Page is loading ...

KHM 400 YS

Instruction

manual

0794 999 936 05/02 Valid for serial No. 443 - XXX - XXXX

Index

KHM 400 YS M

1

02/11/04 79405-GB

Dear Customer,

We wish to thank you for having bought this product.

Please take time to read this manual and familiarize yourself with the machine before attempting to use it.

If you should have questions or problems please contact the nearest authorized Service Center. They

have the experience and original spare parts. The use of non-original spare parts will void the warranty.

TABLE OF CONTENTS

DESCRIPTION PAGE

GENERAL INFORMATION

INFORMATION ABOUT THIS MANUAL M 2

DESCRIPTION - SYMBOLS M 2.1

PRECAUTIONS - GENERAL M 2.5

PRECAUTIONS - ENGINE DRIVEN WELDERS M 2.5.1

TRANSPORT M 4

ASSEMBLY OF SITE TOW FOR KHM 400 M 6.2

INSTALLATION INFORMATION M 2.6

INSTALLATION M 2.7

OPERATION

UNPACKING M 3

PREPARING THE UNIT M 20

STARTING THE ENGINE THE USE M 21.3

STOPPING THE DIESEL ENGINE M 22.1

CONTROLS M 31

OPERATING M 32

USE - WELDING DIGITAL CONTROL M 33, M33.1, M33.2, M33.3, M33.4

NOTE REMOTE CONTROL CONNECTOR PHG1A (WDC) M 38.9

MAINTENANCE M 43, M 43.3,M 44.2

STORAGE M 45

TECHNICAL DATA AND MACHINE DESCRIPTION M 51, M 52

TECHNICAL DATA M 53

SCHEMATICS AND SPARE PARTS

WIRING DIAGRAM – ENGINE EP5 M 61.1

WIRING DIAGRAM – AUXILIARY 1x Y400V / 2x I230V M 61.2

WIRING DIAGRAM – WELDING POWER M 61.3

WIRING DIAGRAM – WELDING CONTROL M 61.4

DESCRIPTION - ELECTRICAL SYSTEM M 60

SPARE PARTS DS 35, DS35.1

SPARE PARTS DS 36, DS36.1

SPARE PARTS DS 37, DS37.1

SPARE PARTS DS 38, DS38.1

KIR DECAL DS 39

SITE TOW FOR KHM 400 KA9

PHG1A KD11

ü

'$1*(5286

ü

:$51,1*

ü

&$87,21

ü

,03257$17

ü

127(

ü

$77(17,21

86($1'0$,17(1$1&(

,1)250$7,21$%2877+,60$18$/

*(1(5$/,1)250$7,21

- In the envelope where you found this manual you will

also find an Owner’s manual for the engine, and ac-

cessories (if required).

This product has been designed for welding and genera-

tion of electrical power for tools and other electrical devices

used in construction; ANY OTHER USE, is not permitted

and we cannot be held responsible for injuries or damages

resulting from such incorrect use.

Our products are made in conformity with the safety norms

in force in order to avoid injury to persons or damage to the

machine or other things.

+ :DUUDQW\ LV QRW YDOLG LI QRW FDUULHG RXW E\

(6$%DXWKRUL]HGVHUYLFHDJHQW

Making modifications to the machine without our written

authorization will void the warranty and release us from

any liability.

$%2877+,60$18$/

Before using the machine please read this manual atten-

tively and follow the instructions contained in it. This will

help avoid problems, possible injury and damage to the

machine.

The manual is written for experienced, qualified personnel,

who are familiar with health and safety laws and related

regulations.

This manual is an integral part of the product and should be

kept in a safe place so that it will be available for consulta-

tion during the life of the product. If the machine is sold the

manual should be transferred to the new owner.

Some figures contained in this manual are designed to help

identify certain parts and may not correspond to the ma-

chine in your possession.

+ 1RWLFHWKHPDQXIDFWXUHUPD\PDNHLPSURYHPHQWVRU

PRGLILFDWLRQVWRWKHSURGXFWRULWVDFFHVVRULHVDVGH

VFULEHGLQWKLVPDQXDOZLWKRXWXSGDWLQJWKHPDQXDO

+($',1*686(',17+,60$18$/

The headings used in this manual are designed to call your

attention to potential hazards and important aspects of the

operation of the machine…

lndìcates a strong possíbility of severe personal injury or

death ìf ínstructions are not followed.

lndìcates a possibìlìty of personal ínjury or equipment dam-

age if ìnstructions are not followed

lndícates that equipment or property damage can result if

instructions are not followed.

These headings give helpful information about the prepara-

tion, operation and care of the machine.

0

2

11/9/00 ESABM2GB

*%

*(1(5$/6<0%2/6

6723²Read with great attention

Read with attention

:5(1&+Use the correct tools for the type of

work being done

:$51,1*6<0%2/6

$77(17,21 If this advice is not followed peo-

ple or things can be hurt or damaged.

+,*+92/7$*( Do not touch – risk of injury

or death.

),5( Risk of fire.

+($7 Hot surfaces.

(;3/26,9( Explosive material or danger of

explosion, in general.

12:$7(5'RQRWXVHZater as it can cause

shortcircuits or other damage.

12602.,1*&igarettes, matches or lighters

can start a fire or explosion.

$&,'6Danger of corrosion or burns.

6$)(7<6<0%2/6

8VHWKHFRUUHFWSURWHFWLYHGHYLFHVIRUWKHW\SHRIZHOG

LQJEHLQJGRQH

Use protective clothing, etc. specifically

designed for the type of welding being done.

3URWHFW\RXUVHOIZKHQGRLQJPDLQWHQDQFHRQWKHPD

FKLQH

It is advisable to protect yourself when carrying

out maintenance, such as filling the battery, refu-

elling, etc.

3D\DWWHQWLRQWRVDIHW\SUHFDXWLRQVZKHQPRYLQJWKH

PDFKLQH

Refer to the instructions before moving the ma-

chine

:HDULQGLFDWHGVDIHW\FORWKLQJ

It is compulsory to wear the personal pro-

tection items shown when using the equip-

ment.

8VHUHTXLUHGVDIHW\GHYLFHV

Safety devices suitable for the type of welding

and the location of the job must be used.

'RQRWXVHZDWHURQHOHFWULFDOILUHV

It is prohibited to use water to put our fires in

electrical equipment.

'RQRWWRXFKZLWKRXWKDYLQJGLVFRQQHFWHGWKH

HOHFWULFLW\

It is prohibited to work on the machine until the

electricity has been turned off.

:HOGLQJSURKLELWHG

It is forbidden to weld in areas containing explo-

sive gases.

06/03/00 ESABM2-1GB

86($1'0$,17(1$1&(

'(6&5,37,216<0%2/6

0

2.1

*%

ü ,03257$17

+ Read and understand these instructions.

+

Before installing, operating or servicing this equipment, read

the operating manuals of the welder and of the engine

.

+

Not observing the information in the manuals can result in

personal injury and/or damage to the equipment and other

property.

+

Respect all safety regulations and laws when operting this

equipment.

ü:$51,1*

'RQRWUHPRYHRUGLVDEOHSURWHFWLYHGHYLFHV

Removing or disabling protective devices on the ma-

chine is prohibited.

'RQRWXVHWKHPDFKLQHLILWLVQRWLQJRRGWHFKQLFDOFRQ

GLWLRQ

The machine must be in good working order before be-

ing used. Defects, especially those which. regard the

safety of the machine, must be repaired before using

the machine.

(1*,1()8(//,1*

⇒ Stop engine when fuelling.

⇒ Do not smoke, avoid open flames and sparks, and

do not use electric tools when fueling.

⇒ Unscrew the fuel cap slowly to let out the fuel va-

pours.

⇒ Do not over-fill the tank.

⇒ Avoid spilling fuel on hot engine.

⇒ Wipe up spilled fuel before starting engine.

⇒ Shut off fuel cock, if present, or remove fuel from

tank before moving machine

)25%$77(5<(48,33('81,7621/<

⇒ Sparks may cause the explosion of battery vapours

:$7(5&22/('(1*,1(621/<

⇒ Slowly unscrew the cooling liquid cap of a hot en-

gine to allow vapours to escape.

⇒ Hot vapor and heated cooling liquid under pressure

can burn face, eyes, skin.

F),567$,' In case the operator shold be sprayed by accident, from corrosive liquids a/o hot toxic gas or what-

ever event which may cause serious injuries or death, predispose the first aid in accordance with the ruling labour

accident standards or of local instructions.

Skin contact Wash with water and soap

Eyes contact Irrigate with plenty of water, if the irritation persists contact a specialist

Ingestion Do not induce vomit as to avoid the intake of vomit into the lungs, send for a doctor

Suction of liquids from lungs If you suppose that vomit has entered the lungs ( as in case of spontaneous vomit ) take the

subject to the hospital with the utmost urgency

Inhalation In case of exposure to high concentration of vapours take immediately to a non polluted zone

the person involved

F),5(35(9(17,21 In case the working zone,for whatsoever cause goes on fire with flames liable to cause se-

vere wounds or death, follow the first aid as described by the ruling norms or local ones.

(;7,1&7,210($16

Appropriated Carbonate anhydride (or carbon dioxyde) powder, foam, nebulized water

Not to be used Avoid the use of water jets

Other indications Cover eventual shedding not on fire with foam or sand, use water jets to cool off the surfaces

close to the fire

Particular protection Wear an autorespiratory mask when heavy smoke is present

Useful warnings Avoid, by appropriate means to have oil sprays over metallic hot surfaces or over electric

contacts (switches,plugs,etc.). In case of oil sprinkling from pressure circuits, keep in mind

that the inflamability point is very low.

06/03/00 ESABM2-5GB

7+(0$&+,1(0867127%(86(',1$5($6:,7+(;

3/26,9($70263+(5(

:$51,1*

ü

&$87,21

ü

:$51,1*

86($1'0$,17(1$1&(

35(&$87,216*(1(5$/

0

2.5

*%

35(&$87,216

The operator of the welder is responsible for the security of the people who work with the welder and for those in the vi-

cinity.

The security measures must satisfy the rules and regulations for engine driven welders.

The information given below is in addition to the local security norms.

⇒ Make sure that the area is safe before starting any

welding operation.

⇒ Do not touch any bare wires, leads or contacts as they

may be live and there is danger of electric shock which can

cause death or serious burns. The electrode and welding

cables, etc. are live when the unit is operating.

⇒ Do not touch any electrical parts or the electrode while

standing in water or with wet hands, feet or clothes.

⇒ Insulate yourself from the work surface while welding.

Use carpets or other insulating materials to avoid physical

contact with the work surface and the floor.

⇒ Always wear dry, insulating gloves, without holes, and

body protection.

⇒ Do not wind cables around the body.

⇒ Use ear protections if the noise level is high.

⇒ Keep flamable material away from the welding area.

⇒ Do not weld on containers which contain flamable ma-

terial.

⇒ Do not weld near refuellng areas.

⇒ Do not weld on easily flamable surfaces.

⇒ Do not use the welder to defrost (thaw) pipes.

⇒ Remove the electrode from the electrode holder, when

not welding.

⇒ Avoid inhaling fumes by providing a ventilation system

or, if not possible, use an approved air breather.

⇒ Do not work in closed areas where there is no fresh air

flow.

⇒ Protect face and eyes (protective mask with suitable

dark lens and side screens), ears and body (non-flamable

protective clothes).

86($1'0$,17(1$1&(

35(&$87,216(1*,1('5,9(1:(/'(5

0

2.5.1

19/6/00 ESABM2-5-1GB

$77(17,21

*%

ü127(

LIFT ONLY THE MACHINE

DO NOT LIFT THE MACHINE AND

TRAILER

'$1*(5LIFTING EYE IS NOT DESIGNED TO SUPPORT

ADDED WEIGHT OF ROAD TOW TRAILER

.

86($1'0$,17(1$1&(

75$163257

0

4

In case you have to move or transport or move the machine, follow the instructions as shown in the figures.

Transport the machine ZLWKRXW petrol in the tank, ZLWKRXW oil in the engine and ZLWKRXW

electrolyte in the battery. Be sure

that the transportation devices are adequate for the size and weight of the machine.

DO NOT

TRANSPORT ACCESSORIES OR OTHER ITEMS WHICH COULD INCREASE THE

WEIGHT AND/OR CHANGE THE CENTER OF GRAVITY OF THE MACHINE.

DO NOT DRAG THE MACHINE OR TOW IT ON PUBLIC ROADS UNLESS

IT IS MOUNTED ON A

HOMOLOGATED TRAILER.

Not following these instructions could cause injury or damage to the machine.

&7/6,7(72:

The machines provided for assembling the CTL accessory (slow towing trolley) can be towed up to a PD[LPXP speed of

.PVKRXU on asphalted surfaces.

☞Towing on public roads or turnpikes of any type ,6 (;&/8'(', because QRW in possesion of the requirements by

national and foreign traffic norms.

22/6/00 ESABM4GB

*%

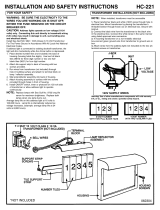

ASSEMBLY OF SITE TOW FOR KHM 350 - 400

M

6.2

Nota

: Lift the machine and assemble the parts as shown in the drawing

The accessory cannot be removed from the machine and used separately (actioned manually or following vehicles)

for the transport of loads or anyway for used different from the machine movements.

For assembling the generating set on the site tow please

keep to following instructions:

1) - Lift the generating set (by means of suitable hook).

2) - Slightly fix the jaw (3) of the parking foot to the bar

with the M10x20 screws, the M10 nuts and the

washers (so as to let the foot sprag go through.

3) - Split (unscrewing them) the two parts of the foot

(4S-4I) to be able later to assemble them on the jaw.

4) - Introduce into the jaw (3) the upper part (4S) of the

foot and screw again the lower part (4I), then tighten

the screws (4V) of the jaw to the towbar and block

momentaneously with the lever (4L) the whole foot.

5) - Assemble on the machine the towbar (5) complete

of foot with the M10x20 screws, nuts and washers

(see fig. page M6.2).

6) - Assemble the axle (7) to the base of the machine

(see fig. page M6.2) with the M 10x20 screws and

relative washers (two per part) so that their supports

coincide.

8) - Insert the wheel (9) on the axle then screw the self

blocking nuts (8).

9) - Pump the tyre (9) bringing the pressure to four atms.

10) - Lower the machine to the ground and place the

parking foot definitively (regulating at the best height).

ATTENTION

Do not substitute the original tires with other types.

!

!

ATTENTION

4

5

3

4S

4I

4L

4V

7

8

9

TRAILERS

The machines provided for assembling the CTL accessory (slow towing trolley) can be towed up to a maximum speed

of 40 Kms/hour on asphalted surfaces.

Towing on public roads or turnpikes of any type IS EXCLUDED, because not in possesion of the requirements by

national and foreign traffic norms.

10/06/00 M6-2GB_ESAB

,167$//$7,21,1)250$7,21

DIESEL ENGINES

• Use in open space with fresh air flow or vent exhaust

gases far from the work area.

POSITIONING THE MACHINE

Place the machine on a level surface at a distance of at

least 1,5 m from buildings or other structures.

If the surface is not level be sure that the angle of the ma-

chine does not exceed the values shown in the drawings

below.

+ Assure that the hot air and/or exhaust gas from the

machine are vented and are not recirculated in the ma-

chine. Hot air and/or exhaust gas which is recirculated wll

cause overheating of the machine and poor combustion

in the engine

+ Make sure that the machine does not move during

operation.

Protect the machine from rain and do not put

it in a location where there is danger of flood-

ing.

:DWHULQILOWUDWLRQFDQFDXVHVKRUWFLUFXLWVZKLFKFDQ

EH GDQJHURXV IRU SHUVRQV DQG FDQ GDPDJH WKH PD

FKLQH

The degree of protection, of the machine is written the

rating plate and in this manual at the "Technical Data"

page.

MOVING THE MACHINE

Before moving the machine turn off the engine and dis-

connect all cables, which could impede the move.

86($1'0$,17(1$1&(

,167$//$7,21,1)250$7,21

0

2.6

20/6/00 ESABM2-6GB

*%

KHM 400 YS

KHM 400 YS

Central lifting eye

Cover opening

Opening cover front

panel

Air inlet

Fuel filling

Air outlet

HOT SURFACE

Gas exhaust pipe

Air outlet

INSTALLATION

KHM 400 YS M

2-7

02/11/04 79405-GB

ü*(1(5$/3$&.,1*,1)250$7,21

813$&.,1*7+(0$&+,1(

1) Take the machine (C) out of the carton.

Locate the User’s Manual (B), which is

packed together with the engine

manual and accessories in a plastic

envelope (A). This envelope may be

under or inside the machine.

2) Check the rating plate on the machine

and confirm that the serial number and

model are the same as shown on the

packing note/invoice.

1% For further information on preparing

the unit for use refer to the related parts of

this manual.

02/03/00 ESABM3G

Upon receipt of the goods make sure that the product

has not been damaged during transport.

In case of damage or missing items you must inform

your freight forwarder immediately.

Packing materials must be disposed of

according to local regulations.

86($1'0$,17(1$1&(

813$&.,1*

0

3

*%

%$77(5<

Take the battery out of

the machine.

Fill the battery to the

maximum level with

electrolyte. Wait for

about 30 minutes and

top up with electrolyte.

In case of spilled acid, rinse with water before putting the

battery back into the machine and reconnecting cables.

/8%5,&$17

Check the level of the engine oil using

the oil dipstick. The level should be

between the minimum and maximum

marks. lf necessary, add more oil.

If the air filter is of the oil bath type, fill it with the same oil

up to the level indicated on the filter.

5(&200(1'('6$(9,6&26,7<*5$'(6

For the type and viscosity of oil refer to owner’s manual

for the engine (supplied with the machine).

+127( %HIRUHVWDUWLQJWKHHQJLQHUHDGWKHLQVWUXF

WLRQVLQWKHRZQHUVPDQXDOIRUWKHHQJLQH

)8(/

Fill the tank with good quality diesel fuel.

+ ATTENTION: Diesel fuel is highly inflammable;

before filling the tank, stop the en-

gine. Do not fuel in the presence of

open flames.

If fuel is spilled on the engine, clean it

immediately before starting up the engine.

&22/,1*/,48,'

Pour the cooling liquid through the hole at the

top of the radiator until it reaches the opening.

For the type of cooling liquid to be used and for mainte-

nance of the cooling system, refer to the engine manual..

*5281'&211(&7,21

A good ground is obligatory

for all models with GFI

(ground fault interrupter). This protective device will not

protect the operator unless there is a good ground.

+ Use a good quality ground cable and connect it to

the grounding point of the machine. Follow all local

rules and/or regulations in force.

Machines with Isometer protection do not need to be

grounded.

Once the above operations have been completed, the

machine can be used.

20/6/00 ESABM20GB

ü

:$51,1*

Sulfuric acid is corrosive.

Protect hands, eyes and FORWKHV....

Take the battery out of the machine for filling.

Warranty 92,'('

for damages due to spilled

acid.

86($1'0$,17(1$1&(

35(3$5,1*7+(81,7',(6(/(1*,1(6

0

20

*%

STARTING THE ENGINE

M

21.3

With E.P.1 engine protection device, use the

accelerator lever ONLY IN EMERGENCY if

engine protection does not work. In this case call

our Authorized Assistance Centers.

!

NOTE

!

Do not alter the factory adjustment of the engine

and do not touch the sealed parts.

Check daily

3000 / 3600 RPM ENGINES

These engines start at low rpm Make sure that the

manual accelerator is pushed completely in.

STARTER KEY

The starter has four positions.

PREHEATER

The preheater must be used for starting

these engines.

STARTING THE ENGINE

Turn the starter key to the position with the glow

plug symbol. The glow plug indicator will come on.

After about 10 seconds turn the starter key

completely clockwise to the START position. Once

the engine starts release the key and leave it in the

ON postion.

Let the engine run for a few minutes to warm-up

before loading it.

AUTO IDLE / ENGINE PROTECTION (with EP1

Version)

The EP1 device has a dual function. It monitors the

engine oil pressure and the engine temperature and

shuts down the engine if the oil pressure is too low

or the temperature too high. In addition the EP1

accelerates the engine when you begin welding or

require auxiliary power. The EP1 enters in operation

when the engine is started and for a few seconds

the shut-down function is inhibited to allow the engine

to start.

LOW (yellow) – low temperature

ENGINE (green) – pressure and

temperature OK

PRESS. (red) – shut-dow due to

low oil pressure

HIGH (red) – shut-down due to

high temperature

“RABBIT” (green) – engine

accelerated

The yellow “LOW” will go on when the engine is

started. A warm-up time of 30 seconds has been

pre-set and during this time the “LOW” light will stay

on and the engine will not accelerate. After this time

the engine will accelerate when the EP1 senses

the need.

☞ N.B.: A longer warm-up time (4-5 minutes) is

advisable for temperatures below +10°C.

After 15 seconds the engine will be checked and if

everything is operating normally, the green “OK”

light will switch on.

After the “LOW” light stops, the engine can be

accelerated either by touching the welding electrode

to the work piece in CC mode and pushing the

switch on the gun in C.V., P1, P2 mode or by

switching on a load connected to one of the auxiliary

output sockets.

In the event of insufficient oil pressure, the red light

(PRESS.) will light up and the EP1 will stop the

engine. In the event of high engine temperature, the

red light (HIGH) will light up and the engine will got

to minimum rpm. To use the machine again it is

necessary to shut it off, let it cool down, and find the

reason for the overheating.

RUNNING-IN

During the first 50 hours of operation, do not use

more than 60% of the maximum output power of

the unit and check the oil level frequently, in any

case please stick to the rules given in the engine

use manual.

CAUTION

!

NOTE

KHM 400 YS

02/11/04 79405-GB

STOPPING THE ENGINE KHM 400 YS

M

22.1

☞ Before stopping the engine it is compulsory to:

- disconnect or shut off any loads which are

connected to the unit auxiliary outputs.

- stop welding

To stop the engine:

Turn the starter key to the off position.

02/11/04 79405-GB

CONTROLS

KHM 400 YS M

31

9

10

12

15

16

59A

59B

59C

59D

86

D

D1

I4

M

Welding socket ( + )

Welding socket ( - )

Earth terminal

A.C. socket

Accelerator lever

Engine thermal switch

Aux current thermal switch

Supply thermal switch wire feeder-42V

Preheating thermal switch

Selector

Ground fault interrupter ( 30mA )

E.P.1 Engine protection

Preheating indicator

Hour counter

M1

N1

Q1

T

V

V4

X1

Fuel Warning light

Battery charge warning light

Starter key

Welding current regulator

Welding voltmeter

Polarity inverter control

Remote control socket

Pos. Description DescriptionPos.

02/11/04 79405-GB

OPERATING

KHM 400 YS M

32

02/11/04 79405-GB

After having prepared the machine (charged the

battery, put in oil and fuel) the machine is ready for

operation.

Before starting the engine please note the following:

• The welder should only be operated by qualified

personnel with experience in working with engine

driven welders.

• Check the oil level daily. Fuel should be put in

before starting the engine.

• Before using the welder or the auxiliary power let

the engine warm up and before stopping the engine

let it run without load to cool down.

Refer to the following instructions regarding the

function of the various controls on the front panel.

Controls and Instruments

OPERATING

KHM 400 YS M

32.1

02/11/04 79405-GB

PUSH AND

TWIST

circuit breaker auxiliary

auxiliary power socket

INSERT

auxiliary power plug

Welding cable connections

For direct current electrode positive, connect work

cable to negative (-) terminal and electrode holder

to positive (+) terminal. For direct current electrode

negative, reverse cable connections.

☞ Make sure that the ground clamp makes a good

connection and is near the welding posítion.

Auxiliary power outlets and thermal circuit

breaker

The unit is equipped with 4 auxiliary output sockets

– one three phase and three single phase. The

voltages depend on the version selected. The three

phase socket requires no protection as the

asynchronous alternator protects itself. The single

phase sockets are supplied with thermal circuit

breakers which pop out when overloaded. After

they have been activated give them a short time to

cool down before re-inserting. If they continue to

pop out check that the load is not too large for the

output of the socket.

ground fault interrupter

raise lever to reset

Starter key

To start the engine, turn the starter key to the left to

the left (“preheat” position indicated by the symbol

for a glow plug). When the green lamp below the

key (has the same glow plug symbol) goes out, turn

the key clockwise to the “START” position to activate

the starter motor. Once the engine has started

return it to the “ON” position.

To stop the engine turn the key to the “OFF” position

cold starting

Starter key

5A

welding sockets

welding cable

connector

PUSH AND TWIST

UNTIL TIGHT

Ground fault interrupter

The ground fault interrupter protects the operator

from injury in the event of a ground fault. If it is

activated, raise the plastic cover and push the lever

up to reset.

Engine thermal switch

EP1 engine protection module and auto-idle

The EP1 engine protection module shuts down the

engine if the oil pressure is too low or if the engine

temperature is too high. There is a series of LED’s,

which show the status of the engine. The top, yellow

LED lights every time the engine is started and

inhibits the acceleration of the engine for about 30

seconds to allow the engine to warm-up. At low

temperatures the engine should be kept at idle for

several minutes after the LED has gone out before

being loaded. After about 15 seconds the green

LED lights up indication that the oil pressure is

sufficient and the engine temperature is not too

high. The two red LED’s light up in the event of an

engine shutdown and show whether low oil pressure

or high engine temperature caused the shut down.

The last, green LED lights when the engine is

accelerated (see below).

The EP1 not only protects the engine but it also has

an auto-idle feature, which keeps the engine at low

speed until welding current or auxiliary power is

required saving fuel, reducing the noise level and

extending the life of the engine. There are two

independent sensors – one for welding and one for

auxiliary power:

OPERATING

KHM 400 YS M

32.2

Welding - touching the electrode to the work piece

will accelerate the engine, which will remain

accelerated as long as current is being drawn. If no

current is drawn for about 20-30 seconds the engine

will return to low speed.

ATTENTION

The auto-idle is not working when you use the

program “Contact starting TIG”. Use the accelerator

lever.

Auxiliary power – plug the tool or other load into any

socket and turn it on. The engine will accelerate and

remain accelerated as long as current is drawn. If

no current is drawn for about 20-30 seconds the

engine will return to low speed.

Liquid cooled - in case of cooling liquid high tempe-

rature, the warning líght will light up and the engine

will be kept at MINIMUM thus preventíng to draw

power.

In this case it is SUGGESTED to stop the engine

and control the cooling liquid level.

D1.1(G) Low oil temperature/

Cold engine

D1.2(V) Engine test/ OK engine

D1.3(R) Low oil pressure

D1.4(R) High temperature

D1.5(V) Engine at maximum

COLORS

G = yellow

V = green

R = red

Accelerator lever

MIN

MAX

☞

Note: This unit is equipped with a manual

accelerator for use in the unlikely event that the

EP1 or the accelerator solenoid should fail. This

manual accelerator can also be used in cases where

the auto-idle function is not suitable for the type of

welding being carried out.

CAUTION: for machines with EP1

engine protection: use the accelerator

lever ONLY IN EMERGENCY when

the automatic idle does not work.

☞

Note: The engine protections of the “EP” type do

not work when the oil is of low quality because not

changed regularly at intervals as prescribed in the

owner’s engine manual.

Low

fuel

Glow

plug

Indicating lamps

10

20

30

operating

hours

welding

voltmeter

Indicating lamps

Battery charge indicator – this lamp lights if the

battery charging circuit is not operating.

Low fuel level shut down indicator - when the fuel in

the tank is at the reserve level this lamp lights and

the engine is automatically shut down to prevent

getting air in the engine fuel lines.

☞

Note: This indicator will go on when the fuel level

is low but may not remain on after the engine stops.

The battery charge indicator and low oil pressure

LED (on EP1) will be on as the engine is stopped

even if the problem is not related to them.

Instruments

Standard instruments include an operating hour-

counter and a voltmeter for welding voltage.

The hour-counter shows the engine running hour

witch permit to plan the periodic maintenance (see

M44.2).

The welding voltmeter show the welding voltage.If

you choose tig,stick or stick arc force program the

welding voltmeter go up about 65V only for about

3”.Than the welding voltage go down about 12V and

stop there,until the welder start welding (see VRD

program - M33.2).

No

charging

USE WELDING DIGITAL CONTROL

M

33.1

02/11/04 79405-GB

GETTING STARTED

1) After having prepared the machine (charged the

battery, put in oil and fuel) the machine is ready

for operation.

Before starting the engine please note the following:

- The welder should only be operated by qualified

personnel with experience in working with engine

driven welders.

- Check the oil level daily. Fuel should be put in

before starting the engine.

- Before using the welder or the auxiliary power let

the engine warm up and before stopping the engine

let it run without load to cool down.

Refer to the following instructions regarding the

function of the various controls on the front panel.

2)

Start the engine of the welder

OFF

ON

START

3) Turn the welding current/voltage

adjusting knob to the minimum

setting.

SETTING THE WELDING PROCESS

There is a manual switch for selecting the various

welding processes on the welding control panel.

There are 5 processes to choose from:

1 for TIG welding

3 for STICK welding (electrode)

1 for MIG/MAG welding (continuous wire).

The switch can also be set to “stand-by” (first

position). In this position there is no current at the

welding connections; led “ON” off.

The process can be selected either before or after

starting the motor powered welder.

After selecting the mode, the “ON” LED lights up

except for the MIG/MAG mode which can only be

selected when the button on the torch is pressed.

USE

WELDING DIGITAL CONTROL

M

33.

2

02/11/04 79405-GB

TIG MODE

Contact starting TIG

This position is specifically for TIG welding. To cre-

ate the arc simply place the tip of the TIG electrode

on the piece that requires welding then gently move

the tip away. The arc starts automatically and at the

same time the welding current rises to the preset

value, first using the welding current adjustment

knob which is on the lower part of the control panel.

The welding current can be adjusted continuously

from a minimum of 10 A to a maximum which

depends on the power of the machine 400 A, 500 A,

600 A.

STICK MODE (Electrode)

Features C.C. (Constant Current)

There are three stick modes which feature

increasing “arc forces” so that the arc has different

levels of penetration according to the electrode

and/or welding position.

MIG/MAG MODE (continuous wire)

Features C.V. (Constant Voltage)

All wire type welding processes can be carried out,

naked or coated.

The voltage can be adjusted using the same knob

which adjusts the current in STICK mode.

Adjustment is continuous and goes from a minimum

of 15 V to a maximum of 36V, 40 V.

Optional remote control

The welding current can also be set from a distance

using the optional remote control. Once the remote

control is connected to the connector (X1), the

current is controlled by the remote control. To return

to front panel control remove the connector.

VRD program (Voltage Reduction Device VRD)

When you choose the program stick or stick arc

force the Open Circuit Voltage (OCV) go up bat

only for about 3”, than the OCV go down about 12V

and stop there, until the welder start welding.

When you make a short circuit with the stick the

OCV immediately go up, so you can start to welding.

VRD don’t work with the program MIG-MAG.

Inversion of polarity (Optional, available on

request)

In order to invert polarity, press the switch on the

remote control unit.

By selecting “inversion” the “ON” LED switches off

and the voltage at the welding socket becomes

zero. The power contactor is witched inside the

electrical box and the voltage reappears at the

welding sockets. The “ON” LED switches back on

at the same time.

The “Invert polarity” LED on the front panel near the

welding current adjuster switches on .

You cannot invert polarity in “MIG/MAG” mode.

PROTECTIONS

The Welding Digital Control features 3 protections

for the control and chopper.

1) “ON” LED blinking

When the engine of the welder is

started the control unit automatically

goes to the stand by mode for few

istants (stand-by LED on) and performs a self-

diagnosis of the current sensor connector and

power source voltage + 15V.

Than the last process selected is loaded (ON led

turned on)

In case of malfunction the “ON” LED blinks.

2) Red LED blinking

The chopper has a thermal protection,

which intervenes in case the operating

temperature exceeds 85°C.

If the protection intervenes, the red LED begins to

flash and the welding current/voltage goes to zero.

In this case do not switch off the welder, since the

alternator fan will help cool down the chopper more

quickly.

After a few minutes, the LED will automatically

switch itself off and the welding voltage/current will

once again be available at the plugs.

3) Red LED continuously lit

If an anomalous current is detected in

the chopper, the control blocks the

conversion immediately, the output

welding current/voltage goes to zero and the red

LED lights up. To reset everything, it is necessary

to switch off the machine.

If the protections 1) and 3) should intervene, it is

best to immediately contact the nearest authorised

Service Centre.

ATTENTION

!

For the EP1 version

it is compulsory to accellerate

the engine manually.

/