--- 14 ---

Max. cutting dimensions Height x Width mm (inch

)

Right 57˚

(C 12FSA

R/L 57˚ )

(C: R60)

Groove cutting width

Right 45˚

Left 45˚

Bevel

107 x 170 (4-3/16" x 6-11/16")

120 x 130 (4-11/16" x 5-1/8")

[with aux. board 25 mm (1")]

45 x 312 (1-3/4" x 12-1/4")

50 x 260 (1-15/16" x 10-3/16")

[with aux. board

25 mm (1")

]

70 x 312 (2-3/4" x 12-1/4")

75 x 260 (2-15/16" x 10-3/16")

[with aux. board

25 mm (1")

]

Miter left 45˚

(C 12FSA R/L 45˚)

((C) R/L 45˚)

+

Bevel left 45˚

Miter right 31˚

+

Bevel left 45˚

70 x 220 (2-3/4" x 8-5/8")

75 x 180 (2-15/16" x 7-1/16")

[with aux. board 25 mm (1")]

Possible

(with bolt height adjustment)

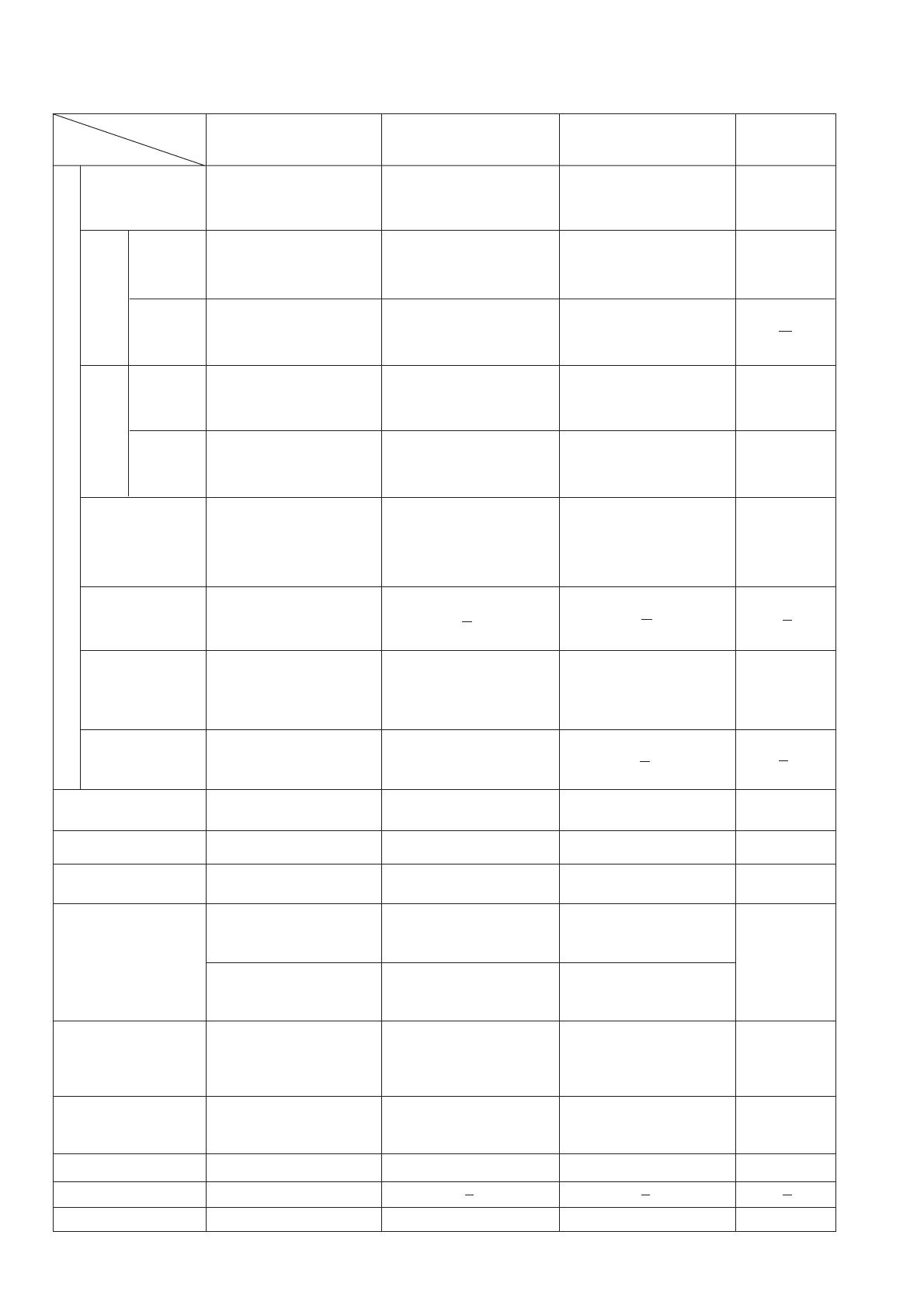

6. COMPARISONS WITH SIMILAR PRODUCTS

Item

Maker

Model

HITACHI

C 12LSH/C 12RSH

0˚ (Right angle)

107 x 312 (4-3/16" x 12-1/4")

120 x 260 (4-11/16" x 10-3/16")

[with aux. board 25 mm (1")]

107 x 220 (4-3/16" x 8-5/8")

120 x 180 (4-11/16" x 7-1/16")

[with aux. board 25 mm (1")]

Miter

Left/right

45˚

Miter cutting ranges

Bevel cutting ranges

Left and right 0˚ --- 45˚

Compound

(miter + bevel)

cutting ranges

Angle stopper positions

Left 0˚ --- 46˚, right 0˚ --- 57˚

Miter left 0˚ --- 45˚/

Miter right 0˚ --- 31˚

Bevel left 0˚ --- 45˚

Miter left 0˚ --- 31˚/

Miter right 0˚ --- 45˚

Bevel right 0˚ --- 45˚

0˚, right and left 15˚, 22.5˚,

31.6˚, 45˚

Miter left 31˚

+

Bevel right 45˚

45 x 265 (1-3/4" x 10-7/16")

50 x 220 (1-15/16" x 8-5/8")

[with aux. board 25 mm (1")]

Saw blade external

diameter mm (inch)

(No. of teeth)

Laser marker

Laser output

305 (12") (60 P)

Provided

70 x 265 (2-3/4" x 10-7/16")

75 x 220 (2-15/16" x 8-5/8")

[with aux. board 25 mm (1")]

Miter right 45˚

((C) R/L 45˚)

+

Bevel right 45˚

45 x 220 (1-3/4" x 8-5/8")

50 x 180 (1-15/16" x 7-1/16")

[with aux. board 25 mm (1")]

<1 mW

Digital display

Provided (C 12LSH only)

107 x 180 (4-3/16" x 7-1/16")

120 x 140 (4-11/16" x 5-1/2")

[with aux. board 25 mm (1")]

40 x 305 (1-9/16" x 12")

45 x 260 (1-3/4" x 10-3/16")

[with aux. board 20 mm (13/16")]

70 x 305 (2-3/4" x 12")

75 x 260 (2-15/16" x 10-3/16")

[with aux. board 20 mm (13/16")]

70 x 220 (2-3/4" x 8-5/8")

75 x 180 (2-15/16" x 7-1/16")

[with aux. board 25 mm (1")]

Possible

(with bolt height adjustment)

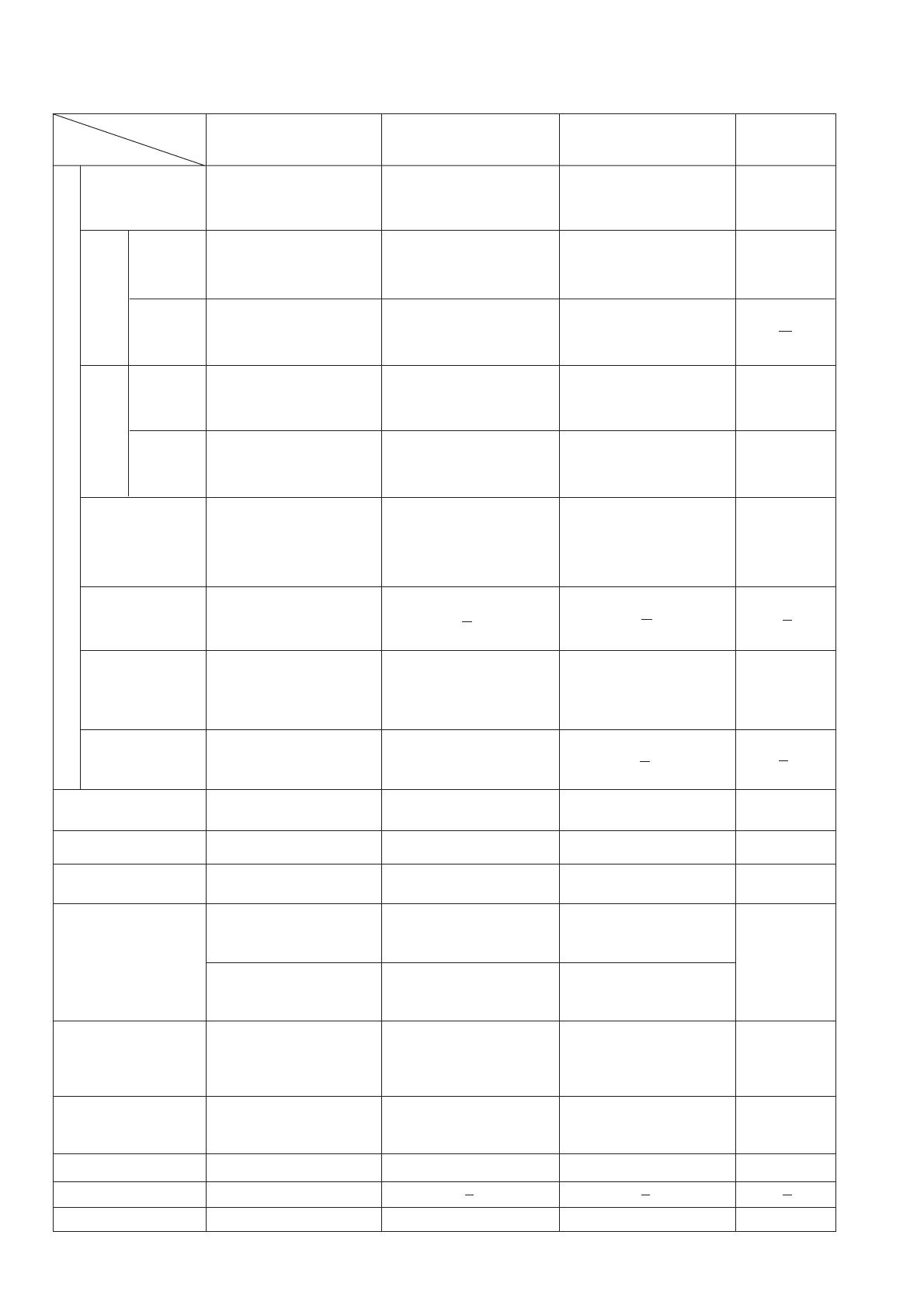

HITACHI

C 12FSA

107 x 305 (4-3/16" x 12")

120 x 260 (4-11/16" x 10-3/6")

[with aux. board 20 mm (13/16")]

107 x 220 (4-3/16" x 8-5/8")

120 x 180 (4-11/16" x 7-1/16")

[with aux. board 25 mm (1")]

Left and right 0˚ --- 45˚

Left 0˚ --- 57˚, right 0˚ --- 57˚

0˚, right and left 15˚, 22.5˚,

31.6˚, 35.3˚, 45˚

40 x 265 (1-9/16" x 10-7/16")

45 x 220 (1-3/4" x 8-5/8")

[with aux. board 20 mm (13/16")]

305 (12") (60 P)

Not provided

40 x 220 (1-9/16" x 8-5/8")

45 x 180 (1-3/4" x 7-1/16")

[with aux. board 25 mm (1")]

98 x 155 (3-7/8" x 6-1/8")

120 x 115 (4-11/16" x 4-1/2")

[with aux. board 17 mm (11/16")]

35 x 310 (1-3/8" x 12-1/4")

49 x 230 (1-15/16" x 9")

[with aux. board 34 mm (1-5/16")]

55 x 310 (2-3/16" x 12-1/4")

69 x 230 (2-3/4" x 9")

[with aux. board 34 mm (1-5/16")]

55 x 220 (2-3/16" x 8-5/8")

69 x 162 (2-3/4" x 6-3/8")

[with aux. board 24 mm (15/16")]

Possible

(with bolt height adjustment)

C

98 x 310 (3-7/8" x 12-1/14")

120 x 230 (4-11/16" x 9")

[with aux. board 34 mm (1-5/16")]

98 x 220 (3-7/8" x 8-5/8")

120 x 162 (4-11/16" x 6-3/8")

[with aux. board 24 mm (15/16")]

Left and right 0˚ --- 45˚

Left 0˚ --- 47˚, right 0˚ --- 60˚

Miter left and right 0˚ --- 45˚

Bevel left and right 0˚ --- 45˚

0˚, right and left 15˚, 22.5˚,

30˚, 45˚

305 (12") (70 P)

Not provided

35 x 220 (1-3/8" x 8-5/8")

49 x 162 (1-15/16" x 6-3/8")

[with aux. board 24 mm (15/16")]

Miter right 0˚ --- 60˚/

Bevel left 0˚ --- 35˚

Bevel right 0˚ --- 45˚

102 x 305

(4" x 12")

115 x 299

(4-1/2" x 11-3/4")

102 x 216

(4" x 8-1/2")

115 x 203

(4-1/2" x 8")

57 x 305

(2-1/4" x 12")

79 x 200

(3-1/8" x 7-7/8")

28 x 305

(1-1/8" x 12")

41 x 270

(1-5/8" x 10-5/8")

57 x 216

(2-1/4" x 8-1/2")

79 x 203

(3-1/8" x 8")

28 x 216

(1-1/8" x 8-1/2")

41 x 203

(1-5/8" x 8")

Possible

(with screw height

adjustment)

Left 0˚ --- 50˚,

right 0˚ --- 60˚

Left and right

0˚ --- 48˚

Miter left and right

0˚ --- 45˚

Bevel left and

right 0˚ --- 45˚

0˚, right 15˚, 22.5˚,

31.6˚, 45˚, 60˚

0˚, left 15˚, 22.5˚,

31.6˚, 45˚, 50˚

305 (12") (60 P)

Miter left and right 0˚ --- 45˚

Bevel left 0˚ --- 45˚

Miter left 0˚ --- 31˚/

Miter right 0˚ --- 45˚

Bevel right 0˚ --- 45˚

Not provided

None None

None

P