. This effect acts on the end-point and amounts to approx. 1%

of the measurement value per 1% of pressure change (therefore, per 10 hPa).

An internal pressure sensor reduces this effect to 0.2%.

Flow rate The flow rate affects pressure in the sample cell and the module’s T

90

times.

The flow rate should be between 20 and 100 liters/hour.

Temperature Temperature has a markedly different effect on all optical components in the beam

path. This effect is reduced by:

either:

• Temperature compensation

A temperature sensor in the first infrared detector’s preamplifier measures the

temperature in the module.

This signal is used for electronic correction.

Zero-point effect:

≤ 1% of span per 10°C

End-point effect:

≤ 3% of measurement value per 10°C

or

• Thermostat (optional)

The temperature influence is further reduced by controlled heating of the optical

components to 55°C.

Zero-point effect:

≤ 1% of span per 10°C

End-point effect:

≤ 1% of measurement value per 10°C

˝

SDE_U14 Chapter 1: Description of functions 1-7

Ex concept

˝

Application The Uras 14-Ex analyzer module is capable of measuring non-combustible and

combustible gases under atmospheric conditions which can form an explosive

environment (Zone 1).

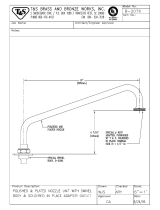

Design For use in Zone 1 and Zone 2 (combustible measurement gas) the analyzer module

is installed in a pressure-tight cylinder.

The analyzer module consists of the following components:

• Flange on which the analyzer is mounted

• Cylinder with threaded cap, the cylinder screws into threads in the flange.

All electrical and gas connections are made through the flange.

• Power supply and system bus lines are routed through pressure-tight cable

openings.

• Gas inlet and outlet lines are routed through flame traps.

Figure 1-4

Ex module

Housing purge To protect the analyzer module sensor electronics against the entry of an

aggressive atmosphere or corrosive sample gas components, a purge gas can flow

through the pressure-tight cylinder.

The purge gas is routed in and out via two flame traps.

Identification EEx d IIC T4

Certification of

compliance

BVS 97.D.2021 X

SHB_U14 Chapter 2: Analyzer module versions 2-1

Chapter 2: Analyzer module versions

Overview

Introduction

This chapter describes the individual module versions.

Chapter contents

In this chapter you will find the following information:

˝

Subject See Page

Summary 2-2

Module versions (principles) 2-5

Module versions (plastic tubing connections) 2-7

Module versions (stainless steel tubing) 2-12

Ex analyzer module 2-14

2-2 Chapter 2: Analyzer module versions SHB_U14

˝

Summary

˝

General

Depending on the measurement task to be carried out, the Uras 14 can be fitted

with the following primary components:

• 1 to 4 infrared detectors

• 1 to 2 beam paths

• Up to 2 infrared detectors per beam path

• Modulator with three possible versions

• 1 emitter in first beam path (second beam path not installed)

• 1 emitter in second beam path (first beam path not installed)

• 2 emitter units

• The following components are permanently installed

•Thermostat-controlled version with heater and controller (option, must be confi.)

•IR module circuit board

•Sensor-CPU circuit board

•Pressure sensor circuit board

• Any additional components depend on the measuring task or desired equipment

level.

• All versions of the module can be installed in a 19" rack or wall-mount housing

without any need for conversion.

• The gas module and oxygen sensor can be combined in an analyzer module gas

path. These components are included in the sensor electronics package.

Special components

According to the measurement task and options ordered, the following components

can be installed:

˝

• 1 to 2 calibration units

• 1 to 2 filter cells

• 1 to 2 optical filters

• Gas paths

• FPM tubing

• PTFE tubing

• Stainless steel tubing

Continued on next page

SHB_U14 Chapter 2: Analyzer module versions 2-3

Summary, continued

Figure 2-1

Analyzer

Uras 14

1 Connection plate with electrical and gas connections

2 Sensor electronics

3 Optical analyzer components with heat shield

˝

Continued on next page

2-4 Chapter 2: Analyzer module versions SHB_U14

Summary, continued

Figure 2-2

Analyzer module

Uras 14

(open)

1 Calibration unit 2

2 Measurement cell 2

3 Main frame with aperture control

4 Beam path 2 aperture adjustment screw

5 Modulator with emitters (not visible)

6 Calibration unit 1

7 Infrared detector 1

8 Beam path 1 aperture adjustment screw

9 Measurement cell 1

10 Infrared detector 2

11 Stop disk (light or dark)

12 Infrared detector 3

13 Gas connections

14 24-VDC power supply, external connection

15 System bus, external connection

/