Page is loading ...

Part No. 1902142 - Version 07.05.2019

FIBER OPTIC CONNECTORS

HE-2000

ASSEMBLY INSTRUCTION

HE-2000 Standard_e

1

0

Index

INDEX

Page

1 INTRODUCTION ______________________________________________________________________2

1.1 Equipment and material used ______________________________________________________________2

2 HE-2000 CONNECTOR SET _____________________________________________________________ 5

3 SAFETY REQUIREMENTS ______________________________________________________________ 10

4 CABLE PREPARATION_________________________________________________________________11

5 MEASUREMENT METHOD IL____________________________________________________________27

HE-2000 Standard_e

2

P.N. Description Image

1049775 Jokari

1040186 Stripping pliers Jonard 3 holes

1020713 Kevlar Cutter

1020483

Side cutters

160 mm

1073457 T-Stripper

1073458 Kevlar scissors

1056892 FTTH Crimping Pliers

1075632 Crimpring Pliers HE-2000

1081071

Crimping pliers AF8 with

adapter (Positioner) UH2-5

1

Introduction

1 INTRODUCTION

This document describes the preparation of cable after splicing the alberino fusion.

Cables that can be spliced to the connectors must have the following characteristics:

- cables with ø 250μm primary coating and 900μm secondary coating

- cables with ø 1.6 to 8.0mm jacket.

1.1 EQUIPMENT AND MATERIAL USED

HE-2000 Standard_e

3

P.N. Description Image

000-002-194C000

Plastic tube mounting

device for stainless steel

and plastic tube

1069194

Ferrule holder for 2°

crimping machine

1041831

Service polishing arm E-2108.6

APC

000-002-193C000

HE-2000 Termini Service APC

polishing arm for cable version

Optional Accessory for polishing arm

000-002-214C000 Modified E-2000 body

1072556 E-2000 assembly tool

1075931 Crimping sleeve mounting device

1049773 Wrench 12mm

1072536 Wrench 19mm

---- Wrench 21mm

1

Introduction

HE-2000 Standard_e

4

P.N. Description Image

1074651 Ferrule extractor

1074744

Hollow pin guide

mounting/demounting tool

1074654 Termini extractor

1074680 Termini assembler

1900109 Marker Pen

1900216 Marker Pen Edding 780

1020537 Ruler L=150mm

1071976

Tube Stripper

3-5.5 mm

1075858

Ferrule puncher for pushing

ferrule out of the body

1075624 Needle 6mm

1

Introduction

HE-2000 Standard_e

5

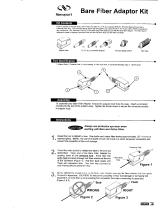

2. HE E-2000 CONNECTOR SET MINI BREAKOUT VERSION

2

Connector Set

HE-2000 Standard_e

6

2.1 HE E-2000 CONNECTOR SET METAL TUBE VERSION

2

Connector Set

HE-2000 Standard_e

7

Item Quantity Description

10 1 Cable boot

20 1 Protection sleeve

30 1 Crimping sleeve

40 1 Ring

50 1 Plastic tube

60 1 Inox tube

70 1 Antirotation

80 1 Ferrule

90 1 Termini crimp version

100 1 Termini fiber version

110 1 Protective cap

120 1 DM4 adapter

130 1 Hollow pin guide

140 1 Ceramic sleeve holder

150 1 Electrical contact protection

160 1 Female electrical contact

170 1 Male electrical contact

180 1 Heat-shrink sleeve

2.2 PLASTIC OR INOX TUBE VERSION

2

Connector Set

HE-2000 Standard_e

8

Item Quantity Description

10 Cable boot

20 Antirotation

30 Ferrule

40 Termini crimp version

50 Tremini fiber version

60 Protective cap

70 Assembled ceramic sleeve

80 Hollow pin guide

90 Ceramic sleeve holder

100 Electrical contact protection

110 Female electrical contact

120 Male electrical contact

130 Heat-shrink sleeve

2.3 PM VERSION

2

Connector Set

HE-2000 Standard_e

9

Item Quantity Description

10 1 Nut

20 1 Inox Washer

30 1 Plastic Washer

40 1 DM 4

50 1 O-Ring

60 1 HE-2000 Bulkhead

70 1 Bronz Ring

2.4 HE-2000 BULKHEAD

2

Connector Set

HE-2000 Standard_e

10

3 SAFETY REQUIREMENTS

Safety glasses for eye protection are required when using epoxy and stikler cleaner, care should be taken

not to get any residue on your skin and avoid touching your eyes.

CAUTION: When using blades handle with extreme care.

CAUTION: Never look directly into a laser light when handling a fault finder or optical equipment.

During the preparation determine which type of cable will be used SM or MM in order to prepare the fiber

and the material correctly.

3

Safety requirements

HE-2000 Standard_e

11

4 CABLE PREPARATION

Insert all the components along the cable before beginning

with the preparation.

Attention: the brass ring (40) must be positioned so that

the groove remains directed towards to the

inner nut (100).

The ring (120) must be placed with the larger

internal diameter directed towards also the

crimping ring (60) must be inserted with the

larger internal diameter directed towards the

ring (50) so that it enters in the crimping ring

(60).

Strip about ~50 mm with a Jokari stripper.

Open the outer jacket about an additional ~50 mm using

the internal ripcord.

Cut the first ~20 mm cable stripped with the side cutter

stripper this to prevent using part of eventually damaged

fibers. You should be left with ~80 mm of stripped

jacket.

Ring housing for (50)

50

60

120

4

Cable preparation

HE-2000 Standard_e

12

At the end of the ripcord cut around the cable watching

to ensure the blade does not cut past the jacket.

Be careful not to cut yourself!

If you prefer use the tube stripper to cut the outer jacket.

Remove the outer jacket and start the stripping procedure.

Cut the cable according to the measurement indicated

on the drawing.

Using a stripping plier or a thermal stripper strip the

900µm coating to the measurement indicated on the

drawing.

Mounting tube

This operation may be done by hand.

For bigger quantities we advise the mounting device

(Drawing N°. 000-002-194C000).

Take care to mount the proper guide depending if you

mount Inox (60) or plastic (50) tube.

4

Cable preparation

HE-2000 Standard_e

13

Gluing the fibre only tube version.

Glue = OD 2002

Dose = 5-6 [mg]

Needle = 6 [mm] P/N 1075624

Using Diamond standard oven the polymerisation program

to be use is PROG1.

Carry out the 1° crimping process fallow the user manual

Minicompact.

For machine fibre cutting fallow the user’s manual

automatic fiber cutter machine.

For hand cutting fallow the user’s manual crocodile

alberino titanium.

Carry out the 2° crimping process according to the user’s

manual active core alignment.

Use the ferrule holder P/N 1069194.

4

Cable preparation

HE-2000 Standard_e

14

After manufacturing, the protrusion end of the ferrule

from the sheath of the cable, should be the following.

ASSEMBLY E-2000 BODY FOR THE POLISHING

PROCESS

In order to polish the ferrules using E-2000 “service” h2/h6

polishing arms you need to mount special E-2000 bodies.

Drawing number: 000-002-214C000.

Assembly procedure of the E-2000™ body using mounting

tool P/N 1058895, see user manual crocodile fusion for

Zeus D50.

Polishing

Polishing is performed using E-2000 “service” h2/h6

polishing arms.

Fallow polishing process as for titanium Crocodile.

1mm

4

Cable preparation

HE-2000 Standard_e

15

Modify E-2000 “service”h2/h6 polishing arms

(Optional).

This modification is applied to avoid that during the

polishing of the ferule, the bodies which are not polished

move freely during the movement of the polishing

process causing breakage to the fiber.

After checking the front face geometry “DAISI” take the

ferrule out from E-2000 body.

To remove the ferrules from the E-2000 body) proceed

as follows:

- Place the service adapter P/N 1010334 on the body.

- Take the ferrule extractor P/N 1074651.

- Slide the fiber in the instrument’s slit.

- Push the instrument into the Body until it clicks.

- Hold the fiber and pull the ferrule out with the help of

ferrule puncher P/N 1075858.

As soon as you have pulled out the ferrule protect it with

the cap.

4

Cable preparation

HE-2000 Standard_e

16

With the help of tweezers extract the kevlar from the

ring (60).

Cut the Kevlar at +/- 6mm.

Clean the cable with alcohol, apply a layer of glue on the

cable jacket surface.

Place the fiber holder into the thermal stripper to strip

the fiber.

The stripped fibre must be cleaned with a tissue dampened

with 99% Isopropyl alcohol or with the Stickler Connector

Cleaner.

A properly cleaned fiber is necessary for a successful

cleave and splice.

4

Cable preparation

HE-2000 Standard_e

17

Place the cable on the device and crimp the sleeve.

Important

After crimping the length from the front face of the ferrule

to the end of the sleeve should be 90mm.

Prepare the ferrules to be mounted into their termini (150).

Take the termini assembler (1074680) with the red point

facing up.

Press the lever and insert the termini by lining up the key

with the red dot.

Once the termini is half way in, release the lever and

push the termini all the way till it clicks.

Remove the cap from one ferrule being very careful not to

bump its front face into the termini edges and damage it.

Hold the fiber about 1,5 inches from the ferrule’s front

and rotate it so that the key faces up. Carefully insert

the ferrule into the termini until it clicks. If all the parts

are properly aligned, the ferrule slides in and gets locked

effortlessly.

Push the termini assembler lever to release termini and

fiber and pull them out.

4

Cable preparation

HE-2000 Standard_e

18

Put back the protective cap onto the ferrule.

Repeat sequence for all 4 ferrules.

At this point your ferrules should look like this:

In case of Re-Polishing the ferrule may be removed from

the termini.

To remove the ferrules from the termini (150) proceed

as follows:

Take the ferrule extractor (1074651).

Slide the fiber in the instrument’s slit.

Push the instrument into the termini until it clicks.

Hold the fiber and pull the termini out as shown in the

picture.

As soon as you have pulled out the ferrule protect it

with the cap.

In case you have a termini polishing arm, you may directly

Re-Polishing without dismantling the ferrule.

Remove the cap from termini being very careful not to

bump its front face.

Align the notch on the DM 4 adapter (150) and the key

of the termini and slide in till it clicks.

4

Cable preparation

HE-2000 Standard_e

19

To remove the ferrules from the terminis (150) proceed as

follows:

Take the ferrule extractor (1074651).

Slide the fiber in the instrument’s slit.

Push the instrument into the termini until it clicks.

Hold the fiber and pull the termini out as shown in the picture.

As soon as you have pulled out the ferrule protect it with the

cap.

Remove the cap from termini being very careful not to bump

its front face.

Align the notch on the DM 4 adapter (150) and the key of the

termini as shown on the drawing and slide in the latter till it clicks.

Be careful that the fiber number matches the letter engraved

on the connector body. The mapping order is as follows:

Green fibre => pos. A

Orange fibre => pos. B

Blue fibre => pos. C

Brown fibre => pos. D

To avoid damaging the fiber, do not push the termini by

applying forces to the fiber; hold the backside of the termini

instead:

Put back the protective cap onto the ferrule.

Keep the fibers nice and straight, do not twine them.

KeyNotch

4

Cable preparation

/